Device pile foundation: how to build a foundation on their own?

Every house foundation must be built and designed very carefully. This fully applies to the variant with screw piles. The seeming simplicity of their installation actually hides a lot of subtleties and nuances that simply cannot be ignored without the risk of facing unpleasant consequences.

Production: stages

Pile-type supports can be made by hand. But it must be admitted that such work is not easy and requires a lot of experience, a thorough study of the specifics of the problem. In order for the fastening part to easily enter the ground, it is necessary to carefully calculate the inclination of the spiral blade, its attachment to the tip cone.The situation is aggravated by the complete lack of state standards and the lack of reference products. It is impossible to buy or get any one pile and make others on its model - even the leading manufacturers often sell low-quality goods.

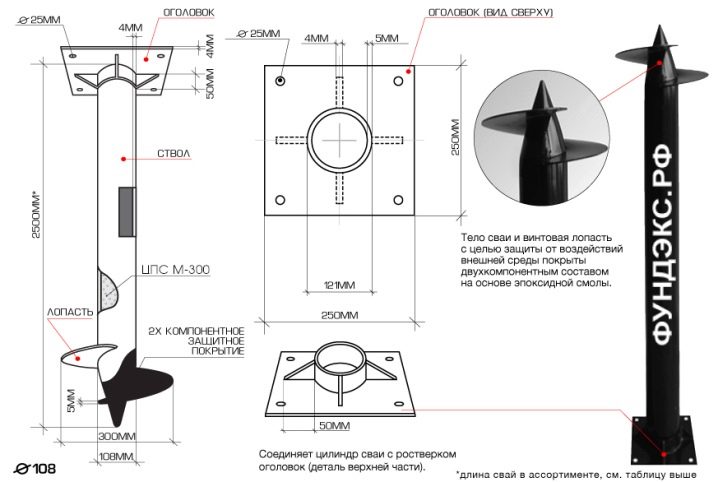

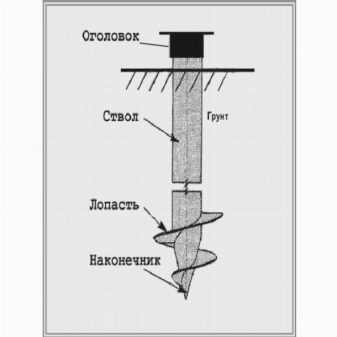

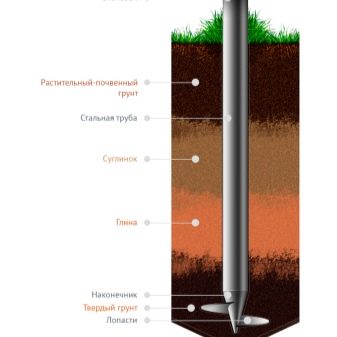

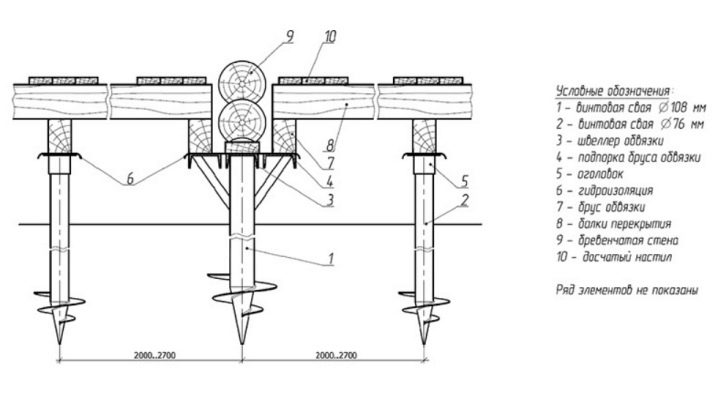

The typical composition of the structure is as follows:

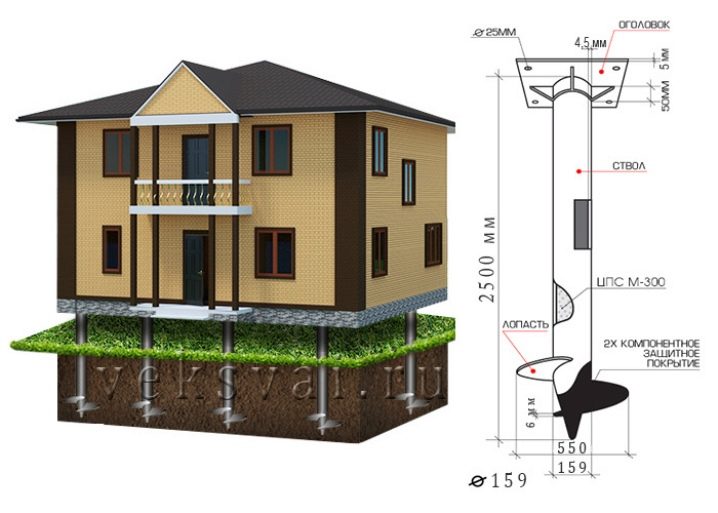

- body - pipe with a diameter of 7.6–35 cm with a wall thickness of 0.4 cm;

- tips obtained by welding or casting peaks, the length of which is 2 of its own diameter, or cones;

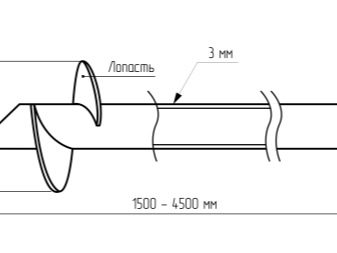

- blades - spirals with one or with two runs, and alternatively a pair of screws 40–70 cm apart;

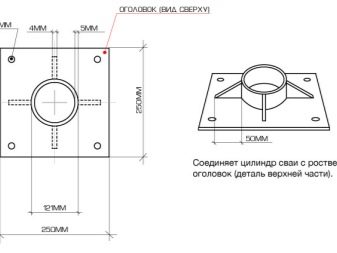

- The cap is used in combination with wooden grills.

A typical tip is made as a plate with special holes and a number of stiffeners. This plate is welded to the coil, made of a pipe, with an inner diameter slightly larger than the outer shell of the pile. Attention: for independent production of screw supports, it is worth using drawings distributed by any manufacturer. Then the risk of an error with blade sizes is eliminated, the number of welds is reduced. The fewer such compounds, the smaller and weak areas around them.

According to professionals, it is worth choosing pipes manufactured according to GOST 8732 and 19281 or by replacing them with TU St20 and 09G2S. Such materials are distinguished by a light cut and a simple bend of the petals. It is most convenient to form a tip from them. Homemade screw piles for the most part do in length from 2 to 3 m, if you want to reach the bearing layers of soil at a considerable depth, after screwing in add a pipe length of 150-200 cm. Speaking about the components, not to mention the tips.

They are made of three different types, the approach concerns not only the nuances of the technology, but also the magnitude of the part used. So, through the dense soil, the peaks of a welded design or obtained from a pipe "body" will best pass. But to pierce the sandy massif, peat deposits and sandy loafs will be easier with cross-shaped tips. How long the foundation will last does not depend on the type of peak. But the obvious differences are found when comparing the tightening force on the lever.

The use of a tubular body means building it up by two diameters., as one of the ends of the workpiece becomes the tip of the future pile. Start with cutting the template.On this template, the edge of the workpiece is divided into sectors. When the pipe is cut, the lines drawn in chalk become a guide for the formation of petals with cloves. Further, such petals are bent in the form of a strict cone, and the top is precisely aligned with the axis of the pipe; Having finished this manipulation, the fragments are welded using the double seam method.

If the pipe diameter is 10.8–20 cm, five petals are prepared. With a smaller value (from 7.6 to 8.9 cm), there are enough four fragments.

In addition to the welding machine, the normal operation requires the use of tools such as:

- plasma cutting machine;

- cutting torch;

- Bulgarian with equipment for slots in the metal.

These cutting units are interchangeable, but it is recommended that you always have at least two options at hand at the same time, and preferably all three. Then in case of some kind of malfunction or difficulty there will be no hitch in work. Then using the received peaks, you can quickly immerse them at the desired depth, pushing the small and crushing large stones. If you have to build small architectural forms and lightweight buildings, you can use welded tips, obtained in a similar way.Recommendation: docking of blades best of all occurs with peaks from tube petals, and not with those obtained from sheet steel.

There is another approach that uses a slightly different scheme. Details are covered in the form of a triangle, supplemented by stiffening ribs and a round plate that muffles the pipe at one end. When assembling, a large triangle and a pair of ribs attached to the plate at an angle of 90 degrees are put on top of the plug. Tack welding needs to be at several points. The final consolidation is done by the type of double seam.

The cross tip requires the auger blades to be attached above the spikes. Therefore, high permeability of various breeds is achieved due to the increased tightening force. As for the blades, they can be easily screwed into the ground by placing a screw at the very bottom of the tip, leaving at least 2/3 of the length on top. The exemplary blade pitch is 50–70 mm. To obtain the blades used sheet steel of large thickness of at least 0.5 cm.

A solid screw with one approach requires to spread the blades with scrap or mount to the selected step.If the design is formed from several blanks at once, it is much more correct to cut single segments (not more than ½ circle). Separate sections are successively welded onto a peak or onto a pile body. The first approach does not allow to create a complex screw, however, provides a stable geometry of the structure. In the second scheme, assembly of the auger with several runs does not present any particular difficulties, but it is necessary to carefully monitor that the type of the helix is not broken.

Before manual cutting, workpieces are laid out on the outer diameter of 150–300 mm, this depends on the load falling on the pile, most often limited to a corridor from 200 to 250 mm. They try to equate the internal diameter to the external size of the pipe. The drawing of the segment connecting the circumference in the cavity and outside is made in a randomly chosen place, but nevertheless it is worth more attention to this work. To cut parts with a plasma cutter you need from a sheet 0.5–0.7 cm thick, instead of a plasma cutter, you can take a gas cutter. When working carefully look to the width of the cut was taken into account, and the seat was processed properly.

During the wiring, the area opposite to the place of the incision is clamped in a vice and moved apart with a crowbar or crowbar. When there is no vice, you can simply use the gap in massive steel structures. But in any case, it is worthwhile to constantly observe whether the screw has a normal screw pitch or not. Other options can be used to get piles with multiple runs. So, in one of them, the marking of the inner diameter is made the same as the external size of the pipe (200–300 mm).

The ring, which is obtained with such marking, is broken by a pair of segments into identical semirings. Figure cutting implies the ability to perform actions in any sequence, but here a professional-class tool is already required. The method of "installation on the pile" suggests that the helical markings grab the initial semiring and verify the right angle. If everything is correct, other half rings are put on the same line - as many as the turns are planned to make. Attention: a slight deflection of the semirings is allowed to more closely match their design dimensions and geometry.

No matter how well the pipe itself is made, the anti-corrosion protection is also very important. According to the results of special engineering surveys, it was found that the annual loss of piles and their blades is 0.01 mm of the walls and this is in almost ideal conditions.If the soil is very chemically active, if the effects are large, wear can be accelerated several times.

After descaling and processing completely new pipes, the following can be used:

- enamel of two components is made specifically for underground metal products, the service life is at least 60 years;

- polyurethane-based enamel requires prior application of VL05 primer, will last at least three decades;

- fiberglass. Before applying it will have to treat the base with cold zinc coating. The total service life (theoretically calculated) reaches 3–4 centuries, stable resistance to electrochemical corrosion is ensured.

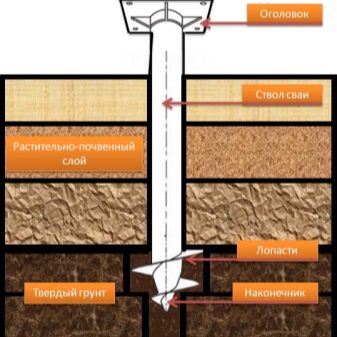

But fiberglass can hardly be called affordable material. In order to save the most commonly used complex coatings based on epoxy resin. With regard to the original steel, the standard St20 or GOST 8732-74 allows you to count on the reliable operation of the support element in conventional home construction. Only under very high loads or with harsh operating conditions, it makes sense to focus on GOST 19281. For the most part, the corresponding piles are used in industrial and multi-storey construction, for the development of the garden plots their characteristics are redundant.Regardless of the type of supports used, their length is chosen in such a way as to accurately reach the layer of solid ground.

At the same time, it is necessary not only to achieve it, but also to leave a reserve for burial by 30–35 cm. When it is planned to bring piles higher above the ground, it is possible even to further increase such a gap. Timely headroom allows you to avoid the subsequent tedious build-up and potential errors associated with it. To determine the required diameter of the pipe in its independent manufacture, as well as in the selection of finished structures, it is worth considering the norms of SNiP 2.02.03-85. Yes, it is quite difficult, but it will help to do everything very precisely and clearly.

Most often, pipes with a diameter of 4.7–7.6 cm are used in the construction of light types of intake and barrier structures. Increasing it to 7.7–8.9 cm, you can be confident in the stability of a brick bath, a capital arbor or a powerful brick fence. But for frame structures, for log houses and houses in two, three floors, it is recommended to use piles with a diameter of 10.8 cm. You should not always strive for the maximum value, since this only entails unjustified consumer spending.Important: in artisanal conditions it is extremely difficult to make piles larger than 10.8 cm.

For such products it is necessary to mount reinforced blades, and only industrial production can make them qualitatively. In addition, increasing the diameter, complicate the formation of the screw. The walls of the trunk with it, even under the lightest buildings on favorable soil, cannot be thinner than 0.4 cm. When choosing the right thickness in a particular case, it is recommended not to forget that the bend of the cone will have to be provided with hammer blows. So here, too, the principle of "the more, the better."

Advantages and disadvantages

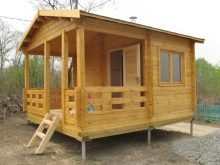

The undoubted advantages of the pile-screw base for the house are the following:

- the ability to do without special machines with a small scale of work;

- elimination of formwork and plinth;

- equally high-quality work in any season;

- providing ventilation under the floor of the house;

- the ability to dismantle any structural element.

But even this attractive solution has a number of drawbacks. It will not be possible to build it on rocks, and regardless of the quality of protection, it is necessary all the time to reckon with the risk of corrosion.The level of load on the foundation is limited; In addition, screw piles are much more demanding on the quality of work. The slightest deviation from the normal technology can provoke the failure of the supports, their curvature or pushing them up. These negative aspects, however, do not allow to ignore the fact that the screw substrate is good on the banks of rivers and lakes, on berths, in wooded areas, and so on.

Design features

Simply preparing the piles for work, even if they are very good, will not be enough. The device of the pile-screw foundation under the house has a number of specific features that cannot be ignored. Screw piles, which look like huge screws, are not susceptible to soil freezing and can penetrate to various depths. Screwing into the ground, composed of any species, is facilitated by the pointed end with the cutting part. Piles compact the soil around themselves and effectively inhibit the swelling of it.

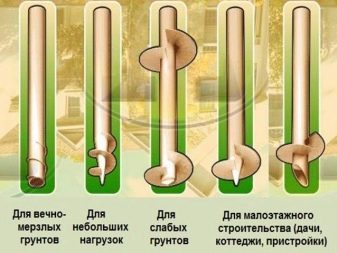

Corrosion resistance is largely determined by the type of protective coating used. Polymers provide the best cover, but it is extremely difficult to apply them to the metal.The use of screw piles for temporary and ancillary facilities, for the infrastructure of homestead plots is widespread. The foundation of them can withstand a total load of 50 tons, and a single pile can easily withstand pressures up to 9 tons during the entire normal service life. When a temporary structure ceases to be necessary or needs to be transferred to another place, even transported, you can take a pile with you and save on materials for the foundation. By the type of the tip used, the screw structures are divided into elements with a narrow and wide blade, and the latter are still divided into ones with one or two turns.

A single-turn product is equipped with only one turn, hence the name. Its top is equipped with special holes that allow to fix and use a drill. One-turn solutions are preferred in the construction of fences and minor structures. The wide blade is attractive during the construction of a two-story house, as well as during any work on areas with unstable soil. The stability of the fastening increases markedly. But even among the piles with narrow blades there is a gradation - on multi-turn and tubular ones.

The presence of several turns allows you to form pointed tips. This solution allows you to successfully penetrate even very dense ground. The tubular product is preferable in the winter months when the ground is frozen and poorly processed. Special holes let the ground through. Going inside, it makes the whole structure much more stable than in full-bodied performance.

To eliminate errors, it is important to remember that even formally belonging to one category of Russian and foreign production piles may differ from each other. The choice of a suitable solution should be made only after consultation with geologists and engineers.

The following factors are taken into account:

- soil characteristics;

- the level of penetration of cold into the ground;

- climatic properties of the area;

- height of groundwater.

Installed piles in any case required to concrete. This will help fix the support in the soil and at the same time cover it from corrosion processes. Coniferous wood can be used as a harness. It is recommended to take for tying blocks that are significantly wider than the mounted piles.The cone-shaped tip is placed on piles filled with cement, and if the cut is made oblique, the support block should be filled with soil when tightened.

Types of Piles

What are the?

Galvanized piles are characterized by high reliability and excellent durability. Zinc can be applied with hot and cold techniques. But even such a good layer will require special anti-corrosion treatment. Hot preparation is considered the best, since such a finish reduces the formation of scratches and other defects during installation. Galvanized pile well manifests itself in the construction of above-ground structures and, if necessary, to ensure the highest environmental performance.

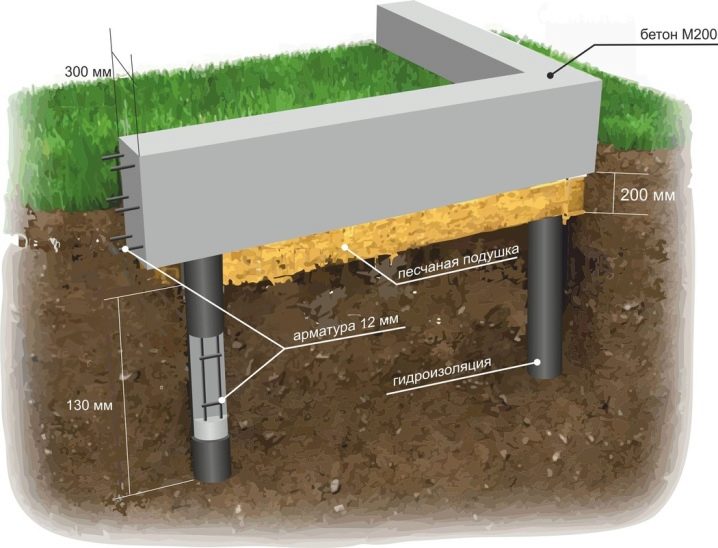

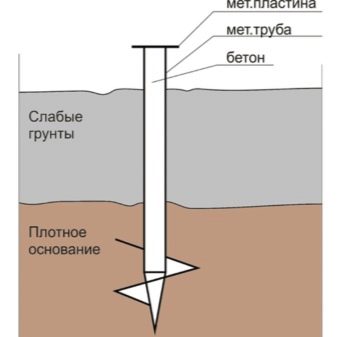

In most cases, concreting screw supports take concretes of low grade brands (M200 and M300). M200 solution is used for single-storey and two-storey buildings with light and medium floors. Cast and welded tips are two key options with which screw piles are equipped. Welded technology involves the attachment of metal blades 0.3–0.5 cm; it is cheaper than casting or concrete products, but reliability is still insufficient.When screwing into solid substrates, occasional destruction or even separation of parts from each other occurs.

The cast variant has another advantage: it is made much more precisely, for the work they use steel of the 25th mark. Heat treatment of castings is necessarily carried out, which increases the strength of the structures. Die-cast tips are equipped with blades with a base of 1.3 cm in thickness, and the closer to the edge, the thinner the product. Such a solution allows you to confidently pass even very complex soil masses, eliminating the need for advance loosening. The variation in magnitude will be minimal, the behavior of the piles during installation will be fully predictable for developers.

For what soil?

Galvanized elements can be embedded in any kind of soil, for this purpose they are equipped with tips in the form of a cone. The use of such supports is quite possible even in mountainous areas. Attention: piles with a screw can not be mounted in the soil, composed of coarse rocks and rocky patches. The coarse base is considered to be such that it is formed from mechanically unlinked fragments of rocky rocks and weathering rocks.In a similar soil from 50% of the total mass and volume falls on debris larger than 0.2 cm.

The reason for the ban is simple - large pieces of stone can cause damage to even the most durable metals and alloys. It should be borne in mind that with the location of the problematic mineral structures deeper than 150 cm, installation is usually not difficult. But the final decision should be made only by qualified engineers, since the slightest mistake can have serious consequences. Sandy soil is more favorable for the passage of screw piles and usually does not bring unpleasant surprises. Already at a depth of 1.5 m, the strength of the substrate material most often makes it possible to support the building as reliably as possible.

Dusty clays are slightly worse because they are prone to very significant heaving. The sandy loam and loam in this plan are slightly better, but they are inferior to the sand base. You can solve the problem by increasing the depth of implementation. If the blades will rest against durable material, the piles will keep themselves in place and will be able to preserve the integrity of the house for many years. As for the subsurface soils, the construction on them is extremely difficult, and it is necessary to carry out test drilling, to evaluate the properties of the soil.

Design and calculation

Having chosen a suitable variant of execution of the piles, it is necessary to proceed to the calculation of their linear parameters and drawing up projects, to the formation of drawings.

Only careful calculations allow you to choose the following:

- required height of structures;

- total number of supports;

- diameter of each of them;

- bookmark depth;

- the cost of building a foundation.

The sequence of calculations is not determined arbitrarily, it is very clearly fixed in SNiP 2.02.03.85. According to this standard, when determining the necessary properties of a structure, it is impossible to limit oneself to data on the terrain relief and the depth of circulation of groundwater. It is extremely important to focus on the actual amount of precipitation falling in a certain climatic zone. If for some reason it is impossible to perform high-quality geodetic research, we must take as a basis the minimum design load. The number of screw piles is determined by multiplying the total load by the result of dividing the reliability coefficient by the maximum permissible load level.

It is recommended that the load on each of the piles be proportional to the total load of the structure. Proper construction, which complies with GOST standards, always provides for uniform distribution of loads under load-bearing walls and under sections of increased pressure. Additionally analyzed roll effort. In many cases, it is possible to guarantee the building’s service life not less than a certain level only when consulting specialists. A simpler method for determining the dimensions and physical parameters of structures is to use special software.

When calculating the emerging load, it is necessary to take into account the mass of overlaps and operating pressure from people in the house, from their property. At the same time, professional architects do not forget about the load generated by wind gusts, building draft and temperature jerks. Piles with a wide blade and a cast tip are considered the best solution for low-rise buildings on relatively simple ground. If you take designs with many blades placed at different levels, it will help to take out even very powerful loads in difficult soil. Variable perimeter products are brought into the project if you need to solve a specific range of tasks; finally,A narrow blade with a cast end that has teeth, perfectly cope with stony ground and even with permafrost.

The least reliable solution is pile driving.made from the seam pipe by the method of welding the blades. It is permissible to use such structures only with limited loads and on “good” soil. It is considered that a pile with a diameter of 8.9 cm with a blade size of 25 cm can withstand a maximum of 5,000 kg. This is exactly the operational load created by a single-storey frame-shield house. The design with a diameter of 10.8 cm with a blade of 30 cm will easily withstand up to 7000 kg, that is, it is already suitable for two-storeyed lumber and block buildings.

When it is planned to use aerated concrete blocks and bricks for building a house, the project envisages the use of piles with a diameter of 13.3 cm and a blade 35 cm wide.

Long-term practice has allowed to form universal requirements and to the length of the supports, namely:

- in loam, located up to 100 cm from the surface, enter the rod length of 250 cm;

- in loose soil and in quicksand they introduce such a pile, which is capable of reaching a dense mass;

- the difference in areas with uneven terrain can reach 50 cm.

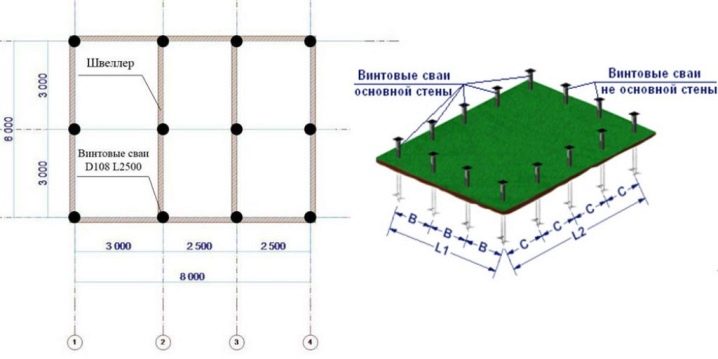

If according to the results of the calculations it turns out that you will have to make this difference more, you really need to either abandon the use of piles at all, or carefully level the unevenness of the relief, remove excess soil or pour it in the lowlands. When you plan to put on top a frame made of wood or a block house, the distance can be from 2 to 2.5 m. A little further you can push the supports that are exposed under buildings made of logs and timber. To ensure that everything is reliable and has served for a long time, the base should not be raised higher than 0.6 m. A 200–300 mm margin is left for the length of the piles.

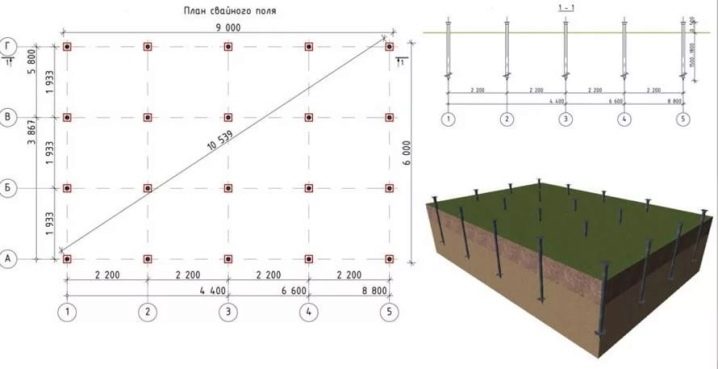

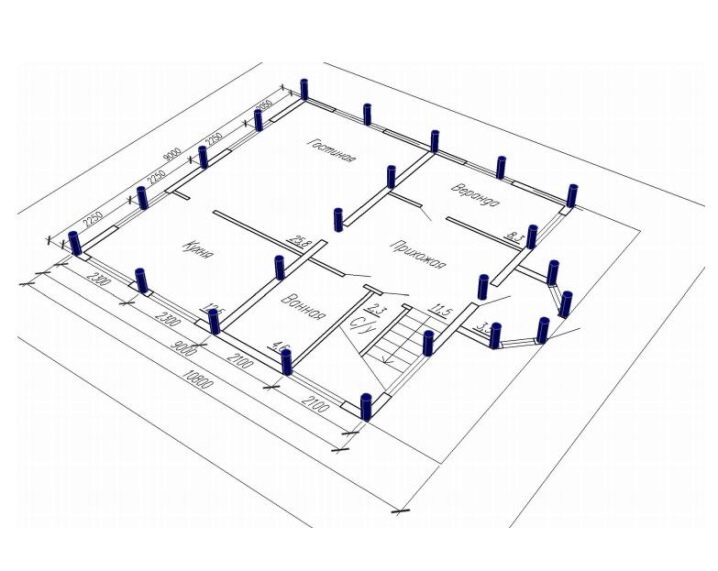

Particular attention should be paid when drafting a project to the most problematic places. Usually they are the corners of buildings and the intersection between the bearing wall and internal partitions. The loads occurring at the entrance groups and along the perimeter are quite large. Enter to hold the stove and fireplace requires at least two piles. At least one support should be placed under the load-bearing walls in those places where the mezzanine and balcony are located.

If the actual operating conditions imply the need to add the number of screw piles compared to the design one, you should not be afraid of such a step.On the contrary, increased durability will provide real cost savings, since the quality of the building will be optimal for the entire period of use. When calculating the grillage of any type and height, they calculate as carefully as possible how the foundation as a whole and every angle will be pressed through. Additionally, calculate the energy of the bending effect. In the variant with a high type of grillage, 100% of the load is superimposed on the piles, and therefore the exact calculation without assistance or at least without specialized software will be rather complicated.

Training

The most careful calculations and the most well-thought-out projects will not give a positive result if you approach the pile driving mindlessly. Although their developers and manufacturers are actively introducing solutions into their designs that allow compensating for a part of construction errors, it is better to install supports for a house or other structure according to all the rules. This means thorough site preparation, even when a “only” bath or garage is being built. The matter is not limited to geological exploration and data collection on the desired type of piles, on the desired depth of their laying and so on.Sometimes it is necessary to twist or hammer pile elements in the form of a sample in order to better assess the characteristics of a particular section by experience.

On construction sites with strong soil it will be enough to level the territory., remove all bushes, trees, grass and their roots, remove garbage of any kind. But where the earth is flowing, very soft or not very stable, you will need to level the site. In places with a high location of groundwater, preparation often involves the removal of melt runoff and drainage. In order to guarantee the absence of any kind of vegetation under the house, sometimes it is even necessary to remove the fertile layer, removing 200–300 mm of soil mass from the surface.

The importance of the initial clearance is not only that it opens up favorable opportunities for construction work. This is the only way to correctly mark the zero level and count the tiers of the building as a whole from it. The marking is made not only on the plan, but also on the ground. Stretching the rope or the wire held by the stakes will help make it more obvious and convenient to use. A simpler option is to dig small holes filled with lime.The connecting reference points of the line are drawn directly on the surface with the help of shovels and other entrenching tools.

Having drawn the lines, they and the boundary points must be checked again with the drawing and plans. It is better to spend on it even a few hours, rather than then for years to lament the mistake. Regardless of the strength of the piles to be mounted, it is necessary to take into account the probability of their destruction from external influences. Experienced builders always take maximum care of protecting the supports from water ingress and the migration of soil masses. Even the warming of the site under the house is fully justified.

When it is decided to pour tape over the pile foundation, the entire area up to its foot is saturated with ground mass. Before pouring the mixture, it is required to cover the free places on the piles with a layer of primer or other means of waterproofing. This will provide an air cushion between the building and the ground for the thickness of the tape. Only when all this is done, you can proceed to work on the installation of the foundation itself. To do it manually or at the expense of special equipment - it is necessary to solve it in each case individually.

Installation

Technology

Knowledge of the installation technology of piles is significant for any developer. If you make a mistake, you can face a decrease in working life and a reduction in the strength of the base. The depth of the reservoir with the required bearing capacity should be determined under the mark of freezing. When purchasing piles, taking into account such depth, it is required to take into account a rise of 50 cm above the ground, which allows leveling the pile field.

The axes of the bearing walls are laid out immediately after that, together with them the marking is carried out for any structures that create the load, such as:

- porch;

- stairs in the house;

- stove or fireplace.

Self-made or purchased piles need to be immersed in advance drilled leading holes. Cutting out the ends sticking out is made under the general horizontal level. The harness is carried out using the grillage and stiffening parts, but you need to resort to both elements only when the pile height is more than 1.5 m above the ground. Piles that do not have a zinc shell must be concreted from the inside to prevent corrosion. This requirement is important even for structures with a polymer or fiberglass layer, which cannot be monolithic inside a pipe for technical reasons.

The role of experimental twisting is great, they complement the picture that geological surveys provide, and in some cases they make it possible to completely refuse to pay for the help of geologists. One pile is alternately inserted in several selected locations to determine the final depth of placement of the bearing soil. In addition, it becomes clear whether there is a top layer, how strong it is, and whether there is a waterproof primer below. Having dealt with all these moments, you should proceed to the markup, which is carried out by cords on the rags. The points where the centers of the piles should be entered are required to be marked with crosses.

Guides are dug along these crosses or they dig out pits. Twist the lighthouse piles (corner), placed in the places of conjugation of the walls, it is necessary in the first place. Only such a technique guarantees the coincidence of the real and project contours of the building. Minor deviations of individual supports are eliminated due to tips with extended platforms. It is rather difficult to do without leading holes, they greatly simplify the vertical positioning of tubular structures and the insertion of spirals into the ground.

The maximum permissible error when using lighthouse piles does not exceed 50 mm. At intermediate points, the support blocks can be installed with less severity. However, if all the beacons are made correctly, the probable deviation will be within the limits of the norms without additional efforts. A pile field in the place of installation of a capital furnace or another heavy center should have from 4 piles with a grillage in the form of a slab. Under stationary pumps over 400 kg should also be a pile.

If the installation of a backup generator is planned on top, the upper part of the grillage is covered with vibration isolating tape. Depending on the expected mass, 2 or 4 piles are placed under the internal stairs. The foundation under the porch is formed strictly individually, while paying attention to the geometry and nuances of the design, the layout of the house and the arrangement of the surrounding area, including the blind area. The main thing is not to forget about all these piles, so that you do not have to screw them in hastily, opening the rough floors and breaking the already debugged system. At this stage of work it is necessary to deal with the installation of engineering communications, with their thermal insulation and with the addition of heating cables.

To screw the pile into the foundation with the help of special equipment is quite expensive.therefore, almost every developer prefers other options. Completely manual work requires the participation of three people, the SHS rotates two of them, and the third controls. Mechanizing the process (using a drill with a planetary gear), you can restrict yourself to two participants. One monitors the vertical entry of the product, and the other facilitates the initial stage of implementation. Despite the increased labor costs, the completely manual technique is more practical, it allows you to immediately identify the entrance to the bearing layers by increasing the pulling effort.

To reduce construction costs, you need to immediately, at the time of design, to decide whether you need tips or not. But it is useful to bear in mind that a significant deviation in the process of working from the normal axis will still force these elements to be mounted. There is no need to put over the caps made of metal and reinforced concrete. Since welding the tips to the piles forms corrosive foci, it is required to use paints containing zinc and aluminum to protect.They perform their function only when slag and scale are removed from the surface.

The twisting of the pile may cause its top to shift to the side. The plates help align the wall axes when a pile floor is tied with a grillage. It is impossible to do without a cap where a grillage made of wood cannot be fixed on a round pipe. And it is also useful where beams are used from welded to the edge channels, the support area of which must be increased, otherwise it will not be possible to form welding seams. As for moving the piles apart from the wall axis, the tip helps to correct defects up to 100 mm in both directions.

In any other case, there is no need to use welded plates. The foundation of the SVF under a brick house necessarily requires a monolithic grillage. Under the log cabins and two-story, three-story frame houses, the reserve of the fortress is achieved by an I-beam or channels. When you plan to put light housing at the top, you can limit yourself to a bar trim or boards. Monolithic grillages are created with formwork, fittings are carried through the bodies of piles, it is bricked into concrete along with caps.

I-beams and channels should be welded to piles without tips. When the pile field turned out to be on a slope with a change in height of over 150 cm from one opposite wall to another, it is impossible to do without the reinforcement strapping with rigid struts or vertical connecting elements. To attach them need flanges. This technology guarantees a common foundation life of at least 70 years.

Work order

When all the necessary data have been collected and the depth of frost penetration has been estimated, it is required to free the construction site from everything that may interfere with work, even to a small extent. Additionally, they check the steel grade and specify the parameters of the required pipes. When marking the territory, you can focus on the drawings both at home and on its first floor. In a certain hole, a pile is installed in advance with a transitional tip at the top and fixed through a hole. When it is hard to rotate the protruding levers, use the tube levers.

When the pile sinks, the tips are changed to shorter ones. If it was not possible to go through the freezing line, the reason may lie in a solid stone. It is simply bypassed, moving nearby.So move the support if necessary, until the barrier is broken. Vkruchennye piles cut to one horizontal and saturated with a solution of concrete.

Details on how to tighten the screw piles, you can see in this video.