Bed attic from the massif of a tree

Baby loft bed - a compact analogue of products for adults is equally effective in optimizing space: it frees up usable space and increases the capacity of the room. Most parents place high demands on the quality of children's furniture, preferring solid wood products. And everything would be fine, but many are confused by the price of the issue, because it costs the finished wooden beds not cheap. Others are satisfied with the design and price, but they are not pleased with the quality characteristics of the product.

The way out of such situations is the independent production of an attic bed from the array.So you can avoid the high costs - once, make the furniture complex of the right size - two, which will meet the aesthetic preferences of the child - three. The models presented by us are universal solutions that will welcome the smallest children's owners, preschoolers and teenagers. Your task is to determine the size and follow the instructions.

Special features

Compared with a bunk bed, where a couple of beds are provided, there is only one sleeping surface at the attic bed, located on the second tier. Its design is characterized by extreme simplicity. The product is represented by a frame, sunbed, design elements - safety sides, stairs, headboard, footboard.

The first floor will be used for:

- working area;

- playground;

- sports complex;

- dressing room with a chest of drawers or wardrobe;

- sitting area with a sofa.

To organize a functional work segment, a sports module or a safe play area, you will need to carefully calculate the load on all parts. As for the design, in small beds, the dimensions of the sliding elements - tables, stairs, storage systems will need to be measured out to a millimeter. Otherwise, in the course of operation, there will definitely be difficulties.

In high beds, filling the lower tier means placing furniture so that access to the drawers remains free, and the casement doors can be opened and closed unhindered.

What material is better to choose?

The choice of material for an attic bed implies two possible options - with a metal or wood frame. Arguments for the manufacture of wooden, not metal construction:

- ease of processing;

- assembly speed;

- weighs less than a metal product;

- does not require the use of special equipment, and to build a metal bed you need a welding machine.

Advantages and disadvantages

Furniture masters at all times preferred wood - natural material with many practical advantages. Advantages of wooden furniture:

- strength, reliability and durability;

- low thermal conductivity, excellent heat retention;

- environmental friendliness. Wood is a material created by nature itself, therefore it is completely harmless to the body;

- health effect - filters the air, neutralizing the action of harmful substances, which contributes to the creation of a healthy microclimate in the house;

- visual appeal.Each tree has its own unique pattern, its contemplation is a visual pleasure;

- organically complements any interior;

- fills the house with a natural delicate aroma;

- tactile comfort - gives a lot of pleasant sensations upon contact.

The disadvantages of the material include the fear of a humid environment and temperature changes, therefore, an array of wood must be treated with protective compounds.

Varieties of wood

- Beech and oak - high-strength, durable materials, but their cost will be appropriate. Alder and linden are used quite rarely. The most affordable option - solid pine. Pine fills the air with phytoncides that prevent bacteria from multiplying, reducing the risk of colds. It has a beneficial effect on the nervous system and normalizes the emotional background.

- Solid pine considered quite soft and pliable material. Therefore, mechanical damage - scratches and dents due to careless operation will inevitably lead to loss of appearance of the product. The softness of pine depends on its age. The older the tree, the stronger.

Tools

The frame is made of wooden timber, the minimum size of the section is 80x100, the best is 100x100 mm. Cladding, railings, stairs are made of rails having a thickness of 20-30 mm. Plywood is used to make the bottom, although it is best to equip the structure with a ready-made rack bottom where the slats are fixed by lato-holders. Such bottom in furniture stores is on sale.

Fasteners:

- furniture bolts;

- universal screws;

- adhesive composition for carpentry.

From tools use:

- circular saw;

- drill screwdriver;

- manual grinder / fine-grained emery cloth;

- clamp;

- hammer;

- roulette, ruler;

- laser / water level.

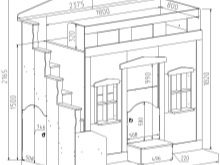

Drawings and diagrams

Even such a simple design as a loft bed has several options for execution. The difference between them lies in the method of fixing.

The basic models are represented by three types of constructive solutions:

- independent construction with four supportsfor which you can choose any place in the room, but the room must have a sufficient height of the ceiling;

- with wall mount system - sustainable design, where the frame part has two supports.

- with ceiling mounts - the most original performance of the bed. The bunk frame part is simply not there, and the sleeping surface is fixed to the ceiling. From this option delighted teenagers.

The popularity of the first modification is due to the ease of implementation and relative mobility.

The video below shows the drawings of the finished loft bed and their detailed description.

Staircase options

Another crucial point is the installation of the stairs.

Stairs can be placed:

- Upright, which is beneficial in terms of space saving, but the safety of this option is questionable. It can be mounted on the right side, on the left, on the end, and sometimes just on the wall. This method of placement is suitable for students, but not for the smallest children.

- Inclined - besides traditional straight lines, there are radial stairs. They are simpler and safer. The convenience of the staircase depends on the angle of inclination; the larger it is, the more comfortable it is to move along it, which, however, also affects the footprint. Often ladders do removable.

For these options, the safe solution will be flat-shaped steps, not round.

- Ladder modules - roll-out and stationary. The full steps in this case are the drawers that form the module. These are the safest options, because the steps are of standard size here, and the march differs in its usual inclination.

- Catwalk models are a hybrid of modular and inclined ladder option. The platform is set to a height equal to ½ the height of the bed, equipping the podium with a short inclined ladder. In order to save space, the podium itself is equipped with an integrated storage system.

We are determined with the size

When choosing sizes, take into account the age of the child and the dimensions of the room. For children in the age group of 2 to 5, mini lofts with a low sleeping surface are ideal. Their sizes are 70x160, and the height is at least 80 cm, and the maximum is 120 cm. For schoolchildren, you can already consider both one-and-a-half and double bed options with sizes 90x200, 140x200 cm, with a height of 1.8 m.

When creating a drawing, you need to remember about the scale, it simplifies the calculation of the required amount of materials.

Manufacturing and assembly

In accordance with the individually developed or finished drawing, the calculation of the required amount of materials.You can use the services of the cut in the store, and you can do it yourself.

Work order:

- Grinding parts with a grinder or sandpaper. From sharp corners, chips and irregularities should not remain a trace.

- Processing boards and bars with antiseptic.

- Drilling holes for fasteners in the course of installation. All at once they do not need to drill.

- Holes are machined with adhesive immediately before joining the parts.

- Assembly of the frame part of the four supports and the frame of the bars with a section size of 100x100 mm.

- The formation of the frame of the support bars and the outer boards of the side stops, fastening the rack with screw connections or metal corners.

- As the assembly periodically checks the clarity of compliance with the vertical angle.

- The reliability of the design will provide additional bond of the supports on the ends and in the rear part with the help of rails, placing them at a height of 0.3-0.4 m.

- Packing rails on the supporting bars. When calculating the required number of rails, the guideline is the intended load.

- The formation of fences by fixing the rails on the supports. The height of the protective bumpers often reach 0.4 m.For kids, fences are filled more tightly, installing in addition to two or three longitudinal boards, a similar number of transverse ones.

- The manufacture of stairs - vertical / inclined, followed by fastening to the frame. The steps of the staircase structure are placed at such a distance from each other so that the process of moving along them is as convenient as possible for the child.

- Processing the finished product with two layers of matte / clear varnish. Each layer requires drying for at least 24 hours. To change the shade of wood stain is used.

Important nuances:

- When selecting lumber, be sure to pay attention to the degree of their drying. Humidity over 18% is unacceptable. A product made of such wood quickly cracks, cracks and deforms.

- The best version of the fastening connection involves docking thorn-groove, which is considered the most durable and reliable. In the presence of a milling tool, do not neglect the possibility of forming studs and drilling holes for fasteners with a router. The assembly is made on the adhesive composition and duplicated with screws.

- Calculating the size of the bed, the size of the mattress is necessarily taken into account. Between the sides of the safety and the soft base from all sides should remain gaps of at least 2 cm.

- In the process of installation, do not forget to use the level, the best laser to check the right angles. At the slightest deviations, immediately correct the shortcomings, since such defects are the cause of instability of the whole structure.

Color solutions

In this matter, do not forget to ask the opinion of the owner of the loft bed. If adults are completely satisfied with the natural color of wood, then children's cloisters on this subject may have a different opinion, which they will have to reckon with. Girls will surely enjoy light pastel colors - pink, yellow, pale green, lilac, not to mention the universal pure white color. Boys fit a darker palette of gray, blue, brown. In priority among adolescents silver metallic and black.

Interesting ideas for baby cots

In the photo gallery you can find original loft beds for children of different ages.