Fireplace grilles: features of choice

Fireplace has become a fashionable element of room design. It can be styled for any interior - from classic to hi-tech. The main purpose of the fireplace - a decorative function, as well as the creation of an atmosphere of comfort with the help of an open fire. Heating the room with a fireplace is worse than using other heating appliances. To improve the circulation of warm air heated in the fireplace, it is necessary to install ventilation grilles on the duct.

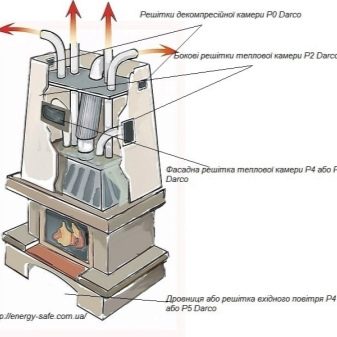

Purpose of ventilation in the fireplace

Usually, one grate is installed below the level of the firebox to take in cold air from the outside. This is an air intake. The other two, installed above the fireplace insert in the duct, are designed to extract warm air.

By installing such gratings in their fireplace, users get several advantageous benefits at once:

- Improved supply of warm air, thereby increasing the heating of the room.

- The probability of overheating of the air duct, facing material of the fireplace and the surface of the firebox decreases, which significantly prolongs the life of the structure.

- The room acquires an attractive appearance due to the external design of the lattices for the style and design of the room.

In the corner fireplace, it is better to install one large upper grille, without breaking the air flow into two directions.

Types of lattices

Ventilation grilles vary in shape, size, material, installation method, the presence of additional elements and capabilities.

Each feature is characterized in its own way:

- The shape of the lattice can be round, square, rectangular, polygonal, oval and complex shapes. It depends on the preferences of the owner of the fireplace. The holes in the lattice also have their shape and depend on the design of the product. Holes can be: slotted, round, square, rectangular, complex shape.

- The size of the lattice is determined by the size of the room and the power of the fireplace.In a small room, you can install small-size grilles. In a larger room, a greater supply of warm air is required for heating. But too large dimensions of the product will not be able to provide the desired stream of warm air.

The size of the holes in the grille is also important to consider. If they are too small, the warm air will not be able to flow freely from the duct, and the very meaning of the ventilation device will be lost. Holes should facilitate the removal of warm streams, giving them time to warm up, but not interfering with the flow to the room. The material must be able to withstand high temperatures and have a long service life.

For ventilation grids are used:

- cast iron;

- steel;

- aluminum;

- ceramics.

A large selection of purchased models saved many from worries about which grid to choose. If you wish, skill and diligence, you can make the most suitable model yourself.

- Lattice models of cast iron have elements of forging and casting. Attractive and stylish look makes you choose such material. The pattern and design are diverse and unique. Masters can create a unique masterpiece in one copy for one fireplace.

- Lifetime cast iron at high temperatures is higher than other materials, which makes it popular. A minus of such material in its big weight.

Steel and aluminum grids are welded from separate parts to obtain the desired pattern with holes of the required size. These grids are coated with heat-resistant paint or treated with a galvanic solution to give them a pleasant appearance and durability.

- Installation method Lattices can have an internal box, to be built in or laid on. Built-in models are more reliable, they fit more closely to the walls of the ventilation holes, do not create cracks and do not allow burning waste. Overhead grilles are easy to install, so they are in high demand among consumers. They can also be made independently.

- The presence of additional elements. The presence of blinds in the grille, which are able to control and direct the movement of air depending on the opening width of the holes, is considered functional.

Opening doors in the form of doors or doors help to regulate the flow of air into the room, as well as open access to the inside of the fireplace for inspection.

Additional mesh with small holes is needed to protect the fireplace from the ingestion of insects, especially in the warm season.

There is the option of a fixed grille and a removable option. In a removable design, the frame is usually mounted in a vent, and the grille itself can either be completely removed or moved aside or down-up. Such a model can open a review inside the fireplace.

Installation Features

Installation of gratings occurs during installation of the fireplace or in the process of its use. When installing it is important to correctly calculate the level of the hole from the floor and the distance from the walls, next to which there is a fireplace.

The calculation takes into account the following points:

- The movement of the air flow inside the fireplace should be directed to the grates.

- The output of the maximum heated air should be at a distance of at least 300 mm from the ceiling level.

- The grate should not be aimed at the wall next to the fireplace, but into the open space of the room.

- The hole under the grille should be as far as possible from the doorway.

- The ceiling of combustible materials should not be affected by the proximity of fireplace ventilation.

For installation in a ready-made fireplace, first an opening is cut at the right distance, which should be 3-4 mm larger than the internal size of the grille. A nail with a wire that is wrapped around the nail is driven into the wall of the box. The protective grid is inserted into the hole and is processed along the perimeter with heat-resistant hermetic material. It is important to achieve a snug fit of the box to the walls of the fireplace.

Impairment of leakage causes heat loss and can create a situation where smoke or soot enters the room.

Product care

Cleaning the fireplace grates as needed. It is advisable to implement it at least once every six months. It is better to do this after the end of the heating season. Grate with small holes must be cleaned more often than with large holes.

Covering with dirt, the grille will not allow warm air to pass through and perform its basic functions. After cleaning, the vent grille can be closed before using the fireplace, which will protect it from external contamination and insects from entering the fireplace.

Making your own hands

A metal grid of square or rectangular size can be made by hand if you have skills in welding machine, grinder and metalworking tools.

For self-production will require:

- metal bar of small diameter;

- steel corner for the frame;

- welding equipment;

- fitting tool.

The order of performance of work:

- Draw a drawing with exact dimensions.

- Make a sketch of an ornament or just a standard grid.

- Based on the drawing, calculate the size of the parts.

- Saw 4 corner parts and weld the frame. The frame must be made 3-4 mm larger than the hole in the fireplace.

- Take the bars in the right quantity and saw off to the required size.

- Try them on by attaching to the frame. Weld rods in accordance with the sketch.

- To process welding seams, achieving esthetic appearance.

- The resulting grid welded to the frame.

- Cover the finished product with heat-resistant paint in several layers.

Installation should be done 2-3 days after production, when the paint is completely dry.

Air direction

To properly use the heated air inside the fireplace install a fan.

The use of a fan to improve air circulation inside the fireplace box should be appropriate. Power and direction should contribute to the optimal heating of air masses and their output through the holes in the grid. Otherwise, the opposite effect may occur.

Screens

Do not confuse grilles with fire screens that are installed directly in front of the fireplace's flue. The screens are designed to protect the premises from the ingress of sparks and other products of combustion of firewood.

The screen is of different types: glass, metal, ceramic or a combination of different materials. Modern heat resistant material such as fireproof fabric can be used. The metal screen can be deaf, mesh or in the form of a lattice with an ornament. Convection screens can be made in the form of a screen, standing alone or fixed to the floor or fireplace. They are straight, curved, single-section and consisting of several sections.

The screen also serves as a decorative interior decoration. In addition, he helps, being near the hearth, to watch the fire without fear of overheating.Looking at the fire more pleasant through the glass or mesh, then the eyes get tired less. The pig-iron grid-iron lattice also will become decoration of an interior.

Ventilation and supply of heated air into the room is required for the operation of any heating device. Fireplace is no exception. Forged ventilation grilles are essential for proper use of the fireplace. They are not needed, unless they use the fireplace for heating, but only perceive it as an interior decoration.

It is better to entrust the installation of ventilation grilles for the fireplace to a specialist who does the installation of stoves and other heating appliances. It will accurately calculate the required number of grids, their size and height adjustment. Competently and professionally performed work will contribute to the long and effective use of the fireplace.

In the video below you can see the manufacture of fireplace ventilation grille.