Pig-iron fireplace insert: device features

The fireplace is an invariable attribute of every private house, it is a symbol of the home hearth, not only performing the heating function, but also giving the room special comfort. The most important part of it is the firebox; it’s good if it is made of cast iron, a material that can retain heat for a long time and withstand high temperatures. This element has its own characteristics that must be considered.

Design feature of cast iron

Firebox - the main device that provides the burning of firewood, laid on the grate. Combustion is carried out by means of air supplied to the chamber.

The combustion chamber performs several tasks at once:

- it can be a major source of heating;

- is an additional component of heating;

- plays a decorative role in the design of the room.

Given these options, you can choose the optimal for power and other characteristics of the furnace.

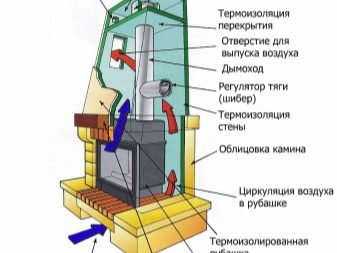

The fireplace consists of a facing part, a chimney and a combustion chamber. The models are closed with different types of dampers and open, which are practically not in demand due to frequent fires and low efficiency.

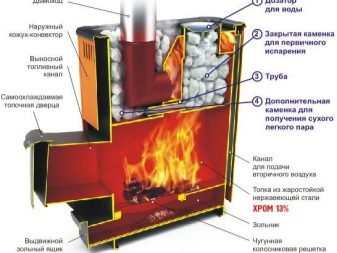

The cast-iron fire chamber consists of several elements important for the workflow:

- a compartment for the combustion of furnace raw materials - in this case, such a solid fuel as wood;

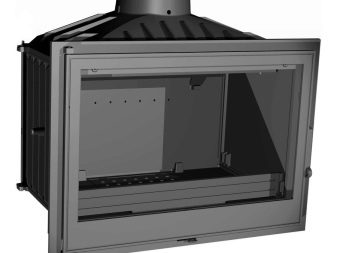

- some models have a door - flap, fireproof glass or forged grille, such models are considered closed;

- necessarily the design provides for a smoke outlet, through which the output of combustion products takes place on the street - this supports the correct operation of the unit;

- a special air supply system with power adjustment details to reduce or increase the burning force;

- an ashpit is the place in the building where the decay products accumulate, it needs to be cleaned regularly, advancing it beforehand and then setting it back.

When choosing ready-made structures, it doesn’t hurt to pay attention to the additional options; they are often quite useful. For example, the system of self-cleaning glass door.

Types and design

Finished furnaces made of cast iron are made in different design options. They may have a classic rectangular shape. But there are models made in radical, ultra-modern variations. The shape can be angular, panoramic and prismatic designs.

There are devices "aqua" with a water circuit for heating water from a centralized heating system. This is the most environmentally friendly type of instrument, equipped with a water jacket, a special cavity placed on all sides of the furnace, due to which the heating is maximum.

Such equipment can act instead of central heating or be operated simultaneously with it, is used for private houses with a large area.

Fireplaces with vermiculite furnace are distinguished by high fire resistance, resistance to critical temperatures and safety. Vermiculite is a modern insulating material of natural origin, free of toxins and durable in use.It can be a complete alternative to the cast-iron "chimney tooth" - the rear inclined wall of the furnace. They are lined with internal surfaces of the combustion chamber that are in direct contact with fire.

By the type of burning, higher-level heat is produced by hearth fireplaces working without a grate, mainly with a steel or cast-iron firebox, for lining of which vermiculite is used.

Also available are cast iron heat chambers for the barbecue, which are a roasting pan with or without a lid used in the open air.

Advantages and disadvantages of the cast iron furnace

Furnaces from cast iron have indisputable advantages over their counterparts - chamotte and steel types.

Advantages of such equipment:

- cast iron has a maximum heat dissipation, can operate in a continuous and economical mode;

- this option has increased resistance to large temperature amplitudes, is not susceptible to deformation, since the material is thermoplastic;

- closed models have an efficiency of up to 80% and can serve large areas;

- the construction of cast iron is more convenient to use, its assembly is simple;

- similar structures have the longest service life - up to 50-60 years.

The undoubted advantage is the mobility of cast iron products - a compact unit can be moved around the house and transported. Standard heat-resistant glass, as a rule, do not pollute, thanks to the channels leading to soot. In addition, different types of fuel are suitable for the cast-iron firebox.

The disadvantages are primarily related to open models, which have low efficiency, since most of the heat (almost 85%) goes through the chimney. In addition, they create a fire hazard situation, and auxiliary equipment at home is required to avoid fire.

In closed versions, especially inexpensive, the quality of glass leaves much to be desired. Also, there is an insufficient review of the viewing windows and a monotonous color scheme - in fact, all versions are made in dark colors.

True, this minus can be eliminated by fixing decorative grates on the fireplace.

Fuel types

How to properly heat - the main issue when installing iron equipment. It is already clear that this is wood, but it is different and has its own characteristics of burning.

Firewood is a natural material that, in addition to good heat, has a pleasant smell, but not everyone knows that not all raw materials are suitable for heating.Wood material that has been stored for at least one and a half years should be used.

Different tree species have their own type of burning, it should be noted that:

- conifers quickly fade and emit large amounts of resin vapors, which may be unsafe for health;

- birch despite the fact that it gives a lot of heat, smokes heavily;

- Apple, juniper and cherry trees are mainly used to create comfort because of the pleasant aroma;

- any soft woods - alder, linden, chestnut, willow, poplar emit some heat and burn quickly.

The most effective use of solid wood material such as oak, pear, ash, poplar. It burns well, produces high heat output. The relative difficulty is only the processing and ignition of these trees.

If you do not attach importance to wood aroma and characteristic crackling, you can heat cast iron stoves and other raw materials, for this purpose anthracite, peat, coke, wood, lignite and bituminous coal are suitable. With regard to different types of coal fuel, accurate calculations should be made, since it can give a temperature above 1200 degrees during combustion, which can cause the cast-iron chamber to melt.

Preparing to install

Do-it-yourself fireplace installation is a tricky job that requires a clear understanding of the workflow and sequence of actions. The quality and quality of the equipment depends on the quality of the installation.

Once a suitable model is selected, it is necessary to find the optimal place to place it. The room must necessarily provide for the normal circulation of air masses - reverse thrust can lead to poisoning of the carbon monoxide gas.

In advance, you should think about high-quality insulation between the wall and the fireplace, taking into account the existing safety standards.

Equally important is the work on the lining. Cast iron stoves have a strong heat to keep warm for a long time, the fireplace should be sheathed with brick, ceramic tile, natural stone or drywall. Some perform exterior cladding with porcelain stoneware, marble or metal.

Finishing with any coating also performs an aesthetic task in order for the fireplace to adequately fit into the interior.

The work will require the following materials and tools:

- coating for heat chamber;

- special thermal insulation products;

- decorative items;

- cement mix for mortar;

- construction level, plumb, spatulas.

To reduce installation time, not to carry out additional insulation for cladding, you can immediately choose a material that tolerates high temperatures - it can be a refractory brick, fireclay, pre-plastered plate, stove tile, specially designed for this purpose. Otherwise, around the perimeter of the furnace body, it will be necessary to conduct insulation with foiled penofol or other refractory materials.

Installation rules cast iron fireplace

In order to carry out the installation correctly, you will need a draft fireplace, designed personally or by professionals.

- First, the base is erected, the floor is removed from the floor, and the platform is made of fire-resistant material. Usually its width is taken equal to the width of the fireplace with the addition of 20 cm on each side with a total length of at least 50 cm.

- Observe the distance from the oven to the wall (20 cm). Between the facing plates and the furnace leave intervals of up to 6 cm - this is necessary for the free passage of air.

- The floor part near the building is finished with special glass or metal.

- The axis of the combustion chamber and chimney should be located as close as possible to each other.

- To harden the connection with the chimney is sealed with heat-resistant materials and pastes.

The thicker the outer shell, the longer and better the fireplace retains heat. It is important that a sufficient amount of cold air comes in from the bottom of the equipment, and hot air can flow out from above. After covering the furnace start to isolate the chimney.

It is possible to decorate the heat chamber with refractory tiles, especially if brick is used for finishing. But this should be done only after complete drying of the brickwork.

Manufacturers

Russian-made cast-iron fireboxes are of high quality and have many positive characteristics, among them - high efficiency, durability, high heat conductivity.

The following equipment is in particular demand:

- Firebox "Selenik" - closed heat chambers with a power of 14 kW. Differ in worthy quality and reasonable price.

- "Promo" (12-14 kW) - these structures are able to heat rooms with a huge area of up to 150 square meters. m

- "Axiom" - a furnace with a gate valve with a capacity of 12 kW. Heat the area to 140 square meters. m

The most popular are the modifications of the group "Meta" - reliable mantels with low price and different power. Overall models cope with the heating of large rooms of 200 square meters. m

Of the foreign analogues of products, there are notable fireboxes from France - Invicta “Grand Vision 900” with a power of 18 kW, Godin B16 and Invicta “Double Port”. They have the best technical and operational characteristics, but they also have a significant drawback - high cost.

Russia produces no less high-quality equipment, but it is much more affordable.

How to make a fireplace with a cast-iron firebox with your own hands, see the next video.