Reinforced concrete piles: technical specifications and installation recommendations

Reinforced concrete piles are the most popular type of support for the organization of pile foundations. This is due to their durability, high bearing capacity, moisture resistance and the ability to install on several technologies.

Special features

Reinforced concrete piles (RC) are a reinforcement cage, which is filled with concrete solution. The length of the finished product can be from 3 to 12 m.

Reinforced concrete piles are used in organizing the foundation of the blocking technology. Their use allows you to strengthen the base and reach the solid layers of soil.

Visually, they are bases with a round (hollow or full), square section.They differ in diameter and height, which determines the carrying capacity and scope of application. In addition, strength values depend on the type of concrete used. The higher it is, the more reliable the elements.

To create reinforced concrete piles, cement is used whose brand strength is not less than M100. From the operational characteristics of concrete depends not only the strength of the pile in compression, but also frost resistance, moisture resistance. The last parameters for M100 concrete are F 50 (that is, the design withstands up to 50 freeze / thaw cycles) and W2 (water column pressure) - 2 MPa. The weight of the support is determined by its dimensions, and also depends on the density of the concrete type used.

Usually, denser grades of concrete M-250, M-300, M-400 are used. Frost resistance of such products reaches 150 cycles, and the water-tightness coefficient is not less than 6.

Due to the increased resistance to the possibility of piling to a greater depth, their use becomes possible on mobile soils (including in the zone of increased seismic activity), on clay, heaving and weak soils, in water-saturated and wetland soils.

RC piles can be used not only as the foundation of the foundation, but also used to prevent the pit from shedding, to strengthen the soil and the existing pile foundation. To this end, the bearings are immersed at a short distance from the existing structures, performing the function of the second pile. In addition, with the additional strengthening of the foundation, the type of support in question can be carried out beyond the limits of the existing base and connected with it by means of beams.

Advantages and disadvantages

Among the advantages of reinforced concrete supports usually distinguish several characteristics.

- Long period of operation - up to 100 years subject to the installation technology. Reviews of owners allow us to conclude that such a foundation can serve, without requiring major repairs, up to 110-120 years.

- High strength - On average, one support can withstand from 10 to 60 tons. Due to this feature, this type of pile is used for the construction of industrial facilities, multi-storey residential buildings, buildings of heavy panels.

- Structural stability on all types of soil, which is achieved due to the significant penetration of the concrete pile.This, in turn, allows concrete elements to rely on the deep layers of soil with a maximum bearing capacity.

- The ability to conduct construction on mobile, relief soils, using piles of various lengths.

Among the shortcomings - a significant mass of the structure, which complicates the process of transportation and installation of elements.

Regulatory requirements

Production is regulated by the technical conditions (technical conditions), the main points of which are regulated according to GOST 19804, adopted back in 1991. The service life of products is 90 years.

Reinforced concrete products corresponding to the specified GOST, are used in single-and multi-storey construction of various materials, the construction of transport, engineering, bridge structures, agricultural and industrial facilities, hydraulic structures.

In a word, on all those objects from which the foundation is required increased strength, maintaining performance even in conditions of constant humidity and under the influence of aggressive media.

Regulatory document regulating the features of the production of driven reinforced concrete piles of factory type, is GOST 19804-2012.If we are talking about reinforcement, then the steel used must meet the requirements of GOST 6727.80 and 7348.81 (requirements for wires based on carbon and low carbon steel used as reinforcement).

Construction of bridge structures involves its own regulatory documents. Used supports must comply with GOST 19804-91. Concrete M350 is used for their manufacture, the structure itself is reinforced with longitudinal reinforcement. Only such elements will ensure the strength and reliability of the entire structure of the future bridge.

The same monolithic piles are used in the construction of high-rise multi-storey buildings, dimensional industrial facilities. The sequence of selection, the method of penetration, quality control and features of the testing of driven piles are reflected in SNiP 2.02.03 -85.

Kinds

Classification of supports of this type can be based on several criteria. In general, all reinforced concrete piles are divided into 2 types - frames, which are poured with concrete directly on the construction site and analogues manufactured in the factory.

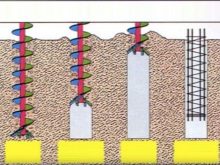

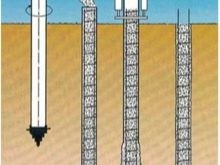

Their type of equipment depends on the type of piles in some way.So, piles, which are poured directly after installation into the ground, can be mounted by hammering with hydraulic hammers, using the method of vibratory penetration or using the indentation technology under the influence of static (constant) pressure.

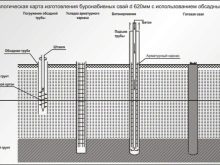

If we are talking about finished structures, then use one of the following methods of installation - ground-cement, bored or buroinjection.

Depending on the design features, reinforced concrete piles are divided into several types.

Monolithic

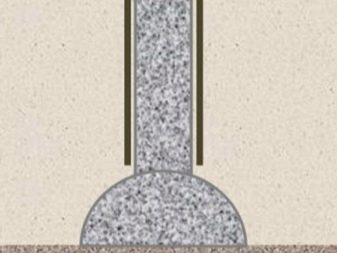

They are a one-piece support with a rectangular or square section, although piles with a circular, trapezoidal or T-section are possible, the size of which is 20-40 mm. The bottom end has a pear shape, it can be sharp or blunt. Such supports are not hollow, so for their immersion in the ground does not need to make holes. The technology of hammer driving or vibroinjection into the soil is used. They are widely used in civil engineering, are also in demand in the construction of a private house (wooden, block, frame).

Hollow (Shell)

It has the form of a shell, for immersion in the soil of which a well is previously prepared.The support can be round or square, but the latter still has a circular cross section. Hollow supports, in turn, are divided into integral and composite (consist of several elements that are assembled immediately before the dive).

Stuffed

But also it is mounted by immersion in previously prepared dredging.

Depending on the type of reinforcement, reinforced concrete piles are of the following types:

- supports with non-stressed longitudinal reinforcement with transverse reinforcement;

- supports with prestressed longitudinal reinforcement with or without transverse reinforcement.

If we talk about the shape of the pile, they are round (hollow or solid), square, square with a round cavity, rectangular. Supports with a square cross section must not be placed in permafrost soil. Even with a little thawing, pile heel and skewing of the building will occur. In regions with increased seismic activity, structures with a circular cross section should be used.

There are solid and prefabricated structures. The second ones consist of several segments, which makes it possible to increase the height of the product.Fixing segments is carried out by welding or by bolting.

Durability and additional reliability of the connection of the segments ensures the presence of a “glass” type on each subsequent segment.

Installation

Installation of piles is preceded by geological surveys and soil sampling at different times of the year. Based on the results obtained during the analysis, a decision is made on the methods of pile driving. And also design documentation is compiled, in which, among other data, the bearing load is calculated for one pile element, their size and quantity are determined.

The estimate includes not only the purchase of piles, but also their transportation to the construction site, the attraction (purchase or rental) of special equipment.

The next step is a trial support blocking, which allows to evaluate how the support behaves in practice. After driving it is left for some time (from 3 to 7 days), during which observations are also made.

To drive piles, dynamic and static forces are applied - the surface of the support is hit with a special hammer. To prevent the destruction and deformation of the elements at this moment allow the end caps, protecting the head of the base upon impact.

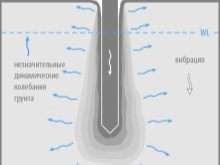

If installation is supposed to be in saturated soil, it is better to use a vibratory pile driver. The installation process is a consistent lifting and subsequent lowering of the pile into the soil. These cycles are repeated until the base of the element reaches the design depth.

If the installation is supposed to be on excessively dense and hard soils, it is possible to combine the method of driving and vibrodiving with washing away the soil. To do this, water is pumped into the well along the pile under pressure. It reduces the friction between the element and the soil, softening the latter.

The method of driving and vibro immersion is applicable for solid and shell supports, but is not suitable for construction in urban environments, as it is accompanied by strong noise and vibrations. The latter can adversely affect the state of the foundation of neighboring objects.

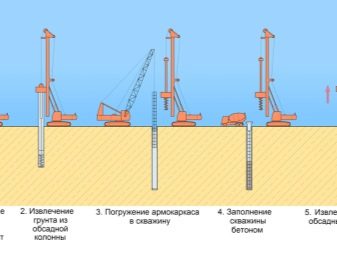

Hollow and stuffed piles are installed on the drilling technology, which provides for the preliminary preparation of the mine. A support is introduced into it, and a primer or cement-sand mortar is poured between its walls and the side surfaces of the mine.

This method is characterized by a low noise level and the absence of vibrations when immersed; it does not require the involvement of a massive padding technique or equipment to create vibrations.

Drilling technology has several varieties. So, for clay soils, the bored method is suitable, in which a hollow pile is lowered into the well and concreted directly in the soil. In addition, ready-made reinforced concrete piles can be used, which are fixed in the well by filling between the lateral surfaces of the base and the walls of the mine with a clay mortar. Instead of the latter, a casing can be used.

Brown injection methods involve injecting fine-grained concrete mortar into the well, while brown injection techniques involve filling the space between the well and a pile of concrete mortar inside it.

Tips

Piles are produced by large factories or production workshops at construction companies. As a rule, the products of the first have a lower cost, but the factories prefer to cooperate with wholesale buyers.

If you need a limited number of supports, it is better to contact the shop with a reputable construction company. As a rule, you can order piles at least one by one, but their cost will be higher. This is due to the fact that small companies can not build up power, and therefore increase their own revenues by increasing the price.

It is better to choose piles of domestic production, since they are made in compliance with the requirements of GOST.

No need to buy cheap products of unknown brands, because the strength and durability of the foundation, and hence the whole house, depends on the quality of the piles.

Typically, the price of the pile depends on its length and cross-sectional dimensions, as well as the grade strength of the concrete used. Three-meter structures with a square cross section, the side of which is 30 cm, have the lowest cost.

As a rule, the larger the batch of purchased concrete goods, the lower the cost of one unit of goods. When making a pickup, in most cases, a discount.

You will learn more about reinforced concrete piles in the following video.