Wood bed do it yourself

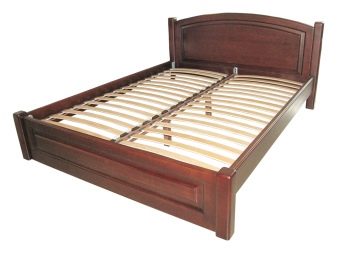

If you visit any major furniture store, it will always be presented with a wide selection of beds of various types and modifications. If desired, and opportunities, you can buy any, but it often happens that one or another option does not fit the existing interior of the house or the bed is too big and bulky, or simply does not like the quality and style of performance. In this case, there is a difficult, but sometimes the only way out: making a bed out of wood with your own hands.

Materials

Since it is high-quality materials that guarantee durability of furniture, if you choose them arbitrarily, there will be much more advantages from this.Of course, when you make your own bed, it will take much more time and effort than simply to buy it or order the assembly from professional furniture makers. However, personal choice and constant control over the quality of your creation will eventually come to fruition and will pay off the long service life of such an important piece of interior, made independently.

Choosing as a material wood, you need to take into account that it has a rather high price and certain difficulties in terms of preparatory work and the process of making beds.

In the absence of proper experience in handling an array, it is better to stop at the choice of simpler options, although any product created, for example, from solid pine or oak, will look very nice and have enviable strength.

A bed made of natural logs looks very impressive, but here there is a difficulty in acquiring them and the unreality of installing such a bed in small rooms.

Given the specifics of working with an array, more frequent in use are different types of lumber: It will be much easier to create a bed from a bar of either planed or trimmed boards.

The only caveat that you should pay special attention to when buying them is good drying: if the product is originally made from a wet bar, when it dries out, the structure will squeak or deform.

Shield Bed - also an inexpensive and good option. Furniture shields are rather massive slabs that are glued together from separate parts of wood.

Such a product will delight you with beauty and practicality, the strength of shields allows you to even make threads on them, but, as in working with wood, here you will need certain skills: the specifics of furniture shields implies the presence of internal stresses with which you should be able to properly handle in practice.

Finely dispersed wood fiber fraction (MDF) - inexpensive and fairly durable material, which, when further processed (for example, with the application of a lacquer coating) looks pretty nice.

MDF boards can be found on sale, both with a finished lacquer coating, and without it, which will be a significant advantage if the manufacturer plans to carry out the treatment on their own.

Chipboard or chipboard - also familiar to many material, characterized by ease of cutting and processing, however, it should be borne in mind that it is better to use it not for the manufacture of supporting structures of the bed, but for boxes, backs and decorative elements. If the plate is already sold with lamination, you can save considerable time.

Accessories for the future bed is better to buy from solid steel, rather than aluminum. Aluminum elements are certainly much cheaper, but steel is much stronger, and it would be better not to save on it, but to take care of quality from all sides.

It is important to keep in mind that the metal fastener will need to be twisted as the wooden base is dry, and if the fastener is steel, the bed will take over all the load at once, and there will be no problems with the strength of the construction.

Choose size

First of all, it is important to determine the size of the future bed: it is on them that the comfort of sleep and the availability of proper rest depend.

The optimal length of a berth can be up to 200 cm, and the width should be selected, depending on individual preferences and characteristics of the build.

By the way, the usual classification of beds (single, double and “lorry”) was once worked out on the basis of width, not length, which should be especially taken into account when planning dimensions and drawing up a drawing.

A single small bed can have a width of 90 and a length of 80 cm, which is optimal for the manufacture of children's models. You can also consider the option with the size of 100x100 cm, if the size of the children's room allows. The bed 150x150 or 150x190 cm is already close to the parameters of one and a half-sleeping, however, the optimal dimensions for an adult are 150 cm in width and 190 cm in length. You can increase them if the room has enough space and the bed will not look bulky in the overall picture.

When drawing up a drawing, it is also important to take into account the fact that the best bed length for a person of any age should always be 15 cm larger than its actual height - with a margin that will ensure maximum comfort and freedom during sleep.

It is not recommended to make a bed too low: the minimum distance from the floor to the mattress should be 50 cm. This will ensure a minimum load on the spine.

There is another subtlety that needs to be considered when making a bed: the older a person is, the higher it should be.

Of course, an important part of any bed is a mattress. It should be purchased in advance in order to plan all dimensions based on its parameters. A standard orthopedic mattress can be from 1.5 to 2 m, with a height of 25 cm. In extreme cases, you can also make it yourself - from foam rubber and other suitable materials.

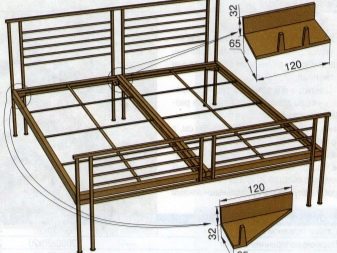

Device

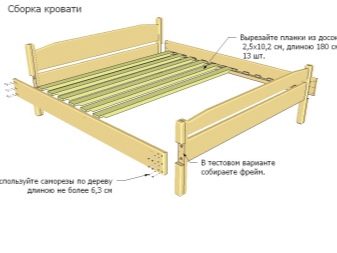

A simple bed of boards and boards can be made fairly quickly, following a certain algorithm of actions.

For this you will need:

- boards 2 pieces (dimensions 250x30 cm) - for the side walls of the bed;

- boards 3 pcs (size 200x30 cm) - front, back of the bed and headboard;

- Bars 5 pcs 4x4cm, length 200 cm - supporting structure of the bed and its legs;

- slats 27 pcs 150x4x2 cm;

- screws and other accessories, depending on the need;

- varnish, "stain", construction glue on wood.

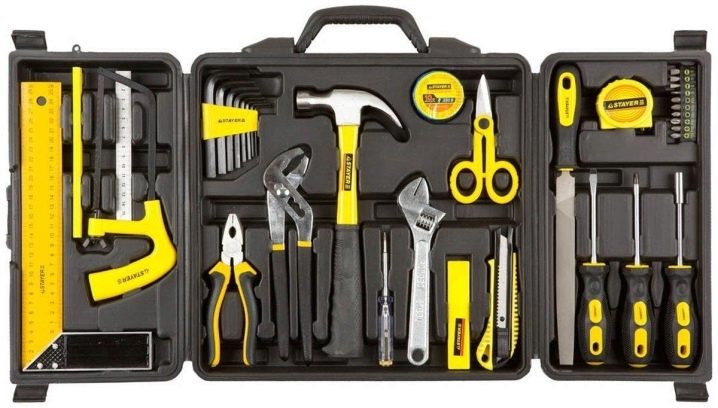

You will also need a small standard set of tools: a screwdriver, an electric jigsaw, a hacksaw, a plane.

For sanding elements - sandpaper, preferably fine-grained, for measurements - a tape measure, for accurate knowledge of the sizes of angles - a square, a simple pencil for marking.

Cutting a tree should be carried out slowly, first having made marking on it with a simple pencil or to take a cutter and make marks with it. Usually in the process of manufacturing elements have to do several of the same. In this case, first cut out the first part, which will serve as a template, and all the rest will already be made with an orientation to its parameters.

When cutting it is necessary to immediately clean up with fine-grained sandpaper.

All corners of the bed should be strictly straight, 90 degrees, therefore, measurements will have to be done often and carefully and only then fasten the parts together. Otherwise, the bed will not be strong and will quickly break under the weight of the human body. All the elements are first carefully glued with construction glue and only after that they are securely fastened to the tree with the help of dowels-self-tapping screws.

We should not forget to remove the remnants of glue, because their presence will significantly complicate the subsequent processing steps.

After cutting all the details, you can proceed directly to the assembly and installation of the bed.

The location of the bars, performing the function of support, must be determined by dividing the length of the front and then the back wall by three. Record the resulting figure.Keep in mind that the mattress should always be at least 5 cm deep in the bed + another 2 cm (thickness of the slats) and + 4s m (thickness of the bars of the longitudinal elements). The final figure is 11 cm. It should be noted at the top of both walls of the future bed, front and back - there will be mounting bars for the main support.

Bars are screwed from the inside. When making the attachment, it is important to follow the screws so that they do not “cut through” the surface of the product - in order to avoid damage to the aesthetic appearance of the bed. The length of the screws is usually calculated in advance.

After fastening the bars, measure 7 cm (from the top of the board for the side parts) and make a mark with a ruler and a pencil. The bars are screwed to the side of the bed with a 6 cm retreat on each side. After that, another 2 small bar pieces are vertically attached to the side of the bars - with a gap of 20 mm to the edge of the board.

Installation of the headboard is carried out to the wall in front. Thoroughly glue all the glued surfaces and edges with glue. Glue the workpiece as tightly as possible so that there are no gaps and unnecessary gaps.

The headboard is strengthened with the help of several slats (usually three). Reiki are glued with construction glue and additionally screwed.All finished items are processed by the stain - so they will get the desired color and shade. After the stain, as usual, should be lacquer treatment, which is recommended to hold twice.

After all the elements are ready, proceed directly to the final assembly. We make the frame, fastening its parts with dowels-screws. Two support bars, pre-bolted to the walls behind and in front, are put on the supporting bars - and fixed. In order to give the construction maximum stability to the supporting bars, legs are additionally attached - it is better to do this from the inside, with the aim of aesthetics.

The supporting structure is ready and securely fixed and you can now lay and fasten the slats, leaving a uniform distance of 4 cm between them. The space between the walls of the bed and the slats should be at least 2 cm. .

Independent production of the podium

As you know, the bed-podium in its many versions is becoming increasingly popular in our country. Furniture makers invent very interesting and practical ways to installIt is precisely such structures to any place: from a large country house to the usual small-sized “Khrushchev”, where it is very problematic to place a large amount of furniture. Podium models abound, however, the most compact of them is exactly the one where there are several under-bed drawers for laundry and other things.

Due to the fact that the presence of such boxes inside the structure allows to significantly free up the surrounding space, this variant of the podium is the most popular among the owners of small apartments and rooms.

Those who want to get a compact bed-podium are often asked how to make a simple model with drawers with their own hands.

Speaking about the simplicity of this model, one should make a reservation that the discussion here will be not about a monolithic, but about a frame basis, which should be as strong as possible in order to withstand the loads ahead.

In order to correctly calculate everything, you need a detailed drawing with inscribing in it the sizes of all the boxes and each beam (or shield) of the frame - depending on the chosen material of manufacture.

Linen boxes located inside the podium or under the bed are characterized by a lack of constant dust collection because they are located near the floor. However, this disadvantage is usually not much taken into account when there is no other way out, but there is a desire to save the surrounding space in the best way.

Despite the fact that such a model in everyday life is considered to be quite simple, a lot will have to be taken into account when planning. The floor has its own mechanics and certain properties, and the bed partitions will interact with it all the time. This is another reason why the frame structure should have a high degree of strength.

For self-production of such a variant of the bed-podium, it is better to use lumber wood materials. This will ensure the strength of the frame in order to avoid subsequent troubles, moreover, the strength of the monolithic bars allows you to "circumvent" possible problems with the load distribution in the following way.

The spar is calculated by analogy with the design of the frame - "ridge", which is usually installed on trucks, designed for large weights.

This means that at the base of the frame there must necessarily be a strong and thick beam, which will take all the loads emanating from the transverse crossbars, “splayed” in different directions.

For the manufacture of such a "ridge" is better to take two large bars of 100x50. The remaining beams of the supporting structure are made of 100x100 bars. Other details can be made either from wood (if time and financial means allow), or from chipboard that will be perfectly combined with any types of wood materials, provided that it will not be used for loading elements of the bed.

It should be remembered that the chipboard, due to its peculiarity to stratify, does not accept either alternating or concentrated types of load.

However, with a great desire, you can make a bed-podium on a frame entirely of chipboard. It will be a shield construction, placed on the crosspiece, which serves as the main support, with the complete absence of small details. Shields are installed "edge" on the floor and support the flooring below. The main cross with pads takes the bulk of the entire load.

Of course, the shield plates must be sufficiently thick, at least 30 mm.

The boxes will fit inside, but this option has one major drawback: due to the fact that it is impossible to position the crosspiece in another way, half of the space under the bed will remain unused.

Of the two proposed options for the podium with the boxes, you can choose any one that will be the most suitable and feasible to manufacture.

How to make a wooden bunk bed?

A wooden bunk bed is an excellent option when it comes to how to place two beds in a nursery or free as much space for a child as possible in the room. The cheapest and at the same time durable materials that can be used in the manufacture - it is boards and pine timber.

When calculating the amount of materials and drawing up a drawing, it is important to consider the distance from the lower tier to the bottom of the upper one - its recommended size is 85 cm. This will ensure a comfortable sitting downstairs not only for the child, but also for the adult.

The following are the basic elements of a bunk bed with their standard sizes (one element):

- vertical rack 38x76x1730 mm;

- strengthening racks 38x76x1730 mm;

- elements of the supporting structure (frame) 38x140x2030 mm;

- headboard planks (bottom and top) 20x140x914 mm;

- strips for footboards (bottom and top) 20x140x914 mm;

- the center bar (ibid.) 20x90x914 mm;

- lateral safety fence 20x90x1800 mm;

- stair railing 20x90x1510 mm;

- stair steps 20x64x482 mm.

The supporting frame is assembled from four boards prepared in advance. For the reliability of the frame, an additional plank is longitudinally glued onto the board and screwed to it with screws.

Bars, glued to the plank, supporting the mattress lengthwise, will play the role of a base on which you need to lay slats across the bed.

Railings for railings are made of simple finished board, and the stair railing is made of boards with the possibility of frame strengthening.

Places for fixing the steps should be marked in advance, and during assembly, make sure that the metal elements fixing them do not come into contact with the frame fixing hardware. The foot and head parts of the bed are fastened with screws - at the bottom with the supporting structure. Screws from the edge should be filed.

The second tier is also assembled in the same way, and the fence with the ladder is also attached.As for the fence, if there is a desire and time, it can be done on the side of the wall. The finished bed to process the stain and varnish, let it dry - and you can put mattresses.

Useful tips

It is sometimes believed that the use of ordinary nails in the manufacture of furniture is inconsistent and impractical, but it is not. Nails can not only become the cheapest element of fittings, but also facilitate the work of the joiner, without requiring any preparatory action in the form of drilling with a drill.

Probably, few people realize that ordinary pallets from building materials can be used as the basis for a solid wooden bed.

They win not only by their cheap price, but also by their good quality, because bad wood is unlikely to be used to transport and store heavy bricks.

In addition, over time, the use of such pallets for the intended purpose tree can perfectly sit down and dry, which is an indisputable advantage.

Pallets can be brought into a more decent look with the help of sanding and connected to each other with long dowels.To give them a minimal aesthetic appearance, they can also be painted and varnished. In order to make a full double bed, you need only four such construction pallets, and from eight pallets or more, you can build any kind of podium.

For the manufacture of the legs of the bed do not use chipboard: as already mentioned, this material, in spite of its wide use, is not suitable for the manufacture of parts that can withstand a serious load. If you take it lightly and make the legs of the bed from wood-based material, at best they will become stratified, and the bed will constantly creak, and at worst they may simply not withstand gravity.

The bed itself is not only designed to support the mattress, but must also have properties that would allow to evenly distribute the load between it and the bed frame. The boards on the bed should be laid freely according to the lamella principle, and the plywood board for the mattress itself is already placed on top.

Lamella boards are best laid transversely, not longitudinally, because this is how they flex slightly down in accordance with the movements of the body.

Beautiful bedroom interior ideas

For the children's room there are a large number of ways to make a two-tier ensemble, which may consist of more than two beds.

For example, there are options in the form of transformers, when in the daytime, using a simple mechanism, the bed at the bottom easily turns into a desktop. If desired, this kind of two-story construction is also really hand-made.

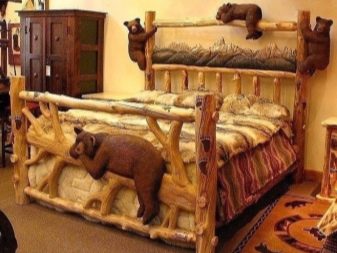

For children of preschool and primary school age, it will be a great decision to make railings and stairs of beds from improvised means, or simply in the forest of logs and small logs, sanded and processed by ordinary joinery methods. Such an unusual interior and decorate the nursery, and will always bring the child the joy and the possibility of additional space for games.

A retractable bed from the podium will be the optimal solution in the case when you need to create a cozy interior space in a small room. In the daytime, it can be removed inside the podium, thereby freeing up space for receiving guests.

The durable frame of such a product, which is based on the ridge structure of a massive bar, will allow you to place a comfortable working room at the top of the podium with a computer desk and shelves for books.If you take care of the exterior of this option with high-quality laminate of natural materials, the room will look just great, despite its small area.

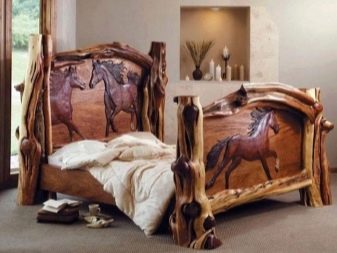

A large bedroom in a country house is an excellent reason to place there a luxurious double bed of any desired design.

A bedroom with a carved bed always looks very attractive, and if one masters wood carving on his own, wide spaces for creativity open up.

You can cut the figures of various animals or birds and attach them to the back and foot of the bed, and if you want to cut patterns, high-quality wood will allow you to do this.

By the way, cheaper materials, such as chipboard, are also not afraid of such work and are quite adapted to use acceptable and simple carving techniques.

Using pallets for building materials for the manufacture of a bed, a true creative artist will certainly be able to find uses for the holes in them.

The pallets themselves can be disguised as they should by sanding and painting in some unusual color, and inside the holes you can place absolutely safe lighting for the bed in the form of LED lamps or lamps.They do not heat up and are quite suitable for such independent design.

If the bed is made in the form of a simple podium with a mattress lying on top, this also opens up vast spaces for creative thought. After all, the headboard of such a bed can be decorated as you like: for example, you can get old boards from the pantry, wash them, cover them with varnish, write something in an incomprehensible language on them, attach them to the wall at the head of the bed — and Handmade ready.

Fans of everything warm and soft can buy several pillows of the same shape and color and also fix them in the headboard - you’ll have a peculiar panel with a touch of simple and cozy home-made humor.

Colored decorative pillows of large sizes can be mounted on a metal pipe mounted in the wall with strong colored ribbons. It is important to remember that feather pillows are not suitable for such purposes, due to the fact that they are quite heavy. Cushions made of padding polyester or holofiber are perfect for decorative design.

A self-made double bed-podium, not adjacent to the wall, can also become a expanse for creativity, if instead of traditional drawers you place shelves with books inside the podium.Books can be both real and "tricks", and if somewhere in the house old books with yellowed sheets were lying around, then, filling them with shelves, you can create in the room an indescribable atmosphere of a truly vintage interior.

Ordinary boards, long lying in the barn, should not be thrown away. They can also be used to create a beautiful rustic atmosphere by decorating the headboard of a small bed in the country. Boards are pre-sized, sanded and varnished. Paint them in a different color is not worth it - it is better to take the stain in order to enhance their dark, time-affected color. On the bed you can put a quilt and multi-colored pillows.

If there is a desire, time and opportunity, it is real not only to make a bed with your own hands, but also to independently design the bedroom so that it looks unusual and cozy, always creating a good mood to its owner.

How to make a double bed with your own hands, see in the video.