Hollow ceramic brick: characteristic and application

Bricks used for the construction of various structures from ancient times. Such structures differ in durability and reliability. The most common is a brick, which is made from certain grades of clay, which determines its operational features while observing the technological process during production.

Brick making and types

A brick is made according to a complex technology, and the process itself is carried out in several stages. Today they use two methods of manufacture.

- The formation of stone from the mass of clay with a water content. For the manufacture of used press for molding products, and then the billet is dried in the chambers and subsequently burned.

- The pressing technology is used under maximum pressure, which reaches 15 atmospheres.

All these processes are carried out in accordance with GOST 7484-78. For the preparation of the composition used special machines that ensures the uniformity of the structure of products.

Drying is done by tonal or chamber method, as a result of which the blanks are placed in an environment with a certain humidity and temperature. After this, firing occurs at a temperature of up to 1500 degrees, and the firing time is two to three hours so that no moisture remains in the structure. This allows for high strength.

The raw materials are used in the fines fraction, and they are usually mined by the open method. Next, it is sifted, and, if necessary, crushed. It is advisable to use the same raw material for the production of one batch so that the products are not marked by their mineral composition and color.

In this way, ordinary and facing bricks are made.

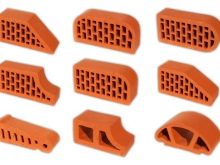

From the use of a particular process, these types of products can be obtained:

- shaped;

- front;

- glazed;

- curly.

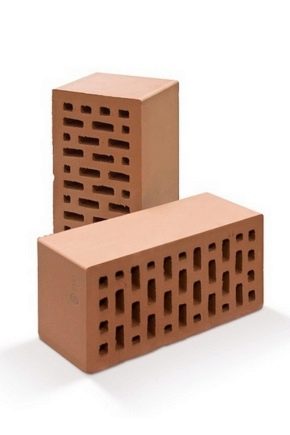

Besides the fact that a brick is hollow or solid, its surface can in some cases get rid of grooved grooves, which allows it to be held more firmly in the masonry.

Specifications

These are the main parameters with which the building stone should correspond. When buying, you must initially determine the type of masonry and choose the best type of brick for work. Consider the requirements that are put forward for this type of building material.

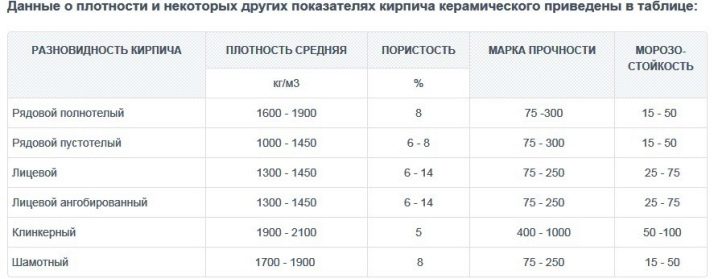

Density

Brick parameters are determined by its structure. The main indicator is density. It is influenced by the composition of the raw material and its fraction. Depending on the density, the class of the product is determined, which is 1.8-2.4. Information about the density is needed to produce design work and determine the load on the foundation, as well as to understand the degree of strength of the building itself and its supporting elements.

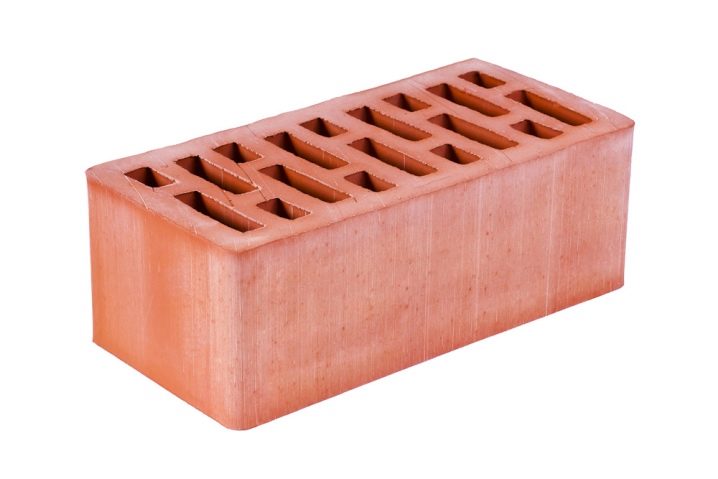

Voidness

To increase thermal conductivity and reduce the mass of bricks, voids of various forms can be made in it. Such brick happens facing or ordinary. The depth and shape of voids is determined by technology. In addition, the location of voids determines the strength of the product.

To improve the performance of double building stone or hollow material, brick porosity is sometimes increased. To do this, in the preparation, straw or other organic components are added to the composition, which, as a result of firing, burn inside the brick and leave voids behind. This allows the brick “M150” to retain heat inside the building erected from it.

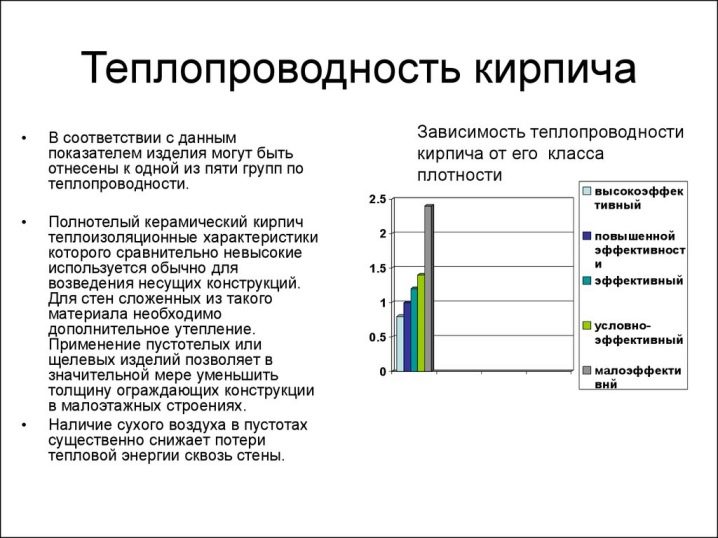

Thermal conductivity

It is determined by the internal structure of the product. Indicators are different, which affects the cost of bricks. Such indicators are important in the construction of external walls, depends on their thickness.

Solid single brick has low thermal insulation characteristics and is usually used for load-bearing structures. Such walls in the future will require additional insulation. If you use a hollow stone, then this will reduce heat loss, but this brick will not be able to withstand a lot of weight, and therefore only low buildings are often made of it.

Water absorption

Since clay is used in the manufacture of bricks, this material can absorb water. The coefficient is determined by various factors, and depends mainly on the density of the product.Water absorption can range from 6 to 14%, and this is the norm. Because any building that is made of brick, can stand for a certain period until the beginning of the destruction.

For example, if there will be a large temperature difference inside and outside the walls, this will contribute to the formation of moisture, which will penetrate into the pores and accumulate in the masonry or bricks. At low temperatures, the water will freeze and it negatively affects the structure. Therefore, during the construction of a structure, this moment must be taken into account. Especially this item applies to bathrooms, baths.

Frost resistance

Ceramic products are widely used in various climatic zones and can withstand extreme cold. In accordance with the standards, each product must withstand a certain amount of frost / thaw. This contributes to the correct calculation when choosing materials.

Frost resistance is determined by the literal value "M" and the numeric value that comes after it. With the right choice of stone for a particular climatic zone, the structure of it can stand for up to 100 years.

High temperature resistance

Fire safety of each building is determined by the type of material from which it is made. Ceramic product does not burn. It has a high fire resistance and can withstand high temperatures over 5 hours. This stone is resistant to fire and can withstand temperatures up to 1000 degrees. Nevertheless, it is still not recommended to build a chimney or fireplace from it, since the constant effect of heat will gradually destroy the material.

Application involves the use for the construction of:

- educational institutions;

- residential buildings;

- cafe, canteens;

- production facilities and so on.

Ceramic bricks compete in this parameter with natural solid wood, monolithic concrete structures and natural stone. In those buildings that are built from it, a positive environment is formed, where people can live.

Geometry accuracy

In the production of bricks, it is important to follow the rules of manufacture and parameters, which is controlled by GOST No. 530.

Currently produced bricks of such formats:

- Euro;

- normal;

- modular;

- thickened.

These standards are binding and must be observed in any industry.In some cases, deviations are allowed, but not more than 4 mm. Such requirements allow the laying of various structures with small variations. Also, the standards allow the production of bricks with other indicators and sizes, but this is usually done by special order, and after all points are agreed between the parties to the contract.

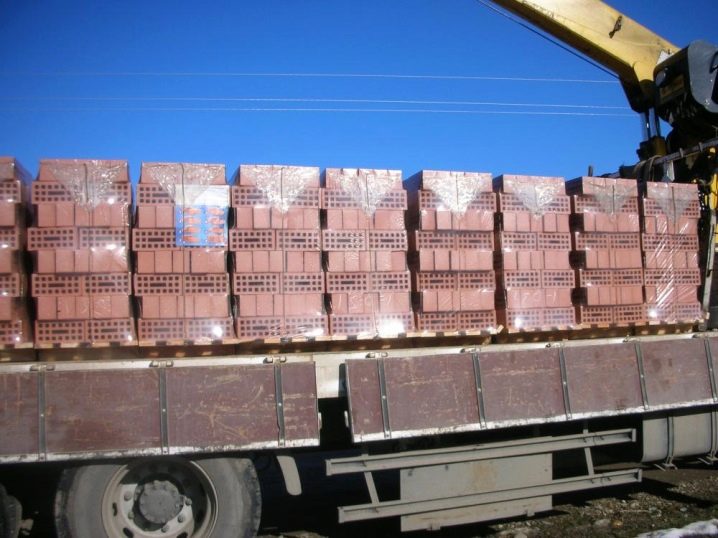

Storage and transportation

Transportation of this type of material is allowed by various modes of transport in compliance with certain rules. To ensure the safety of materials during transportation, they are placed on pallets. Bulk transportation is not allowed, which may cause damage.

If necessary, ensure long-term storage of the brick is placed on sites with a hard floor. Putting it can be in piles or on pallets. Loading / unloading operations are performed using mechanized transport or manually.

Laying features

Ceramic bricks are laid out in order, which ensures its ligation. It is recommended to reinforce every 5-6 rows of bricks in order to reinforce the walls. When laying, cords are tensioned, which ensure the evenness of the base and facilitate the work.The laying begins to be made from corners with strict observance of horizontal position.

Let us dwell on some tips from bricklayers:

- to avoid differences in the color of building stones, you need to buy them to fulfill the entire building order from one lot;

- it is recommended to wet the hollow brick before laying with water in order to achieve greater strength of the base;

- when laying it is necessary to ensure that the mortar does not dry quickly in the wall, and other external factors do not affect it until it seizes;

- it is better to make laying at a temperature not lower than +10 degrees;

- when laying walls in winter, plasticizers should be added to the solution so that it does not freeze and no cracks appear on the base;

- it is recommended to order the volume of bricks for work by 10% more than is required by calculations;

- Before buying, you need to check the quality certificates for products.

On the production and laying of ceramic bricks you will learn from the video.