Natural drying oil: properties and features of application

In Soviet times, linseed oil was practically the only means by which wooden surfaces and structures were treated. Fans of this material have remained to this day.

Drying oil is a film-forming paintwork substance. based on natural oils or heat treated alkyd resins.

It reliably protects wood from rotting and fungus, and is also used for the manufacture of oil putty and paint.

Types, composition and properties

Nowadays, many homeowners seek to protect themselves and their households from unnecessary chemistry. In this regard, linseed oil is considered to be a unique material! More than 90% of its composition accounts for the components derived from the seeds of flax, hemp, sunflower or rape.The remaining 5% fall to the share of synthetic compounds, but their amount is so small that they can not have any adverse effects on humans. Moreover, the lower the percentage of synthetics in the linseed oil, the longer the wood product is used after processing.

When choosing a varnish, by all means focus on its composition - the more natural components it contains, the more protection wood will receive.

In the old varnish called “boiled butter”. Today the technology of its production practically does not differ from the “ancient” methods. However, the variability of the composition led to a large number of varieties of varnish with a variety of properties.

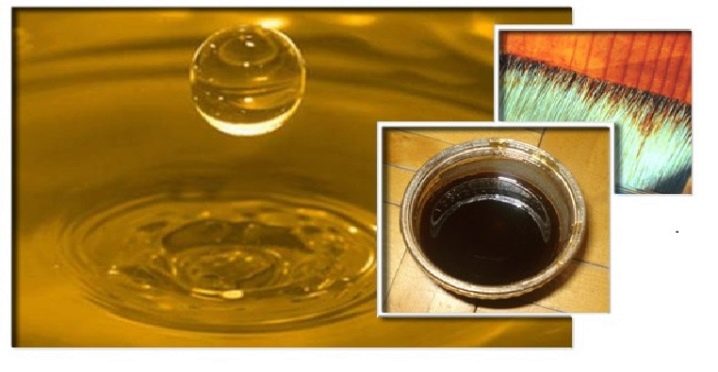

Oil drying oils are made from vegetable oils with the addition of special substances.causing acceleration of their drying - sukkativs. For this purpose, compounds of cobalt, lead, strontium, zirconium and iron are used - the name of these elements is doubtful of their safety for human life and health, however, their share is negligible, so you can not be afraid of the negative effects on the body. But if you want to be safe,then give preference to cobalt formulations - this metal does not adversely affect the physiological processes of the adult and child organisms. You can also purchase the composition without additives from 100% oil.

The desiccant absorbs oxygen from the air, thereby oxidizing the oil. Moreover, after it dries, oxidation reactions do not stop, which is why the proportion of such additives is extremely small, otherwise the coating darkens quickly and becomes brittle.

Drying linens with and without desiccants have some differences in their operational parameters:

- Oil varnishes harden for 24 hours, and in the hot season they need 5 hours to form a dense protective film. Drying oil without dryers dries for 5 days, keep this in mind when planning repairs in the house.

- The composition without a desiccant penetrates deeper into the wood fibers and in the future more reliably protects it from moisture ingress and mold. Compounds with additives are not so deeply absorbed, and in the future the film may crack and peel off.

The performance characteristics, in particular, the rate of drying, are also affected by the oils used for production. The linseed linseed oil and hemp oil harden the fastest. This is due to the large amount of polyunsaturated acids in their composition (the iodine number indicator is 175-204 for the first and 145-167 for the second). Sunflower oil dries much slower, therefore, in its composition there are always desiccants in small amounts, but the olifes from nut and poppy seed oil without additives will take quite a lot of time to set. Castor, olive and surpoly linseed oil will not harden at all without desiccatives, it will only thicken without forming the necessary film coating - the iodine number of the oils in their composition is negligible.

To speed up the rate of drying, manufacturers have produced a series of drying materials based on synthetic components.

The combined compositions are most close to oils - they consist of 2/3 of oil and 1/3 of white spirit or other solvent. These mixtures are characterized by lower cost and high speed of solidification, therefore they are widely used for exterior facade work.By the way, contrary to popular belief, the combined drying oils have almost no sharp odor.

When a large amount of additives is added to the oil, linseed oil is obtained. Its composition contains oil (55%), white spirit (40%) and desiccant (5%). Oksol has a good rate of hardening, but it has a pungent chemical smell that does not erode for a long time.

Oksol in appearance is no different from the natural, but its price is significantly lower than oil formulations.

Distinguish between B and PV mark. Drying oil B is made using linseed or hemp oil; it has found its use in the paint industry for the breeding and production of facade paints.

For the manufacture of oxol VP use sunflower, safflower or corn oil. This composition is popular due to its extremely low cost. However, its performance qualities leave much to be desired - such an oxol does not create a durable and durable coating, therefore its use is limited to the dilution of paints.

It is not recommended to use it to cover wood products.

Another type of drying oil - alkyd. They are made from resins diluted with solvents and modified oils. By analogy with oil linseed oil, driers are added, as well as white spirit. Such compositions are more economical than oil, because in order to produce 1 ton of alkyd drying oil, only 300 kg of oil are required. This significantly reduces the cost of the product, but makes it unsafe to use inside premises.

In addition, alkyd compounds are resistant to the negative effects of the external environment, temperature and humidity, they are resistant to direct ultraviolet rays. Such linseed oil is recognized by consumers as the most optimal in terms of price / quality ratio.

Separately in the assortment of drying oil are synthetic brands. They are made from petroleum products, they are not covered by GOST 7931-76, they are manufactured according to TU. They harden for a long time, smell unpleasantly, and after hardening they give a glassy fragile film.

Such compositions are usually used to dilute enamels.

Advantages and disadvantages

Oil linseed oil has a number of undoubted advantages, due to its technical parameters:

- the share of oil and additives is 97: 3;

- drying speed does not exceed 24 hours at an air temperature of 20-22 degrees Celsius;

- density - 0.93-0.95 g / m3;

- sucks - no more than 0.3;

- acid number - 5 (mg KOH).

The advantages of the material are obvious:

- Natural drying oil has practically no solvents, so it does not give a strong odor and is considered safe for the health of children and adults.

- The oil components penetrate deep into the wood fibers, thereby increasing their lifespan by several decades, even if the surface is operated in conditions of high humidity.

- Impregnation with natural linseed creates a film that protects the wood from fungus and rotting.

- The use of natural and affordable raw materials makes drying oil not only environmentally friendly, but also a cheap material, proving its effectiveness for many years.

- The use of linseed oil at the stage of preparation for finishing finishes leads to savings in the consumption of materials for painting.

The disadvantages of many include the speed of drying - after processing the surface dries during the day, so the repair work stops.

Manufacturers

Very often, from people who have covered varnish with plywood, window frames and other surfaces, it can be heard that it hardens for too long. Experts say that if the material does not dry out within 24 hours at room temperature and humidity up to 60%, then most likely it is a low-quality product, an oil mixture, sold under the guise of natural drying oil.

A dry compound is a marriage or a fake.

In order to avoid unpleasant consequences associated with the acquisition of inappropriate composition, buy products from proven manufacturers.

High-quality drying oil in Russia is admitted:

- Ufa paint factory;

- Kotovsky paint and varnish factory;

- Perm paint factory;

- Management Company ZLKZ;

- Azov paint-and-lacquer plant "Divo";

- Bobrovsky experimental plant.

Very well proven linseed production of the Estonian company Vekker.

Thanks to exceptional quality, its scope has gone beyond the construction industry. This composition is widely used by painters to create and restore icons.

How to choose?

Before you buy a linseed oil, it is worth looking at its color and texture. Normally, the shade varies from yellow to dark brown. In the solution should not be observed suspended particles, delamination and lumps.

The label always indicates the number of GOST or TU, if you buy a composite linseed oil, the name and address of the manufacturer, the composition and technology of use.

As for the applications of different types of drying oil in the repair work, then follow the simple rule: for external coatings, combined formulations with an oil content of up to 45% are suitable; for internal coatings, an improved brand in which the percentage of natural ingredients is 70 and above is preferred.

Can I do it myself?

It is possible to make a varnish with your own hands at home. For this, as a rule, use sunflower and linseed oil.

The production will require a metal container, a heating device, manganese peroxide, rosin, as well as personal respiratory and skin protection.

The technology of making drying oil is simple, but requires caution and compliance with safety regulations.

Oil is poured into a container and heated to a slow fire to a temperature of 110 degrees.

At this point, evaporation of water will begin, which is visible to the naked eye. Oil should be boiled down within 4 hours. During this period, you must ensure that the temperature does not exceed 160 degrees. After the required period of time, a siccative is added to the oil (it can be made from rosin and manganese peroxide in a ratio of 20 to 1) at the rate of 30 g of substance per 1 liter of oil. The mixture should boil for another 3 hours, after which the linseed is considered ready. Willingness, by the way, is checked very simply - a drop of the composition is placed on the glass, and if it is transparent, then the linseed oil is ready.

When adding a desiccant, there is increased foaming and flocculation, to reduce the intensity of this process, you can add a little ready-made drying oil to the container.

In the next video you can see how to make natural linseed oil linseed oil at home.

Application features

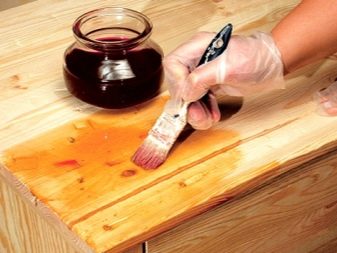

In order to apply the linseed oil does not require special construction skills.

The technology is extremely simple for both repair and artwork:

- Before applying, the treated surface should be cleaned from traces of old coatings, grease and dust;

- The surface should dry out, as using the composition on wet wood does not make sense;

- Coating requires a roller or a brush — large, even surfaces are treated with a roller, and small elements and corners with a small brush;

- To achieve the desired result, one or two layers are enough.

Some tips:

- Thickened drying oil can be diluted with a solvent or nefras.

- Before use, the drying oil should be thoroughly mixed. This gives the structure an increased saturation with the necessary oxygen.

- When carrying out interior work it is imperative to ensure maximum ventilation. It helps to reduce the time of drying and weathering unpleasant odors.

- When working, protect your hands from getting into the substance. If you are still dirty, moisten the skin with vegetable oil, and then rinse well with running water and soap.

- Remember that linseed oil is highly flammable, so keep it in places inaccessible to sparks, do not carry out welding work and do not smoke near the treated surface.