How to calculate the amount of cinder block?

Novice builders are often faced with the problem of the correct calculation of the required amount of material. In order not to be mistaken with the figures, it is necessary to take into account the dimensions of the material and the future structure, the necessary cutting stock, debris and other features. Our article is devoted to the subtleties of the calculation of such a building material as a cinder block.

Pros and cons of the material

The appearance of cinder blocks is directly related to the natural human desire for non-waste production. In the USSR, in the postwar years, production developed at a rapid pace. Metallurgical plants literally overgrown with mountains of slag. Then it was decided to use this waste to create building materials.

Slag served as a filler for the cement-sand mixture. The resulting mass was molded into large "bricks".The finished blocks were too heavy - weighed 25-28 kg. To reduce the weight they made voids. Hollow pieces were a little easier - from 18 to 23 kg with standard dimensions.

The name of cinder blocks is used today, although not only slag, but also other components are used as fillers. In modern blocks, you can find granite screenings or rubble, river gravel, glass breakage or expanded clay, volcanic mass. The release of cinder blocks is most often engaged in small business. Small private enterprises produce building blocks on vibromachines, filling several forms with cement mixture at once. After molding and tamping, the “bricks” gain strength for at least a month.

Slag blocks are endowed with certain advantages and disadvantages.

- The advantage of a block building material, first of all, is its low cost. That is why the material is in great demand.

- This building material has other positive characteristics. For example, blocks do not change their sizes after laying out. The structure will not shrink, which means that the design calculation will not be adjusted during construction.

- The strength and hardness of the “big brick” determine its service life. This is nothing less than 100 years! Durability is not calculated, but time-tested. There are many buildings of the middle of the last century, "firmly standing on their feet." The houses did not squint and crumble, only the facades require redecoration.

- Blocks react poorly to ultraviolet and temperature drops. The material is not edible for rodents and insects.

- Due to the increased size, the construction takes place at a rapid pace. Much less masonry is used for laying blocks than, for example, a brick wall of similar dimensions.

- Behind a cinder block wall, noisy street noise is heard, because it is capable of absorbing sounds.

- Finally, with simple equipment and desires, blocks can be made at home, which will make construction even more expensive.

The disadvantages of a building material are no less than merits.

These include the following characteristics.

- Plain appearance.

- Problem fixing to the walls because of the voids in the body of the block.

- The need for lining to make the structure attractive and protect the building material from exposure to external moisture.

- Fragility.If the unit falls during work, during transportation or loading, the unit may break.

- High thermal conductivity. Without additional insulation the structure retains heat poorly.

- Wide tolerance limits. Sizes may differ significantly from the nominal.

Dimensions

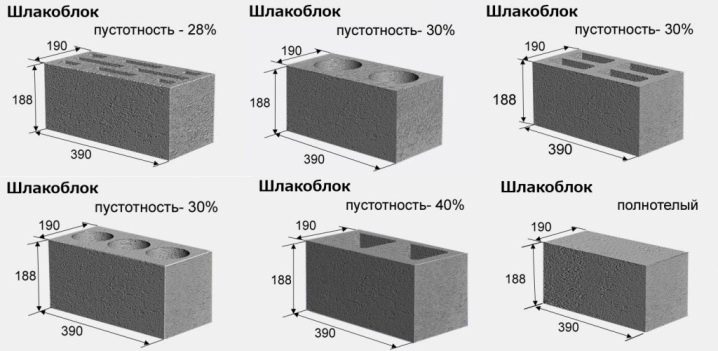

The dimensions of cinder blocks directly depend on their types.

Standard slag blocks are products with the following parameters, measured in millimeters:

- length - 390;

- width - 190;

- height - 188.

Due to the small difference between width and height, both values are often assumed to be the same, equal to 190 mm.

Similar sizes have hollow and corpulent products. The first, as lighter, are used exclusively for laying walls. The latter can serve as a source material not only for walls, but also for foundations, columns, or other structural elements of buildings that are subject to the greatest loads.

The semi-blocks of slag are always hollow. Overall dimensions can differ only in thickness (width). The length is constant and remains equal to 390 mm, height - 188 mm.

Thicker semi-blocks have a width of 120 mm, and thinner - only 90 mm. The latter are sometimes referred to as longitudinal slag blocks.The scope of the semi-blocks is internal walls, partitions.

Available in the slag family "giant" - a building block, enlarged in size. Its dimensions are 410x215x190 millimeters.

Payment

For the construction of any object (home, garage or other ancillary structure) requires information on the number of cinder blocks. Excess building material is useless, and a deficiency can lead to downtime and additional costs for loading, transporting and unloading the cinder block. In addition, different batches even from the same manufacturer may differ slightly. What to say about buying the missing blocks from another supplier!

Problems with the construction of the building due to lack of basic material is guaranteed not to be, if you pre-perform the calculation of the need for slag stones with maximum accuracy. Of course, you will have to buy more. Firstly, because it always needs a stock. And secondly, the blocks do not sell by the piece. Manufacturers stack them on pallets and fasten them so that upon delivery to the buyer the goods do not break, and it would be convenient to load them into transport.

If necessary, you can purchase the material and the piece.However, the lack of reliable fastening is fraught with chipping and even complete destruction. In order to calculate the need of building blocks, for example, for a house, you need to know the dimensions of this building.

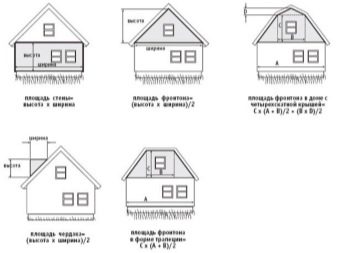

First of all, you need to remember the school curriculum, more precisely, the definition of areas and volumes. The task is simple, accessible to everyone and does not require any engineering knowledge.

The number of cinder blocks required can be calculated in two ways.

- By volume. The volume of the walls of the building is determined, the number of bricks in 1 m3 is calculated. The volume of the building in cubic meters is multiplied by the number of blocks in one cube. It turns out the required amount of slag bricks for the whole house.

- By area. Calculates the area of the walls of the house. The number of blocks per 1 m2 of masonry is found. The area of the walls of the house is multiplied by the number of pieces of cinder block in one square meter.

If you need to count the number of standard units in a square meter, two sizes are taken into account: length (390 mm) and height (188 mm). We translate both values into meters and multiply together: 0.39 mx 0.188 m = 0.07332 m2. Now we will find out: how many cinder blocks fall on each square meter. For this, 1 m2 is divided by 0.07332 m2. 1 m2 / 0.07332 m2 = 13.6 pieces.

Similar calculations are performed to determine the amount of building material in one cube. Only here all block sizes are involved - length, width and height. Calculate the volume of one cinder block, given its dimensions not in millimeters, but in meters. We get: 0.39 mx 0.188 mx 0.190 m = 0.0139308 m3. The number of bricks in 1 cube: 1 m3 / 0.0139308 m3 = 71.78 pieces.

Now you need to find the volume or area of all the walls of the house. When calculating these parameters, it is important not to forget to take into account all openings, including door and window. Therefore, each construction is preceded by the development of a project or at least a detailed plan with doors, windows, openings for laying various engineering communications.

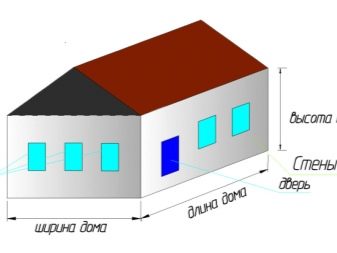

Consider the calculation of the need of the material at home "volume" method.

- Suppose a house is planned to be built square, with a length of each wall of 10 meters. The height of a single-storey building is 3 meters. The thickness of the outer walls is the thickness of one cinder block, that is, 0.19 m.

- Find the volume of all the walls. Two parallel walls will take equal in length to ten meters. The other two will be shorter in length by the thickness of the walls already recorded: 10 m - 0.19 m - 0.19 m = 9.62 m. The volume of the first two walls: 2 (number of walls) x 10 m (wall length) x 3 m (wall height) x 0.19 m (wall thickness) = 11.4 m3.

- Let us calculate the volume of two “shortened” walls: 2 (number of walls) x 9.62 m (wall length) x 3 m (wall height) x 0.19 m (wall thickness) = 10.96 m3.

- Total volume: 11.4 m3 + 10.96 m3 = 22.36 m3.

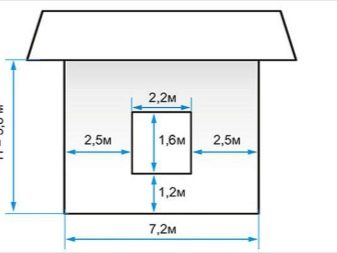

- Suppose that the house has two doorways with a height of 2.1 m and a width of 1.2 m, as well as 5 windows with dimensions of 1.2 mx 1.4 m. We need to find the total volume of all openings and subtract it from the previously obtained value.

The volume of doorways: 2 pcs. x 1.2 m x 2.1 m x 0.19 m = 0.9576 m3. The volume of window openings: 5 pcs. x 1.2 m x 1.4 m x 0.19 m = 1.596 m3.

The total volume of all openings in the walls: 0.9576 m3 + 1.596 m3 = 2.55 m3 (rounded to two decimal places).

- By subtraction, we obtain the required volume of cinder blocks: 22.36 m3 - 2.55 m3 = 19.81 m3.

- We find the number of blocks: 19.81 m3 x 71.78 pcs. = 1422 pcs. (rounded to integer value).

- Given that there are 60 pieces on the pallet of standard cinder blocks, you can get the number of pallets: 1422 pcs. / 60 pcs. = 23 pallets.

The same principle is used to calculate the need for building material for interior walls. With other dimensions, for example, a different thickness of the walls, the calculated values need to be adjusted. It should be understood that the calculation gives an approximate number of cinder blocks, a fact almost always differs from the calculation in one direction or another, but only slightly.The above calculation is made without taking into account the seams, which account for from 8 to 10 mm and a margin of approximately 10-15% of the calculated value.

Information on the amount of material needed is useful for determining the material costs of acquisition and construction, as well as for allocating the territory for its storage.

How to calculate how many cinder blocks in 1 m3, see the video below.