Varnish for concrete: types and application

Today, concrete is used to design both residential buildings and for public and commercial institutions. It is used to finish the walls, ceiling and floor. Even despite the strength and durability, concrete needs additional protection and processing. For this special varnishes are used. Compositions for concrete foundations are used in the process of carrying out internal and external works. Lucky differ in composition, appearance and technical characteristics.

Benefits

Professional finishers have long used lacquers thanks totheir positive qualities.

- They are resistant to abrasion, are not afraid of constant loads and mechanical damage. Varnish is recommended to use on the basis of premises with high traffic.

- Flame retardant compounds protect concrete walls and floors from fire.

- The coating protects the base from the adverse effects of frost and sudden changes in temperature.

- Lacquering increases the durability and durability of concrete.

- High-quality varnish has anti-corrosion properties, is not afraid of high humidity.

- After coating, the concrete will acquire an attractive appearance, whether it is a colorless or colored composition.

- It is easy to varnish the surface. Simple operation has played an important role in the popularity of the products.

Spheres of use

Lacquer products are used in various construction sites and for processing such objects:

- in an apartment, residential building or country building;

- on the basis of storage facilities;

- buildings from the field of pharmaceuticals and industry;

- concrete fences;

- playgrounds, terraces and verandas;

- tracks and screeds.

This is the main list of the use of such finishing composition.

Kinds

The range of varnish for concrete is diverse.Each product has certain characteristics.

Experts identify several classifications, depending on such indicators:

- ability to reflect light;

- main cast;

- fire resistance.

Color and various additives

The first segment is divided into separate types depending on the aesthetic effect.

Varnish can be:

- matte;

- glossy;

- semi-matt;

- semi-glossy.

This criterion is chosen depending on the style of the interior, as well as the texture of furniture.

Varieties of compositions

The main aspect influencing the choice and classification of varnish for concrete is the composition. Most often, this is the main component with various additives that affect the texture, color, elasticity, resistance to the effects of the external medium, and other indicators.

The following varieties of concrete varnish are distinguished:

- Polyurethane composition. It is the best choice for processing surfaces that are exposed to moisture. The components will retain the practicality of the base with high dampness.

- Acrylic. This varnish has a high aesthetic properties. It is more often used not for protection, but for decoration.This material is notable for its considerable cost, especially if you compare it with numerous analogues.

- Silicone. The composition successfully combines increased resistance to moisture and decorative properties.

- Polymeric. Varnish of this type dries quickly and demonstrates excellent productivity in the design of large surfaces.

- Epoxy. Before using such a varnish, you must carefully prepare the surface. At the heart of - epoxy resin. These are two-component formulations that must be mixed before application.

On sale you can find a special alkyd varnish, but for processing concrete, it is usually not used.

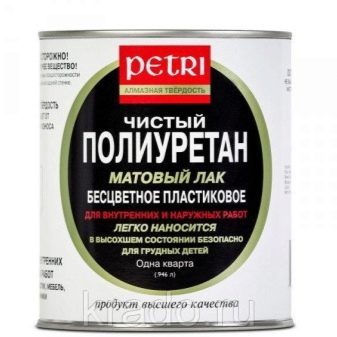

Polyurethane

Varnish of this class is the most popular and widespread when it comes to processing concrete. This material has a special property to penetrate into small cracks on the surface, increasing the protective properties. Experts recommend using such a varnish together with impregnation based on the same component.

Processing will prevent moisture from entering the top layers of the coating. The composition is ideal for use in areas such as garages, warehouses, shops, as well as garages.

Advantages of polyurethane varnish are - simple and clear use; attractive visual effect; high resistance to oil products; affordable cost; wear resistance and reliability; protective properties are preserved even with frequent wet cleaning.

Polymeric

Typically, the main component of such a material is styrene. Polymer varnish boasts excellent protective properties and other positive characteristics.

This finishing material has various features:

- Constant loads and pressure are not afraid of him. Layer retains strength regardless of external influence.

- Indicators of strength and durability of the concrete base increases significantly.

- High resistance to moisture and dampness.

- High degree of protection even in harsh conditions.

- The drying process takes a little time. With this varnish you complete the repair faster.

- The best price.

- Varnish can be used when decorating surfaces from the inside or outside.

- Corrosion protection.

- A stylish decorative layer is formed on the surface.

- Easy application.

- Low degree of abrasion.

- Resistance to various atmospheric influences.

Silicone and acrylic based

The above two varnish categories can be combined into one due to similar properties. The price of such material is much higher than the same expendable finish. The cost of one kilogram may be about 700 rubles. The high price is justified by applying a thin layer to the surface. A small amount of varnish is enough to protect the plane or concrete product.

Many buyers are attracted by the possibility of finishing, not looking up from the main works. After complete drying a thick matte film is formed.

Epoxy

Such varnishes are recommended to be used on the basis of such objects:

- Food industry buildings;

- Warehouses;

- Living spaces.

The material is used in areas where the smell of solvents is contraindicated during the finishing work. As an impregnating composition, such varnishes are somewhat inferior to polyurethane, since their penetrating power is lower. Despite this, epoxy varnish boasts excellent protective qualities. They will be quite enough to treat the surfaces of industrial and commercial buildings.

Advantages of epoxy varnish:

- favorable cost;

- excellent mechanical strength;

- health safety (due to the absence of hazardous components);

- remarkable light reflecting ability.

Experts point out the following disadvantages:

- material inferior in terms of elasticity;

- to make a product, it is necessary to strictly follow a special technique.

The above products (varnishes for concrete) are also used to process materials such as stone or hardboard. When choosing products make sure that it can be used on concrete.

Water based

Waterborne varnishes are rarely used for treating concrete surfaces, especially if a slope is made on the protective coating. Material is chosen for colorless decoration of products and planes. The certified water-based lacquer can protect the substrate from the damaging effects of the external environment.

How to apply?

Before using the varnish it is necessary to carry out the preparatory work. This process is necessary for the staff to lay down evenly and also seamlessly perform all the functions assigned to it. The work should be carried out in two stages. The first is preparatory, and the second is basic.

Training

In preparing the base, a number of actions are required:

- Clean the concrete surface. Delivering dust and other contaminants.

- If there are white marks on the surface, it is necessary to get rid of them by thorough grinding. Such a raid appears due to the accumulation of salts.

- Next is the primer. This will significantly increase the service life of additional processing.

Applying varnish

The main work on applying lacquer should also be done in several steps:

- Apply varnish on the prepared surface. To do this, use pussy of various sizes, roller or spray.

- Wait until the first layer is completely dry. The average drying time is approximately 2 hours.

- Only after complete drying (if required) the next layer is applied.

Remember: walking on the treated concrete floor is possible only after 5 hours. Use heavy and large equipment should be only a day after the application of varnish.

In the next video you will see a fragment of the process of applying a polyurethane matte varnish "Litapur 2KM".

Selection rules

When choosing a varnish you must adhere to several basic rules.

- Do not save on consumables. Purchase products from trusted and reliable suppliers. Certified product - a guarantee of quality results and long service.

- If it is difficult for you to make a choice among a huge range, pay attention to popular and popular brands. The trust of buyers earned the brands "Teksol" and "Tistrom".

- Each composition has its own expense. You need to know it to purchase the required volume of products.

- Pay attention to the technical characteristics: thermal protection, abrasion resistance, wear resistance, resistance to cold, moisture, heat. From the correct choice will depend on the service life of the treatment and its practicality.

- The external effect is also important. For some rooms matte texture is better suited, for others - glossy. Also, customers have the opportunity to choose semi-gloss and semi-gloss compositions. Matt varnish for exterior trim will make the exterior softer and more versatile, as well as create an excellent background for landscape design. While the glossy texture will attract the attention of the game of light and brilliance.