Ribbon Foundation: features and stages of construction

Everyone knows the old adage that a real man in his life must do three things: plant a tree, raise a son and build a house. With the last item, there are especially many questions - what material is better to use, choose a one or two story building, how many rooms to count on, with or without a veranda, how to establish a foundation and many others. Among all these aspects, it is the foundation that is fundamental, and this article will be devoted to its tape type, its features, differences, construction technology.

Special features

Despite the fact that there are several varieties of bases for the home, preference in modern construction is given to strip foundations.Due to its durability, reliability and durability, it occupies a leading position in the construction industry of the whole world.

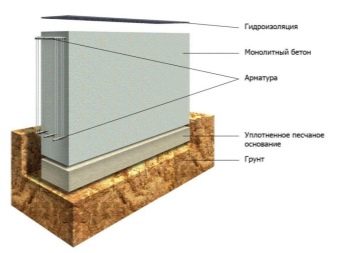

Already from the name it is clear that such a construction is a tape of a prescribed width and height, laid in special trenches along the borders of the building under each of the outer walls, thus forming a closed loop.

This technology gives the foundation the utmost rigidity and strength. And due to the use of reinforced concrete during the formation of the structure, maximum strength is achieved.

Among the key features of the tape type foundation can be identified the following:

- reliability and long service life already mentioned;

- quick construction of the structure;

- accessibility in terms of cost relative to its parameters;

- ability to install manually without using heavy machinery.

According to the norms of GOST13580-85, the strip foundation is a reinforced concrete slab, the length of which is from 78 cm to 298 cm, width - from 60 cm to 320 cm and height - from 30 cm to 50 cm. The base mark with the load index from 1 is determined. to 4, which is an indicator of the pressure of the walls on the foundation.

In comparison with the pile and slab types of tape base, of course, wins. However, the columnar foundation overpowers the base with a ribbon due to the significant consumption of materials and an increase in labor intensity.

Estimated tape designs can be calculated taking into account the sum of the cost of installation and the cost of building materials. The average price for a finished meter of a tape of a concrete foundation is from 6 to 10 thousand rubles.

This figure is affected by:

- soil characteristics;

- the total area of the basement;

- type and quality of building materials;

- depth;

- dimensions (height and width) of the tape itself.

The service life of the strip foundation is directly dependent on the correct choice of the site for construction, compliance with all requirements and building codes. Accounting for all the rules will extend the service for more than a decade.

An important feature in this matter is the choice of building material:

- brick foundation will last up to 50 years;

- prefabricated construction - up to 75 years;

- rubble and solid concrete in the manufacture of the base will increase the operating life of up to 150 years.

Purpose

It is possible to use tape technology of construction of the base:

- in the construction of monolithic, wooden, concrete, brick, frame construction;

- for a residential house, bath, economic or industrial building;

- for the construction of fences;

- if the building is located on a platform with a slope;

- great if you decide to build a basement, veranda, garage or basement;

- for the house, where the density of the walls is more than 1300 kg / m³;

- for both light and heavy buildings;

- in areas with inhomogeneous stratified soil, which leads to uneven shrinkage of the base of the structure;

- on loamy, clay and sandy soil.

Advantages and disadvantages

The main advantages of the foundation tape:

- a small amount of building materials, as a result, and low cost relative to the characteristics of the foundation;

- arrangement of garage or basement is possible;

- high reliability;

- allows you to distribute the load of the house over the entire area of the base;

- the construction of the house can be made of various materials (stone, wood, brick, concrete blocks);

- does not need land acquisition throughout the whole area of the house;

- able to withstand heavy loads;

- rapid erection - the main time required for digging a trench and building a formwork;

- simple construction;

- This is a time-tested technology.

Among all the many advantages, it is worth mentioning some of the flaws in the strip footing:

- for all the simplicity of the design, the work itself is quite laborious;

- difficulties with waterproofing when installed on wet ground;

- unsuitable option for soils with weak bearing properties due to the large mass of the structure;

- reliability and durability is guaranteed only at reinforcement (reinforcement of the concrete base with steel reinforcement).

Kinds

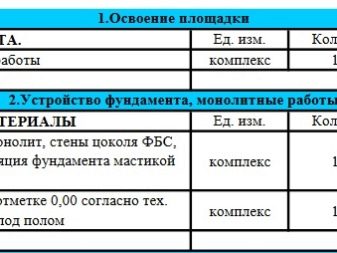

By classifying the selected type of foundation by device type, it is possible to distinguish monolithic and precast bases.

Monolithic

Assume the continuity of the underground walls. They are characterized by low cost of construction in relation to strength. This type is in demand when building a bath or a small wooden house. The disadvantage is the large weight of the monolithic structure.

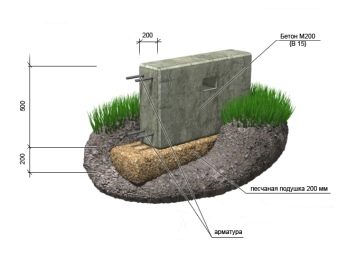

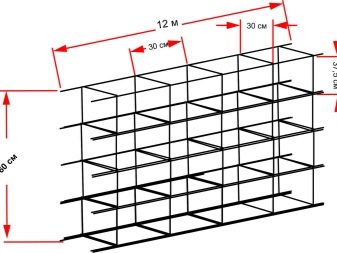

The monolithic foundation technology assumes a reinforcing metal frame that is installed in a trench, after which it is poured with concrete.It is due to the frame that the necessary rigidity of the foundation and resistance to loads are acquired.

Cost for 1 square. m - about 5100 rubles (with characteristics: plate - 300 mm (h), sand cushion - 500 mm, brand of concrete - M300). On average, the contractor for the filling of the foundation 10x10 will take about 300-350 thousand rubles, taking into account the installation and cost of materials.

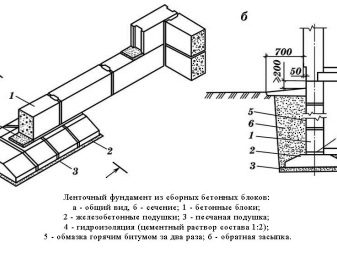

Prefabricated

The precast strip foundation differs from the monolithic one in that it consists of a set of special reinforced concrete blocks interconnected by means of reinforcement and masonry mortar, which are mounted with a crane on a construction site. Among the main advantages - reducing installation time. The downside is the lack of a unified design and the need to attract heavy equipment. In addition, the strength of the precast foundation is inferior to the monolithic by as much as 20%.

This foundation is used in the construction of industrial or civil buildings, as well as for cottages and private houses.

The main costs will go on haul and hourly rental crane. 1 running meter of the precast foundation will cost at least 6,600 rubles. About 330 thousand will have to be spent on the basis of a 10x10 building. Save will allow the installation of wall blocks and pillows with a short distance.

There is also a tape-slot subspecies of the structure, which in its parameters is similar to a monolithic strip foundation. However, this base is adapted for casting exclusively on clay and non-fossil soils. Such a foundation is cheaper due to the reduction of land works, since the installation takes place without formwork. Instead, they use a trench that visually resembles a slit, hence the name. Slot-hole foundations allow in low-rise, non-massive buildings to equip a garage or utility room.

Important! The concrete is poured into damp ground, since in a dry trench some of the moisture goes into the ground, which can cause the quality of the foundation to deteriorate. Therefore it is better to use concrete of higher grade.

Another subspecies of precast strip foundations - the cross. It includes glasses under the columns, support and intermediate plates. Such foundations are in demand in the conditions of row buildings - when the column foundation is located in proximity to the base of the same type. Such an arrangement is fraught with drawdown of structures. The use of cross foundations implies the contact of the lattice of the end beamsthe building being erected with an already constructed and stable construction, thus allowing to evenly distribute the load. This type of construction is applicable to both residential and industrial construction. Among the shortcomings is the complexity of the work.

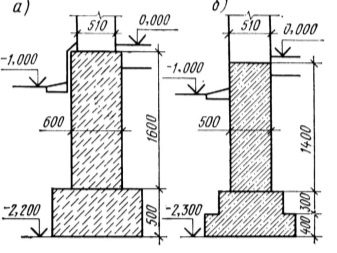

Also for the tape type of the foundation it is possible to carry out a conditional division with respect to the depth of the bookmark. In this connection, the magnitude of the load emit deeper and shallow-deeper species.

Deepening is performed below the established level of soil freezing. However, within the limits of private low-rise buildings a shallow foundation is acceptable.

The choice in such typing depends on:

- building masses;

- the presence of the basement;

- soil type;

- height difference indicators;

- groundwater level;

- level of soil freezing.

The definition of these indicators will help in choosing the right type of strip footing.

The recessed appearance of the foundation is designed for a house of foam blocks, heavy buildings made of stone, brick or multi-storey buildings. For such foundations are not afraid of significant height differences. Perfect for buildings in which the planned arrangement of the basement.It is being built 20 cm below the ground freezing level (for Russia it is 1.1-2 m).

It is important to take into account the frosty buoyant forces of the swelling, which should be less than the concentrated load from the house. For confrontation to these forces, the foundation is set in the shape of an inverted “T”.

Shallow-tape is different ease buildings, which will be located on it. In particular, it is wooden, frame or cellular structures. But it is undesirable location on the ground with a high level of groundwater (up to 50-70 cm).

The key advantages of the shallow foundation are the low cost of building materials, labor-intensive and short installation time, in contrast to the recessed base. In addition, if there is an opportunity to get by with a small cellar in the house, then such a foundation is an excellent and low-cost option.

Among the disadvantages are the inadmissibility of the installation in unstable soils., and for a two-story house such a foundation will not work.

Also, one of the features of this type of base is the small area of the lateral surface of the walls, in connection with which the buoyancy forces of frost heaving are not dangerous for a light construction.

To date, developers are actively introducing the Finnish technology to install the foundation without penetration - pile-rostrum. Rostverk is a plate or beam connecting the piles between them already above the ground. A new type of zero-level device does not require the installation of boards and the installation of wooden bars. In addition, it is not necessary to dismantle the hardened concrete. It is believed that such a construction is generally not subject to heaving force and the foundation is not deformed. Mounted on the formwork.

In accordance with the norms regulated by the SNiP, the minimum depth of the strip footing is calculated.

The depth of frost penetration of conditionally non-rocky soil | The depth of freezing of poorly eruptive soil of solid and semi-solid consistency | Foundation depth |

up to 2 m | up to 1 m | 0.5 m |

up to 3 m | up to 1.5 m | 0.75 m |

more than 3 m | from 1.5 to 2.5 m | 1m |

Materials

Tape foundations are predominantly made of brick, reinforced concrete, and crushed concrete, using reinforced concrete blocks or slabs.

Brick is suitable in the event that the house is supposed to build a frame or with thin brick walls. Since the brick material is very hygroscopic and easily destroyed due to moisture and cold,then such a deep foundation is not welcome in places with a high level of groundwater. It is important to provide a waterproofing coating for such a base.

The popular reinforced concrete foundation, despite its cheapness, is quite reliable and durable. The composition of the material - cement, sand, crushed stone, which are reinforced with metal mesh or rods reinforcement. Suitable for sandy soil in the construction of monolithic bases of complex configuration.

Ribbon foundation made of butobeton is a mixture of cement, sand and large stone. Rather reliable material with length parameters - no more than 30 cm, widths - from 20 to 100 cm and two parallel surfaces up to 30 kg. This option is perfect for sandy soils. In addition, a prerequisite for the construction of a concrete foundation should be the presence of a gravel or sand pad 10 cm thick, which simplifies the process of laying the mixture and allows you to level the surface.

The foundation of reinforced concrete blocks and slabs is a finished product manufactured by the company. Among the distinctive features - reliability, stability, durability, the ability to use for houses of various designs and types of soil.

The choice of material for the construction of strip foundations depends on the type of device.

The base of the prefabricated type is made:

- from blocks or plates of the established brand;

- a concrete mortar or even a brick is used to seal the gaps;

- completed with all materials for hydro-and thermal insulation.

For monolithic foundations it is recommended to use:

- the formwork is constructed of wooden boards or polystyrene foam;

- concrete;

- material for hydro and thermal insulation;

- sand or crushed stone for pillows.

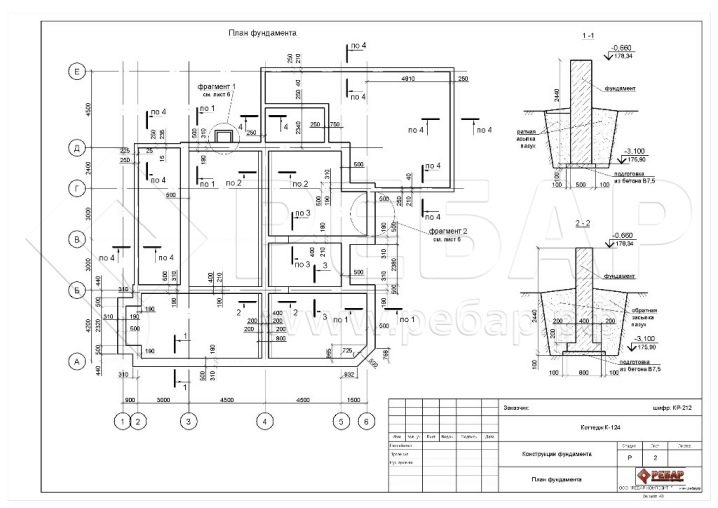

Calculation and design rules

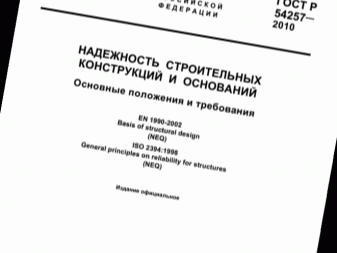

Before a project is drawn up and the parameters of the foundation of a building are determined, it is recommended to review the regulatory building documents that describe all the key rules for calculating the foundation and the tables with established coefficients.

Among such documents:

GOST 25100-82 (95) “Soils. Classification";

GOST 27751-88 "Reliability of building structures and bases. Basic provisions for the calculation ";

GOST R 54257 "Reliability of building structures and bases";

SP 131.13330.2012 "Construction Climatology". The updated version of SN and P 23- 01-99;

SNiP 11-02-96. “Engineering surveys for construction.The main provisions ";

SNiP 2.02.01-83 "Foundations of buildings and structures";

Allowance to SNiP 2.02.01-83 "Allowance for the design of the foundations of buildings and structures";

SNiP 2.01.07-85 "Loads and Impacts";

Guide to SNiP 2.03.01; 84. “Manual on the design of foundations on a natural basis for columns of buildings and structures”;

SP 50-101-2004 "Design and construction of foundations and foundations of buildings and structures";

SNiP 3.02.01-87 "Earthworks, foundations and foundations";

SP 45.13330.2012 "Earthworks, foundations and foundations." (Updated edition of SNiP 3.02.01-87);

SNiP 2.02.04; 88 "Foundations and foundations on permafrost".

Let us consider in detail and in stages the plan of calculations for the construction of the foundation.

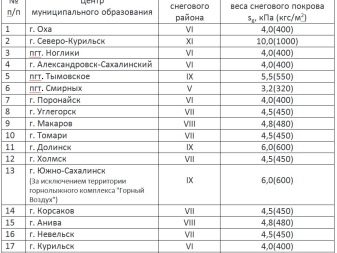

To begin with, a total calculation is made of the total weight of the structure, including the roof, walls and floors, the maximum allowable number of residents, heating equipment and domestic installations, and the load from precipitation.

It is necessary to know that the weight of the house determines not the material from which the foundation is made, but the load that is created by the whole structure of various materials. This load is directly dependent on the mechanical characteristics and the amount of material used.

To calculate the pressure on the bottom of the base, it is enough to summarize the following indicators:

- snow load;

- payload;

- load of structural elements.

The first item is calculated using the snow load formula = roof area (from the project) x set snow cover weight parameter (its own for each region of Russia) x correction factor (which is influenced by the slope of a single or gable roof)

The set parameter of the mass of snow cover is determined by the zoned map of SN and P 2.01.07-85 "Loads and Impacts".

The next step is to calculate the potential payload. In this category are household appliances, temporary and permanent residents, furniture and bathing equipment, communication systems, stoves and fireplaces (if available), additional engineering routes.

There is an established form of calculation of this parameter, calculated with a margin: parameters of the payload = total construction area x 180 kg / m².

In the calculations of the last point (load of parts of the building) it is important to list all the elements of the building to the maximum, including:

- directly reinforced base;

- ground floor of the house;

- the bearing part of the building, window and door openings, stairs, if any;

- floor and ceiling surfaces, floor and attic flooring;

- roof covering with all the resulting elements;

- floor insulation, waterproofing, ventilation;

- surface finish and decorative items;

- all the many fasteners and hardware.

Moreover, to calculate the sum of all the above elements, two methods are used - mathematical and the results of marketing calculations in the building materials market.

Of course, there is also the option of using a combination of both methods.

The plan of the first method is:

- breaking into the project complex structures into parts, determine the linear dimensions of the elements (length, width, height);

- multiply the data to measure the volume;

- using the all-Union norms of technological design or in the documents of the manufacturer to establish the proportion of used building material;

- setting the parameters of volume and specific gravity, calculate the mass of each of the elements of the building, using the formula: mass of the part of the building = volume of this part x is the parameter of the specific weight of the material from which it is made;

- calculate the total mass allowed under the foundation, summing up the results of the parts of the structure.

The method of marketing calculation focuses on data from the Internet, media and reviews of professionals. The specified specific weight is also summarized.

Accurate data have the design and sales departments of enterprises, where possible, by calling them, to clarify the range or use the manufacturer's website.

The general parameter of the load on the foundation is determined by summing all the calculated values - the load of parts of the structure, useful and snow.

Next, the estimated specific pressure of the structure on the soil surface under the base of the designed base is calculated. For calculation the formula is used:

approximate specific pressure = mass of the whole structure / size of the foot of the base.

Having determined these parameters, an approximate calculation of the geometric parameters of the strip footing is permissible. This process occurs according to some algorithm established in the course of research by specialists of the scientific and engineering department.The scheme for calculating the size of the foundation depends not only on the expected load on it, but also on the construction of the documented norms of foundation depth, which, in turn, are determined by the type and structure of the soil, the groundwater level, and the depth of freezing.

Based on the experience gained, the developer recommends the following parameters:

Type of soil | Soil within the estimated depth of freezing | The interval from the planned mark to the level of groundwater during the period of freezing | Foundation Depth |

Non-lax | Coarse, gravel sands, coarse and medium-sized | Not standardized | Any, regardless of the boundary of freezing, but not less than 0.5 meters |

Puffy | Sand fine and silty | Exceeds the freezing depth of more than 2 m | Same indicator |

Sugar | Exceeds the freezing depth of not less than 2 m | Not less than ¾ of the estimated level of freezing, but not less than 0.7 m. | |

Loam, clay | Less than estimated frost depth | Not less than the estimated level of freezing |

The strip width parameter should not be less than the wall width. The depth of the pit, which determines the parameter of the base height, should be calculated on a 10-15 cm sand or gravel pad.These indicators allow in further calculations to decide on: The minimum width of the base of the foundation is calculated depending on the pressure of the building on the foundation. This size, in turn, determines the width of the foundation itself, pressing on the soil.

That is why it is so important to make an examination of the soil before starting the design of the structure.

- the amount of concrete to fill;

- volume of reinforcing elements;

- the amount of material on the formwork.

The recommended parameters of the width of the sole for the strip foundation, depending on the selected material:

Crushed stone:

- basement depth - 2 m:

- basement wall length - up to 3 m: wall thickness - 600, basement base width - 800;

- basement wall length 3-4 m: wall thickness - 750, width of the base of the foundation - 900.

- basement depth - 2, 5m:

- basement wall length - up to 3 m: wall thickness - 600, basement base width - 900;

- basement wall length 3-4 m: wall thickness - 750, the width of the base of the foundation - 1050.

Botobeton:

- basement depth - 2 m:

- basement wall length - up to 3 m: wall thickness - 400, width of the base of the foundation - 500;

- basement wall length - 3-4 m: wall thickness - 500, width of the base of the basement - 600.

- basement depth - 2, 5m:

- basement wall length up to 3 m: wall thickness - 400, width of the base of the foundation - 600;

- the length of the basement wall is 3-4 meters: the wall thickness is 500, the width of the base of the foundation is 800.

Clay brick (ordinary):

- basement depth - 2 m:

- basement wall length up to 3 m: wall thickness - 380, width of the base of the foundation - 640;

- the basement wall length is 3-4 m: the wall thickness is 510, the width of the base of the foundation is 770.

- basement depth - 2, 5m:

- basement wall length up to 3 m: wall thickness - 380, width of the base of the foundation - 770;

- the length of the basement wall is 3-4 meters: the wall thickness is 510, the width of the base of the foundation is 900.

Concrete (monolith):

- basement depth - 2 m:

- basement wall length up to 3 m: wall thickness - 200, basement base width - 300;

- the length of the basement wall is 3-4 m: the wall thickness is 250, the width of the base of the foundation is 400.

- basement depth - 2, 5m;

- basement wall length up to 3 m: wall thickness - 200, basement base width - 400;

- basement wall length 3-4 m: wall thickness - 250, the width of the base of the foundation - 500.

Concrete (blocks):

- basement depth - 2 m:

- basement wall length up to 3 m: wall thickness - 250, basement base width - 400;

- basement wall length 3-4 m: wall thickness - 300, basement base width - 500.

- basement depth - 2, 5m:

- basement wall length up to 3 m: wall thickness - 250, basement base width - 500;

- basement wall length 3-4 m: wall thickness - 300, basement base width - 600.

Further, it is important to optimally adjust the parameters, adjusting the norms of the specific pressure on the soil of the foot in accordance with the design resistance of the soil - the ability to withstand a certain load of the whole structure without its settlement.

The design resistance of the soil should be greater than the parameters of the specific load from the building. This item represents a weighty requirement in the process of designing the foundation of a house, according to which to obtain linear dimensions, it is necessary to solve arithmetic inequality in an elementary fashion.

Making up the drawing it is important that this difference be 15-20% of the specific load of the structure in favor of the magnitude of the ability of the soil to withstand the pressure from the building.

In accordance with the types of soil, the calculated resistances are derived:

- Coarse gravel, crushed stone, gravel - 500-600 kPa.

- Sand:

- gravelly and large - 350-450 kPa;

- medium size - 250-350 kPa;

- small and dusty dense - 200-300kPa;

- average density - 100-200 kPa;

- Cored firm and plastic - 200-300kPa;

- Hard and plastic loam - 100-300 kPa;

- Clay:

- solid - 300-600 kPa;

- plastic - 100-300 kPa;

100 kPa = 1kg / cm²

By adjusting the results obtained, we obtain the approximate geometric parameters of the foundation of the structure.

In addition, today's technologies can significantly simplify calculations with the help of special calculators on developers' sites. By specifying the dimensions of the base and the used building material, one can calculate the total cost of building a foundation.

Installation

To install the strip foundation with your own hands you will need:

- round and corrugated reinforcement elements;

- galvanized steel wire;

- sand;

- edged boards;

- wooden bars;

- a set of nails, self-tapping screws;

- waterproofing material for the foundation and formwork walls;

- concrete (mainly factory) and the corresponding materials for it.

Markup

Having planned to build a building on the site, it is worthwhile to pre-investigate the place where construction is planned.

There are certain rules for choosing a place for the foundation:

- Immediately after the snow melt, it is important to pay attention to the presence of cracks (indicate the heterogeneity of the soil - freezing will lead to a rise) or failures (indicate the presence of water veins).

- The presence of other buildings on the site makes it possible to assess the quality of the soil.It is possible to verify the uniformity of the soil by digging a trench at an angle from the house. Imperfection of the soil indicates unfavorable site for construction. And if there are cracks on the foundation, then the construction is better to be postponed.

- As mentioned above, to conduct a hydrogeological assessment of the soil.

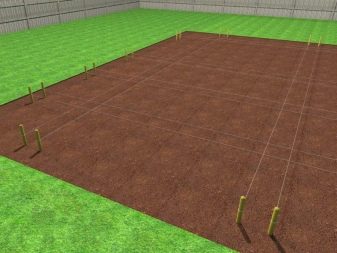

Having determined that the selected site meets all standards, you should proceed to marking the site. First of all it needs to be leveled and rid of weeds and debris.

For marking work will require:

- marking cord or fishing line;

- roulette;

- wooden pegs;

- level;

- pencil and paper;

- hammer.

The first marking line is decisive - all other boundaries will be measured from it. At the same time it is important to establish an object that will serve as a guideline. It may be another structure, road or fence.

The first peg is the right corner of the building. The second is set at a distance equal to the length or width of the structure. Between themselves, the pegs are connected with a special marking cord or tape. In the same way, the rest are slaughtered.

Determining the external boundaries, you can go to the internal.For this purpose, temporary pegs are used, which are set at a distance of the width of the strip foundation on both sides of the corner marking. Opposite marks are also interconnected by a cord.

Lines of load-bearing walls and partitions are established using a similar method. Estimated windows and doors are highlighted with a peg.

Excavation

When the marking stage is completed, the cords are temporarily removed and, following marks on the ground, trenches are dug under the external load-bearing walls of the structure around the perimeter of the overlay. The inner space is pulled out only in the event that the basement or basement premises are planned.

The established requirements for carrying out earthworks are specified in SNiP 3.02.01-87 on earthworks, foundations and foundations.

The depth of the trenches should be greater than the estimated depth of the foundation. Do not forget about the mandatory preparatory layer of concrete or bulk material. If the excavated dredging significantly exceeds the depth taking into account the reserve, you can fill this volume with the same soil or rubble, sand. However, if the search exceeds more than 50 cm, you should contact the designers.

It is important to take into account the safety of workers - excessive depth of the pit requires strengthening of the trench walls.

In accordance with regulatory documents, fasteners are not required if the depth is:

- for loose, sandy and coarse soils - 1 m;

- for sandy loam - 1.25 m;

- for loam and clay - 1.5 m.

Usually for erecting a small building, the average depth of a trench is 400 mm.

The width of the notch must comply with the plan, which already takes into account the thickness of the formwork, the parameters of the underlying preparation, the protrusion of which beyond the lateral boundaries of the base is allowed at least 100 mm.

The usual parameters are the width of the trench, equal to the width of the tape, plus 600-800 mm.

Important! In order for the bottom of the pit to be a perfectly flat surface, a water level should be used.

Formwork

This element is a form for the intended foundation. The formwork material is usually wood because of its availability in terms of cost and ease of implementation. Removable or fixed metal formwork is also actively used.

In addition, depending on the material, the following types differ:

- aluminum;

- steel;

- plastic;

- combined.

Classifying formwork depending on the type of construction, there are:

- large shield;

- small-plate;

- volume-adjustable;

- block;

- sliding;

- horizontally movable;

- lift-adjustable.

Grouping types of formwork for thermal conductivity, differ:

- insulated;

- unheated.

The structure of the formwork are:

- deck with shields;

- fasteners (screws, corners, nails);

- supports, racks and support frames.

For installation you will need the following materials:

- lighthouse;

- board for shields;

- fight from longitudinal boards;

- tension hook;

- spring clip;

- ladder;

- shovel;

- concreting site.

The number of listed materials depends on the parameters of the strip footing.

The installation itself provides for strict adherence to the established requirements:

- the installation of the formwork is preceded by a thorough cleaning of the site from debris, stumps, plant roots, and the removal of any irregularities;

- the formwork side in contact with the concrete is perfectly cleaned and leveled;

- replenishment occurs in such a way as to prevent shrinkage during concreting - such deformation may adversely affect the entire structure as a whole;

- formwork panels as closely as possible with each other;

- all formwork mounts are carefully checked - a barometer checks the compliance of the actual dimensions with the design ones, the level is used to control the horizontal position, and the plumb line is used to control the horizontal position;

- if the type of formwork allows you to remove it, then for reuse it is important to clean the fasteners and shields from debris and traces of concrete.

Step-by-step instructions for arranging solid formwork for a tape base:

- To level the surface, the installation of the lighthouse boards is made.

- With a gap of 4 m, formwork panels are fastened on both sides, which are fastened with the aid of braces for stiffness and struts, providing a fixed thickness of the base tape.

- The foundation will turn out to be equal only if the number of shields between the light boards will be the same.

- Contractions, which are longitudinal boards, are nailed to the sides of the boards for horizontal alignment and reliability.

- The contractions are stabilized with inclined struts, which allow the shields to be vertically aligned.

- Shields are fixed with tension hooks or elastic straps.

- Solid formwork is usually obtained with a height of more than a meter,which requires the installation of stairs and platforms for concreting.

- If necessary, the design is analyzed in the reverse order.

Installation of the stepped construction goes through several stages. Each next formwork tier is preceded by another similar tier:

- first step of formwork;

- concreting;

- second stage of formwork;

- concreting;

- installation of the necessary parameters is carried out according to the same scheme.

The installation of step formwork is also possible at once, like the assembly mechanism of a solid structure. In this case, it is important to adhere to the horizontal and vertical arrangement of the parts.

During the construction phase of the formwork, the layout of the ventilation holes is an important issue. Products should be located at a minimum height of 20 cm from the surface of the earth. However, it is necessary to take into account seasonal flooding and vary the location depending on this factor.

The material for the vent hole is best served as a round plastic or asbestos cement pipe with a diameter of 110-130 mm. Wooden bars have a peculiarity to stick to a concrete base, which is why it will be difficult to remove them afterwards.

The diameter of the airways is determined depending on the size of the building and can reach from 100 to 150 cm. These ventilation openings in the walls are strictly parallel to each other at a distance of 2.5-3 m.

With all the necessity of productions, there are cases when the presence of holes is not required without fail:

- the room already has vents in the floor of the building;

- between the pillars of the base material is used with sufficient vapor-permeable ability;

- there is a powerful and stable ventilation system;

- vapor-proof material covers sand or soil that has been rammed in the basement.

Understanding the variety of material classifications contributes to the correct selection of reinforcement.

Depending on the manufacturing technology of reinforcement may vary:

- wire or cold rolled;

- rod or hot rolled.

Depending on the type of surface rods:

- with a periodic profile (corrugations), providing maximum connection with concrete;

- smooth.

By purpose:

- rods used in conventional reinforced concrete construction;

- prestress rods.

Most often, fittings according to GOST 5781 are used for strip foundations, a hot-rolled element applicable to conventional and prestressed reinforced structures.

In addition, in accordance with the steel grades, and consequently, the physicomechanical properties, the bars of the reinforcement differ from А-I to А-VI. For the manufacture of elements of the initial class using low-carbon steel, in the high classes - properties close to alloyed steel.

Construction of the foundation with a tape is recommended to be made using rods of rebar class A-III or A-II, which are at least 10 mm in diameter.

At the planned sites with the greatest load, mounting fittings are installed in the direction of the supposed additional pressure. Such places are the corners of the structure, the areas with the highest walls, the base under the balcony or terrace.

When installing the structure of the reinforcement formed intersections, abutments and angles. Such an incompletely mounted unit may result in a crack or subsidence of the foundation.

That is why for reliability are used:

- legs - L-shaped limb (internal and external), attached to the outer working part of the frame of reinforcement;

- cross clamp;

- gain.

It is important to remember that each class of reinforcement has its own specific parameters for the permissible bending angle and curvature.

In a one-piece frame, the parts are connected by two methods:

- Welding, involving special equipment, the availability of electricity and a specialist who will perform all this.

- Knitting, possible with a simple screw hook, wire (30 cm at one intersection). It is considered the most reliable way, albeit time consuming. Its convenience lies in the fact that if necessary (the load on the bend), the rod can be slightly shifted, thereby relieving the pressure on the concrete layer and protect it from damage.

You can make a hook, if you take a thick and durable metal rod. With one edge for more convenient use make the handle, the other is bent in the form of a hook. Having folded the mounting wire in half, they form a loop at one of the ends. After that, it should be twisted around the reinforced assembly, winding the hook into the loop so that it rests on one of the “tails”, and the second “tail” is wrapped around the mounting wire, carefully tightening around the rebar.

All metal parts are carefully protected with a layer of concrete (minimum - 10 mm) to prevent acid corrosion.

Calculations of the amount of reinforcement that will be needed for the construction of strip foundations require the determination of the following parameters:

- dimensions of the total length of the basement strip (external and if there are internal lintels);

- the number of elements for longitudinal reinforcement (you can use the calculator on the manufacturers website);

- the number of reinforcement points (the number of corners and junction points of the foundation tapes);

- overlap parameters of reinforcement elements.

Norms of SNiP indicate the parameters of the total cross-sectional area of longitudinal reinforcement elements, which will be not less than 0.1% of the cross-sectional area.

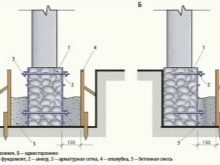

Fill

It is recommended to pour the monolithic foundation with concrete in layers of 20 cm in thickness, after which the tier is compacted with a concrete vibrator in order to avoid voids. If you pour concrete in the winter, which is undesirable, then you need to warm it with the help of scrap materials. In the dry season it is recommended to use water to create the effect of moisture, otherwise it may affect its strength.

The consistency of the concrete must be the same for each layer, and the filling must be done in one day., since a low level of adhesion (a method of adhesion of surfaces of dissimilar solid or liquid consistencies) can lead to the formation of cracks. In that case, if it is impossible to fill in one day, it is important to at least plentifully pour the surface of the concrete with water and, in order to preserve the moisture, cover it with plastic wrap on top.

Concrete must stand. After 10 days, the walls of the base are processed outside with bitumen mastic and a waterproofing material (usually roofing material) is glued in to protect it from water penetration.

The next stage is backfilling of the cavities of the strip foundation with sand, which is also laid in layers, with each tier being carefully tamped. Before laying the next layer of sand watered with water.

Useful tips

Properly installed strip foundation - a pledge of long years of operation of the building.

It is important to clearly maintain the constant depth of laying the foundation over the entire area of the construction site, since minor deviations lead to the difference in soil density, moisture saturation, which jeopardizes the reliability and durability of the foundation.

Among the common omissions in the construction of the building foundation are mainly inexperience, inattention and levity to installation, as well as:

- insufficiently careful study of hydrogeological properties and ground level;

- the use of cheap and low-quality building materials;

- builders' incompetence is demonstrated by damage on the waterproofing layer, curved markings, unevenly laid pillows, violation of the angle;

- non-compliance with the timing of removal of formwork, drying of the concrete layer and other temporary stages.

In order to avoid such errors, it is of fundamental importance to contact only the specialists involved in the installation of structural foundations and try to follow the stages of construction. If the installation of the foundation is planned on its own, it would be preferable to consult with experts in this field before starting work.

An important topic in the construction of the foundation is the question of the recommended time of year for such work. As mentioned above, undesirable time is considered to be winter and late autumn, since frozen and sodden soil causes inconvenienceslowing down construction work, and, importantly, shrinkage of the foundation and the appearance of cracks in the already finished structure. Professionals indicate that the optimal time for construction is warm and dry periods (depending on the region, these intervals fall on different months).

Sometimes after the construction of the foundation and operation of the building comes the idea of expanding the living space of the house. This question requires a close analysis of the state of the base. In case of insufficient strength, construction may cause the foundation to burst, creep in, or cracks will appear on the walls. Such an outcome can lead to the complete destruction of the building.

However, if the condition of the foundation does not allow to finish the building, you should not be upset. In this case there are some tricks in the form of strengthening the foundation of the structure.

This process can be carried out in several ways:

- in case of minor damage to the basement, the restoration of the hydro- and heat-insulating tier is sufficient;

- more costly is the expansion of the foundation;

- often use the method of replacing the soil under the base of the house;

- using various types of piles;

- by creating a reinforced concrete jacket that prevents collapse when cracks appear on the walls;

- reinforcement with monolithic clips strengthens the base throughout the thickness. This method involves the use of double-sided reinforced cage or tubes that inject a solution that freely fills all the cavities of the masonry.

The most important thing in the construction of any type of foundation is to correctly determine the necessary view, to carry out a thorough calculation of all parameters, precisely follow the instructions to perform all actions step by step, adhere to the rules and expert advice and, of course, enlist the help of assistants.

Tape foot technology is in the next video.