Doorhan Gate: a step-by-step guide for self-installation

Car as a means of transportation has become an indispensable attribute for many residents of megalopolises. Its service life and appearance are greatly affected by the conditions of operation and storage. A garage equipped with a new generation gate is a reliable marina for a vehicle.

Special features

Products represented by Doorhan company are in great demand. This company is engaged in the production and production of a large range of gates. It is noteworthy that the panels for such structures are made directly in Russia, and are not transported from abroad.

The gates are installed by many car owners in their garages. Automatic adjustment, as well as tuning and programming of the key fob, allows you to freely enter the place of its storage without leaving the car.

A distinctive feature of the products of this company is reliability and a long period of operation. The degree of its protection from the penetration of outsiders in the garage is very high. The purchase price is quite affordable.

With the skills of installation and welding, you can install the gate yourself, without the help of experts. It is necessary to follow the instructions step by step (it is always included in the bundle of the product being purchased), tune in to scrupulous preparatory work.

Kinds

Doorhan company produces and sells almost all types of garage doors:

- sectional;

- roll (roll);

- lifting and turning;

- mechanical swing and sliding (recoiling).

Sectional gates for the garage is very practical. Their insulation is large enough - not lower than that of a 50 cm thick brick wall; they are strong and durable.

This product is available in various designs. Doorhan company provides for a built-in gate in the garage door.

Sectional doors are made of sandwich panels. The thickness of the canvas consists of several layers. The inner layer is filled with foam, which allows you to retain heat.Installation of such structures is possible in garages with small side walls.

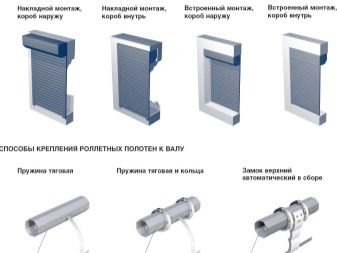

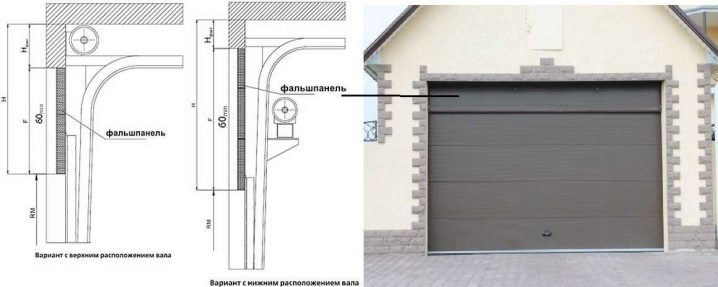

Rolled (roll) The doors are a set of aluminum profiles, which, through automation, are rolled into a protective box. It is located at the top. Due to the fact that the gates are set vertically, their installation is possible on garages, where the adjacent territory (place of entry) is insignificant or there is a sidewalk nearby.

Its name lifting and turning The gates got due to the fact that their canvas (a shield with a system of rollers and locks) moves in space from a vertical to a horizontal position, thus forming a 90 degree angle. Electromechanical drive controls the process of movement.

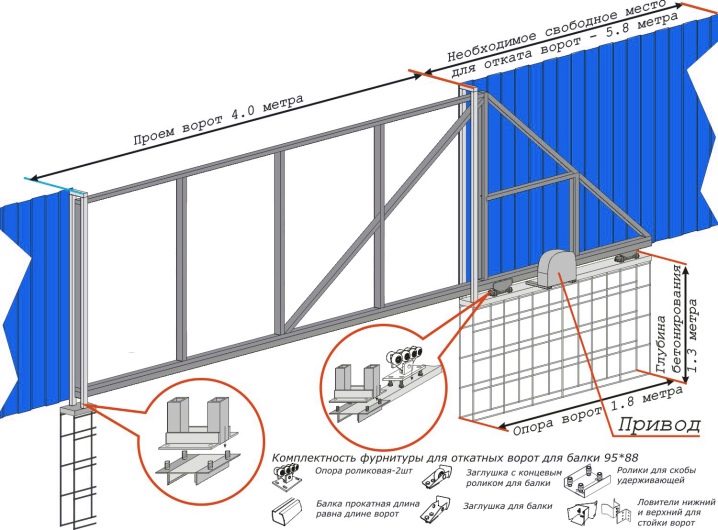

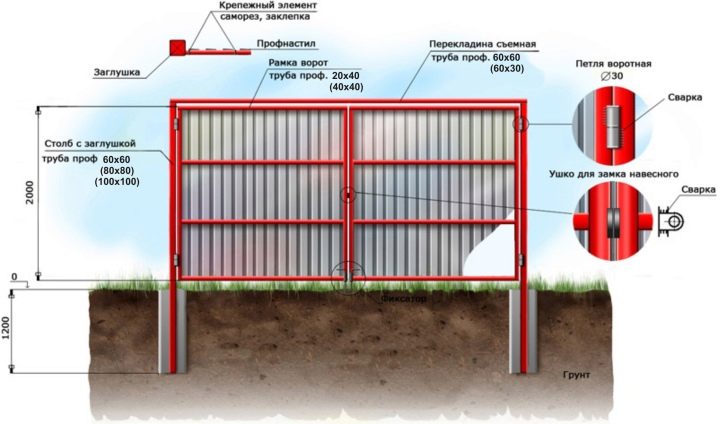

Sliding gates Made of sandwich panels with a smooth or structural surface. Bearing beams of sliding gates are made of hot rolled steel. All steel elements are covered with a thick layer of zinc. It provides corrosion protection.

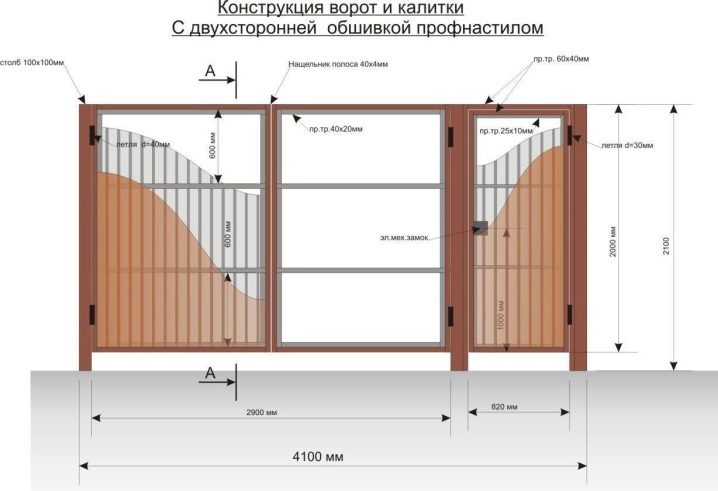

The most common gates are swinging They open outwards or inwards. They have two leaves, which are mounted on hinges with bearings on the sides of the opening.To open the gate outside, you must have an area in front of the house 4-5 meters.

The Doorhan company has developed and introduced high-speed rolling gates into production. A good moment for intensive use is the speed of the workflow. The heat inside the room is preserved due to the ability of the gate to quickly open and close. Heat losses are minimal. Make them from transparent polyester. This makes it possible to see the territory outside.

Training

Before purchasing doors made by Doorhan, it is necessary to thoroughly analyze and prepare them at the installation site.

Often, the enclosed area is not enough to install a favorite type of gate. It is necessary to properly assess the situation (to make calculations and measurements of all parameters, to clarify how the structure in the assembly will look like).

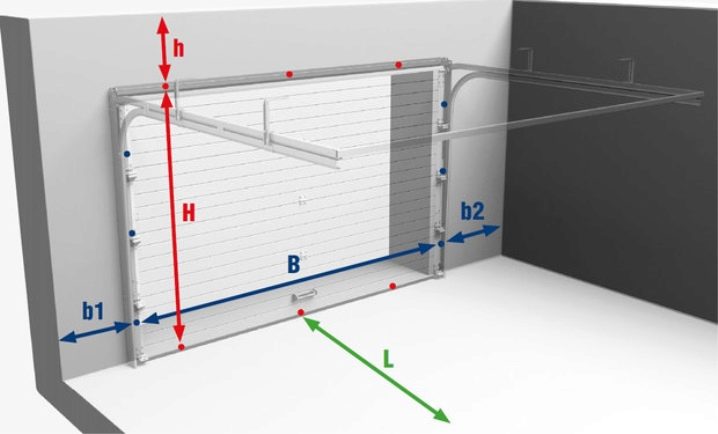

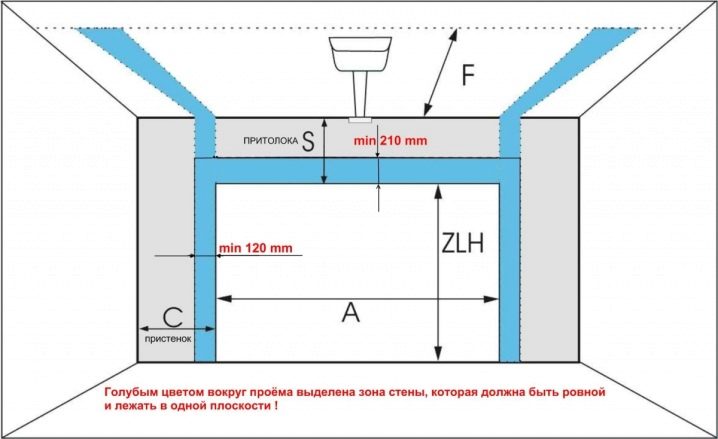

At the beginning of work, measure the height of the ceiling (frame attached to it) in the garage, as well as the depth of the structure. Then measure how wide the walls are. After you need to find out what is the distance between the top point of the garage opening and the roof (maybe no more than 20 cm).

The opening is checked for defects. Cracks and irregularities should be eliminated by smearing them with a mortar, and then level all irregularities with plaster. This should be done from two sides of the opening - external and internal. The whole further work package will depend on the quality of the prepared foundation.

Before you start installing the gate, you need to carefully check their equipment.

The kit includes the following mechanisms: sets of parts for mounting and guide profiles; torsion motor; sandwich panels.

Independently install the purchased gate, tighten the cables, program the automation by the presence of tools:

- tape measure and screwdriver set;

- building level;

- drills with a set of drills and nozzles;

- riveting tool;

- hammer;

- wrenches;

- jigsaw;

- knife and pliers;

- grinding machine.

- marker;

- fixtures for fastening profiles;

- screwdriver and bits to it;

- wrench set;

- tool for winding the spring coils.

You should be dressed in special clothes, protective gloves and goggles.

All assembly, welding, and electrical connections are carried out only by serviceable power tools.

Installation

The algorithm for installing the gate is clearly stated in the instructions of the company producing them.

Installation of each type is made taking into account the individual characteristics of the structure.

Sectional garage doors are installed according to this scheme:

- mounted vertical opening;

- the fixing of the bearing panels is carried out;

- set balancing springs;

- connect automation;

- handles and bolts are fastened (on the door leaf);

- adjust the tension of the lifting cables.

After connecting the electric drive, the quality of movement of the web is checked.

Let's stop in more detail on installation. At the very beginning you will need to prepare and install the frame. When the gate is purchased, it must be unpacked and unfolded to check for a complete set. Then vertical posts are attached to the opening and they mark (bait) the places where they will be.

Be sure to over the edge of the garage opening should go lateral sides of the lower part of the canvas. In the case when the floor in the room is uneven, metal plates are placed under the structure. Panels are placed only horizontally. Vertical profiles are installed along the bottom section and fixing attachment points for racks. A distance of 2.5–3 cm from the end edge to the guide assembly must be maintained.

Then on both sides of the opening fix the rack. Bolts and angular connecting plates fix horizontal guides. They are twisted, pressing tightly to the surface. So make the frame assembly. Upon completion of this operation proceed to the assembly of the sections themselves.

Gate manufacturers have facilitated the assembly process. There is no need to mark or drill holes for mounting panels, as they already exist. Put side supports, hinges and corner brackets (in the bottom panel). The design is placed on the bottom panel, which must be adjusted horizontally, and secure with screws.

The next section is taken. On it you need to fix the side holders and connect with the inner loops. Side supports are placed in the previously made holes. After that, roller bearings, holders and corner brackets are fixed on the top panel. All elements are very tightly fastened in order to avoid the breakage of structures and their loosening. The holes in the section should coincide with the holes at the bottom of the loops.

The panels are inserted into the opening one after the other. Installation begins with the bottom section; it is fixed in the guide side.The panel itself should go sideways behind the sides of the gate opening equally. Roller rollers are placed on the corner brackets.

Separately, in the room, fixing profiles are assembled and installed in a vertical position. Racks attached to the sides of the opening. After a special plate fasten all horizontal and vertical guides. Formed frame. Periodically level check the panel so that it is placed strictly horizontally.

After attaching the lower section, the middle one is attached, then the top one. All of them are interconnected, fastening the loop. At the same time, the correct operation of the upper rollers is regulated, the canvas at the top should fit as closely as possible to the lintel.

The next step is to fix the support stand to the assembled gate with the screws.

On both sides of the section there are places for fixing the cable, which is fixed in them. Later it is used for the operation of the torsion mechanism. In the process of work, you need to install the rollers in the places intended for them. After the assembly of the shaft and the drum is done. The drum is mounted on the shaft, there also put the torsion mechanism (spring).

Next is the top section.The shaft is fixed in a pre-prepared bearing. The free ends of the cables are fixed in the drum. The cable is pulled into a special channel, which is provided for the construction of the gate. Mounted drum special sleeve.

The next stage of work involves adjusting the rear torsion springs. Buffers are installed in the middle of the opening, the cross member's cloth is fixed to the ceiling beam with the help of corners for fasteners. Further, on the outer side, the place where the handle and the latch will be attached is marked. Fix them with a screwdriver.

A sleeve is put on the shaft, and a drive is placed on the top of the guide and the whole structure is joined together. Bracket and traction fasten to the profile and fasten all with self-tapping screws.

The final installation operation is the installation of the guide profile, which should be above all ceiling profiles. Next to the drive is a beam with fasteners, which ultimately fix the second end of the cable.

Cable tension is the final stage of the entire work process. After this stage, the gate system, assembled and installed by hand, is checked for operability.

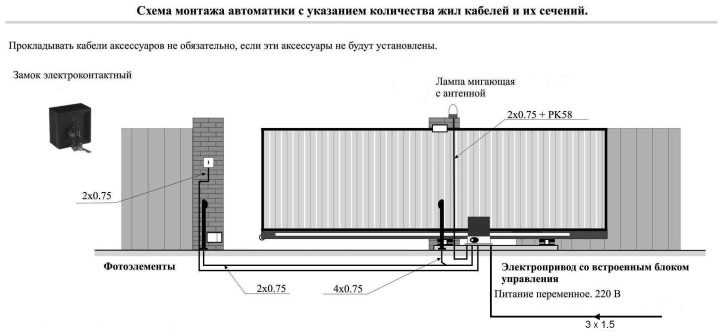

Automation of any structures is carried out with the help of a drive and a control unit. The selection of the drive depends on the frequency of their use and the weight of the valves. The connected automatic equipment is controlled by means of a key fob, a programmed remote control, a button or a switch. Also, the structures can be equipped with an electric drive with a system of manual (hoisting) lifting.

Sectional doors are automated using chain and free drives.

To lift heavy sash, use the valal. In the case when the opening of the gate is low, use a chain. They regulate the stopping and lifting of the canvas. The signal coded device, the built-in receiver, the radio button make these devices comfortable and very convenient to use.

For sliding gates install hydraulic actuators. To the section moved smoothly, use special rollers. In this case, the foundation must be prepared for roller carriages in advance.

In the swing gates for automation use electric drives (connected to each leaf). They have automatics inside the gate as they open inwards or outwards. What kind of automation to put on their gates, each owner will decide for himself.

Tips and tricks

In the operating instructions, the doorhan door designers give advice on the proper use of their products:

Car owners of overhead doors are not recommended to put their cars close to the garage. Door leaf opening forward can damage the vehicle.

When choosing a design, you should pay attention to the appearance of the canvas. It will be a central component of the entire garage complex.

Pay attention to the garage walls. If they are made of ordinary bricks, then they should not be strengthened. Walls from foam concrete blocks and other materials (inside hollow) are subject to strengthening. Their strength does not allow to insert the gate and use the force of the torsion. In this case, the frame is welded, which is inserted into the opening of the garage and fixed.

Reviews

Most of the buyers were very pleased with the Doorhan products. High performance characteristics are inherent to sectional and rolling gates. Their key feature is simplicity and ease of adjustment. Control of automation is so simple that not only an adult, but also a child can cope with it.

Installation and installation do not require special knowledge and the power of anyone. The main thing is to strictly follow the instructions. The products themselves are reliable and durable. Purchased goods are delivered as soon as possible. Prices are reasonable. Qualified specialists are always ready to help and advise on any issues.

See below for how to install the Doorhan gate.