Pile foundation foundation: design features and installation technology

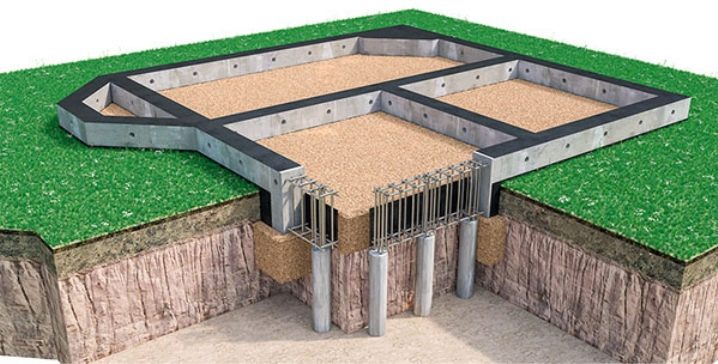

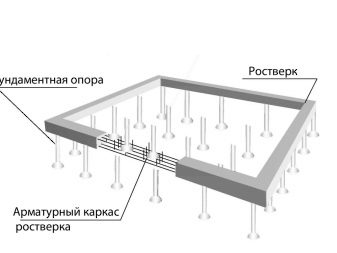

For the construction of residential and industrial buildings, various types of foundations are used, but a pile-rostrum construction deserves special attention. It is usually chosen in cases where on the land there are sharp differences in relief, heaving and weak ground. This type of base is also well suited for development of areas located in the permafrost zone.

Specifications

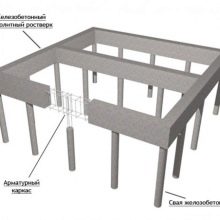

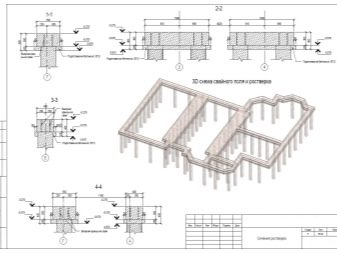

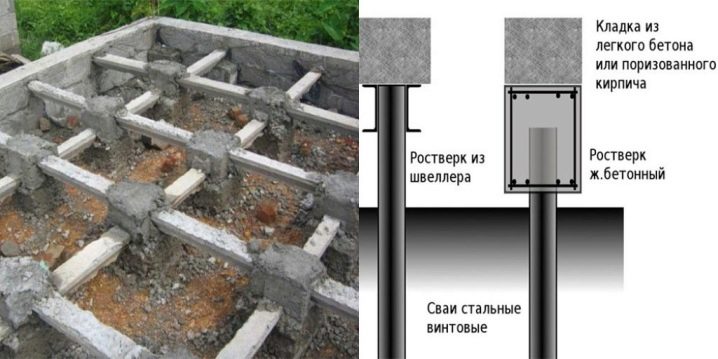

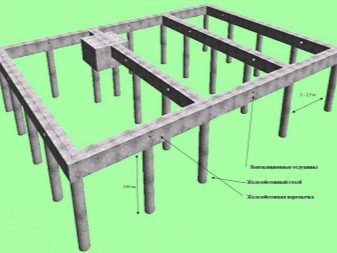

The pile-grillage foundation is a reinforced concrete, wooden or steel base, filled with concrete, in which all the elements are connected in a single structure. Its device can be either with a monolithic view of a bookmark (covered with a slab) or built with a hanging grillage.The hanging foundation is characterized by an open gap between the soil surface and the grillage, it must be further warmed and covered with waterproofing. As for the monolithic option, it is formed from a concrete frame, in which the height of the platforms is aligned with piles of different lengths.

Since during the laying of the base piles are used, buried in the ground between the bearing layer and the lower level of freezing, it is difficult to distribute the building load between them. Therefore, often the pile-grillage foundation is performed by teams from the channel and beam. All supports of this design are mounted in a knot with the help of special tapes and concrete. It is worth noting that the combination of grillage and piles gives reliability and stability to the bearing base.

Depending on how the foundation is laid (wooden, metal, concrete or reinforced concrete), the foundation for building acquires different technical characteristics. According to the regulations of the SNiP, it is allowed to construct structures with low and high grillages, which are located above ground level. They are usually made of metal pipes of large cross section or of concrete.In this case, making grillages of concrete is much more difficult, since it is necessary to accurately calculate the place of pouring the tape from the soil.

The main feature of the foundation is that the grillages included in its device, perfectly withstand uneven loads, providing a rigid mate to the base. The grinders redistribute the load, as a result of which the already “leveled” weight of the building is transferred to the piles, and the building is protected from the formation of cracks in the walls.

Purpose

Unlike other types of foundations, the pile-grillage foundation ideally distributes bearing loads from buildings to the ground; therefore, choosing it, you can be sure that the new building will reliably last more than a dozen years and will be protected not only from sudden temperature changes, but also from seismic activity. Such structures are widely used for both public and individual construction. Especially well suited for areas located on a slope with heaving permafrost soil and complex terrain.

In addition, such foundations are recommended:

- for the construction of a brick house;

- in frame construction;

- for constructions from gas silicate blocks;

- on soils with high density;

- at high placement of ground waters;

- on unstable ground with quicksand.

The pile-grillage construction also allows laying the floors directly on the ground without performing additional leveling of the surface and pouring deep tape, since the piles installed with different heights compensate for all the irregularities, eliminating the height difference. It is possible to use such a foundation in the construction of buildings with a weight in excess of 350 tons - it will be much more reliable and economical than a strip or tile base. But in this case it is necessary to lay in the project a higher factor of safety, which should not be 1.2, as usual, but 1.4.

Advantages and disadvantages

The pile-grillage foundation is a single system consisting of grillage and supports.

Due to the presence in the structure of the concrete base, reinforced with reinforced elements, the base acts as a reliable support for buildings and is characterized by several advantages.

- High economic benefits. Installation does not require large financial costs, since the land works are minimized.

- Sustainability.The large bearing capacity makes it possible to erect high-rise buildings using heavy building materials in their decoration.

- Advanced construction coverage. Compared with other types of foundations, land development can be carried out on any type of soil that is not suitable for laying traditional foundations. Difficult geometry of the landscape, slopes and slopes are not an obstacle to work.

- The possibility of forming piles separately from the grillage. Thanks to this nuance, the concrete mix is significantly saved. In addition, you can use both ready-made and self-prepared solution.

- Convenient location of piles with cable lines and underground pipelines. This simplifies the creation of the project and does not violate the functionality of the settings.

- High strength. The monolithic bundle of the grillage and supports protects the structure from the shrinkage of the soil, so the structure during operation does not break or deform.

- Lack of preparatory work. To lay the pile-grillage foundation, there is no need to form a pit, which simplifies the construction process.

- Good thermal insulation.The space between the ground and the base due to the improved arrangement of the grillage does not allow cold air flows - this reduces heat loss and makes the building warm.

- No risk of flooding. Pile structures, elevated above the ground to two meters, protect the structure from possible flooding.

- Easy installation. Possessing minimal construction skills, it is possible to build such a foundation with your own hands, without resorting to the help of craftsmen and without using earth-moving devices.

- Short terms of work.

The above advantages are relevant only if the installation of the base is made in compliance with all construction technologies, and the building is operated according to the calculated loads for it.

In addition to the advantages, this type of foundation also has disadvantages:

- The impossibility of building on rocky soil - solid mineral rocks make it impossible to install piles.

- Problematic installation in areas with horizontal displacement. It is not recommended to carry out work on soils that can subside, otherwise the stability of the supports will be broken, and the ground will fail.

- For buildings, the construction of which is planned in harsh climatic regions with low temperatures, we will have to consider additional measures for laying high-quality thermal insulation.

- Such grounds are not provided for the implementation of projects of houses with a basement and basement.

- The complexity of the calculation of the bearing capacity of supports. Independently calculate this figure is difficult. In the case of the slightest inaccuracies, the foundation may skew, and as a result, the geometry of the whole structure will change.

Despite the shortcomings, the pile-grill foundation has worked well with builders and received only positive feedback from home owners.

Kinds

The supports that are used in the construction of the pile-gravel foundation are selected in accordance with the load of the building, the type of soil and climatic conditions. They can be made from metal, concrete, wood, or from composite materials.

Therefore, depending on the characteristics of the piles and the method of their installation, certain types of foundation are distinguished.

- Screw. It is made from hollow metal pipes with an open end.Works are performed manually or with the help of special equipment. To make the construction on screw supports strong, and the pipes are protected from oxidation, their hollow part is poured with mortar.

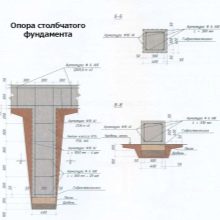

- Bourbonated It is formed on a land plot by pouring concrete into a previously prepared reinforced well located on driven piles. Padded foundation has high strength.

- Reinforced concrete. Installation is carried out using prefabricated reinforced concrete pillars arranged in the well.

- Hammerhead As a rule, such bases are chosen for the construction of large objects. The supports are clogged with the help of special equipment, after which the concrete solution is poured.

In addition, the foundation may differ in the depth of the foundation grillage and it happens:

- recessed;

- ground;

- elevated above the ground to a height of 30 to 40 cm.

In-ground grillage is usually used when installing piles intended for heavy structures of aerated concrete or bricks. In this case, additionally perform the trim plate, and the foundation can serve as a basement of the building. As for the construction of wooden structures,then a foundation with a raised grillage is ideally suited for them - this saves money on building materials, and a raised structure will protect against ground heaving.

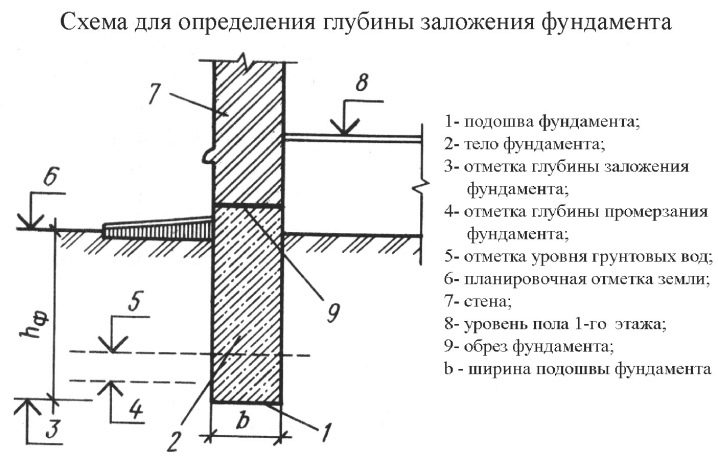

Design and calculation

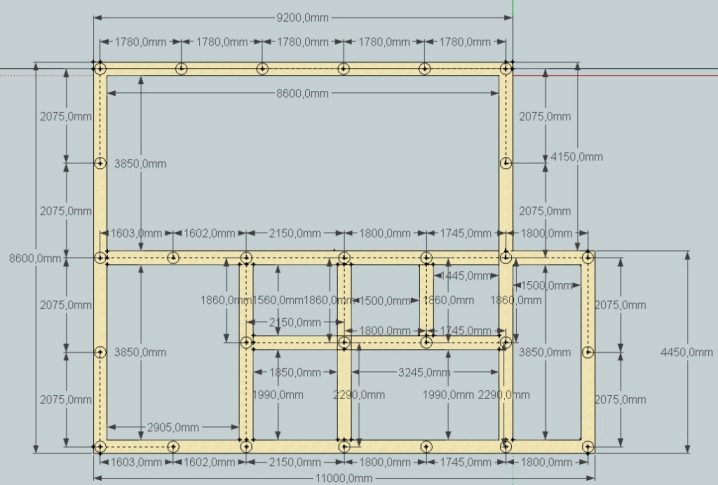

An important point before laying the foundation is its exact calculation. To do this, create a project and a plan for the future of the building. Then a baseline drawing is drawn, and the layout of the piles should be indicated, given their location at the intersections with the walls and in the corners. It is necessary to provide so that the width between the piles is at least 3 m. If the distance to their edge is more than three meters, then additional supports will need to be installed. In addition, it is necessary to calculate the area of the piles - for this, first the determination of their number is done, the minimum height and thickness is selected.

For correct calculations, it is also necessary to know some other indicators:

- the mass of the future building - it is necessary to calculate not only all the finishing materials, but also the approximate weight of the internal “filling”;

- the bearing area - using the known weight of the structure and the reliability coefficient, the load on the supports is easily determined;

- dimensions and cross-sectional area of piles - due to the known number of supports, their number can be multiplied by the selected area and the desired value can be obtained.

All results should be compared with the previously defined reference area. In some cases, it is necessary to reduce or increase the area of the supports, since their bearing capacity will depend on the diameter and type of soil.

Stages of construction

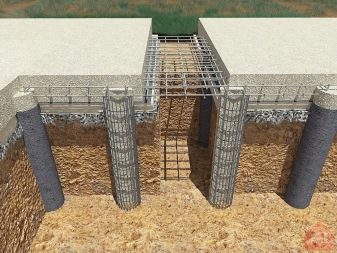

The foundation on stilts and grillage is a complex structure, but it is quite realistic to make it yourself. In order to reliably serve such a foundation, special TISE technology and step-by-step installation instructions should be used during the work.

The construction of the pile-grillage foundation provides for the following works:

- calculation of the basis and creation of the project;

- preparation and marking of the construction site;

- well drilling and trenching;

- formwork formation;

- reinforcement;

- pouring concrete mortar and rigid joints.

Each of the above items is important, so at each stage of construction should be checked quality control, since the slightest mistake or inaccuracy and then a negative impact on the operation of the building.

Marking

Before the start of construction, the workplace is carefully prepared. To do this, first of all, the site is cleared of mechanical obstacles in the form of stones, roots and trees. Then the ground is well leveled and the fertile layer is removed. After this put markup indicating the location of the piles. Work is performed using a cord and wooden stakes.

The markup must be set strictly along the diagonals. Cords are stretched to mark the inner and outer surface of the walls. If there is an inaccuracy, then deviations from the project will be obtained, and the foundation may be distorted during operation.

In the case when there are small differences in height at the site, the markup is easy to perform. For areas with complex terrain will require the help of experienced craftsmen. Particular attention should also be paid to the corners of the building - they should be 90 degrees.

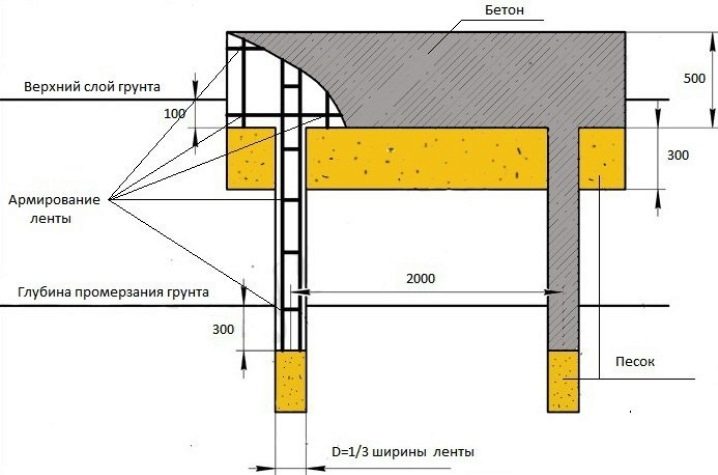

Trenching

After defining the boundaries of the foundation, you can proceed to earthworks. First, dig a trench under the grillage, then drill holes into which the piles will be installed later. Works are usually carried out with the help of such a hand tool as scrap, shovel and auger.If financial opportunities allow, you can order specialized equipment.

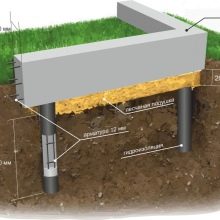

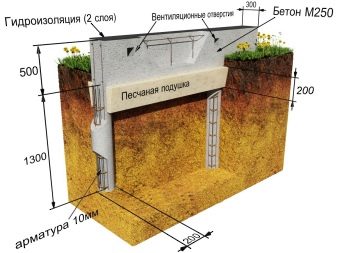

Depending on the purpose of the future construction and the type of soil, the optimal width of the grillage is chosen. For household objects, a permissible figure is 0.25 m, for mobile - 0.5 m, and for residential buildings, this figure rises to 0.8 m. As for the depth, the grillage may lie at 0.7 m.

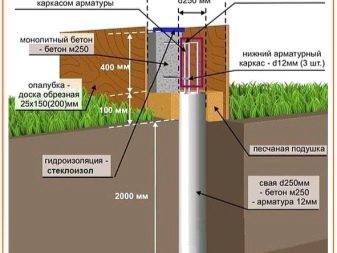

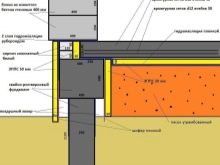

In the dug ditch, you need to check the bottom and walls for evenness - this will help the laser level. After that a sand cushion lays down at the bottom of the trench, the sand is chosen as a large fraction. After its laying the surface is moistened with water and carefully tamped. Sand pillow can not be less than 0.2 m. The next stage of excavation work will be the preparation of holes for vertical piles: holes are drilled with a depth of 0.2-0.3 m.

Then pipes are installed in the finished pits that will play the role of formwork, and the bottom is covered with waterproofing material - this will protect the structure from moisture.

Installation grillage

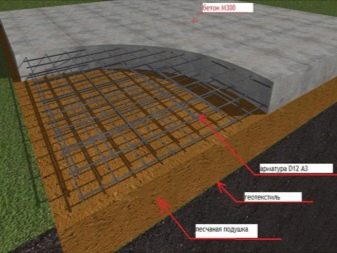

An important point in the construction is the installation of the grillage. Most often for work choose a metal element that is easily welded to the tips of the piles.In order for the structure to evenly transfer loads, it must be placed strictly horizontally. In the event that the device of the foundation for the project involves the use of reinforced concrete low grillage, then additionally perform the filling of crushed stone of the middle fraction. Crushed stone poured into several layers of 5 cm and well compacted.

Formwork is placed on the prepared base. The width of its tape must exceed the width of the walls, and the height is calculated in accordance with the indicators of the base. Assembling the stops and assembling the boards is in many ways reminiscent of the work technology for strip foundations.

As for the reinforcement, in most cases, similar to the construction of the tape, two belts are made of ribbed reinforcement from above and below. They are tied together with piles. The ends of the reinforcement coming out of the piles, bend: one row is tied to the upper belt, and the other - to the lower.

Outlets of the reinforcement should not be less than 50 mm from the diameters of the rods. For example, if reinforcement with a cross section of 12 mm is used, then it is recommended to bend it by 60 mm.

Laying embedded parts

After all the work on the manufacture of the frame is completed, it is necessary to consider the placement of communication systems.To do this, lay the boxes and pipes through which will be sewage, electricity, plumbing and heating. We should not forget about the laying of pipes for engineering systems and airways. If this stage is not performed, then after construction for installation work it is necessary to hammer concrete, which may compromise its integrity and damage the building.

Pouring solution

The final step in the installation of the foundation is to pour a concrete solution. For concreting is usually used cement brand M300, crushed stone and sand. The mixture is prepared in a ratio of 1: 5: 3. At the same time, the solution is not just poured - it is additionally vibrated. Due to this, the surface is durable and uniform.

First of all, the concrete is poured holes for piles, and then - the formwork itself. The workflow is desirable to perform in one go. If, however, to concrete in stages, then the appearance of irregularities and air bubbles. The optimal temperature for casting is + 20C - with this indicator, the formwork can be removed after four days. During this period, the concrete will acquire strength and will be ready for further construction work.

Sometimes the laying of the base is carried out at a temperature below + 10C - in this case, you will have to wait for complete drying for at least 2 weeks. In winter, the poured concrete will need to be further heated and warmed.

Useful tips

The pile-foundation foundation must be erected properly, adhering to all construction technologies - this will help to increase its technical and operational characteristics.

If construction work is performed by novice craftsmen, then they need to take into account some of the recommendations of experienced professionals.

- Installation should begin with the calculations. To do this, determine the type of soil and the depth of the grillage. With an insufficient depth of laying the support, the building can shrink and crack, after which it can even collapse.

- A huge role is played by the study of the soil, on which the bearing capacity of the structure depends. Rock formations and stony soils have the highest rates. If it is incorrect to determine the composition of the soil, this will lead to errors in the calculations of the load of the structure, as a result of which it will sink into the ground.

- There must be a good connection between the piles and the grillage, because under the influence of the soil pressure the unstable structure can collapse.

- Regardless of the type of foundation, a sand cushion should be laid on the depth of frost penetration, especially with regard to the operation of the base during the winter period. Frozen ground may expand and cause the grillage to break.

- The rostverk should not be in contact with the ground or be buried in it. It is necessary to remove a small layer of soil around the perimeter of the site, then install a formwork, cover the sand and pour concrete.

- It should accurately count the step between the piles. This indicator is determined in accordance with the load on the foundation, diameter and number of reinforcement.

- During the reinforcement is to provide the necessary number of ventilation products. All internal compartments need to be connected to the exits to the street.

- A huge role in the device base plays insulation and waterproofing. They should be laid before pouring the foundation with concrete.

- The bottom of the pit or trench must be made rammed and not loosened. Do not allow the ground to crumble from the walls. In addition, sedimentary waters must flow away from the trench or excavation, otherwise the bottom will get wet and will be unsuitable for pouring the solution.It is also unacceptable in the trenches the presence of excessive steepness of the slopes.

- Weak soil requires strengthening with piles and good backfill.

- The sand that is used to backfill the air cushion should be moistened and distributed under the contour at a 45-degree angle.

- The formwork must be securely fastened, because when it is poured with concrete it may not withstand the load and collapse. Formwork deviation from the vertical of more than 5 mm is not allowed.

- The height of the foundation is made with a small margin of 5-7 cm from the height specified in the project.

- During the reinforcement of the frame, it is recommended to use rods with a total cross-sectional area of at least 0.1% of the area of the concrete element. It is best to choose a smooth reinforcement, with no traces of rust, dirt and paint.

- It is undesirable to fix the reinforcement with the help of welding - this may impair its strength at the joints.

- The brand of concrete to fill should be chosen depending on the design of the base and the climatic conditions of the region.

About what are the design features of the pile-grillage foundation, see the following video: