Monolithic strip foundation: features of the construction

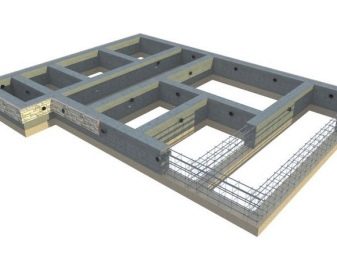

Monolithic strip foundation is an indivisible system of steel reinforcement and concrete. This type of foundation is laid along the perimeter under all walls and partitions of a building. With proper calculation and construction, the monolith is durable, reliable and stable, it is suitable for buildings and structures of various sizes and purposes.

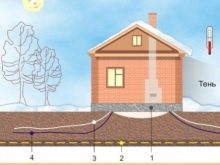

The organization of a monolithic strip foundation is most expedient in case of low groundwater occurrence; otherwise, it is necessary to arrange a drainage system.

Special features

The design of the foundation collects all loads from the building and distributes the load on the foundation soil, which protects the walls from deformation due to soil movements.The main design feature of the strip foundation is the rule - the height must be at least twice as wide as wide. Under the condition of reinforcement of concrete, it can carry significant loads, more than pile, columnar and grillage foundations. Monolithic strip foundation used for the construction of various objects. It can be used to build both low-rise buildings for various purposes (individual houses, cottages, bathhouses, outbuildings) and ancillary buildings (greenhouses, extensions, fences).

In the design and installation of a monolithic ribbon, several regulations must be taken into account. When calculating, they are guided by the data according to the construction region according to SNiP 23-01-99 "Building climatology", SNiP 2.02.01-83 "Foundations of buildings and structures". At the stage of selection of materials and installation of formwork, GOST R 52085-2003 “Formwork. General technical conditions ”, GOST 5781 82“ Armature ”.

The foundation of this type has many advantages.

- Strength. With proper calculation, the monolith will withstand the load from the building in any conditions.

- Durability.The service life of a monolithic strip foundation is from 150 years. This duration is achieved due to the integrity of the structure and the absence of seams. Compared to “ribbons” of brick, concrete blocks, which have a service life of 30–70 years, the choice of a monolith for durable buildings is more expedient.

- The possibility of the device basement and basement.

- The possibility of building a building of any configuration, because a monolithic strip foundation is poured on the spot directly into the formwork, the shape and size of the foundation can be any. The binding to the factory size of blocks is absent here.

- The possibility of self-embedding. The technological process of installation and casting is quite simple, so there is no need to attract specialized construction equipment or hire highly qualified specialists. You can lay a monolithic "tape" with your own hands.

The monolith also has disadvantages, among which, first of all, it is worth highlighting the high cost of the foundation, which consists of the material costs (concrete, fillers, steel reinforcement, backfill materials, waterproofing), the cost of work (excavation, bundle of reinforcement, formwork installation) .

When self-laying, you will need a team of 4–5 people, a concrete mixer, and an apparatus for vibrating concrete.

Device

Reinforced concrete foundations can be of two types.

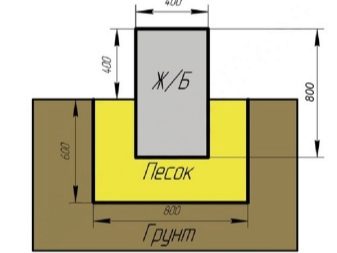

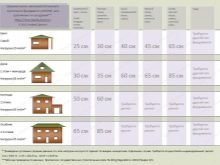

- Shallow depth options can be used on calm, non-piley soils with a good bearing capacity for small buildings (frame buildings, wooden houses). In this case, the tape is sufficient to be submerged by 10–15 cm in a solid layer of soil, which is under the fertile soft layer. It should be noted that the total height of the foundation in accordance with the regulations must be at least 60 cm.

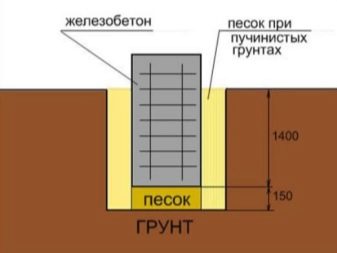

- Monolithic strip foundations deep foundation suit under heavy houses. As a rule, they are lowered below the soil freezing level according to climatic norms by 10–15 cm. It is important that the base rests against a solid layer of soil, which has a high bearing capacity. In this regard, it may be necessary to deepen the foundation to the necessary support.

The production technology of strip foundations varies. Such foundations are as follows:

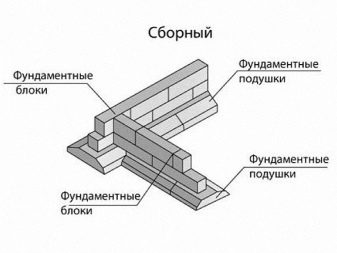

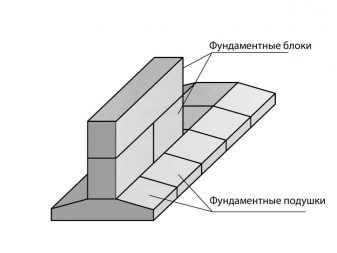

- prefabricated - consist of reinforced concrete blocks and prefabricated pillows.Prefabricated foundations are being built very quickly; construction equipment will be required for installation;

- monolithic - such structures are made immediately at the construction site. Reinforcement is laid in the formwork and concrete is poured. Monolithic reinforced foundation does not require the involvement of construction equipment, because it can be done independently, even without specialized skills.

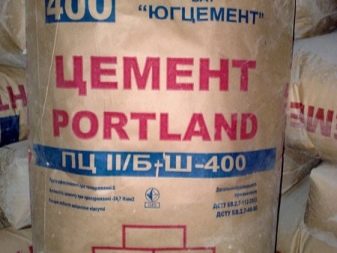

The main material of the concrete structure is Portland cement. His brand is selected according to the project. For the construction of individual low-rise residential buildings, Portland cement M400 is usually used. And also in the composition of the concrete fill includes fillers (gravel and sand) and water. The design can be buttobetonnoy, in this case, rubble stones are used as a filler.

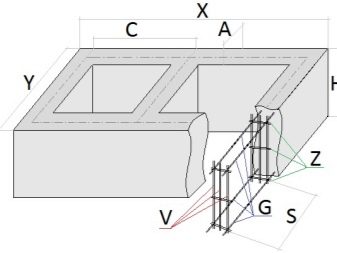

Reinforced concrete has the best strength characteristics for the foundation. This is a concrete frame reinforced with a steel frame. The reinforcement mesh consists of longitudinal and transverse rods interconnected by knitting wire. Formwork is a required element of the monolith. It is collected from wooden boards, sheets of plywood and chipboard.The most common use of boards 25–40 mm thick from coniferous woods. Of them mount shields, which are fixed in the pit.

By the type of material and filling of the concrete mix, monolithic foundations are divided into such types as:

- concrete;

- reinforced concrete;

- butobetonny.

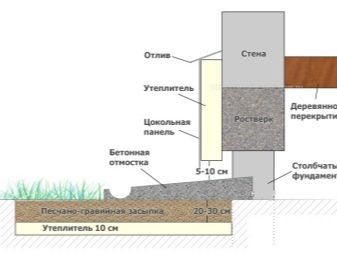

An important issue in the design and installation of foundations is a constructive solution of floors. When constructing a monolithic strip foundation, the soil under the floor remains saturated with moisture, from which the floor needs protection. With a low base, floors are made on the ground. The pit in order to avoid subsidence is filled up on the tamped soil back with rubble and sand. Over them the waterproofing layer is arranged. The floor slab is made not connected to the foundation tape, the joints are provided with waterproofing. In addition, for the removal of excess moisture arrange a drainage system around the building, which includes storm sewers to divert rainwater from the basement. These activities are quite expensive.

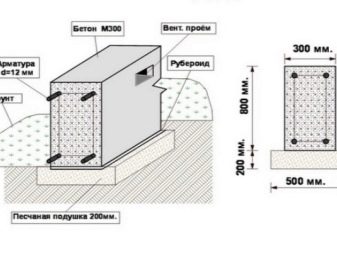

A striking example of the device monolithic strip foundation is a version with a blind area.Floor slab in the form of floors is usually used to create underfloor space. In this case, in the basement of the house are made vents that are open during operation year-round.

When creating a ventilated underground space, you can use any heat-insulating materials.

Payment

Designing the foundation begins with the calculation. Initially, it is necessary to determine the depth of laying, the height of the above-ground part, and the width of the tape. The parameters of the depth and width of the monolithic strip foundation depend on the type of soil, the depth of freezing, the mass of the building. If the “tape” of the foundation is buried, then the depth of the structure is calculated based on the maximum depth of frost penetration at the design site plus 25–30 cm.

If the foundation is shallow, then its foundation is determined by the nature of the soil with the following minimum depths:

- clay soil - 75 cm;

- sandy and loamy soils - 45 cm;

- rocky and rocky grounds (including artificially prepared, with sanding, rubble, gravel) - up to 45 cm.

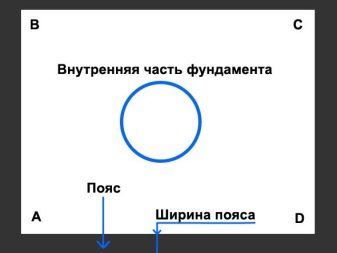

The width of the foundation must ensure that no more than 70% of the bearing capacity of this soil is transferred to the ground.The minimum size of the thickness of the monolithic strip foundation is 30 cm. The width calculation consists in collecting the entire calculated load on the foundation, which must be divided by the total length of the foundation and the bearing capacity of the soil.

When collecting loads, the following values are taken into account:

- project weight at home. It consists of the mass of all building structures - walls, ceilings, roofing. Approximate values can be taken from SNiP II-3-79 "Building heat engineering";

- snow and wind loads. They are determined for each climatic region and are calculated according to SNiP 2.01.07-85 "Loads and Impacts";

- weight of house equipment, furniture, people. It is calculated according to regulations. A value of 195 kg per square meter of each ceiling is taken, including the floor overlap on the first floor.

The total weight is multiplied by a factor of 1.3 to determine the final load on the foundation. The value is obtained in kilograms. The length of the foundation is considered in total under all bearing walls and partitions. The carrying capacity of the soil at the site is determined approximately. Minimum is 2 kg / cm².It is suitable for all types of soils, except clay and loamy.

The height of the above-ground part of the strip foundation depends on the depth of its foundation and the width of the “tape” of the base. For this parameter, the maximum value is calculated at which the structure will be stable and firmly held at the base.

It is possible to determine the allowable height in two ways:

- values are taken in a 1: 1 ratio;

- the height is calculated relative to the sole. The projected width of the "tape" is multiplied by 4.

After calculating the parameters of the foundation of the building, the required amount of building materials is also calculated. Drawing an approximate estimate will allow for a continuous construction process. From this point of view it is important to calculate the required volume of concrete. The volume of the casting is considered according to the height, width and length of the foundation, using the formula for calculating the volume of the parallelepiped.

The total height is taken into account here: aboveground and underground parts.

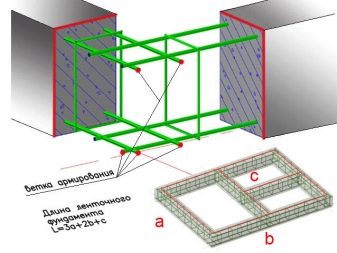

The amount of reinforcement is calculated in total for the frame on the basis of the length of the longitudinal rods and vertical rods, as well as their number. Vertical rods are usually set at 50 cm, and at the corners.Their height is less than the height of the foundation by 10-15 mm. It is also necessary to calculate the formwork. The area of all surfaces on the side can be calculated by multiplying the height of the foundation by twice the perimeter. After that, you need to determine the area of the board (the length should be multiplied by the width). The area of the side surfaces is divided by the area of the board, and the number of formwork boards is obtained.

The estimates for self-laying monolithic strip foundation include the following:

- materials for backfilling "pillows" (sand, crushed stone, cement);

- ready-mixed concrete;

- fittings;

- soft wire for binding reinforcement;

- boards for formwork;

- waterproofing materials (bitumen, roofing material, plastic film);

- blind area materials (slab, concrete, sand, foam plastic);

- Building tools;

- hiring workers or equipment for earthworks;

- equipment for concreting (concrete mixer, vibropress).

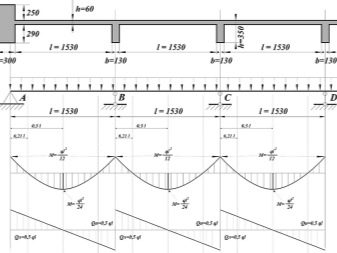

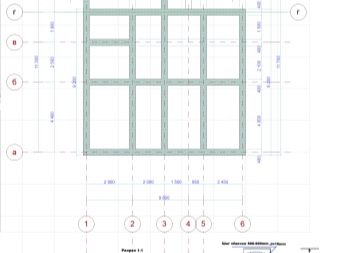

After determining the required dimensions of the monolithic strip footing, develop a drawing of the plan of the foundation, joints and fit. The example shown shows the layout of a monolithic strip foundation for a house with dimensions along the axes of 9800x11300 mm.It includes the basement plan, section, reinforcement scheme.

The resulting diagram explains the following information:

- main structural elements and their sizes;

- the exact dimensions of the building in the axes;

- the distance between the elements in the axes and in size;

- exact level of foundation;

- waterproofing and heat insulation. The drawings sign the used building material for the works;

- the diagram indicates the place of formation of the base and the blind area;

- the device of the future floor covering with a knot of a prileganiye of a floor

Building

Regardless of whether you make a foundation with your own hands or with hiring workers, knowing the technology is very important. Step-by-step process control is required at all stages of the installation.

Installation of a monolithic strip foundation includes several stages.

- Preparation of the construction site. The first step is to clear the area of debris, to prepare a place for storing materials. Dimensions of the pit are carried to the cleaned area. According to the marked dimensions of the house, a fertile soil layer is dredged. The corners of the future foundation are marked with pegs, the direction of the walls is marked with cords.The marking work is done using the building level.

- Excavation. The cord is dug a trench to the depth of the foundation. The width of the trench is determined by the design width of the tape, taking into account the installation of formwork. Usually for this leave 20-30 cm on each side.

- Preparation of the base. The bottom of the trench is covered with a layer of sand, depending on the type of soil. For heaving soils, the layer thickness must be at least 20 cm. The bedding is rammed and lined with a waterproofing layer.

- Assembly and installation of formwork. For the installation of formwork prepare boards of boards. When installing the formwork, the shield wall should be strictly vertical, while the edge of the boards should be 5–10 cm higher than the formwork pouring. It is important to make this stage very carefully so that when the concrete is poured the formwork retains its shape. The formwork walls are covered with a film or mastic for easy disassembly after the concrete has set.

- Knitting reinforcing cage. After installing the formwork, you can begin reinforcement. The framework of the armature is knitted from longitudinal bars A-III and transverse steel rods.Reinforced mesh when placed in the formwork provide a protective layer of 30 mm. For this you can use trimming rods.

- Pouring concrete mix. After the installation of the fittings is necessary to pour concrete. Quality control, process continuity and its temperature are important here. Filling formwork produce evenly. To achieve density, uniformity, removal of air bubbles, concrete must be vibrated after pouring.

- Curing. All further work is carried out after the concrete has set. On average, wall installation can begin 1–2 weeks after pouring. For waterproofing monolithic strip foundation side surfaces of the tape covered with bitumen mastic. After that, you can backfill.

Tips

When building the foundation of the house you need to take into account many nuances.

- The temperature of the process of hardening of concrete depends on the temperature during the work. In hot weather, the poured foundation is covered with plastic wrap to preserve moisture and the top of the pour does not dry out.

- The optimum temperature level during the pouring of concrete is considered to be about + 20 ° C, with a mass fortress of 50% being achieved on the third day.Further, you can remove the formwork and perform further work. At a temperature of about + 10 ° C, this period is 10-14 days. Temperature of + 5 ° C requires formwork heat insulation or concrete heating; naturally, the concrete does not solidify at this level of heat. About 28–30 days should pass before the final solidification of concrete.

- It is important when installing a monolithic strip foundation to take into account the place of passage of communications. For this, plastic pipes of the appropriate size are laid through the formwork.

For how to make a monolithic strip foundation, see the following video.