How much does silicate brick weigh?

The first silicate bricks appeared at the end of the XIX century. Germany is considered the birthplace of building material, although experiments on the production of similar bricks were carried out in many other countries.

Our article is devoted to varieties of silicate brick and its mass.

Varieties and their parameters

Inexpensive high-quality building material consists mainly of quartz sand (about 90%), lime (slightly less than 10%) and a small amount of additives. Manufacturing method - autoclave. The original components are mixed, pressed and subjected to treatment with water vapor at a temperature of 200 degrees.

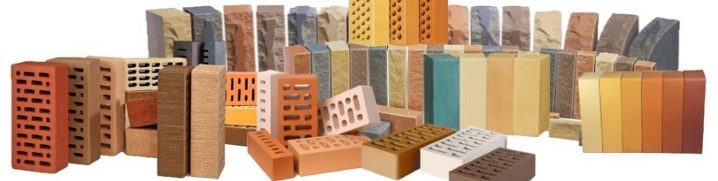

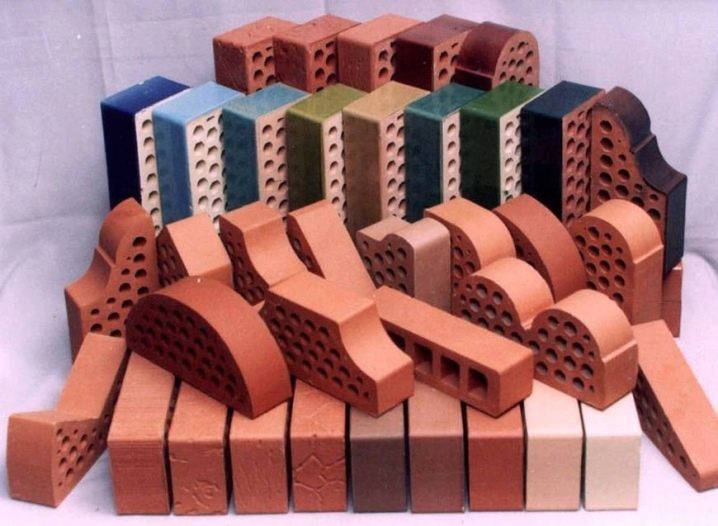

There are several types of silicate bricks. By design features they are divided into:

- corpulent;

- hollow, voids can be both through and non-through (hollowness can be up to 45%).

By purpose:

- Private (used for the construction of masonry);

- facing (is a finishing building material).

In appearance:

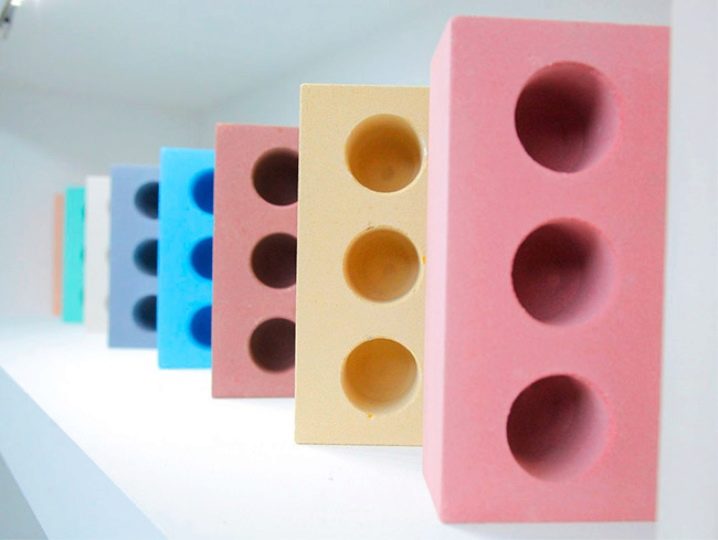

- unpainted;

- color.

By dimensions:

- double;

- one and a half;

- single.

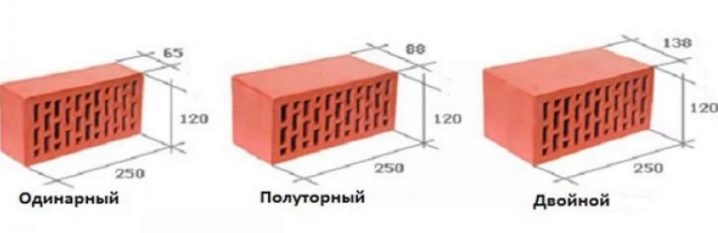

The length and width of all bricks are the same. The parameters are strictly adhered to, as established by a special state standard (GOST 530-2012). The first parameter (length) corresponds to 250 mm, the second (width) is 120 mm. Only the silicate height is affected.

By size, you can determine the type of bricks. So, single has parameters 250x120x65 mm, one-and-a-half - 250x120x88 mm, and double - 250x120x138 mm.

Bricks are painted by adding pigments in the production process. Over time, the color practically does not change, since the dyes are resistant to the external environment. Colored bricks (they can be pink, yellow, red or blue) are used for facing works.

Difference between specific and volume weight

Distinguish between volume and specific gravity of bricks. Bulk weight depends on the design features of the building material.Of great importance on this value have voids in the body of the stone, as well as its density. To determine the volumetric weight of the mass of brick in kilograms should be divided by its volume in cubic meters.

The smallest indicator of volumetric weight have facing products with voids. The considered value for such bricks is only 1,200 kg for one cubic meter for double and 1,400 kg for one-and-a-half products. From 1300 to 1640 kg per cube falls on working blocks with voids.

Unary solid bricks have the largest indicator of bulk density. The cube of building material weighs 1900 kg. On a cube of one-and-a-half corpulent bricks there are 1700 kg. Volumetric weight is involved in the calculation of the load masonry on the foundation. The value is obtained by multiplying the specific weight by the masonry volume.

The quality is influenced by the quality of raw materials and porosity. To determine this value, the volume of all voids is subtracted from the total brick volume. Then the mass of the stone must be divided into "pure" volume. The normal value of the specific weight is in the range from 2000 to 2400 kilograms per cubic meter. A decrease in the rate will indicate a low quality material.

Weight calculation methods and their features

Silicate brick is often used in the construction of residential buildings and technical facilities. Capital construction will not last long if you do not comply with technical requirements. The main condition for the durability of any building is the correct ratio of the selected base (foundation) and the load on it. Therefore, at the design stage it is necessary to determine the weight of the silicate brick.

Due to the variety of types of silicate bricks, you should decide on the desired type of masonry, the presence or absence of a facing layer. The walls are most often erected from white bricks. Unlike single, one and a half significantly speeds up the construction process. The mass of a standard one-and-a-half copies without holes on average corresponds to 4.9-5 kg. As moisture increases, weight increases.

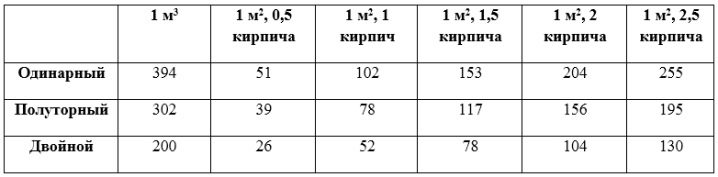

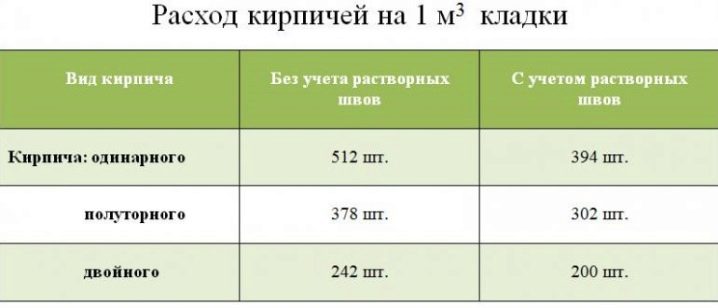

When performing calculations of a building structure, it is not enough to know how much 1 piece weighs. single, double or one-and-a-half bricks. As a rule, another indicator is used - cube. It is important to determine the masonry weight in cubic meters.

Calculating the required value, do not forget to bring the results to one unit of measurement.So, the sizes of a standard brick are given in millimeters, and the volume, as a rule, is calculated in cubic meters. To perform the calculations, the length, width and height of one block must be converted to meters.

Delivery of building materials to the customer is carried out in batches installed on a pallet. The number of bricks on a small wooden pallet is always the same. For example, single units in a pack of 280 pieces. Given that the weight of 1 pc. is 3.7 kg, it turns out that in one package 1036 kg.

By simple calculations, you can determine the number of different types of bricks in one cube, as well as their weight.

Based on the results, you can find the number of required packages.

Counting example

The weight of a brick can be obtained by multiplying its volume by the specific density. Specific density - reference value established by the standard. True, this rule applies only to full-bodied copies. Hollows and grooved surfaces reduce the weight of bricks. The more voids, the less building material weighs.

Consider an example of calculating the weight of one standard full-bodied silicate brick for each of its types. Baseline data are dimensions and density.The second indicator remains unchanged for all options. It varies in the range of 1.8-1.95 g / cm3. For calculations, we take the minimum density of 1.8 g per cubic centimeter.

Calculations require you to determine the volume of one piece of bricks. In this case, the overall dimensions should be considered in centimeters:

- 25x12x6.5 = 1950 cm3 (for single);

- 25x12x8.8 = 2640 cm3 (for one and a half);

- 25x12x13.8 = 4140 cm3 (for double).

Weight is obtained by multiplying the obtained volumes by density and converting the result into kilograms by dividing by 1000:

- 1950 x 1.8 / 1000 = 3.510 kg;

- 2640 x 1.8 / 1000 = 4.751 kg;

- 4140 x 1.8 / 1000 = 7.453 kg.

For hollow bricks, void volumes should be considered. The easiest way to determine the parameters of through cylindrical voids. Due to the fact that the slots are strictly perpendicular to the largest plane of the bricks, the length of the cylinder is known. It is equal to the height of the block:

- 6.5 cm in single;

- 8.8 cm in one and a half;

- 13.8 cm in double.

From the school curriculum, the formula for the area of a circle is known: πr2. The number π = 3.14. It remains to measure the diameter of the hole.

Suppose the diameter of the through hole is 40 mm, then the radius is half as much - 20 mm. Take the number of holes equal to 3 pcs.In this case, the volume of bricks will decrease by the amount of volumes of voids. The volume of each of the voids is: 6.5 (cylinder length) x 3.14 (dimensionless constant π) x (2x2) (radius of the hole in the square) = 81.64 cm3. The result is tripled by the number of holes. 81.64 x 3 = 244.92 cm3.

The volume of a single stone in cubic centimeters: 25 x 12 x 6.5 = 1950 cm3. Removing the volume of voids, we get the original volume of the brick to determine the weight: 1950 - 244.92 = 1705.08 cm3. The specific density of hollow blocks is within 1.1-1.5 g / cm3. Density multiplication by “pure” volume will give the brick weight. For example, we take the maximum density, we get the weight: 1.5 x 1705.08 = 2557.62 g, or 2.55 kg.

Knowing the principle of calculation, you can independently determine the weight of any silicate brick.

All you need to know about silica brick - see the video below.