Features and purpose of caps for screw piles

During the construction of the foundation, among other types of supports, screw piles are often used. The main advantage of this type of piling is their moderate cost. In addition, such supporting elements make it possible to adjust the height of the base of the entire structure and erect buildings on the ground with non-uniform relief. At the final stage of the foundation construction, the installation of the caps on the upper ends of the supporting structures is carried out.

Purpose

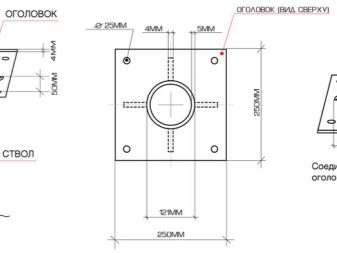

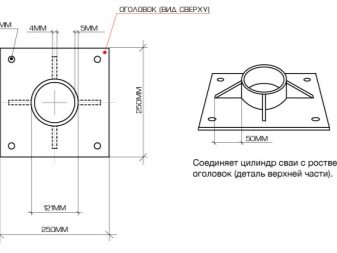

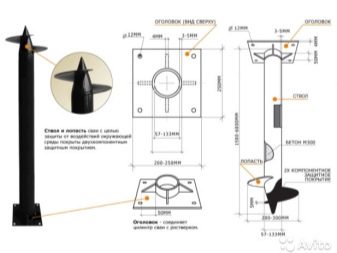

The construction element called the tip is a metal plate with a short pipe welded to it and stiffening ribs. Ogolovkom covered the upper end of the pile after its deepening. It is attached to the support element by welding or by bolting.

The function of the end caps is to support the subsequent levels of the superstructure and evenly distribute the load on the foundation from the entire structure. Building slabs and beams will be supported on the plane of the tips. Also, they can be made fastening timber. In this regard, all supporting elements must be located at the same level relative to each other.

But in most cases, driving piles to a strictly identical depth is simply impossible. To ensure a flat plane for the installation of slabs and beams, the upper ends of the piles are cut at the same level with a single horizontal.

Also due to the installation of the end cap, the degree of damage to the pile by corrosion is significantly reduced.

Ogolovki can be of different shapes and types, depending on the type and configuration used in the construction of piles.

Face elements are made of high-strength structural steel. For additional protection, tips are coated with alkyd based primers.

Types of supporting elements:

- Screw. Such piles are metal pipes of various diameters with a screw base.When the metal leg rotates, it sinks into the ground to the desired depth. For fixing the support element after penetration, concrete solution is poured into the pipe cavity. The dimensions of the diameter of such support structures vary from 108 mm to 325 mm.

- Bored or concrete base. For installation requires penetration of the soil by the auger. A framework of reinforcement is placed in the recesses and concrete is poured.

Advantages of screw piles:

- well hold the structure with extensive floods;

- can be used for construction on unstable soils and non-uniform relief;

- installation of support elements can be made in any weather conditions, including frost;

- uniform distribution of the load from the entire structure, with the exception of foundation overload and distortions;

- allow you to carry out an adjustable rise of the structure above the ground.

Kinds

Screw pile heads have a base in the form of a round short pipe of various diameters.

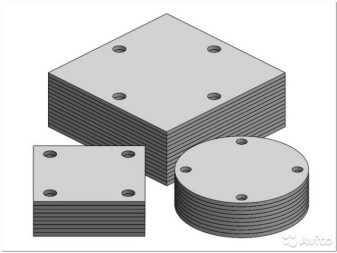

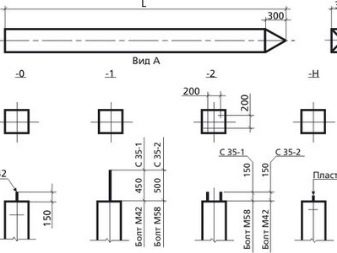

The face elements for piles, above all, differ in the shape of the top plate. They can be P-and T-shaped.

U-shaped elements have brackets on their surface. They are mounted on piles for the subsequent laying of beams or timber on them. Moreover, it is important to choose the width of the brackets, strictly appropriate for the dimensions of the beams.

The second type of tips has a completely smooth surface. It can fit and tile grillage.

The next parameter of the caps on the piles is the diameter of the plate and the tubular base. These dimensions depend on the diameter of the supporting elements installed in the foundation of the erected structure.

The minimum diameter of the round tube of the lower part of the tip is 57 mm. The maximum load that can be laid on a similar basis is no more than 800 kg. Such thin piles are usually used for the construction of lightweight buildings and structures: garages, sheds, gazebos.

The most common in private construction are medium in size and strength piles. Their diameter is 89 mm. They are even used in peaty and marshy areas for the construction of country houses, baths, fences, garages.

The maximum size of the base tip is 108 mm. It is mounted on a thick and strong support. Such structures can withstand mass up to 3.5 tons. They can be buried in any type of soil.Used for the construction of supports for heavy buildings and structures, including bridges.

Also caps can be welded or removable. The first type is attached to the base by welding. Removable face elements can be bolted.

Piling fit

To give the supporting elements the same height, their chipping or trimming is applied. This process is somewhat laborious and requires skill, but still quite do it yourself.

Stages of work:

- At the beginning you should choose a control support pile. It is precisely at its height that it will be necessary to orient when adjusting the length of other supporting elements.

- On the remaining supports, a line is applied with a marker along which the chipping or trimming of the pipe will be performed. The unity of the horizontal should be checked with a laser or hydraulic level.

- Cutting of the ends of the supporting elements is carried out using a heavy jackhammer. Pre-line the chipping cleaned with a file. The blow is applied horizontally on the upper edge of the pipe.

- For trimming the base pipe, you can use a grinder or abrasive saw. The cut is made along the line marked with a marker along the diameter of the base or towards the center of the pile.

- Another option for cutting the ends of piles is to use hydraulic equipment. Its rent, and especially purchase, are expensive. However, this method makes it possible to cut very smoothly, without damaging or chipping the entire base.

End installation:

- Prepared piles should be stripped of paint with the help of grinding equipment.

- The cap is placed on the base. Using a level you should check its horizontal position.

- The element is pre-welded in 3-4 places by spot welding.

- The welding head cap is welded around the entire circumference. It is necessary to leave a small area of 5-10 cm not welded. It is necessary for the passage of air and ventilation inside the base pipe.

- Weld the weld seam and apply paint or primer.

Cost of

The price of each specific tip for a screw pile can vary considerably. First of all, its cost will depend on the size, quality of the material and the location of the manufacturer. Foreign end elements are often more expensive due to the cost of the manufacturer to transport their products.

On average, round-shaped caps cost between 200-250 rubles.Reinforced tips of large diameter have a lower price limit of 350 rubles.

When planning the cost of construction work, you should also include the cost of delivery to the site. If you do not have your own equipment for welding and cutting piles, you will have to rent it.

For how to trim the screw piles, see the video below.