Features and main characteristics of porous bricks

Porous (porous) brick is a hollow ceramic block widely used in private and commercial construction. This material is made using a thermal method.

The finished product has high strength and good insulating qualities. Its use allows to reduce the power load on the foundation, accelerate the pace of construction and reduce the risk of structural shrinkage.

What is and what is needed?

Porous brick is a building material that is made from sand mixture, clay and specialized additives,subject to rapid burnout (these include sawdust or peat).

The production process includes several basic steps.

- Preparatory. At this stage, the clay and sand mass is cleaned, as well as their grinding using special equipment to a uniform state. In addition to this, special rapid-release additives are added to the raw materials. The quality of the preparation of raw materials will largely determine the technical characteristics of the finished product.

- Pressing. The prepared mass is subjected to pressure under vacuum presses. As a result of this effect, products with specified dimensions are obtained at the outlet.

- Drying. Materials are sent to the drying chambers in order to remove excess moisture from them.

- Burning. It is made in the special furnace equipment. In the kilns, straw, chips, sawdust or peat burn out (depending on the raw materials used), and microscopic hermetic air voids are formed in their place.

During heat treatment of the blocks, the organic material quickly burns out, resulting in small tight pores in the blocks.Due to its good technical characteristics and performance, porous blocks are widely used for the construction of various facilities.

They are used in construction:

- residential buildings;

- public buildings, the height of which does not exceed 24 meters.

Porous bricks can withstand a power load of at least 150 kg per square centimeter. Because of this feature, the material is used in the construction of internal partitions and supporting structures.

Advantages and disadvantages

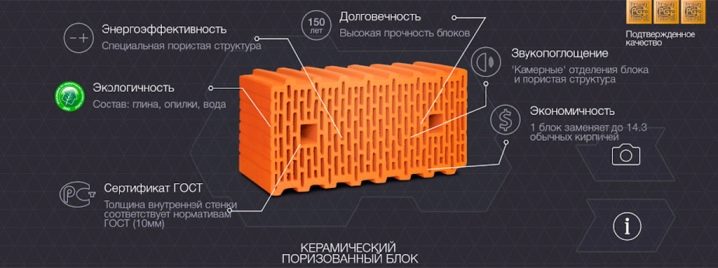

Porous ceramic block has numerous advantages that determine the high demand for such products.

The main advantages of porous bricks include several factors.

- High strength material.

- A small mass. Due to the minimal weight, the load on the foundation of the building is noticeably reduced, due to which there is no need for arranging a powerful foundation base.

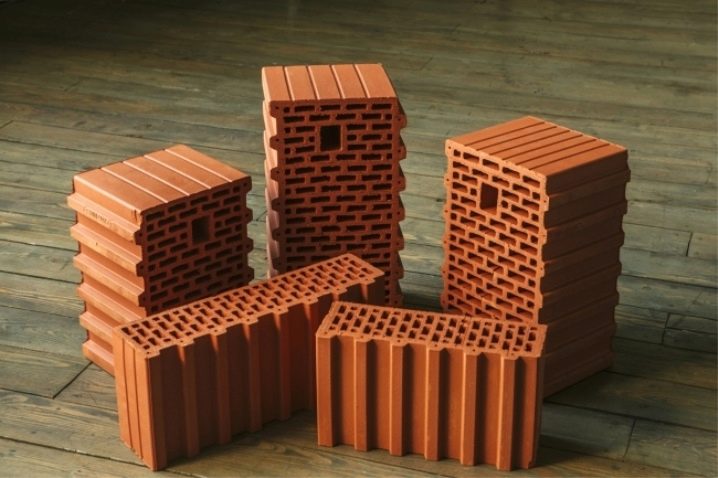

- The possibility of choosing the optimal size for any scale of construction. Manufacturers produce ceramic blocks of the following sizes: 250x120x140, 250x380x219, 510x250x219 and 380x250x219 mm.

- Environmental friendliness.This type of blocks is made from natural raw materials, so that they do not emit toxic substances during operation.

- Excellent heat and sound insulation.

- Resistance to negative external influences. Porous brick buildings are “not afraid” of precipitation. In addition, they withstand the same number of defrost and freeze cycles as usual bricks.

- Good sanitary and hygienic indicators. On objects erected from porous blocks, mold and fungus are not formed.

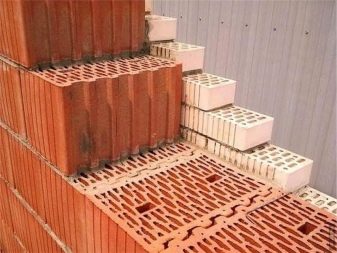

- The presence of tongue-and-groove system on the side parts of bricks, ensuring their reliable connection without the use of cement mortar.

- Fire resistance A porous brick not only does not support the combustion process, but is also able to withstand the effects of a flame for several hours.

Despite the fact that porous blocks have numerous advantages, some builders refuse to use them in the construction of civil or industrial facilities. Often they are repelled by the rather big cost of this material, which is why consumers decide to buy budget products.

Main characteristics

Porous brick has good technical parameters and performance.

Consider the main ones on the example of a double block with a size of 510 mm:

- density 800 g / m³;

- strength mark M-75;

- thermal conductivity 0.17 W / m ° C;

- frost resistance up to 100 cycles of freezing and thawing;

- vapor permeability up to 0.14 mg / (mch · Pa);

- water absorption up to 6%;

- sound insulation 51 dB (meets the requirements of the SNiP 23-03-2003);

- fire resistance up to 10 hours.

Technical characteristics of porous blocks fully comply with all standards and regulatory documents adopted in the construction industry. To purchase quality products with the stated parameters, you should ask the seller to provide certificates for the goods or the manufacturer's passport for this material before purchasing.

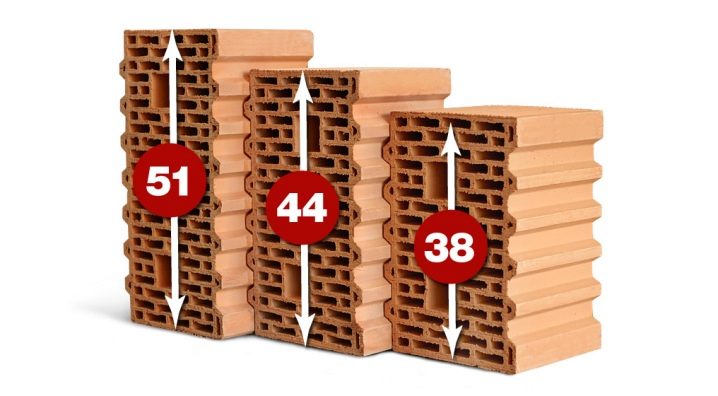

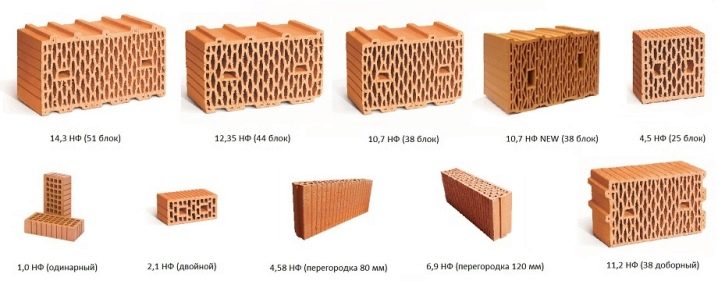

Block dimensions

Modern manufacturers produce porous ceramic blocks in several standard sizes. They are intended for the construction of objects with different indicators of wall thickness.

If you plan to build a single-layer structure, most often choose a brick 410 and 510 mm. It should be noted that no insulation is required for such a wall thickness.

For structures with two and three layers, stones with dimensions of 380, 300 and 250 mm will be optimal. Such walls will require insulation and external cladding.

In addition to the standard size of bricks, manufacturers are engaged in the release of additional porous stones. Often they are made in the form of halves of blocks.

Additional construction materials are used for laying corners, and they can also be used for more convenient ligation of adjacencies of external and internal walls.

Differences from a hollow product

Ceramic porous blocks are visually very similar to hollow bricks. However, these two materials have significant differences. Hollow materials have through cavities or voids. These openings can have a different shape: oval, round, square or rectangular. Due to such air formations, brick has less strength than porous material.

Hollow products are used only for the construction of:

- lightweight exterior walls;

- curtain walls;

- to fill the skeletons of objects for various purposes.

Porous bricks, in contrast to hollow bricks, have numerous small voids - pores.Compared with hollow products, porous materials have a lower density and a greater coefficient of thermal conductivity.

Reviews

Builders prefer porous brick due to its excellent strength, low thermal conductivity and environmental cleanliness.

According to consumers, the structures of this material are durable and durable. In addition, these units practically do not conduct heat, because of which a favorable microclimate for a person is created indoors, regardless of the temperature conditions outside.

When constructing structures from porous blocks, the occurrence of cold bridges is excluded. Thanks to this feature, it is not necessary to hire a construction crew to seal the external seams of the object. According to users, due to the use of porous ceramic blocks, one can hope for good sound insulation. This feature is most important for apartment buildings located in busy areas of the city.

Other benefits of this building material buyers include:

- ease of bricks;

- quick laying;

- refractoriness;

- resistance to mold.

It has this material and some drawbacks. According to consumers, the use of porous brick has its drawbacks.

- The need to protect the external walls of building structures from moisture. Neglecting this recommendation will lead to a large moisture absorption of the blocks and their premature destruction. Facing the structure will result in additional financial costs.

- Often the presence of a cavity or air voids leads to difficulties when drilling holes.

- The fragility of the material. When careless transportation of products or with their careless loading and unloading a lot of scrap.

- Difficult cutting of products due to the presence of cavities in the material.

- Restrictions on the number of floors. In residential construction porous brick is used only for the construction of houses up to 9 floors.

- The high cost of products. According to buyers who monitored prices for building materials, prices for porous blocks are 2-3 times higher than for other types of bricks.

The last flaw is considered conditional. According to the statements of experienced builders, using porous blocks, it is possible to accelerate the process of erection of structures,save on the amount of material used (other types of bricks will need more because of their smaller size). In addition, it is not necessary to insulate buildings, saving money on thermal insulation materials and insulation work.

Porous brick - the best alternative to hollow or ordinary ordinary artificial stone, as well as aerated concrete blocks.

Its technical characteristics in many ways surpass the parameters of conventional ceramic building materials. This is a "breathable" product that will provide coolness in the summer heat and retain heat in the winter frosts.

For information on how to put a porous brick with your own hands, see the following video.