Device and installation of formwork for strip foundations

Construction of a private house is impossible without the construction of its main part - the foundation. Most often for the small one-and two-storey houses choose the most inexpensive and easy to erect the construction of the strip base, the installation of which is impossible without formwork.

What is it for?

The formwork for strip foundations is a support-shield construction that gives the liquid concrete solution the necessary shape. Its main task is to ensure the strength of the entire building.

Properly installed design must meet the following requirements:

- keep the original form;

- distribute the pressure of the solution throughout the base;

- be airtight and quickly erected.

How is the design?

Form for the solution can be built from different materials. These include wood, metal, reinforced concrete and even polystyrene foam. The formwork device of each such material has its advantages and disadvantages.

Wooden

This option is the most economical - it does not require special professional equipment. This formwork can be made of edged boards or plywood sheets. The thickness of the board should vary from 19 to 50 mm, depending on the required strength of the shield. However, wood is rather difficult to install in such a way that cracks and gaps do not appear under the pressure of concrete, therefore this material requires additional fixation with auxiliary stops for reinforcement.

Metallic

This design is a durable and reliable option for which steel sheets up to 2 mm thick are needed. There are certain advantages of this design. First of all, due to the flexibility of steel sheets, complex elements can be erected, and they will remain airtight, moreover, they have high waterproofing. Secondly, the metal is suitable not only for band, but also for other types of formwork.And finally, the part of the formwork projecting above the ground can be decorated in various ways.

Among the shortcomings of this design, apart from the complexity of the arrangement and the high cost of materials, it is worth noting the high thermal conductivity and considerable specific weight, as well as the complexity of its repair (argon welding will be needed).

Reinforced concrete

The most expensive and heavy construction is reinforced concrete formwork. It is necessary to additionally purchase it, or you can rent professional equipment and fasteners. Nevertheless, this material is not so rare due to its strength and service life, as well as the opportunity to save on the consumption of concrete solution.

From EPPS (extruded polystyrene foam)

The material is also from a high price category, however, it is gaining more and more popularity due to the variety of shapes and sizes, low weight and high heat and waterproofing properties. It is easy to install it with your own hands, and even a beginner can handle it.

There is also the option of erecting sheet formwork from corrugated slate. However, this option is difficult to insulate and strengthen properly, so it is used quite rarely and only if there is no other material at hand.And the use of expensive plastic panels, which are removed and transferred to a new site, is justified only if it is planned to build at least a dozen different foundations.

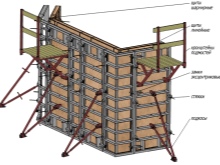

The construction of the small-panel formwork is fairly standard for any material and consists of several basic elements:

- shields of a certain weight and size;

- additional clamps (struts, struts);

- fasteners (trusses, castles, fights);

- various ladders, crossbars and struts.

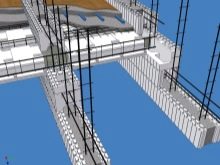

For large-scale formwork erected during the construction of heavy multi-storey structures, in addition to the above, the following additional elements are necessary:

- jacks on the jack to put shields on the level;

- scaffolding where workers will stand;

- bolts for screeding shields;

- various frames, racks and ties - for the stability of a heavyweight structure in an upright position.

There are also lift-adjustable formwork used for high towers and pipes, as well as beam and beam-shield options, various complex structures for the construction of tunnels and long horizontal structures.

Depending on the design features, formwork is also divided into several types.

- Removable. In this case, the shields are dismantled after the solution hardens.

- Non-removable Shields remain in the basement and perform additional functions. For example, polystyrene blocks insulate concrete.

- Combined. This option is made of two materials, one of which is removed at the end of the work, and the second remains.

- Sliding. By raising the shields vertically mounted wall of the basement.

- Folding and portable. It is used by professional construction teams. Such formwork of metal or plastic sheets can be used up to several dozen times.

- Inventory. It consists of sheets of plywood on a metal frame.

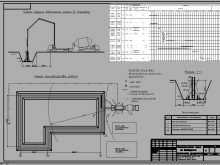

Manufacturing

In order to make the calculation and installation of the formwork with your own hands, it is necessary, first of all, to chart the future foundation. According to the received drawing, it is possible to calculate all the amount of material that will be required for the installation of the structure. For example, if standard edged boards of a certain length and width will be used, then the perimeter of the future base should be divided by their length, and the height of the base - by their width.The obtained values are multiplied together, and the number of cubic meters of material, which is required for work. The cost of all the boards are added to the costs of fasteners and fittings.

But it is not enough to calculate everything - it is necessary to properly assemble the entire structure so that not a single shield falls and the concrete does not flow out of it.

This process is quite time-consuming and is carried out in several stages (for example, shield formwork).

- Preparation of tools and materials. After the calculations, purchase wood, fasteners and all the missing tools. Check their quality and readiness for work.

- Excavation. The site where the work is planned is cleaned of debris and vegetation, removed the top layer of soil and leveled. With the help of ropes and stakes, the dimensions of the future foundation are transferred to the finished site and a trench is pulled along them. Its depth depends on the type of foundation: for a buried version, a trench is deeper than the level of soil freezing, for shallow buckets - about 50 cm, and for a non-buried one - just a few centimeters is enough to simply mark the boundaries.The trench itself should be 8-12 cm wider than the future concrete tape, and its bottom should be compacted and flat. At the bottom of the dimple they make a “pillow” of sand and gravel up to 40 cm thick.

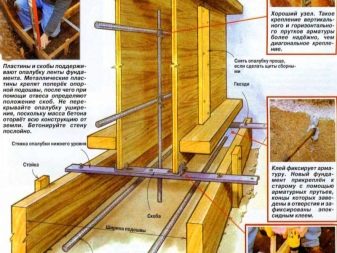

- Formwork manufacturing. Panel formwork under the tape type of the foundation should slightly exceed the height of the future tape, and the length of one of its elements should be between 1.2 and 3 m. The boards should not bend under the pressure of concrete and pass it at the junction points.

First, the material is cut into boards of the same length. Then they are fastened with the help of bars, which are driven from the basement with nails to them. The same bars are mounted at a distance of 20 cm from the side edges of the shield and through each meter. Several bars make the bottom longer and sharpen their ends so that you can stick the structure into the ground.

Instead of nails, you can make shields with screws - so it will be even stronger and they do not need to bend. Instead of boards, you can use sheets of OSB or plywood with reinforcement with metal corners on the frame of the beam. According to this algorithm, all other shields are made until the required number of elements is collected.

- Installation. The process of assembling the entire formwork begins with the fastening of the shields inside the trench by hammering in the pointed bars. You need to drive them in until the bottom edge of the shield touches the ground. If such pointed bars are not made, then it will be necessary to fasten an additional base from the bar at the bottom of the trench and attach the shields to it.

With the help of the level, the shield is set in a flat horizontal, for which it is pushed from the right sides with a hammer blow. The vertical of the shield is also set by level. The following elements are mounted on the markup of the first so that they all stand in the same plane.

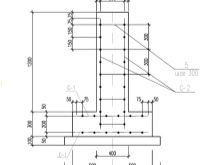

- Strengthening the structure. Before pouring mortar into the formwork, it is necessary to fix all installed and verified elements into a single system both from the outside and from the inside. Through each meter, special props are installed from the outside, and both sides of the structure are supported in the corners. If the formwork in a height of more than two meters, the bracing set in two rows.

So that the opposite shields are at a fixed distance, they mount the studs of metal with a thread from 8 to 12 mm thick on washers and nuts.Such studs should be 10 centimeters longer than the thickness of the future concrete strip - they are placed in two rows at a distance of 13-17 cm from the edges. Holes are drilled in shields, a piece of plastic pipe is inserted and a stud is put through it, after which the nuts on both sides are tightened with a wrench. Upon completion of the reinforcement of the structure, it is possible to lay waterproofing, reinforcement tie and pour the mortar into it.

- Dismantling formwork. It is possible to remove wooden boards only after the concrete has hardened enough - it depends on weather conditions and can be from 2 to 15 days. When the solution gains at least half the strength, the need for its additional retention is eliminated.

First of all, all corner struts are unfastened, external props and stakes are removed. Then you can proceed to the dismantling of shields. Nuts, wound on top of the studs, are removed, metal pins are removed, and the plastic tube itself remains in place. Shields with fasteners on nails are removed more difficult than on self-tapping screws.

After the entire tree has been removed, it is necessary to carefully inspect the entire tape of the foundation for excess concrete or voids and eliminate them, and then leave it until it is completely cured and shrink.

Tips

Although independent production of removable wooden formwork for a concrete basement tape is the best option in terms of price and quality, such a design is not the cheapest purchase at all stages of construction, since with a large depth of the foundation material consumption is very high. There is an opportunity to save money by pouring in not all the foundation at once, but in parts.

Fill with layers

With a foundation depth of more than 1.5 meters, the fill can be divided into 2 or even 3 stages. A low formwork is placed below the trench, and concrete is poured to the maximum possible height. After a few hours (6-8 - depending on the weather), it is necessary to remove the top layer of the solution, in which the cement jelly will rise. The surface of the concrete must be rough - this will improve adhesion with the next layer. A few days later the formwork is removed and set higher, after which the whole procedure is repeated.

When pouring the second and third layers, the formwork should slightly grab the already frozen layer along the upper edge. Since in this way there are no foundation gaps in length, this will not affect its strength in any way.

Vertical fill

With this method, the foundation is divided into several parts, the joints of which are spread over a distance. In one of the parts, a section of the formwork with closed ends is established, and the bars of the reinforcement should extend beyond the side plugs. After the concrete has hardened and the formwork has been removed, the next section of tie will be attached to such reinforcement. The formwork is disassembled and installed on the next section, which at one end is adjacent to the finished part of the foundation. At the junction with semi-hardened concrete, a side plug on the formwork is not needed.

Another way to save money is to reuse wood formwork for household needs. So that it is not saturated with cement mortar and does not become an indestructible monolith, the inner side of such formwork can be covered with dense polyethylene. Such formwork also makes the surface of the basement strip almost mirror-like.

In order not to make mistakes in the first experience of manufacturing and installing the formwork on its own, it is necessary to choose suitable materials and fix all the elements well.

Properly constructed construction will create a solid foundation that will last for many decades.

How to make a formwork for strip foundation, see the following video.