Thermal insulation of fireplaces and stoves: the choice of materials

The device of modern fireplaces and stoves is reduced to the creation of a chimney and a metal furnace, but in rich variations there is also a fireplace made of pure stone, almost without the use of metal. But in most cases, the final appearance makes not only a well-boxed fireplace, but also a chimney. But not all materials are suitable for thermal insulation of these nodes.

Features of the procedure

In fact, a fireplace is nothing more than a regular stove that served as a heating appliance with an open hearth and often a direct chimney (in remote villages).However, the direct chimney, which is not a very reliable and successful construction, is widespread among the Russian population due to its price and incompetent workers. But the times of heating from the fireplace have passed and now he is a decorative element of the house, which gives charm and elegance to the room.

The main mechanism that gives heat is a metal construction of the “stove” type with a smoke outlet coming out of it. Of course, only the principle of this famous stove remained in modern fireplaces, although it was known long before it appeared.

To ennoble such a design, they resort to finishing it with a box of natural stone. (or brick) or its imitation, leaving the so-called portal (place of burning) and forming a high-quality chimney. Often you can meet and option with tiles, which is placed on a special box of plasterboard (fire-resistant).

In fireplaces that run on solid fuel, the exhaust gas temperature is about 440 degrees, but the temperature of the firebox (portal) itself is noticeably lower - it can reach 120 degrees during operation.

This is a very important point.since it is necessary to pick up and design everything around the firebox so that the gypsum cardboard does not overheat (during long-term overheating it loses its properties, is destroyed and deformed by melting), and the decorative finish did not deteriorate (like tiles and other finishing materials).

Inside the case, a special heat-insulating circuit is installed, which provides high-quality insulation from internal heat, which makes it possible to touch external parts without fear of getting burned. The warm air comes out through special holes.

The selection of fire-fighting elements for interior and exterior decoration serves as a real protection against the ignition of the room as when a chimney burns through., and the output of sparks from the portal (which is a signal of violation of the rules of use, for example, overfilling the furnace). With quality work on the fire resistance of the fireplace finishing materials do not light up.

Often fireplaces are located along the wall or in the corners of the room. In this case, the insulating material must be applied to all adjacent surfaces. It is necessary to protect the house from overheating, sparks on the walls, as well as fire.In addition, the insulation will help focus the heat in the furnace, which well improves the profitability and efficiency of the fireplace as a whole.

When laying the furnace and chimney panels are used that have a heat-resistant appearance.

Types of finishing materials

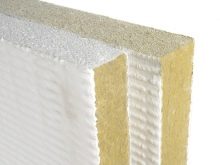

When insulating fireplaces, special materials are used, mainly from stone wool slabs, such as:

- Fire batts (Rockwool), the price for 1 package (8 pieces of 1000x600x30 mm in size) is about 3 thousand rubles;

- PS17 (Ragos), the price of 1 pack (7 pieces of 1200х600х30 mm) is about 2 thousand rubles;

- TECHNO T 80 ("TechnoNIKOL"), the price of 1 pack (6 pieces of 1200x600x50 mm in size) is about 3400 rubles.

The main feature of such materials is the operating temperature range, which varies from 170 to 800 degrees. Such plates are common, with a fire resistance index and glued (on a special heat-resistant adhesive, whose temperature threshold is 20–30% higher than this threshold near the product itself) to one of the sides with reinforced heat-resistant foil.

Foil additionally increases the thermal insulation characteristics of this material by reflecting heat.

In case you correctly select the finishing material, when arranging the stove, follow the advice of both manufacturers of fireplaces and manufacturers of insulating materials,during the operation, observe ordinary precautions and safety (do not leave a functioning fireplace unattended, do not leave inflammable products and objects near it or near it), then you will enjoy fireplace heat and fire for a long time without putting housing at risk nor yourself.

Selection of thermal insulator

Numerous individual developers often overlook the fact that in the product line of any large manufacturer of thermal insulation made of stone wool materials for various purposes were presented.

Despite the external similarity, they have a different structure, have different characteristics from each other, are used when working with different materials: for steel and brick structures, options of "stainless steel".

If for general construction insulation the range of operating temperatures ranges from approximately -50 to +100 degrees, then in this case special products of combustion, for example, designed to work in a high-temperature environment (in direct proximity to fireplaces, stoves and other heating devices), are calculated for other loads, and the heat of the insulated plane they can vary from -180 to +750 degrees.The selection of such materials must be approached most thoughtfully, otherwise ordinary insulation at high temperatures will be ineffective.

In addition, for these purposes, it is necessary to use products of combustion of considerable density (no less than 90 kg / m3), since they isolate the surface more accurately and better at high temperatures.

There are 2 types of plates of special high-temperature thermal insulation:

- without foil;

- with dural foil attached at one end with a special heat-resistant glue.

The maximum allowable temperature of the edge with foil is 500 degrees, the edges with stone wool are 750 degrees.

In order to not aggravate the properties of the product, packaging with the material must be kept indoors or under a canopy (in a horizontal position, on a dried, smooth surface), covered with polyethylene.

Stone wool is made from fire resistant material. (in fact, non-combustible) - rocks of the gabbro-basalt category with the addition of an insignificant number of binder in order to give shape, and in high-temperature insulation it is very small (less than 2% according to the mass fraction).

Thin fibers of this heat-insulating material can withstand, without melting in any way, heat up to 1000 degrees: they are not damaged at all, remain connected to each other, store strength (which also speaks of their durability), shape and will not collapse without mechanical effects on the material itself.

Products made of stone wool are referred to the group of fire-resistant building materials (NG according to GOST 302W), which are used both in low-rise country houses and in high-rise buildings. In addition, in case of fire, such thermal insulation for a certain time keeps the process of destruction of the supporting structures of the structure.

Since the operation of the fireplace and its chimney is associated with the combustion process and high temperatures, their installation will require a very careful and balanced approach. There is a joint venture 7.13130.2013 “Heating, ventilation and air conditioning. Fire Safety Requirements ”, which clearly describes the basics of the installation and installation of furnace chimneys, penetrations and the installation of thermal insulation, based on the requirements of fire safety.

Neglect of these laws can cause extremely sad consequences.

Based on the practice, most of the owners of individual houses that had a sauna or a house burned, without the help of others, put a stove or a fireplace, where they committed very gross violations, did not follow the rules for isolating the chimney from overlapping or did not adhere to the fire protection distance between the fireplace and the wall , despite the fact that this parameter is specified both in the installation instructions and in the above joint venture.

Therefore, it is recommended not only to buy high-quality insulating materials, but also to hire specialists to help you competently and efficiently install all this. After all, even, in your opinion, a minor mistake can cost the life of you or someone of your loved ones.

Methods

The principle of chimney insulation is approximately the same as the process of isolation of the fireplace itself. It should be borne in mind that in this case there is no open flame, but the temperature is much higher. Basically for installation they use stone wool, stitching it under a plasterboard box. Wool is also fastened to heat-resistant glue, but variants with screws are also possible, depending on the material from which the chimney was made.

Depending on the type of chimney pipe, heat insulation can be performed by different types of materials: round pipes should be insulated only with rolled insulation, square or angular forms should be insulated with insulation boards only. This is due to the requirements for fire safety.

But the chimney, which goes beyond the construction (on the roof), is slightly warmed by a different technology, generally similar, but there is a significant difference: weather protection is also needed. In cases where the chimney pipe is metallic, it is sheathed with rolled or lumpy cotton wool for glue and in rare cases for self-tapping screws. Often these pipes are hidden in one false-pipe, which serves as both additional thermal protection and protection from external factors.

Pipes made of brick or similar materials are insulated with heat-insulating wool in slabs, fastening it to screws and "roses". After this wool in several layers is covered with a special glue (street, facade), which is able to withstand high temperatures without damage. Then, a special paint net and perforated corners are applied to the second leveling adhesive layer.This is done in order to strengthen the surface of the structure. After that, the surface is again covered with the same material, but already the final layer.

Insulation of the passage of steel pipes through the ceiling to the outside of the walls should be done only in accordance with safety regulations.

How to make yourself?

- First, take the required number of insulating plates, which are cut to the size of the fireplace.

- After that, a special heat-resistant glue is applied (mineral, cement-based), and the application should be done with a point.

- When mounting the foiled material, the glue is applied to the non-coated part.

- After that, the plates are mounted on the walls. Joints and other openings must be sealed with special heat-resistant aluminum tape, which can also be reinforced.

- When the main heat-insulating part of the fireplace itself is completed, the installation process of the decorative portal (firebox) begins, but it is important to remember that between this framework and the thermal insulation layer there should be at least 4 cm, but not more than 10 cm. Then profiles are installed where they install additional thermal insulation plates with respect to size.

It is not difficult to make thermal insulation for boiler rooms or in the bath of a private house with your own hands if you follow our recommendations.

Pro tips

In order to increase the fire safety of the ceiling that crosses the chimney or chimney, install a decompression chamber in a horizontal position by installing a heat insulating plate.

In the box it is preferable to provide 2 fan grilles: one - in order to cool the decompression chamber, and through the other warm air will be transmitted through the room. Sheets of plasterboard are attached to the iron guides with self-tapping screws: they will be the base for decorative decoration of the fireplace.

Conclusion

It is important to remember that for greater fire safety the chimney must function properly, and the fireplace itself must be made qualitatively, otherwise it will lead to smoke in the room. This is one of the basic requirements for fire safety. In the presence of such a problem - do not rush to sew up the design in the box: this will lead to a waste of money on expensive items.

If everything is in order with the smoke discharge, then the insulation can work quite well.The main thing in this business is a high-quality selection of materials and, very importantly, a good specialist.

You yourself can make the fireplace heat insulation in your house, but it is very dangerous (in the final result) and can lead to sad consequences, therefore it is worth turning to professionals in this matter.

Learn how to conduct a heat protection furnace, learn from the following video.