Fireplace doors: selection and installation

Since ancient times, much attention has been paid to the arrangement of the home hearth. He performed several functions at once: he was a source of heat, light, and an assistant in cooking. Everyone tried to make their hearth unique. Therefore, today the market offers a wide variety of various fireplaces.

To protect the fire burning inside the device, use special doors. They are installed in the front part of the structure. To this element impose increased requirements.

When choosing a door for the fireplace, it is necessary to take into account not only the technical characteristics, but also the appearance, because the design as a whole should look aesthetic.

Special features

Regardless of whether you buy a finished product for the fireplace or make it yourself, it must meet certain parameters:

- The door should be made of natural heat-resistant material (refractory glass, natural stone, steel, ceramics).

- To ensure fire safety, it is necessary to ensure the tightness of the door. Often the cause of the fire becomes exactly the faulty fireplace door. Therefore, during installation, special attention should be paid to checking for cracks and cracks.

Also, when choosing a door, you should consider the type, design features and size of the fireplace.

It is recommended to purchase products from trusted manufacturers, to beware of cheap and low-quality fakes.

Species

Doors themselves are roughly the same type of design. They are divided only by the materials from which they are made.

The most popular on the market won the glass doors. This material allows you to monitor the combustion process in the furnace. The kind of measured flaming fire gives aesthetic pleasure, gives a feeling of peace, warmth and comfort. At the same time reliable heat resisting glass ensures absolute safety. In addition, through transparent doors it is easy to control the processes occurring inside the fireplace.

For example, if the glass quickly darkens from soot, it means that there are problems in the chimney system, it is necessary to clean the device or repair it.

Thanks to a special treatment, the glass from which the doors are made acquires heat-resistant properties. Such a product can withstand high temperatures for a long time.

The biggest minus of glass products is their fragility. Despite the production of impact-resistant glass and resistance to high temperatures, the material is very sensitive to mechanical stress. Therefore, it requires careful operation and careful maintenance.

As for the design, glass goes well with many materials: marble, natural stone, metal. Therefore, this door will be a great addition to any fireplace.

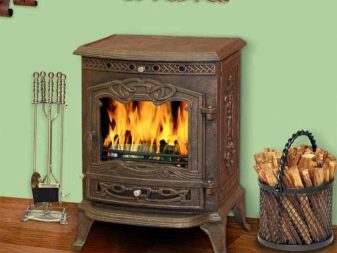

Metal doors for the fireplace are of several types:

- steel;

- forged;

- cast iron.

Such doors are considered the safest. They received widespread use due to relatively low prices. Today the most popular are steel doors with glass inserts.

Ceramic products are rarely used for the design of heating devices.However, if according to the design of the designer, the entire structure has a ceramic surface, the doors should not stand out. To the product to withstand the effects of high temperatures, it is burned. This type of door is quite expensive. In addition, in operation, it is impractical. Make a choice in favor of such an element can only be solely for the purpose of aesthetic harmony of the appearance of the fireplace.

How to choose?

To choose the most suitable option of a door, it is necessary to consider all nuances. In order to achieve security and visual harmony, the door must comply with the design of the fireplace. So when choosing a glass element, you can purchase a model with flat or convex glass. It can also be a single-layer, segmented or rounded panoramic option.

It is necessary to choose the right glass thickness. Its heat-resistant properties will depend on it. It will also affect the warranty period claimed by the manufacturer.

Casting and forging are used to frame the glass window in the door. As a result, the door turns hard. Auxiliary mechanisms and devices are being developed to increase the ease of opening.

It is also important to remember that when selling glass elements for fireplaces, Russian manufacturers provide a spare set of heat-resistant glass (in case of replacement). Imported manufacturers only sell pieces, which is not very convenient. If you need a replacement in this case, you have to spend a lot of time and money.

When choosing it is worth considering the method of heating the device. If the fireplace is heated only with wood, then use metal doors or models with glass inserts. When using coke or coal, it is necessary to install a cast-iron version.

If you take into account all the recommendations, your fireplace will serve you for a long time. Properly selected door must withstand temperatures from 600º C to 1000º C.

As for the way of opening, the most reliable and safe are double-leaf, guillotine and opening on the side models.

Manufacturing

Making the door for the home with their own hands is a job that does not require special knowledge and skills. It is necessary to make the product before the construction of the fireplace. In this case, the finished door is simply inserted into the masonry, there are no problems during installation.

For the manufacture of the fireplace door you need to perform a series of successive operations:

- From the corner make blanks to the dimensions of your drawings. Collect the blanks in the desired shape.

- Check all connections of your product with the help of a square.

- On the metal sheet mark the inner contour of the frame from the corner. The outer contour should be made slightly larger than the frame size. This will ensure the tightness of your product during installation.

- Use an abrasive disc grinder to cut a blank from a steel sheet.

- Assemble the structure and grab the sheds. Check the location of the sheds. If everything is done correctly, scalp them.

- All welds should be stripped. Then install the bolt and handle.

If everything has been marked and done correctly, the door can be easily opened and closed.

Installation

The complexity of mounting the product is directly related to its design and model. To perform the installation of the door yourself, you need a set of special tools and tools.

You will need:

- angle grinder;

- cutting disc;

- sealing cord;

- hammer drill or hammer drill;

- set of drills;

- screwdriver;

- self-tapping screws;

- permanent marker;

- heat-resistant furnace mixture.

To perform the installation, you must perform a series of sequential actions:

- Attach the door to the fireplace hole. You must ensure that the body of the product corresponds to the design of the fireplace. Use a permanent marker to mark the surface of the firebox through the mounting holes in the housing. Carefully remove the product.

- To make the grooves in the brickwork, you need a Bulgarian with a diamond wheel. This work requires a lot of attention and additional equipment. You will need special glasses to protect your eyes and a respirator to protect your respiratory organs. After cutting out the grooves, it is necessary to break off pieces of bricks with a chisel and a hammer.

- A perforator or impact drill can be drilled using the marked marks for mounting the product body. Try on the frame and make sure that the holes in the frame and the brickwork match.

- Heat-resistant furnace solution must be diluted according to the manufacturer's instructions. Impregnate the asbestos sealing cord in the kiln mixture. Wind it tightly onto the frame. Insert the prepared product into the structure by tapping it with a rubber hammer.If cracks remain, it is necessary to clog them with an asbestos cord and level the heat-resistant furnace mixture.

- Use screws to fasten the frame to the fireplace.

- After the solution dries, insert glass into the door.

- The control furnace can be made in 3-4 days.

Useful recommendations

If the door is chosen for a fireplace under construction, problems with selection and installation are usually avoided. It is much more difficult to complete the door with an already ready fireplace. In such cases There may be a number of problems that can be avoided by following the advice of experts:

- When choosing a model, it is necessary to determine the dimensions of the door. Measure the prepared doorway in the fireplace. The frame must fit or be slightly larger. This will ensure the tightness of the product during installation.

- It is better to purchase solid structures, rather than collapsible. The second type is more difficult to mount with uneven walls of the fireplace. Tightness also suffers.

- When installing glass in the door, it is necessary to leave thermal gaps. This is necessary so that the glass does not crack when expanded under the influence of high temperatures.

- Before installing the glass model, you must remove the glass from the door. This is a simple operation. Usually glass is fixed with two bolts.

- All cracks and gaps along the perimeter of the frame should be sealed with an asbestos sealing cord and lubricated with a furnace mixture. This way the tightness of the door installation is achieved.

- It is important to remember the conditions for proper operation of the fireplace. The installed door should not be heated from the outside more than 40 ºС. It is necessary to choose those models that are made of several layers of different materials with an air gap.

- The safest type of doors - double doors. Due to the presence of a gap between the flaps, the optimum amount of air necessary to maintain the combustion process gets into the fireplace hearth.

How to install a furnace door, see the following video.