Polyurethane foam mattresses

Everyone knows that well-being and good mood depends on a comfortable and comfortable bed. Such qualities gives him a mattress. Sleeping on an uneven and falling mattress will not only prevent a person from sleeping, but also cause painful sensations. In order for this not to happen, you need to find a reliable quality option at an affordable price. The polyurethane foam mattress meets these requirements.

What is the foam in the mattress?

Polyurethane foam mattresses are a good replacement for mattresses with orthopedic effect, the more their price is lower, and the quality is just as good.

Polyurethane foam, which is the basis of mattresses, is nothing but foam rubber, only with improved properties. The name Porolon received the material thanks to the Scandinavian company that was called so. Today, only the name remains of the quality and properties of that material.Thanks to modern technology, foam rubber has received not only a new name, but also acquired a lot of new and useful qualities that allowed it to be used in the production of mattresses.

All manufacturers producing PPU, as a rule, produce it using the same technology that corresponds to a specific scheme. To begin with, two substances are mixed in certain proportions, to which water is added. In the course of a chemical reaction, carbon dioxide is released, due to which the foaming of substances takes place and a porous structure is formed in the future. During the reaction, which lasts no more than 20 minutes, catalysts and stabilizers are added. Then the mass is poured into a special form and remains for two days for the final polymerization.

Thanks to the technology of mixing in certain proportions of substances, polyurethane foam, containing in its composition 90% of air, acquires the main characteristics, such as elasticity, heat resistance, density and rigidity.

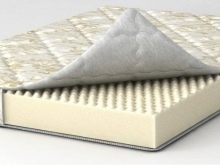

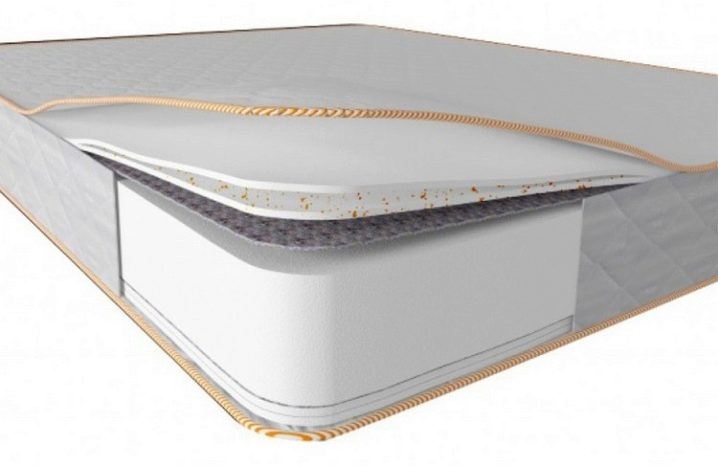

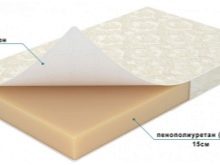

In addition to these indicators on the quality of mattresses also affects the multi-layer or solidity of this material. The basis of good mattresses is a monolithic block of polyurethane foam, having a thickness of 16 cm.In cheaper models use a multilayer block of glued foam layers. A mattress 15 cm thick will consist of five layers of three centimeters. Products, which are basically glued blocks, are much cheaper.

The health benefits of filler

It is no secret that chemicals are used to produce PUF, this fact causes a lot of controversy about its negative effects on the body. There are confirmed data that the elements that make up polyurethane foam are hydrocarbons obtained from petroleum, and during open burning these substances are released into the air in high concentrations. But it is not yet known whether components cause such great harm in normal conditions.

It is believed that when the mattress is heated, which includes this polymer, a specific odor appears before the body temperature, caused by the release of harmful components that make up the PUF. Therefore, it was argued that using this material as a filler for the mattress is not safe. But in fairness it should be noted that the toxicity of this filler occurs only when non-compliance with the production technology.

Therefore, you should not save on your own health and buy a mattress from little-known manufacturers. Large firms monitor the quality of their products.

It is believed that the polymer is completely reacted, that is, the technology was observed in and out, is inert, which means it is safe and suitable for use as a filler. The barely perceptible odor and residual vapors disappear in a maximum of two weeks and the further exploitation of the mattress does not pose a threat to health.

In addition to chemical properties, according to some experts, PPU is accused of being too soft. They claim that mattresses, which are based on polyurethane foam, cannot ensure the correct position of the spine, as it flexes strongly, and with it the spinal column also flexes. Over time, such a deflection can lead to a curvature of the spine and many other problems. For children under two years old, the use of PPU as a filler is highly undesirable, for such babies there are their own fillers.

But modern technologies used in the production of polyurethane foam, allow to produce this material with improved properties.A good quality filler has rigidity indicators higher than the average value, and the cost of a mattress with PU foam is significantly higher than that of a product with a spring block. To date, it is impossible to unequivocally argue that PPU is harmful to human health, but there is also no certainty that it is absolutely safe. Therefore, each person should decide for himself whether to buy a mattress in the composition, which is polyurethane foam or to refuse to buy.

Advantages and disadvantages

PUF, which is the basis for the mattress, gives this product many properties. Among them there are both positive qualities and some disadvantages.

Of the advantages of this material should be noted resilience and elasticity. Thanks to these qualities, good support is created for the musculoskeletal system.

Acceptable PPU price is a significant advantage. Especially when you have to choose between models with a similar cost. A bonell spring block mattress costs about the same as a PU foam mattress, but the benefits of a product with polyurethane foam are much greater. The dependent spring block bonell is not able to provide proper support to the spine, especially since this type of orthopedic properties are absent. And at mattresses with modern PPU they are expressed.Moreover, polyurethane foam mattress, not prone to deformation, is recommended for use by people with various disorders of the musculoskeletal system.

The positive quality of this mattress is viscosity.

Thanks to her, PU foam can withstand considerable pressure. Therefore, people with greater weight can safely sleep on these mattresses - no dents or creases on it will not. Viscosity is precisely the property by which joint relaxation of couples with different weights will not be overshadowed. The pressure exerted on the surface by a partner with a large weight does not affect the lighter partner, there is no hammock effect. In addition, due to the viscosity, the mattress with PU foam is not pressed for a long time.

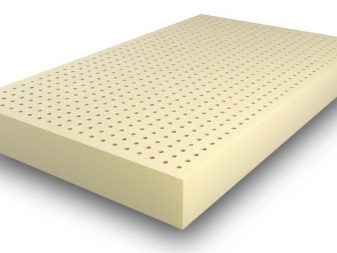

Polyurethane foam is a polymer with a cellular structure and therefore it is able to pass air well. Air permeability gives products with polyurethane foam excellent hygienic properties. And, of course, an important advantage of the polyurethane foam mattress is its good transportability. These mattresses are rolled into a roll for convenience, because they are not afraid of deformation and twisting.

Numerous advantages do not cancel some minuses peculiar to mattresses with PPU. Such an advantage as the price can turn into a significant disadvantage. This happens if the desire to reduce the cost of the product reaches the limit. In very cheap models, quality suffers noticeably and service life is significantly reduced. At best, such a mattress will last 3-4 years.

The porosity of polyurethane foam contributes to the absorption of odors, liquids and vapors, and cleaning of such products at home is impossible. Polyurethane foam mattress can only be specialized processing. Some inconvenience brings the smell emanating from the new mattress, but it disappears in a few days.

Which is better: holofiber, latex or polyurethane foam?

Polyurethane foam, latex and holofiber are often used in the manufacture of mattresses. In order to compare them, it is necessary to analyze the properties of materials:

- Latex - natural material, obtained by processing the rubber tree, and the foam and holofiber are of artificial origin. Latex has an antibacterial effect, has a porous structure, a pronounced orthopedic effect, breathable and easy to clean.Among the shortcomings can only be called a high price.

- PPU It has similar characteristics with latex, but is more affordable. In addition, this material has a shorter service life compared to latex, as well as a smaller amount of permissible load.

- Holofiber - the material is synthetic and most often consists of polyester, polyamide, polyacrylonitrile and some other fibers. This bulk material has a lower cost compared to polyurethane foam and even more so with latex. The volume of the holofiber after a very short period of time is very much reduced, in six months it can lose more than 2 cm in height. And yet, this material is often used in the manufacture of mattresses, the reason is simple - its cost, and the cheaper the filler, the greater the profit of manufacturers. Holofiber can be used in mattresses, but only as an extra layer, not as a base.

Polyurethane and latex are more suitable as a base for mattresses, and holofiber as an additional layer.

Kinds

There are different types of mattresses based on polyurethane foam. These include highly elastic models with a memory effect, viscoelastic, standard, soft, ultra-soft, models with increased stiffness.

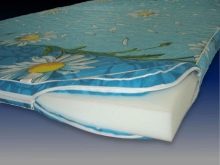

Most often in the production of polyurethane foam manufacturers are not limited, since the height of the product is obtained only 15 cm, and therefore additionally invest in mattresses of various fillers. These include coconut coir, felt, jacquard fabric. Such combined models not only become taller and denser, but also acquire additional properties that improve the quality of products.

Coconut coir adds rigidity to the product, increases its service life and has an antibacterial effect. Polyurethane foam mattress with this extra layer is suitable for children. Jacquard fabric is used for covers. To impart orthopedic properties to mattresses, manufacturers make the surface of polyurethane foam relief.

Dimensions

In addition to degrees of rigidity, mattresses with PU foam are classified by size. There are single options, one and a half, double and non-standard. As a rule, manufacturers try to produce sizes adapted to the dimensions of modern furniture.

Single mattresses are sizes: 80x190 cm, 80x200 cm, 90x190 cm, 90x200 cm and a slightly shortened version adapted to a specific type of bed 80x180 cm.One and a half-sleeping models can be attributed to the dimensions: 140x200 cm, 120x200 cm. These sizes are most in demand, especially the size 140x200 cm, as it is suitable not only for one and a half beds, but also for double beds. After all, a width of 140 cm is very often found in beds designed for two people.

For double mattresses are products with dimensions of 160x200 cm, 180x200 cm. Manufacturers produce non-standard sizes only for individual orders. For example, the size is 190x130 cm, which can not be attributed to either a half-sleeping or a single mattress.

The height of the side - another indicator by which you can classify mattresses from the foam. Products with a height of 5-10 cm are considered thin. Models with such low sides are made either for sofas, armchairs, folding beds, or for children. Standard mattress height starts at 15 cm.

Density and stiffness

This cellular filler has two main indicators: density and stiffness. The ratio of these two values affects the quality of the material, while the density is a more significant indicator compared to the stiffness. The higher it is, the better the mattress, which is based on this material, and the stiffness index can be low.

Such factors as the permissible load for one berth and the service life of the product, which is based on the foam, depend on the density and stiffness.

The cheapest mattresses have a hardness index not higher than average, the service life of products containing such a filler is not more than 3 years, and the permissible load on a berth is not more than 90 kg. The second group includes mattresses with an average stiffness index slightly higher, with the service life of such products 5-7 years, and the load increases to 110 kg per berth. Good quality products have a service life of about 10 years, their stiffness is above average, and the permissible load increases and reaches 140 kg.

the cloth

As a cover for products from polyurethane foam various mattress fabric is used. Most often it is jacquard, knitwear, coarse calico, polycotton and in more expensive models the membrane:

- Good quality fabric incorporates cotton. Thanks to him, the fabric acquires such a quality as breathability. Compared to cotton fabrics, synthetic fabrics have a lower air permeability rate, with the exception of some types of expensive fabrics.

- Jacquard The fabric is durable and exquisite appearance. It consists of both natural and synthetic fibers. Synthetic jacquard is resistant to friction, stretching and denser knitted fabric, but inferior in comfort.

- For children's mattresses used calico or polycotton. These fabrics incorporate cotton fibers, thanks to which the fabric is well ventilated.

- Membrane represents the nonwoven cloth having high water-repellent properties. In addition, this canvas is very resistant to high temperatures, has a high breathability and wrinkle.

Colour

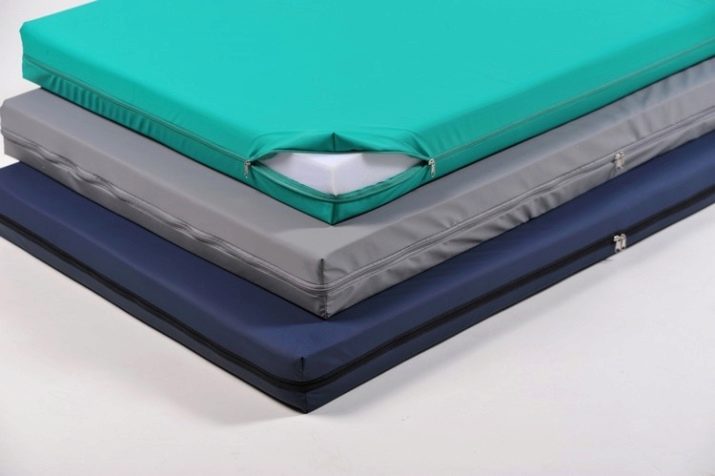

Companies that produce mattresses, focus primarily on consumer preferences. For children, covers, as a rule, have bright colors. The color range intended for the mass consumer does not differ in a wide range. But this is not particularly necessary.

Mattresses are mainly purchased for beds installed in bedrooms that have already been designed in a certain color range and therefore bright colors will not be appropriate. The most popular color is white.The best option, suitable for almost all bedrooms, decorated in any style. Sometimes there are models with a light gray cover. In the exclusive models of the case may be black with an interesting pattern.

For medical institutions, manufacturers produce models that have covers of dark shades. Burgundy, dark green and emerald green are the most sought-after shades for these institutions.

Manufacturers Rating

There is a rating of models from different manufacturers:

- In the first place is a hard mattress Askona Basic High with a side height of 21 cm, manufactured by Ascona. The model can withstand a maximum load of 110 kg. The jacquard fabric at the base of the cover is resistant to friction and washing. For convenience of transportation, the mattress is twisted into a roll and has a weight of 9 kg.

- The honorable second place is occupied by a mattress from the same company. Askona Comfort Plus. In this model with an average degree of stiffness, polyurethane foam is used in combination with an independent spring block. It is located on the surface and around the perimeter. Permissible maximum load 110 kg.

- The third place is occupied by a mattress from the company. Consul. The Consul Philo model with an average degree of rigidity and high density PUF withstands loads up to 120 kg. For ease of transportation, it is twisted into a roll. The cover has a fixed.

- Model Vegas hit 4 with a removable cover and a maximum load of 120-130 kg is produced by the Belarusian company Vegas. The relief zonal surface of the mattress has increased elasticity on both sides of the model.

- Mattress Relax Eco 1 with a low degree of stiffness, it is equipped with a 14 cm thick PU foam block. In this mattress, the load on a berth is not more than 90 kg. A distinctive feature of this model is a case impregnated with a solution that prevents fabric from burning.

- The most affordable model Dreamline Classic Roll Slim with an average degree of stiffness and a height of a side of 10 cm is suitable not only for beds, but also for sofas, folding beds, couches. Maximum load on the berth 100 kg. Universal model, but with a low orthopedic effect.

How to care?

In order for the mattress to serve for a long time, it is necessary to properly care for it. Any model needs to be periodically turned from one side to another. This rule is relevant not only for models with different surface stiffness, but also for variants with the same degree of stiffness of both surfaces.Turning is necessary to restore orthopedic properties.

To extend the service life of the foam mattresses need to be ventilated. To do this, you must remove the product from the base of the bed and arrange it in such a way that the air access to both surfaces would be free. To remove dust from the mattress is better to use a vacuum cleaner.

In case of accidental spilling of any liquids, you can wipe off the stain with a mild detergent and dry naturally without using an iron or other heating devices.

Reviews

Most reviews of people who bought mattresses with polyurethane foam are positive. Many note the convenience of transporting such mattresses, thanks to which it is possible to save a certain amount. Most customers note that a slight smell when unpacking a new product evaporates quite quickly and does not appear during further use. Many agree that sleeping on mattresses with polyurethane foam is convenient and comfortable, there is no hammock effect, and the possibility of a suddenly stuck spring is also excluded.

How to choose the right mattress, see the following video.