Error codes and malfunctions of gas boilers Ariston

Even in the most reliable technology breakdown occurs sooner or later. You have probably chosen a heating boiler of a famous brand in the hope that it will serve you faithfully for more than a dozen years. However, to avoid at least one repair is unlikely. In the presented article we will discuss the failures of Ariston gas boilers.

About company

Hotpoint-Ariston is a worldwide trademark owned by Indesit Company. The company itself was founded in 1975 and at first engaged exclusively in mechanical engineering. However, in the following years, Indesit Company entered the home appliance market. Products under the brand Hotpoint and Ariston quickly gained popularity in many civilized countries. In 2007, these two brands were merged.

One of the most popular Hotpoint-Ariston products in Russia are boilers, mainly gas.

Special features

The demand for heating equipment of this brand in our country is due to high quality products. The Russian resident always chose the goods more reliably, although somewhat more expensive. In addition, Ariston boilers have an affordable price. With proper operation, they will be able to serve for about 20 years or more, which makes such a purchase very profitable.

Another advantage that affected the popularity of Ariston equipment is its wide range. You can find a boiler based on your preferences and requirements.

As a rule, all heating boilers are divided into four types:

- gas;

- electrical;

- liquid fuel;

- solid fuel.

In this article we are talking about gas boilers. So let's take a closer look at their subspecies.

First of all, gas heaters are divided by the number of circuits.

- Single-circuit boilers. Simple, why more reliable and cheap equipment. It is aimed exclusively at heating the premises, without the possibility of heating water. Consists of one heat exchanger, circular pumps and expansion tanks.

- Double-circuit boilers. Suitable for those who want to have hot water in the house, but do not want to purchase additional equipment. Inside these boilers have two heat exchangers. At the same time, their sizes practically do not differ from the sizes of single-circuit boilers. The water in the hot water circuit is heated by water from the heating circuit circulating through the heat exchanger. This technique is more complex, why less reliable.

Double-circuit boilers can be bithermic. Their reliability is even lower. They differ in that the second heat exchanger is located inside the first.

All gas boilers need air flow.

Depending on how it is provided, the heaters are divided according to the type of combustion chamber.

- In boilers with an open chamber, oxygen enters from the room where they are located. Such equipment has low productivity, but it is demanding for the organization of conditions: the room must be equipped with good ventilation and a chimney through which the products of combustion will be removed. It is necessary to strictly observe the rules of fire safety. The advantages of such boilers include reliability and low noise during operation.

- Boilers with a closed combustion chamber are less reliable, but more productive. Also, they are not so demanding to the arrangement of the room and practically not harmful to the environment. At the heart of their work - a special burner and fan. With the help of the latter, air is taken in and the combustion products removed. However, keep in mind that the fan makes a lot of noise during operation.

Also, heaters can be divided by the type of their placement.

- Wall mounted. Due to its compact size, it is most often purchased for placement in apartments. They are lightweight and easy to install. They usually have a closed combustion chamber and are easy to handle, thus providing themselves with additional demand. Wall-mounted boilers do not have high power, but it is enough to warm a residential apartment.

- Outdoor. Have increased power. But in terms of size and weight, they are noticeably superior to wall counterparts. The price is also somewhat higher. Such boilers are usually used for heating rooms and buildings with a large area.

Whatever level of reliability your chosen boiler has, it is unlikely that you will be able to avoid mistakes in operation.Fortunately, most modern units are equipped with control sensors and a self-diagnostic system.

The first ones will stop the operation of the boiler in order to prevent more serious damage. In addition, the sensors will block all functions of the unit. You will have to fix the problem to release the lock. The second will notify you of the problem that has occurred by highlighting the error code on the display.

They are divided into two types:

- problems that the user can fix with his own hands;

- breakdowns that need to be addressed by specialists to correct.

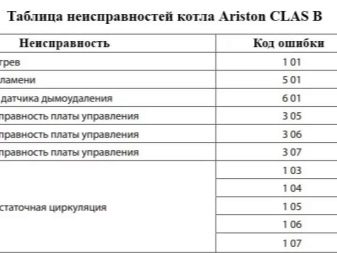

All code values can be found on the Internet or in the instructions for your specific model. Next, we describe the most common mistakes that occur in the operation of Ariston boilers.

Causes of breakdowns

Here we will talk mainly about the error codes that are displayed on the displays. But not all models of boilers are equipped with them. Some units instead of small screens have a light indication. In the event of a problem, colored lights on the panel turn on and flash. To understand their specific meaning, refer to the instructions.

Consider the most common error codes and how to eliminate them.

- 501 is one of the most frequently occurring codes. It means that there is no ignition in the boiler. In this case, first of all, check whether the gas supply valve is open. Pay attention to the ionization sensor. If its contacts have oxidized, they need to be cleaned. The distance between the sensor and the comb should be 8 millimeters. Also, it would not be superfluous to tighten the electrode connections with the control module.

- 108 - arises due to lack of pressure in the circuit. There was probably a leak in the system. It can be found in the heat exchanger, pipes, expansion tank (do not forget to check the membrane in it), connections, radiators, or in several places at once. Almost all of them can be sealed with the help of soldering, but it is better to entrust this business to a professional. If the damage on one part is too much, it is better to replace it entirely.

- SP3 - in some models known as 5P3. This code reports the flame breaking. Most often the problem occurs in the area of the coaxial chimney. Adjust its position and clear debris. At the same time check the gas supply valve.

- 101 - boilers are equipped with overheating protection. The code signals that it worked. There may be several reasons.To eliminate an error, it is necessary to carry out the whole complex of procedures. First check the gas supply. Probably increased pressure in the valve. Then clean the filter. In the heat exchanger may form scale, which will reduce heat transfer. In this case, you will have to disassemble the knot and clean the coil with chemicals. Check the operation and speed of the pump. Inspect the electronic board and thermal sensor. Heavily damaged parts should be replaced.

- 103, 104, 105, 105, 106, 107 - have approximately the same origin as the previous error (overheating, reduced pressure, low heat emission), and are eliminated by the same methods. It is also recommended to bleed air. In some models, a separate button is set aside for these purposes. Read the instructions to learn the details of this procedure. Then make sure the pressure recovers to 1.2 bar.

- 601 - reports that there is no thrust in the system. You can verify this with a match. Light it and bring it to the control window. If the flame burns smoothly, without deviating, then there really is no traction. In this case, it is worth checking whether the sensor is working properly. If so, clean the chimney.It may accumulate soot or other debris. Also, coaxial pipes are often clogged with accumulated condensate.

- 109 - occurs when the pressure rises above 3 bar. To reduce it, use the Mayevsky cranes, which are located on the radiator. With their help, you can bleed air in the system. This error sometimes occurs in the second heat exchanger of double-circuit boilers. Due to a malfunction, hot and cold water can mix in it, which leads to an increase in pressure. Replace defective parts.

- 117 - means that the water circulation is disturbed in the system. To eliminate it, simply restart the equipment.

- 6P1, 6P2 - insufficient amount of oxygen. There can be two reasons: either there is too little air in the room, or smoke accumulates in it. Check if the ventilation and chimney are working properly. Clean them up. If everything is fine with them, then the problem is probably in the relay. Its compounds sometimes stick, they need to be replaced.

- SP2 - reports that failed to re-ignite. The problem may lie in elements such as a gas valve, an ionization sensor, or a chimney.If any of these parts are faulty, they should be replaced with new ones.

- 201 - the system issues this code when a sensor break or short circuit occurs on the hot water supply. Check all wiring and connections. If some areas have oxidized, replace them. At the same time pull contacts.

- 302 - communication with the display and the electronic module is lost. In this case, it is worthwhile to carry out the same repair as with error 201.

- 607 - lights up when the fan relay sticks. The problem is solved by replacing the relay with a new one.

- 307, 308 - a failure occurred in the electronic module. Simply press and hold the reset button.

- 111 - low pressure in the circuit. It occurs in the systems of boilers equipped with an automatic coolant feed. The situation is the same as when code 108 occurred. It is necessary to find the leak and fix it.

- 110 - problem with the thermistor of heating. Occurs due to open circuit or short circuit. The best way out is to replace the part with a new one.

- 102 - damaged NTC thermistor of the heating system. This is also due to an open circuit or short circuit. Check the terminals of the main module. Replace it in case of malfunction.

- 112 - incorrect data of the thermal sensor.Just replace it with a new one.

- 114 - there is no connection with the thermistor of the waste products. Check the wires and pull them up.

- 116 - lost contact with the external thermal sensor. Just reboot the system.

- 303, 304 - the electronic board failed. Replace it with a new one.

- A01 - occurs only in models equipped with electronic ignition. The code means that the ignition does not work. Most often arises due to voltage outages. From this saves the connection of the stabilizer. If it does not help, check the ionization sensor. Clean its contacts and make sure the part is installed correctly.

- E34 - refused pneumorele. Replace it with a new one.

- H45 - Thermistor malfunction detected. Inspect and clean its flow sensor and safety valve.

- 604 - the fan is not working properly. Check out what the problem may be. Also pay attention to the board and the Hall sensor. If any of the parts are out of order, replace them. On models without a display, a yellow light comes on in the event of this problem.

- 608 - the pressure switch does not work correctly, despite the correct functioning of the fan. The pressure switch should be replaced. The problem may also be in the wiring.

There are also cases when the equipment does not report a problem. For example, a double-circuit boiler does not heat the water, although it should, or the unit hums unnaturally when turned on. To find the source of the problem, you will need to consult a service center.

Remedies

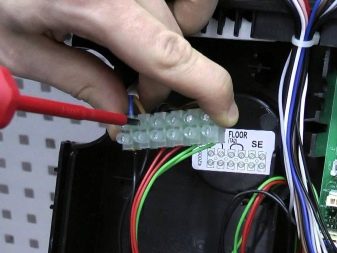

By following the above instructions, you can fix the problem yourself. But if you are not confident in your own abilities, you should not start such repairs.

Even electric boilers can be spoiled out of ignorance by damaging the electronics. And damage to gas boilers is completely life threatening: there is a risk to provoke a leak. In severe cases, it is better to contact a master who is able to correct such damage in advance.

Of course, with simple mistakes, it’s not necessary to call someone. For example, you can increase the pressure or bleed the air yourself.

Without the risk of serious damage, you can clean the heat exchanger, which is clogged due to overheating. But use extreme caution.

Also self-repair can be fan pressurized. If it rotates slowly but noisily, it is necessary to check the bearings. Oil them or replace with new ones.But if this does not solve the problem, pay attention to the winding. However, its repair is better to entrust an expert in electronics.

Tips and tricks

At the end of the article we will share with you some useful tips:

- It is worth regularly carrying out maintenance and cleaning of boilers - about once a year. This will reduce the likelihood of damage to a minimum. Broken or similar parts should be replaced as early as possible so that they do not cause more serious problems.

- Do not save on installation of equipment. Entrust this matter to knowledgeable people. Errors in installing the boiler or improper placement conditions may adversely affect its operation.

- Follow the instructions. The manufacturer knows better how to handle the equipment, and describes in detail the rules in the attached documentation.

- In the event of a serious malfunction, contact the service center - do not try to deal with them yourself. The consequences we described above. Experts can diagnose damage after an external examination. Unobvious malfunctions are rare. After a thorough diagnosis, service center staff will be able to accurately answer how much you will repair.

As it was said at the beginning of the article, Hotpoint-Ariston brand boilers are distinguished by a very high-quality assembly. Follow the recommendations, and you do not have to spend large sums on new equipment for several decades.

How to repair the boiler if the chimney is faulty, see below.