How to calculate the amount of cement on the foundation?

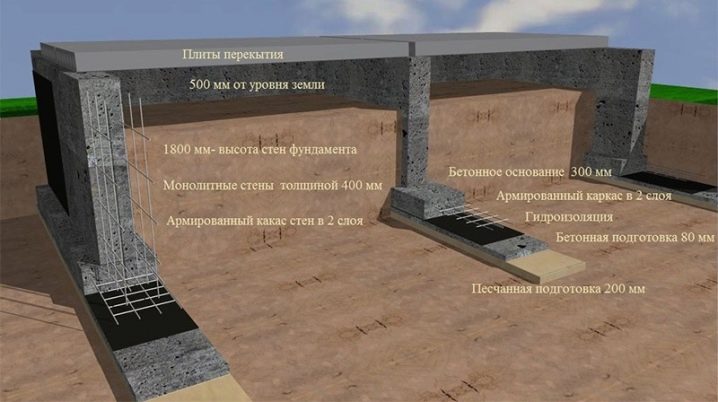

Building the foundation of a house is the most difficult both in material terms and in terms of labor intensity. To ensure reliability and not to spend an excess amount of money, effort, you need to carefully calculate the amount of cement. This procedure has its own subtleties, taking into account the properties of the soil, the characteristics of the supported structures and much more.

Special features

When drafting a project, you must immediately enter into it an estimate of the total consumption of bulk building materials, including cementitious mixtures. Buying and transporting even “just” extra 10 kg can be very expensive; lack of them will break the cycle of work at best,at worst, it will not allow them to be properly executed. The role of pouring is very large: it helps to extinguish the deformation stresses and to avoid the precipitation of buildings. In most cases, if there are no weighty reasons for counting differently, the ratio between the components of the mortar (sand, cement and gravel) is taken to be 3: 1: 5 (in fractions).

How is it applied?

For the construction of the foundation of the house used only carefully selected grades of concrete. Cooking them requires a certain skill from the builders. For the finished mixture to be as durable as possible, granite crushed stone is used in the form of fractions of 1-4 cm. To obtain a foundation solution, alluvial grades of quarry sand with a grain size of 0.12—0.35 cm are used.

The concentration of impurities in this inert material can not exceed 5%.

For an accurate calculation of the consumption of the finished cement mixture, you must take into account the brand of the main binder reagent. M-100 is considered not enough quality.

Such material is intended mainly for:

- rough floor screeds;

- plastering work;

- surface finishes;

- calculations of internal partitions.

Since the carrying capacity of such a material, which can be seen already in the areas of its application, is small, per 1 cu. m base of the house consumes 220 kg of binder composition. The M-200 brand is officially recognized as a plaster-masonry coating, it is suitable for facial floor concreting. Compared to the M-100, it is stronger, but costs relatively little. This brand of cement can be used only where there is no risk of flooding or serious loads. The specific consumption is 280 kg.

According to professional builders, for the foundation it is better to use cement brand M-300. It was he who was designed for this kind of work in the best way. Resistance to contact with water, to sulphates, low heat transmission confirm this.

On the basis of practice, we can assume that 1 cub. m base must be applied 380 kg of dry binder reagent.

M-400 differs in addition excellent resistance to hypothermiaIt is recommended for the field of transport construction and for the construction of underground structures. The disadvantage is only the high price (and consumption - 440 kg). M-500 differs from M-400 in increased elasticity and durability of the stone. On the formation of 1 cu.m consumes exactly 0.5 tons of the substance, or 10 bags of 50 kg each.

Important: cheaper versions of the base solution can be improved by introducing special additives.

But it is better to determine the exact type of it, as well as the expendable value, as precisely as possible.

Not just the brand decides.

It is not necessary to be a professional architect or foreman to understand that the exact cost of cement is determined not only by the quality of the binder produced at the plant. It is necessary to take into account the fact that from the increase or decrease in the proportion of each component of the mixture changes the time of the final maturation of concrete. The framework is mainly made from cements of the M-300 group. But the brand from 600 to 800 is not recommended: they are intended for the construction of only the most solid structures, including high-rise buildings.

What is important - for the construction of small private houses it is not recommended to build on the calculations on online calculators: the figures obtained in this way are not always accurate and have significant errors.

It is much more correct to calculate the volume of the forthcoming foundation construction using ready-made formulas:

- for the slab - multiplying the area by the height;

- for a ribbon, the multiplication of the total length of the structure to be created and the area in the diameter;

- for piles, the cross section of a single support is multiplied by the total number of support blocks.

Important: planning to dilute the mixture without rubble, the ratio of water and cement is required to be reduced by 10%. But it should not be forgotten about the dependence of the amount of water consumed on the volume of sand and the size of the fraction of stony materials. In typical proportions, which are given in reference books for non-specialists, such subtleties are omitted. But to ignore this circumstance in real construction means to face very unpleasant consequences.

Let them take for work:

- crushed stone of 2.5 cm with a density of 2700 kg;

- sand mass with a fine grain with a density of 2500 kg;

- Portland cement M-400 with a density of 3 tons.

To obtain a solution of the M-300 group from these components, a factor of 0.53 is required. At 1 cu. m. solution will have 195 kg of water, or 0.195 cu. The proportion indicates that you need to choose 368 kg of portland cement. Knowing the proportion of the most important dry part, it is easy to calculate the required volume of fillers, their percentages, and, consequently, the total mass.

Although the cement of higher grades is consumed more significantly, it is quite appropriate to take it, because it helps to strengthen the base to a reasonable limit.

Tips and tricks

A logical question arises: “Is there enough strength for the chosen solution for building a house?”. It is best to check its quality in practice. Having prepared a kind of bar from the calculated mixture, they wait for it to solidify and, using a medium-sized hammer (with a working part mass of 0.5 kg), try to drive the chisel in one blow. If the blade of the tool has penetrated more than 0.5 cm, it is no good. An artificial stone that is more or less suitable for a foundation should discard a chisel during such an impact.

There is another nuance - the load exerted on the foundation by the house, its roof, accumulated snow at the top and everything in the dwelling. Ignoring this indicator, one can never build a good foundation. Because 200 kg per 1 square. cm are considered the minimum level at which you can at least talk about reliability. Such a bearing capacity of concrete is achieved when the cement mortar M-400 is correctly laid in a ratio of 1: 3: 5.This requirement fully applies to monolithic supports, and to tapes under low-rise buildings.

You can approach the solution of the problem in a slightly different way. Let it be required to pour 1 square. m solution per 100 mm thick. This unit can be accurately filled with a standard bag of cement M-400, but if you use M-300, you will need another 1 kg of binder extra. As a result, in both cases, concrete of category M-150 is obtained, suitable only for correcting defects or for holding secondary buildings. Another important fact that is always useful to remember is that 1 cu. m of concrete of 300 group is obtained from 600 kg of cement category M-400.

In order not to be mistaken with the calculation of the necessary building materials, it is necessary to focus on the formulation of the concrete mix, specified in the SNiP. Strict adherence to technology will help eliminate frustration as a result of its calculations and the mixed solution. According to her, the concrete should stand from 28 to 30 days at a temperature of about 20 degrees. In addition to the exact observance of quantitative proportions, it is worth thinking about indicators such as moisture and cement granularity: they sometimes have no less impact on the outcome of construction work than a strict calculation of the total consumption of individual components in the mixture.

You can find out how to fill the ribbon foundation with your own hands from the video below.