Features and technology of production of raw bricks

Raw material (brick, which consists of clay and straw and is not burned during the production process) is quite common in those regions where the climate is hot, it has been used there for thousands of years. From it you can build houses, household buildings and other buildings.

Benefits

The main advantage, which has a raw brick, is its low cost. That is why such a building stone is preferred long ago. Everyone knows that clay can soak, and therefore a brick that does not burn, has a high degree of water absorption. Therefore, this material is not used in those placeswhere the climate is humid or long winters.

Brick raw, in addition to cost, has a lot of additional benefits, among which are:

- good thermal insulation;

- excellent sound insulation;

- fire resistance.

Composition

This material can be produced according to various recipes, but mainly pure clay is used for its production and, if necessary, various components are added to its composition, which improve the quality and characteristics of the finished product. Among such components are the following:

- shavings (increases the strength of the stone);

- straw (improves ductility).

When harvesting raw materials for production, it is important to correctly identify and select the desired grade of clay. It may differ in its characteristics depending on the location. Usually it is located in the ground at a depth of 1 m. Production can be conducted on its territory, which will make the production of building material even cheaper. Clay can be bought in the quarries.

To choose the right raw material, you need to determine its quality. To do this, you need to take the clay, moisten it with water and squeeze it in your fist. If after squeezing the hand will be oily, it indicates the high quality of raw materials.If the clay is non-greasy, then it may fall apart during a fall and high-quality brick will not work out of it.

Production

Raw material preparation

After purification from impurities, organic fillers (sawdust, straw, manure, etc.) are added to the clay. The components are mixed together with the addition of a small amount of water to make the composition viscous. Mixing is done in concrete mixers. When the mass becomes homogeneous, it is laid out in the form.

Form creation

For the manufacture of bricks with cut straw or chips, you can use various forms that will be optimal in each case. But if it is necessary that the products in appearance do not differ from the shop ones, then it is recommended to adhere to the manufacture of standard parameters forms - 25x12x6.5 cm.

For the manufacture of forms you need to prepare the boards from which the side walls will be made, as well as plywood for the construction of the cover and bottom. Forms can be made single or with different numbers of cells. For the manufacturing process to be continuous, it is necessary to prepare a sufficient number of forms. Also in the manufacture of the form must be borne in mind that the brick in it will dry up,therefore, initially it should be about 10% more than the estimated volume, so that when drying the brick is obtained in standard sizes.

If necessary, you can nail the form to the handle, it will simplify the process of its movement. To improve the adhesion of individual stones to each other, you can insert pegs into the bottom or lid during their manufacture. They will help to hold the brick in the masonry more tightly, since on their basis there will remain cells after drying.

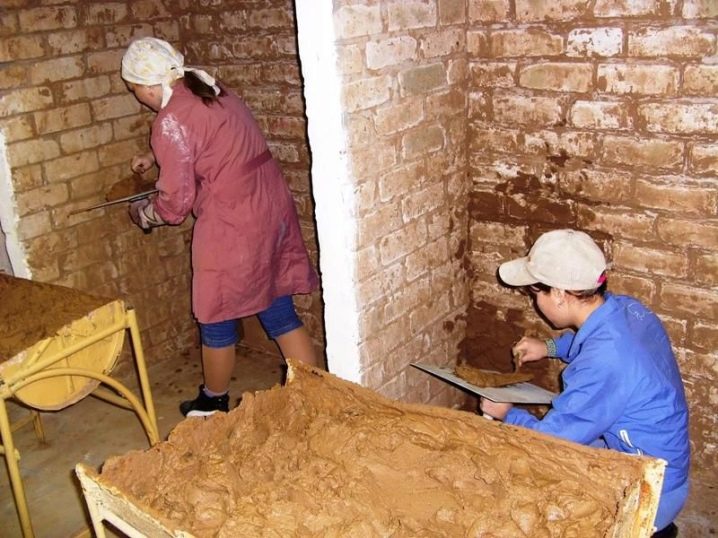

Main process

In the artisanal production do not use the press, so it is important to properly develop the technology for the formation of raw bricks and filling out forms. This will simplify and speed up the work. Pre-forms should be moistened with water and sprinkled with cement or clay. You can also use chalk or sand for this purpose. These compounds will help the brick fall out of shape more easily.

In order for bricks to turn out with even angles, it is necessary to fill the forms tightly with raw materials, and then ram the clay. To do this, use a shovel or trowel. Excess clay is removed, after which the form is closed and shaken.

After that, it is necessary to remove the form, and the workpiece must remain in place for a while until it dries out, so that it does not get damaged when moving.It is better to install ready-made bricks on a flat platform, sprinkled with sand on top, so that the material does not stick to the ground. The distance between the individual bricks should be at least 3 cm, so that they dry well.

It is important to ensure that the moisture evaporates from the bricks not too quickly, so that they do not burst, so it is recommended to put them in a dry place for the first time to dry. Then they can be transferred under the open rays of the sun. It is necessary to periodically turn over the bricks, checking whether they can keep the shape.

Drying and storage

The strength of the raw brick depends primarily on the proper drying of the product. From this depends on its appearance. If the moisture evaporates unevenly, it will cause a violation of the geometry of the bricks, so you need to organize a long drying and do it under a canopy.

After the products gain strength, they can be stacked in piles, leaving small gaps between the rows for blowing. The height of such stacks is no more than 1 m. Each row wakes up with sand.

Drying periods are different and depend on such factors:

- drying mode;

- weather;

- quality of raw materials.

The readiness of the material is checked as follows: the brick breaks and the fracture site is inspected. If there are no dark spots there and a clear sound is heard when struck, it means that the brick can be used for laying or firing.

Application area

Since this brick can absorb moisture, its scope is limited. External walls cannot be made of such a brick, since they will have to be additionally protected from external negative factors and moisture. From this material, you can make internal walls or partitions, which will differ in good sound insulation and do not let the heat. Also, this material can be used for arranging stoves in the house.

As you can see, producing brick raw is quite simple and you can cope with such a task yourself. If you approach the process correctly and observe all the conditions for its production, you can get a fairly inexpensive and high-quality building material.

On the technology of production of raw brick, you will learn from the video.