Pile caps: characteristics and subtleties of use

During the construction of residential buildings with several floors, piles are used. These structures provide reliable support for the entire structure, which is especially important for wetlands, as well as areas with shallow groundwater. The framework of the foundation is attached to the piles with the help of their end surfaces, called tips.

What it is?

The cap is the top of the pile. It is firmly fixed to the surface of the pipe part of the pile. The size and shape of the tip can be completely different. This element can be installed beam grillage, plate.

Since the piles serve as a reliable support for the foundation of the house, their material must have high strength properties. Most often, such structures are made of metal, concrete or wood.

The shape and size of the piles should be the same; the evenness of the foundation surface and its stability depend on it

The use of support piles allows you to evenly distribute the weight of the structure, build buildings on an uneven surface, do not worry about the close location of wetlands, seasonal floods.

Types and sizes

The shape of the tip may be in the form of a circle, square, rectangle, polygon. It corresponds to the shape of the pile itself.

Pile cap can be in the form of the letter "T" or "P". The design in the form of the letter "T" allows you to install formwork or slabs for subsequent pouring of the foundation. Designs in the form of the letter "P" allow you to install only beams.

The most common types of piles used in the construction of buildings are reinforced concrete and screw.

Reinforced concrete

Concrete pipes are installed in the drilled plot of land. Piles have high strength properties, corrosion resistance,temperature drops. They are used in large-scale construction of high-rise buildings, shopping centers, industrial buildings. Installation of such structures requires considerable financial investments.

Screw

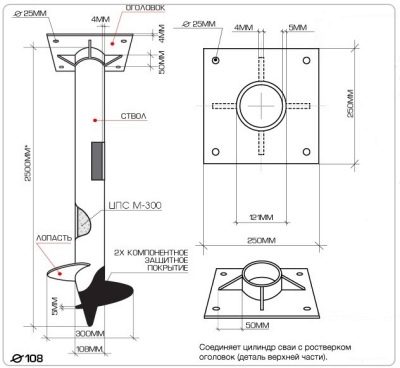

The structures are metal pipes with a helical surface. Immersion into the ground of such elements is made by twisting the pipe around its axis. Piles are used in the construction of smaller objects, for example, private residential buildings. Their installation does not require the use of expensive equipment, as well as large investments.

Among the screw piles are the following types:

- a design that looks like a medium-sized screw;

- design with a wide-blade surface with a curl at the bottom of the support;

Wood

Such supporting elements are used in the construction of one-or two-story buildings.

There are two types of support structures.

Collapsible

Ogolovki fastened with bolts. Removable elements are used when pouring the foundation on heavy ground, when installing supporting structures manually, as well as in wooden supports.

Not separable

Ogolovki attached to piles with welds.It should be noted that such a seam has a small gap. This is necessary so that air enters the inner surface. Such elements are used in the case of a drill to install supports.

The sizes of the head are selected depending on the type, diameter of the pile, as well as the weight of the structure, which is installed on the head. Its diameter should be slightly larger than the diameter of the pile. This is necessary so that the design can be easily connected.

For example, the diameter of the middle part of the screw support is in the range from 108 to 325 mm, and the diameter of the tip itself can be 150x150 mm, 100x100 mm, 200x200 mm and others. 3SP5 steel is used for their manufacture. Such piles are capable of withstanding loads of up to 3.5 tons. They are suitable for any type of soil.

E series heads made of JV 5 steel, which is 5 mm thick, have dimensions of 136x118 mm and 220x192 mm. The caps of the M series have dimensions of 120x136 mm, 160x182 mm. The caps of the F series used for fixing the strapping are 159x220 mm, 133x200 mm in size. U series caps made of steel have dimensions of 91x101 mm, 71x81 mm.

The smallest tip diameter is represented by the R series. Piles have a diameter of 57 mm, 76 mm or 76x89 mm.Such structures are able to withstand a relatively small weight of the building. Therefore, they are often used in the construction of pavilions, garages, summer houses.

Piles with a diameter of 89 mm are used in the construction of small buildings in areas of high groundwater content.

Concrete piles have a square-shaped cap, the minimum dimensions of which are about 20 cm. The length of such piles depends on the weight of the structure being erected. The greater the weight, the longer the pile should be.

Choosing the right support structure will provide a truly reliable foundation that will last more than a dozen years.

Installation

Before installing the piles made a breakdown of the pile field. The surface area is calculated, as well as the number of support elements required. Piles can be divided into rows or staggered.

Installing supports on the same level is a very difficult task, almost impossible. Therefore, after the pipe supports are tightly fixed in the ground, work on leveling their dimensions begins. This can be done using various methods, for example, by:

- log house;

- cut.

Technology logging includes several actions.

- At one level from the ground draw a mark on the support.

- Along the mark line, make a furrow around the pipe support. To do this, use a hammer.

- Produce felling of the protruding section of the pipe. Using movements from the top to the bottom or, conversely, from the bottom up, parts of the waste surface are chipped.

- Cut off the armature.

Felling of the surface can be done in different ways.

Hammer

In this case, a groove is made around the support along the marked line, then with the help of hammer blows I cut off parts of the concrete surface. This leveling process is characterized by great laboriousness, duration. In one day you can align no more than 15-18 supports.

Hydraulic shears

The alignment method is to install the nozzle on the support along the line of the mark, then biting off its protruding part. The process is less time consuming, takes less time. The quality of the surface is much higher than when using a hammer.

But there is also an alternative method of alignment with cutting ends. This method is faster, more economical. Depending on the type of material, various tools are used, for example, machine mills, discs, saws, manual tools.The method is characterized by low cost, as well as relatively low labor costs.

The technology of cutting protruding parts of the pile includes several stages.

- Before starting work, make marks on piles. It is important that they are on the same level, so they are noted on all sides.

- On the marked line make a small incision.

- Sawing off part of the pipe.

In the case of metal structures, at a distance of 1-2 cm from the cut point, a layer of anti-corrosion metal coating is removed. This allows you to extend the life of the piles.

After alignment of the supporting structures proceed to the installation of tips. They are put on top of the pipe, and then they check the level of all the piles. If some support structure will stand out on the surface, this will have to be corrected by removing the surface of the protruding support.

After all the tips are at the same level, proceed to their attachment to the support tube.

The method of installation of caps depends on the shape, type, and also on the material. Metal heads are installed by welding with an inverter converter. Current is supplied with a power of 100 amperes. Welded supports have high waterproofing.

The process of fixing the tip by welding consists of the following steps:

- putting on, leveling the tip;

- welding;

- verification of the perimeter support structure;

- cleaning of welds from dirt, dust, foreign particles;

- surface coating paint with protective properties.

After leveling, concrete heads are poured with a solution of concrete after formwork has been installed on them to fill the foundation.

It should be noted that all pile work must be carried out in accordance with the GESN.

If necessary, you can always dismantle the piles. Works consist of the following stages:

- removing the top with a hammer and grinder;

- specialized equipment, such as an excavator, is used to remove the entire support.

You can proceed to the installation of new piles only after the complete removal of the previous bearing surfaces.

Correct installation of piles will facilitate the subsequent work on pouring the foundation and the further construction of the building.

Tips

When installing the tips, it is necessary to observe the sequence of actions. When working with cutting tools, you should observe safety rules.

After fitting the tip on the pile, it is recommended to remove it and thoroughly clean the surface of the pipe from the edge to the length on which the tip is installed. This procedure further allows to obtain high-quality welds. Cleaning can be done with any tools at hand. More often used for this Bulgarian.

In order for all the supporting structures to be on the same level, you should choose one pile, the rest of which will be equal in length. It is important to put bright labels so that they can be clearly seen.

Installation of piles requires a special skill, so it is not recommended to neglect the help of professionals, especially at the initial stage of work.

In the video below you can see how the piles are cut.