Features of sealants for concrete

Concrete surfaces can be considered among the most durable and durable. Anyway, they are also endangered. Temperature extremes, violation of technology in the manufacture of mortar, moisture exposure - factors that cause cracks in the concrete. Such defects not only spoil the appearance, but also carry a danger: they are more easily absorbed by moisture, and an excess of liquid can affect the destruction of concrete. Also, from the dampness may appear fungus or mold.

In such cases, a friend who will help reliably seal up the gaps and seams will be a sealant for concrete. With this tool, you can firmly block the holes and prevent moisture and gases from entering them.

Special features

Sealant is a viscous substance resembling a paste in its consistency.They are formed on the basis of polymers. In addition, there are differences in composition. For example, you can buy a sealant, which added acrylic or silicone. Depending on which substances are part of this tool, the way they are used varies.

These funds are characterized by a wide range of qualities. They have good water resistance, adhesion, impermeability, resistance to many negative environmental phenomena. If you use sealant correctly and accurately, the durability and strength of your work will be the result.

One of the most suitable means for eliminating joints in concrete is acrylic sealant. Silicone sealant is also suitable. They are highly resistant to various destructive environmental conditions.

Adhesion

In the course of construction work, the processing of concrete is of paramount importance. It consists of most of the significant structures of the building: the foundation, floor, walls. Needless to say, what will happen if an excessive amount of fluid gets into the formed cracks?

In this process, adhesion plays a special role, that is, the adhesion of different bodies.In our case, the treated surface and sealant.

Other surfaces suitable for processing:

- tree;

- tin;

- a rock;

- brick;

- ceramics;

- plastic;

- non-ferrous and ferrous metals.

Variety of sealants

There is a huge variety of sealants for concrete and their classifications.

Sealants can be divided by the way they act.

- Surface. As a result of their use, a strong impermeable film is formed on the base, preventing the penetration of external aggressors. Depending on the sealant used, the film can be either matte or glossy.

- Penetrating. They completely cover the hole and protect against various environmental conditions.

They differ in the components that are part of:

- silicone;

- acrylic;

- polyurethane;

- silicate;

- butyl rubber;

- bitumen;

- polysulfides.

Sealants can be divided by the criterion of their readiness for use.

- Single or single component. Such tools are ready for use: they do not require additional intervention before the work.

- Two-part or two-component. These sealants need preparation before work.Before you apply them, it is worthwhile to study the technology written on the packaging or bottle well.

There are several more criteria by which the types of sealants are formed.

According to the method of solidification:

- non-hardening (they resemble rubber in properties);

- drying out (harden through time);

- vulcanized;

- polymerized.

By the method of application:

- spatula (applied with a spatula);

- brushes (a brush is necessary for applying sealant);

- potting (special devices are used, for example, a gun).

Despite the fact that there are a large number of different classifications, most often sealants are divided into one-component and two-component ones. Therefore, it would be more convenient to consider their special properties on the example of these sealants.

Single component

Typically, these sealants are silicone products. This is the most common type used almost everywhere. They have a number of advantages and positive qualities.

Pros:

- high resistance to various weather conditions;

- resistance to extremely low and very high temperatures;

- durability;

- complete impenetrability;

- good indicator of adhesion to most surfaces;

- resistance to ultraviolet radiation, which has a destructive effect;

- elasticity.

Minuses:

- You can not apply another layer of sealant (if you need to seal, you will have to clean the surface of the old sealant);

- silicone sealants should not be painted, as the paint begins to peel off, however, dyes can be added as an additional substance before applying the sealant;

- Do not use indoors with high humidity.

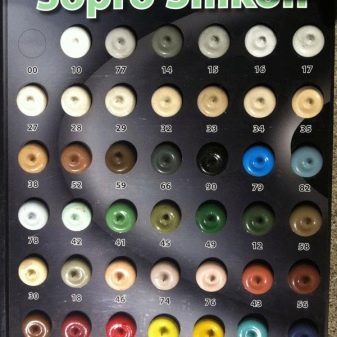

At the moment, not only standard transparent sealants can be purchased on the market of building goods and services, but also colored ones. Moreover, the color spectrum available to customers is very wide.

Bicomponent

It is indispensable when working with many surfaces, in particular concrete, sealants. With them, you can seal cracks of different sizes and varying degrees of severity. They are made by adding reagents to a ready solution in compliance with certain proportions, so careless actions can spoil the result.

The most popular sealants of this type are thiokol or polysulfide.

After their application, a rapid polymerization process takes place.however, shrinkage may occur after a few days. Appears inelastic durable film, impermeable to acids and alkalis, chemicals, oils, fats and gasoline. Due to these properties of polysulfide compounds, they are used at gas stations, service stations, warehouses and facilities, whose activities are closely related to electricity. Also, these sealants are used for energy-efficient glazing. The temperature range at which you can work with this tool is quite high: from -50 to + 130 ° C.

Pros:

- durability if properly used;

- good adhesion with a variety of materials: from wood to ceramics;

- assistance in creating durable structures;

- high speed of hardening.

Minuses:

- the need to accurately observe the proportions in the manufacture;

- working with chemicals;

- if you make a mistake in the process, the resulting sealant will be undesirable;

- you need to quickly work with the composition, as it quickly hardens.

When working with two-component sealants, it is very important to avoid contact with the skin. An unpleasant consequence of non-compliance with this rule can be a chemical burn.

Application

Two-part sealants require their preliminary preparation. Carefully read the instructions and accurately follow the technology that has been described by the manufacturer on the packaging or container. Basically, all that needs to be done is to mix a viscous paste with a substance that causes solidification, but do not forget that proportions matter a lot. The density of the sealant depends on how much hardener you add. Other chemicals may be used.

Before you start sealing, you need to carefully prepare the surface. concrete or, for example, iron. To do this, clean it from dirt, dust, grease, plaster and other materials, and then apply a primer on cracks. If this is problematic, it is necessary to widen the crack. Next, you need to ensure that the seams are well saturated with the substance. This will create a strong adhesion of the sealant to the treated area.

It remains to apply a sealed composition.For convenience and to facilitate this process, you can use a gun. So filling the gaps in the concrete will be somewhat easier.

Acceptable temperature for work should not be lower than -10 ° C. Otherwise, the process of hardening the sealant for interior work will be delayed for a longer time. The higher the temperature level, the faster it will harden.

Some types of formulations are sensitive to precipitation. In such cases, it is necessary to provide protection from adverse weather events.

After the sealing process is complete, ventilate the room.

findings

If the surface is cracked, then a suture waterproof sealant will come to the rescue for a quality seal of the deformation flaws. It will help to repair the rings, joints and seams from the inside.

There are many different types of sealants, each of which is used in certain cases. In order to choose the right tool, it is worth exploring its characteristics. And the use of some of them can be complicated by additional actions that need to be performed before the work is done.

For information on how to properly use a concrete sealant, see the following video.