Yacht varnish for interior woodwork: features and application

Using wood, it is necessary to take care of its proper protection, since this material is too strongly absorbs moisture. Some use paint, thus limiting wood products from water and its destructive properties. However, this option is not suitable for those who wish to preserve the natural beauty of the tree. Most users want to get rid of the harm of water and not hide the color of real wood, and this way is the use of clear varnish. Such products are quite diverse, but it is yacht or, as it is often called, “ship lacquer”, which is especially popular.

Composition and properties

The presented varnish variant did not accidentally get such high appreciation due to its extraordinary durability in any unfavorable situations.This is not surprising, since it has to mainly protect the tree, which is regularly in contact with water.

This ship's lacquer does not do without:

- high quality resins;

- organic solvents;

- various specialized supplements.

This composition is made specifically for wood parts. Having appeared put on the destination, the listed substances together create a film of special durability.

The film, in turn, boasts a number of protective properties:

- It is not negatively affected by the sun.

- It is not erased for a very long time.

- She is not afraid of the effects of any chemical elements.

- With such a film, the wood is not in danger of even the highest humidity.

Notes on possible harm

However, despite the many positive qualities, the compositions have negative sides: they add toxic substances - toluene and xylene. The first, endowed with carbon and hydrogen, during its evaporation has a bad effect on the body, contributing to the appearance of irritation of the mucous membrane and dizziness.Evaporation usually occurs rather slowly, so the negative effect also lasts no less than long.

The second toxin is a pure benzene in its pure form, which is easily able to be in the human body not only when a person breathes. He is also available penetration through the skin. Xylene is often the culprit in the emergence of a large number of internal diseases, which include nervous system disorders.

Knowing all the shortcomings, we can conclude that yacht varnish should not be used as a means for indoor use to avoid health problems. It will be much better if the product becomes a protector of wood from the outside of the building.

Freedom from fear

Do not fear the use of yacht varnish, because today most of the manufacturers are seriously thinking about expanding their clientele and the health of people in general. Now the ship's lacquer is made with a solvent that is completely free of harmful substances, and it is called white spirit. Using this option, you will be able to protect yourself and calmly engage in internal work.Extremely positive reviews of real people have long managed to confirm that the modern deck lacquer does not bring anything but good.

Kinds

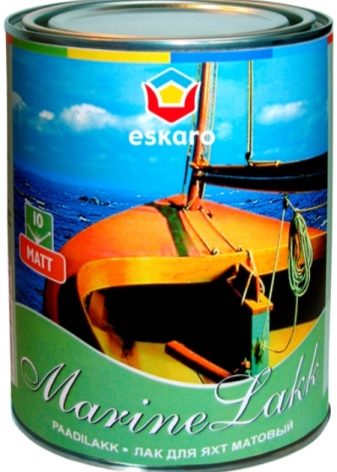

Distinctive signs of various models of the presented varnish consist in appearance and as a part of each of them. Appearance is divided into a matte version and gloss. Glossy lacquer makes the surface more specular and shiny. The tree treated in this way looks great, but this beauty will not last long if the product is not properly maintained.

For those consumers who have practicality in the first place, a better solution would be to opt for matt varnish. The latter type is not able to make the surface shiny, but due to its properties, dust and dirt will be much less noticeable, therefore, it is several times easier to care for matte wood.

For external works

The compositions of deck varnishes differ somewhat among themselves, therefore for the sake of convenience of choice they are divided into types.

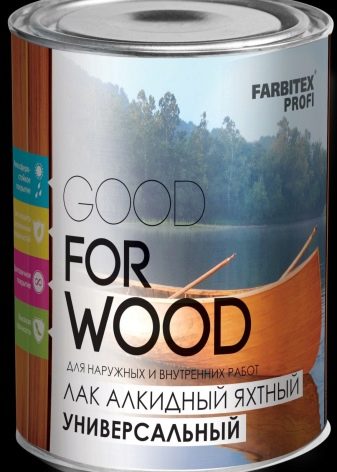

- Alkyd This type is quite inexpensive, and partly due to this factor, products are very widespread among the mass consumer.Despite its price, it is very resistant and well penetrating wood. The downside is the presence of toxic substances that evaporate for too long. For use in rooms where there are people or animals, alkyd varnish is prohibited.

- Alkyd-urethane. This composition has an increased level of alkyds, which help the lacquer to remain in a weather-resistant state for a long time and dry quickly (in about six hours). However, this option is not less toxic, so it can not be used for residential buildings. When working with him should stock up on items of protection during construction work, in order to avoid poisoning.

For interior work

Such varnishes will cost more, but also do not harm health.

- Urethane-alkyd. Urethane plasticizer does not allow toxins to evaporate, and also improves the durability of the lacquer film, which is formed after use, helping not to react to temperature changes. Accordingly, this varnish is excellent for the home, because they can protect even underfloor heating.

- Acrylate. The basis of this type is water, making it minimally toxic.The environmental friendliness of the lacquer composition greatly elevates its cost, but also eliminates any risks when used in absolutely any room, except, for example, a wooden vessel, since a harmless base is not capable of providing high water resistance.

Application technology

It is quite simple to varnish wood surfaces, but good quality requires increased attention to various details. It is not necessary to be a professional to achieve a decent result.

It is enough to study a small instruction and follow the instructions exactly:

- Varnishing a product that was once subjected to a similar operation requires prior removal of the existing layer. Otherwise, we should expect the swelling and crackling of the new varnish.

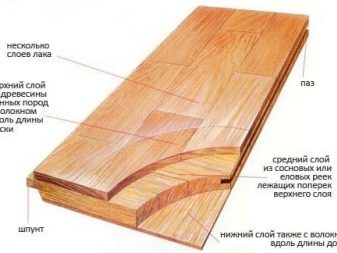

- If everything happens for the first time, the wood will definitely need to be dried so that its moisture does not exceed 20%.

- Primer dried surface also does not hurt, but you should choose one where there are no antiseptic additives.

- A layer of proper strength can not do without processing in a couple of varnish layers with a roller or brush.

- The initial layer is applied along the wood fibers.The second - only after complete drying of the first and third - across the fibers.

- The second layer is applied in about six hours, and the third - in a day.

- Giving the product a specific desired tone is also possible if it is diluted with a suitable color that is compatible in composition;

- Use the room preferably after 48 hours.

Other applications

Yacht lacquer often began to be used to protect ordinary household items, among which the most common:

- wooden floors;

- furniture, usually located in the garden;

- wood trim in the house.

Today, special cans or spray cans are used to store and sell ship lacquer.

The decision to use such varnish requires each buyer to carefully examine all the recommendations and warnings of the manufacturer indicated on the packaging. Only in the case of a correctly selected option, it is possible to obtain a suitable final image of the product.

How to restore the lacquer coating, described in the video.