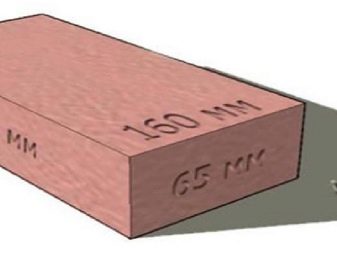

Facing brick weight 250x120x65

Construction and finishing materials should be selected not only for strength, resistance to the effects of fire and water, or thermal conductivity. Of great importance is the mass of structures. It is taken into account in order to accurately determine the load on the foundation and plan the transportation.

Special features

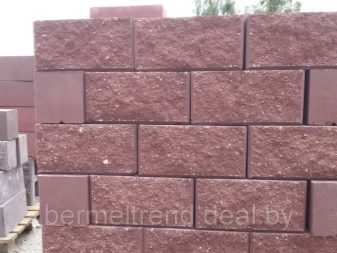

To order several pallets of facing brick is much more practical than using decorative blocks. The latter are inferior to facing material in terms of service life and protection from all external destructive factors. Such a coating reliably covers the main part of the wall from possible deformations. Facing (other name - front) brick is unsuitable for the construction of the main part of buildings and structures.The point is not only cost, but also insufficient performance.

Facade bricks are different:

decent mechanical strength;

wear resistance;

stability in various meteorological conditions.

There are blocks with both completely smooth and with a marked relief surface. It can be painted in different colors or have a natural shade. The material has a considerable thickness, so that mechanical impact on it is not affected. High-quality facing brick will be able to serve for several decades. But even all these parameters, including high frost resistance, are not all.

Knowing how much a facing brick weighs is very important. After all, this material is used quite actively. In addition, it has a lot of weight, which has a significant impact on the walls, and through them - on the foundation. It should be borne in mind that facing bricks can be very different in form. And therefore the question, what is the mass of the building block as a whole, does not make sense. Everything is relative.

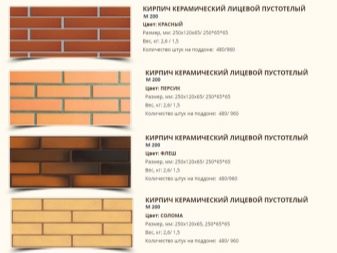

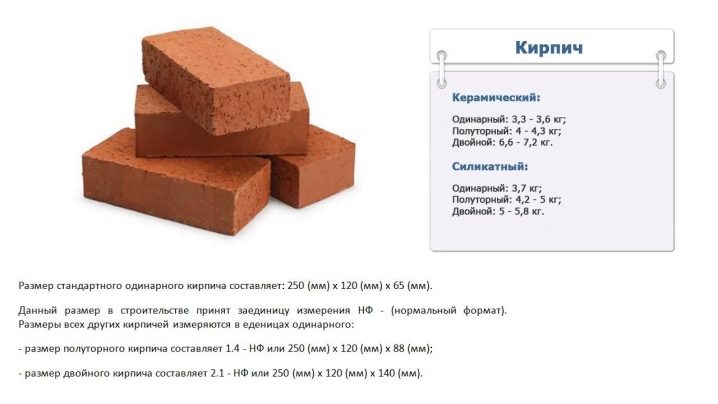

Species

The weight of facing brick 250x120x65 mm, containing voids, is from 2.3 to 2.7 kg.With the same dimensions, a solid building block has a mass of 3.6 or 3.7 kg. But if we weigh the hollow red brick of the euroformat (with dimensions of 250x85x65 mm), its weight will be 2.1 or 2.2 kg. But all these numbers refer only to simple varieties of the product. An empty brick with dimensions of 250x120x88 mm thickened inside will have a mass of from 3.2 to 3.7 kg.

Hyper pressed brick with dimensions of 250x120x65 mm with a smooth surface, obtained without calcination, has a mass of 4.2 kg. If we weigh a ceramic hollow brick of increased thickness, made according to the European format (250x85x88 mm), the scales will show 3.0 or 3.1 kg. There are several types of clinker bricks:

full-weight (250x120x65);

with voids (250x90x65);

with voids (250x60x65);

extended (528x108x37).

Their mass is respectively:

4,2;

2,2;

1,7;

3.75 kg.

What buyers and builders should consider

According to the requirements of GOST 530–2007, single ceramic brick is produced only with a size of 250x120x65 mm. This material is used if you want to lay load-bearing walls and a number of other structures. Its severity varies depending on whether hollow or full-fledged facing blocks will be laid. A red facing brick with no voids will weigh 3.6 or 3.7 kg.And in the presence of internal grooves, the weight of 1 block will be at least 2.1 and maximum 2.7 kg.

When using standard one and a half facing bricks, the mass of 1 pc. is assumed to be 2.7-3.2 kg. Both types of decorative blocks - single and one-and-a-half - can be used to decorate arches and facades. Full weights may contain a maximum of 13% voids. But in the standards for material containing voids it is indicated that cavities filled with air can occupy from 20 to 45% of the total volume. The lightweight brick 250x120x65 mm allows to increase the thermal security of the building.

The specific gravity of facing bricks with such dimensions is the same as that of a hollow single piece. It is 1320–1600 kg per 1 cu. m

Additional Information

All of the above applies to ceramic facing brick. But he also has a silicate variety. This material is stronger than ordinary products, created by a combination of quartz sand with lime. The ratio between the two main components is selected by technologists. However, when ordering a silicate brick of 250x120x65 mm, as with the purchase of its traditional counterpart, it is necessary to carefully calculate the weight of the blocks.

On average, 1 piece of building material with such dimensions weighs up to 4 kg. The exact value is determined by:

the size of the product;

the presence of cavities;

additives used in the preparation of the silicate block;

geometry of the finished product.

A single brick (250x120x65 mm) will weigh from 3.5 to 3.7 kg. The so-called one-and-a-half full-bodied (250x120x88 mm) has a mass of 4.9 or 5 kg. Certain types of silicate, due to special additives and other technological nuances, can weigh 4.5-5.8 kg. Therefore, it is already quite clear that the silicate brick is heavier than the ceramic block of similar size. This difference must be taken into account in projects, to strengthen the foundation of the constructed buildings.

The hollow silicate brick with a size of 250x120x65 mm has a mass of 3.2 kg. This allows you to significantly simplify both construction (repair) work, and transportation of ordered blocks. It will be possible to use smaller vehicles. In addition, there is no need to strengthen the walls. Therefore, the foundation of the erected structure will be made easier.

We will carry out simple calculations. Let the mass of a single silicate brick (in a full-bodied version) be 4.7 kg. Typical pallet holds 280 pieces of such bricks.Their total mass without taking into account the gravity of the pallet itself will be 1316 kg. If you keep the calculation for 1 cu. m of facing bricks made of silicates, then the total weight of 379 blocks will be 1895 kg.

A bit different situation with hollow products. Such a single silicate brick weighs 3.2 kg. Standard packaging includes 380 items. The total weight of the pack (excluding the backing) will be 1110 kg. Weight 1 cu. m. will be equal to 1640 kg, and this volume itself includes 513 bricks - no more and no less.

Now it is possible to consider a one-and-a-half silicate brick. Its dimensions are 250x120x88, and the mass of 1 brick is all the same 3.7 kg. The package will include 280 copies. In total, they will weigh 1148 kg. And 1 m3 of silicate single-and-a-half brick contains 379 blocks, the total weight of which reaches 1400 kg.

There is also crushed silicate 250x120x65 with a weight of 2.5 kg. In its usual container 280 copies are located. Therefore, the packaging is very light - only 700 kg exactly. Regardless of the type of bricks, it is necessary to carry out all the calculations very carefully. Only in this case will it be possible to ensure the long-term operation of the building.

If you need to determine the weight of the masonry, you can not calculate its volume in cubic meters.You can simply calculate the mass of one row of bricks. And then a simple principle is applied. At a height of 1 m has:

13 rows of single;

10 one and a half bands;

7 lanes of double bricks.

This ratio is equally true for both silicate and ceramic varieties of material. If you have to revet a large wall, it is better to choose a half or even a double brick. It is recommended to start your choice with hollow blocks, because they are easier and more versatile. But if there is already a solid, solid foundation, you can immediately order full facing products. In any case, the final decision is made only by customers of construction or repair.

How to calculate the number of facing bricks, see the video below.