Characteristics and application of brick M200

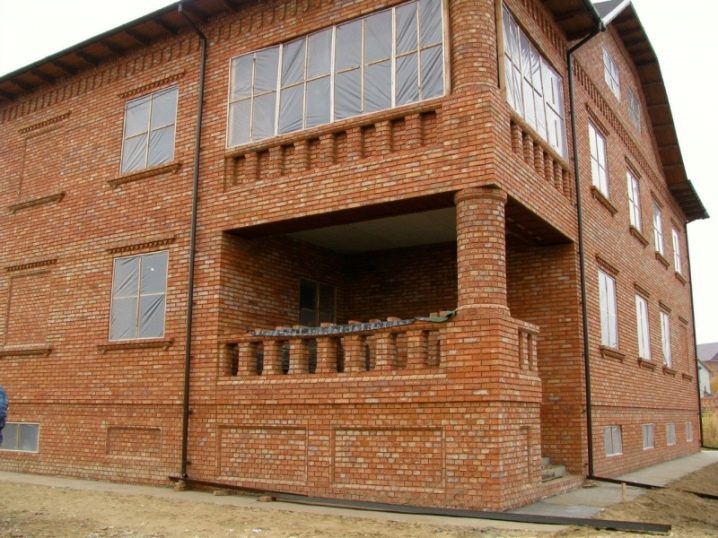

Many cities in our time are built up with high-rise buildings. This applies primarily to housing. The urban population is increasing from year to year, and it is not always possible to expand the territory. So the settlements are growing not so much in breadth as up. And for multi-storey buildings you need an appropriate quality building material. Since the most popular among home buyers are brick new buildings, which are distinguished by their environmental friendliness and heat-saving features, construction companies are trying to build housing out of bricks. For such homes is best suited brick brand M200. Consider why this statement is true.

Special features

The brand of brick has an index of strength M200, meaning they endure the load on each square centimeter of its area of 200 kg.Therefore, it is safe to call such a building material the most reliable for the construction of residential and other buildings over the standard 9 floors. Due to its increased strength, this brick has a truly universal construction features. It is applicable for laying of bearing walls and other supporting structures, lower floors of high-rise buildings, basements, as well as foundations, including in conditions of high moisture and temperature drops.

Mark 200 is characterized by high frost resistance. Frost resistance index, denoted by the letter F, has a figure from 50 to 100. This means how many cycles of freezing and defrosting can a brick mark withstand without any changes to its basic properties. Sometimes this figure is taken for the longevity of the brickwork.

If the house is brick-paved with the index F100, it means that the building can stay for at least 100 years without any special changes.

Kinds

Depending on the purpose, the following types of brand M200 are distinguished:

- facing, used for various purposes of facing works and finishing;

- private, used for laying walls, foundations and other construction objects;

- furnace with thermal stability and necessary for the installation of furnaces, chimneys and pipes.

Brand 200 and the composition used to make bricks differ.

- Silicate. Brick has a white color. It is made from a mixture of quartz sand, water and lime, which is exposed to high pressure steam before being petrified.

- Ceramic. It is produced by firing clay with various technological additives in autoclaves at temperatures up to 1 thousand degrees. The color of such products is red with different shades (depending on the composition of clay impurities).

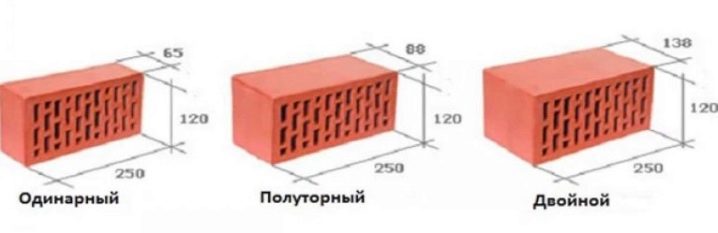

In size according to GOST, M200 brick is divided into the following types:

- single with dimensions (length / width / thickness) equal to 250/120/65 mm;

- one and a half - 250/120/88 mm;

- double - 250/120/138 mm.

Building material density

It should be noted that only single brick can be full-bodied. One and a half and double its similarity are available only in the form of slot products. No matter how different are the varieties of the brick brand M200, they are united by the presence of two undoubted properties:

- high strength;

- absolutely eco-friendly composition - sand, clay, lime, impurity minerals and water.

Where does it apply?

The ordinary corpulent ceramic brick possesses high sound insulation and water resistance therefore it has advantages over other types of the M200 brand. A full-silica brick, unfortunately, has a too high moisture absorption. With all other equal virtues, it cannot be used in the construction of foundations and basements. For these purposes, its ceramic counterpart is best suited. At the same time, due to its lower cost, the full-bodied silicate building material can be perfectly used for the erection of supporting structures and lower floors of high-rise constructions, possessing high strength and noise insulation indicators.

One-and-a-half and double brick types of grade 200 have a low thermal conductivity due to their air voids, so they are used, taking into account strength and frost resistance, for the construction of both external and internal walls of buildings. In addition, hollow material is often used for cladding facades. One-and-a-half and double building material is also beneficial because it requires less consumption of mortar and time for masonry, which is an important factor in the modern construction industry.

Even full fireplaces can be laid out of solid ceramic bricks. He conducts heat well and gives it to a heated room. However, it cannot be used to lay out directly the furnace and fireplace chambers, since the material will quickly collapse when interacting with fire.

For fireboxes, it is necessary to use only furnace brick (chamotte), specially processed for such conditions.

As you can see, the brick brand M200 is very popular and is used in the construction of various structures, including foundations, ground floors, lower and higher floors, for cladding facades, internal fillings of building structures, as well as for laying out stoves and fireplaces. When choosing a material, it is very important to require from the seller a certificate of quality of the goods, as well as an external inspection to ensure that the type of brick complies. You can break one copy to check its strength and quality of burning red brick (there should be no internal blackness). Try to break the material - cracks on the surface are allowed, but the ease of breaking a brick proves its failure.

For advice on the choice of brick brick specialists, see the video below.