Features and technology of facing a house with bricks

Houses lined with bricks meet with enviable regularity. Such structures are not only distinguished by their aesthetic appearance, but also by their reliability and durability. Many owners independently trim their homes with high-quality and wear-resistant bricks, saving money on the services of professionals. Of course, you can really do it yourself, but it is important to take into account the peculiarities of the specified building material and to familiarize yourself with the instructions.

Material Features

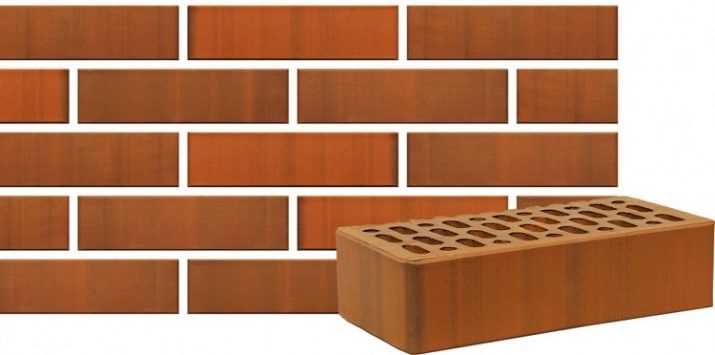

Brick is rightly recognized as the most popular building material,which is very common. Brick houses and buildings lined with brick can be found on every street. Many consumers opt for this particular product. The distinctive characteristics of modern facing bricks can be easily attributed to its attractive appearance, coupled with durability.

In addition, this raw material does not fear negative external influences, bad weather conditions and mechanical damage. It is not so easy to break or break a high-quality brick, therefore it is simply irreplaceable in facing of private houses and villas.

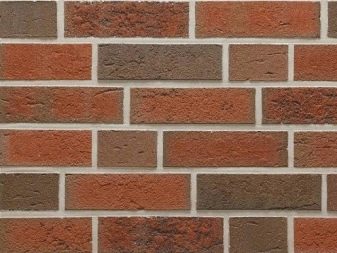

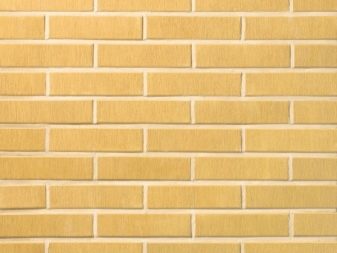

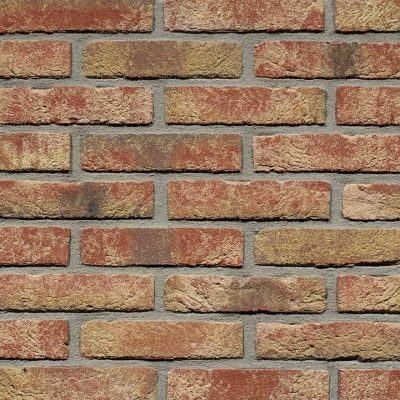

According to experts and home craftsmen, today's facing bricks may be somewhat inferior to other facing materials in their external characteristics. Recently, however, this trend has ceased to be relevant. In different outlets, people can meet different variants of bricks. It can be not only red and smooth elements. There is an opportunity to pick up textured versions of other colors, which look very interesting.

Using a reliable facing brick, it is possible to form an additional protective layer for the walls.Thus, it will be possible to save these bases from penetration of pernicious dampness and moisture. In addition, the heat loss from the brickwork is usually significantly reduced, which is noted by many owners.

In most situations, in the desire to decorate the house with brickwork, people rely on their "Wishlist". At the same time, a lot of important moments are missing, having a direct impact on the brick itself and the facade of it. Experts say that the material design of the facade of the house must be thought out at the design stage. Leaving this case "for later" is not worth it.

If you do not pay attention to this rule, then after the manufacture of the box there may be a lot of problems. It may be that the width of the foundation is not enough to support the facing brick, because during the construction the owner has decided to further insulate the wall structures.

Thus, the facade of the front brick has a more significant bearing capacity, which is able to exceed these indicators of the foundation, which as a result will lead to cracking of the masonry. It is quite possible to make a house lining with brickwork.Of course, this process cannot be called very simple and easy. In fact, it is laborious work, but to cope with it is real. The main thing is to comply with all the nuances of facing and act in stages, observing the technology.

Advantages and disadvantages

Today, many users choose brick as a facing material. For this reason, facades from it are most common. Such popularity of brickwork is explained by the many positive qualities that are inherent in it.

Let's get acquainted with their list.

- First of all, you should pay attention to the attractive appearance of the lining of the brick. Thanks to this design, the house can be much more aesthetic.

- Brickwork is able to provide good protection to the main wall material (for example, from a foam block or timber). Being behind the bricks, the foundation will not be exposed to the ravages of precipitation and other external factors that can cause serious damage.

- There are many different materials with which you can effectively decorate a residential structure, but the brickwork is recognized as one of the most reliable and durable solutions.For example, the same facade plaster is more susceptible to mechanical damage.

- The brick is not afraid of the effects of aggressive ultraviolet rays. When in contact with them, masonry does not lose its color and presentation, which cannot be said about today's popular vinyl siding or painted professional sheet.

- Making the facade of the house with brickwork allows you to further warm the residential building, as many experts say. Of course, the insulating properties of bricks are not highly efficient, but the combination of hollow building material and insulation allows for a good effect.

- Another significant advantage of brick cladding is that it makes the house even more fireproof. By itself, a brick is a non-flammable building material, and it does not support burning itself. If there is a wooden base under it, then it simply needs to be closed, as it is subject to fire.

- The facades, lined with brick, boast durability and durability. They are not afraid of exposure from outside or harsh weather conditions.

- The brick is characterized by minimal absorption of moisture, so over the years it does not crack and does not lose its positive qualities, even if it is in a region with frequent rains.

- The facade revetted by a brick does not demand difficult and regular leaving in contrast to the same wooden one.

It does not need to be treated with antiseptic formulations and other protective agents. Brickwork is the defense itself.

- Such building material is famous for its environmental safety. It does not harm either human health or the environment. Moreover, the brick has the ability to destroy harmful substances - they are simply removed from the base. During the rains, this lining is self-cleaning.

- The brick can be used both at external, and at internal finishing of buildings.

- The facing brick is famous for the frost resistance. You can safely contact him, even if you live in a northern climate. In addition, these materials are not afraid of temperature drops - under their influence, the clutch is not damaged and does not lose its positive qualities.

- It is not necessary to trust professionals to work with facing bricks.It is quite possible to decorate the house yourself - you just need to adhere to the guidelines and use high-quality raw materials.

- Brickwork has a good soundproofing effect. A house with such a facade will always be protected from annoying street noise.

- Modern facing brick is presented in a wide range. In retail outlets there are products of different textures and colors, so everyone can choose the best models.

As you can see, the brickwork has many advantages. That is why it is so common. Many consumers do not even have a question about how to decorate the facade of the house - they immediately acquire the right batch of facing bricks. But we must not forget that, like any other building material, it has its own weaknesses, which must also be read.

- The brick is subject to the formation of a noticeable white bloom, called salting. Because of such formations, the appearance of the lined building can be seriously affected.

- It should be borne in mind that brick cladding is not cheap, especially when compared with other options.For example, the use of the same Don board will cost much less.

- There are too many low-quality building materials in the stores, which do not last as long as we would like, and during operation such products bring many problems. That is why professionals argue that it is necessary to use only European bricks - marriage practically does not occur in them. But such options are not as common, and their authenticity is not always possible to check.

- Selecting facing bricks, you need to make sure that all building materials are selected from one batch. In the case of a mismatch of shades, it will simply not be possible to correct the situation, and this will be very noticeable.

- Despite the fact that the brickwork can be built independently, still such works can hardly be called simple and light. Facing the house with bricks is time consuming and sometimes very expensive.

- Brickwork creates a serious load on the foundation. That is why experts strongly recommend to work on this issue at the stage of preparation of the project and the scheme of the future construction.

- It must be borne in mind that the use of facing bricks can lead to a noticeable decrease in ventilation. Because of this, moisture can accumulate in the insulating materials, which will negatively affect their properties.

- With such a finish, the shrinkage of the wall bases will be different, so it is impossible to firmly and firmly tie the base to the lining.

- Bricks are often found in shops that do not differ in perfect geometry. Working with similar products can be difficult.

- Such lining materials can be shed if you choose products of unsuitable brand (with insufficient strength).

- Brick is a building material, which is very often damaged during transportation. Often he is stabbed - the edges fall off. It is impossible to continue working with these elements.

- A brick can collapse if low-quality raw materials are used in its manufacture. Incorrectly processed limestone, always present in clay, often remains in the mass of products. Because of this, noticeable “quotas” appear in the bricks. In these places, products especially absorb moisture, and then completely destroyed.

It can be noted that there are also a lot of flaws in facing bricks. However, many of them can never be encountered if you initially purchase quality products manufactured according to all the rules and regulations.

There are several varieties of facing bricks. Consider them in more detail.

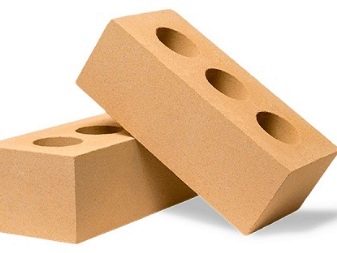

- Ceramic. This species is the most common. Such products are made of clay and special mineral additives, from which a special mixture is obtained. It is passed through the spinnerets, and the output is a formed block, which is then sent to the kiln. In such conditions, the building material is very practical and then serves for a very long time. It is characterized by durability, low moisture absorption, reliability and resistance to wear / destruction.

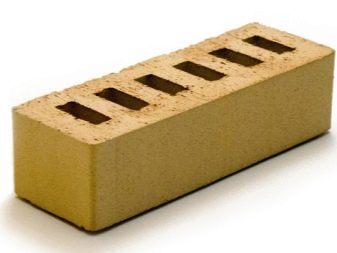

- Clinker. This type of brick is divided into a separate category, although it is one of the varieties of ceramic products. Clinker models are also made, and the starting materials are similar. The difference is only more rigid mode of firing. After this stage, the brick turns out to be almost monolithic - it acquires enhanced strength characteristics.Serves such products for a long time, and damage it is extremely difficult. However, one must keep in mind that clinker is not the most effective sound insulator.

- Hyper pressed. This building material is made without the use of clay. Used lime-cement mixture with a number of specialized additives used in order to obtain a higher level of strength and different colors. In the manufacturing process, the hyperpressed building material is not fired. Similar products also differ in impressive weight. They can have a beautiful stone texture.

- Silicate. Silicate sand brick is produced from silicate sand, water and lime. This building material is characterized by high moisture absorption, therefore, are not resistant to frost. Service life due to this feature also suffers. For this reason, silica brick in recent years, buy quite rarely.

Types of masonry

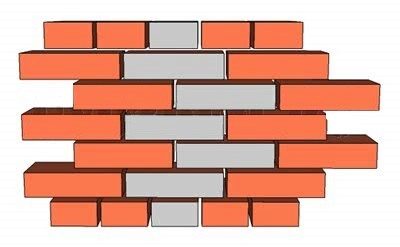

There are several types of brickwork. Let's get to know them better.

- Spool type dressing. This is the easiest clutch. With it, the stones are shifted by a quarter or half the length.In the construction of houses, such options are used very rarely, but in facing works this is a common solution.

- Chain dressing. With the construction of wall structures in one brick such a ligation will be the most reliable. In such works, one row is a butting, and the second is a spoon with a parallel display of two stone elements with a gap of seams.

- Dressing multi-row type. In the process of carrying out work in extremely rare cases, every second row is jabbed, and there is no need for that, because of this, the level of strength of wall structures will suffer minimally. For this reason, in most cases with one butcheral row, from 2 to 5 (sometimes 6) of spoons are combined.

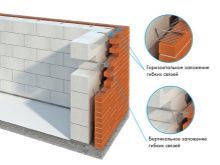

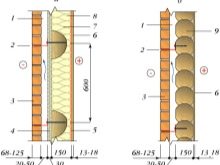

- Lightweight. As for lightweight masonry, it is usually resorted to at low-rise construction. This method is characterized by the presence of large voids in the construction of walls. Most often they are filled with insulation.

The walls, built on a lightweight technology, are two walls, combined with each other with the help of bandages made of brick or special ties of metal.

- Reinforced. This type of masonry is used if it is necessary to build high-strength and strong brick structures. Reinforced masonry is relevant if you need to connect the cladding with the bearing wall, to take care of the additional strength of structures.

- Decorative. Thanks to this method of masonry, it is possible to create a beautiful architectural image of the facade of the house. If we turn to this option, then the building can be made very effective, it will stand out among other erections.

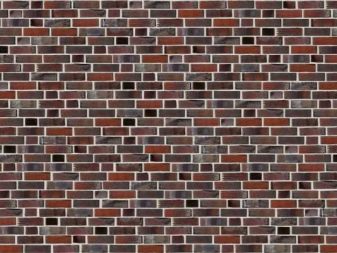

- Bavarian. This technology is considered to be German masonry, but this type of design has many different buildings, located in many European countries and even in Russia. With this technique, the bricks of different color are mixed - they do not alternate evenly.

- Facial. With this method, only personal building materials are used, which can be found in modern outlets with various kinds of decorative effects. Varieties of such clutches just do not count. However, in most situations, classical techniques are used to finish the facades - half masonry (half-brick).

- Openwork. With this option, masonry get spectacular perforated structures.They are erected using a spoon method of laying in half-brick, just between the joints of the bricks next to each other, small gaps are intentionally left and the seams are scrupulously closed.

Required tools

As mentioned above, it is quite possible to make facing works both inside and outside with your own hands. But before this is extremely important to stock up on all the necessary tools and fixtures.

Let's get acquainted with their list.

- Trowel (this is another name for such a device as a trowel);

- hammer pick;

- Bulgarian (with its help it will be possible to cut bricks as accurately and accurately as possible);

- level and plumb;

- the rule;

- order;

- jointing;

- special construction cord;

- gon.

Note that the number of tools used depends largely on the qualifications of the master who carries out the facing work. So, more experienced masons with a wealth of knowledge can use very few tools. If the worker is less prepared, he may need a much wider toolbox.

Preparatory stage

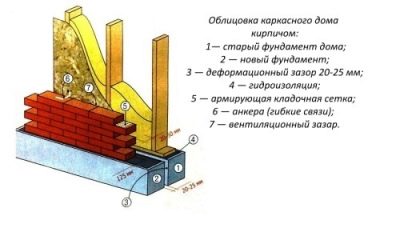

If you decide on your own to decorate your home with brickwork, then you should first carry out a series of preparatory work.You should not neglect them if you want to achieve a good and sustainable result. Make sure that the foundation of the house, as well as its construction as a whole, is designed for the installation of brickwork. The foundation must necessarily be built in compliance with all building codes. It must withstand significant loads. Cheap and simple bases in this case will not work.

You should also make sure that the base of the house is made of such raw materials as monolithic concrete (concrete blocks are also permissible). The foundation itself must be sufficiently wide. This requirement is especially important because the facing brick will be based on the foundation construction. In some situations, bricks are placed on special steel corners that are attached to the base using anchor bolts.

In addition, it is allowed to organize an additional foundation, if the quality of the core leaves much to be desired. Another base should be poured around the perimeter of the structure, departing about 30 cm from the first foundation.

Additional construction will need to close the waterproofing material.For this purpose, ruberoid laid in two layers is ideal. It can be fastened to the former base with anchor bolts.

Next you should pay attention to the roof structure. It is very important to look at the roof. In most cases, in old houses, the eaves part does not protrude more than 25 cm beyond the perimeter of the structure. With such a structure, the bricks will become infinitely wet and may even be destroyed. After about 5 years of this use, the brickwork will become unusable. This problem can be solved in one correct way - it will be necessary to coat the walls of the dwelling with a special water-repellent compound every year, but keep in mind that such funds are quite expensive.

If you plan to close the main walls of wood with brickwork, then before starting work you will need to coat the wooden bases with antiseptic compounds. If you design the exterior walls, then the means for them must be bought appropriate. For external works, it is not necessary to acquire internal impregnations - there will be little sense from them. In addition, it will be necessary to attach a vapor barrier material to the wooden walls using a construction stapler.Lay these coverings should be with overlap (minimum - 10 cm).

You will also need:

- carefully examine the surface of the walls of the house, remove all unnecessary details, such as flashlights, drains and other similar objects;

- it is necessary to remove the old paint layer, delaminated elements, fall;

- all defects should be necessarily covered with a layer of putty;

- if the damage to the walls is too severe, you will have to completely plaster them;

- in order to mount a heat-insulating layer, it is necessary to put a layer of primer, which will be responsible for better adhesion of the wall and glue.

In addition, it will be necessary to properly prepare the solution. A simple cement mixture is hardly suitable here, because the facing brick is resistant to water absorption. This problem is especially acute when it comes to the installation of clinker bricks, which simply need specialized additives that provide more effective adhesion.

The correct solution consists of the following ingredients:

- cement brand M500 - 1 part;

- sand - 4 parts;

- water.

The finished masonry mortar should have a consistency on which the bricks will not “ride”.It is better not to apply to the addition of a variety of additives. The only exceptions are pigments, which give the seams and joints a contrasting shade, creating an interesting decorative effect.

Some masters add some clay to the solution in order to achieve greater plasticity of the composition. However, here the opinions of different masons differ - someone sees in it only harm because of washing out the clay component from the composition and reducing its strength, and someone, on the contrary, believes that the clay makes the seams of brickwork more durable. In this issue, each user relies on their own opinions and experiences.

DIY cladding technology

Let's consider step by step how to revet the facades of houses with bricks.

- Do not proceed to such works in rain or snow. Wait for dry and warm weather.

- First lay out the starting row around the perimeter of the construction. The bottom brick layer must be laid very carefully and carefully - it should be perfect.

- In areas with windows, brick should be laid without breaking the row.

- Apply the mortar to the bricks using a special tool - a pattern.

- Next, on both edges of a row of bricks, 4-5 stone levels should be laid out - they will play the role of lighthouses. Stretch the thread between them, and then mount the remaining rows. Be sure to check their horizontal position.

- Aligning the rows of bricks with the topmost lighthouse, you should repeat the arrangement of the following beacons. So you need to act as long as the entire wall will not be faced.

- Stir the cement mortar more often before building bricks over the wall so that the sand in the composition does not settle.

- If you want to lay bricks correctly, you should remember about the seams between them. These elements should be as smooth and accurate as possible. The thickness of the seams should not exceed 12 mm.

- Leave thin ventilation gaps between the internal load-bearing walls and external brick planes.

- In the second bottom row of lining, you will need to make a small hole and close it with a special grid. This will be required to ensure natural air circulation.

Beautiful examples

- Houses lined with brick look more attractive and fresh. Moreover, it can be not only a standard red building material with a perfect geometry, but also an original hand-molded brick with a brownish-burgundy shade.Such facing will be combined with a high gable roof of a gray-blue shade and snow-white window frames.

- The facade, lined with a small red brick, combined with a rich roof, decorated with red tiles, will look great if you add it with white double doors and windows with white frames. Around the house should be divided paths, decorated with gray paving tiles.

- For lining, you can use bricks of different colors. For example, a combination of yellow and brown building materials looks stylish and attractive. Against the background of this trendy tandem, dark window frames and the same dark roofing materials look harmonious.

In the next video you are waiting for the main and important nuances when facing the finished structure.