Liquid sodium glass: what is it used for?

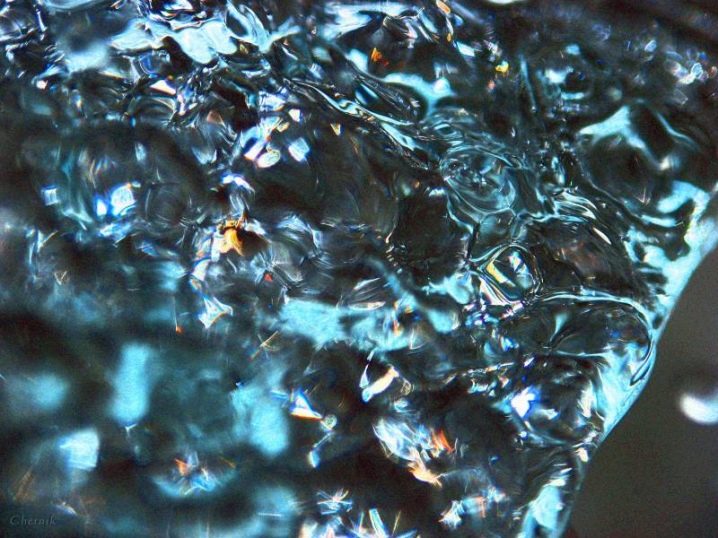

Liquid sodium glass is a proven tool with high adhesive qualities and not losing its relevance for a long time. The use of this inexpensive universal material allows you to quickly and efficiently waterproof structures, strengthen concrete screeds, clean household utensils.

Liquid sodium glass is a kind of adhesive composition.which is widely applied when carrying out construction and waterproofing works. The basic component of the material is sodium silicate, the presence of which is due to the high performance properties of the solution.

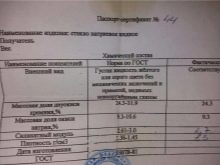

Technical specifications

Liquid sodium glass is produced in accordance with GOST 13078 81.It consists of oxides of sodium, iron, aluminum with the addition of silicon dioxide, sulfuric anhydrite, caustic soda and silicate module. The presence of sodium in the composition is determined by 9%, the potassium values are much lower, they are about 0.2%. The time of complete solidification of the composition used in its pure form is 10 minutes, while as a part of various solutions the time increases to two hours.

The density of the material is 1.45 grams per cubic cm, the specific gravity of the substance is 1.45, the shelf life is 2 years, and the melting point corresponds to 1088 degrees. Unlike potassium compounds, sodium solution is able to form a more stable and durable joint, which distinguishes it from other silicate mixtures.

The manufacture of liquid glass is a rather complicated process and consists of several stages. Soda, potash, sodium sulfite and other components are added to the crushed quartz sand. Then the mass is placed in autoclaves and smelted in the form of a monolithic ingot, which is subsequently dissolved at a temperature of 170 degrees. The resulting solution is a liquid sodium glass.

Application area

The composition is widely used in the repair and construction. Its addition to plaster and putty solutions multiply increases their fire resistance, strength and moisture resistance. Means eliminates cracks, chips and other defects of floors and walls. The material is well established and as an additive to primers for various purposes.

Especially effective priming such mixtures of concrete screeds. The use of sodium glass significantly increases the strength of concrete, giving it fire-resistant and antiseptic properties. With the help of sodium glass, you can easily remove old paint or oil coating. And the addition of a variety of dyes allows you to use the tool as a silicate paint.

The mixture can also be used to prevent corrosive processes on metal substrates. For the preparation of anti-corrosion composition of the cement is mixed with sodium glass in a ratio of 1: 1 and pour a small amount of liquid. The material tolerates aggressive environmental effects and can be used not only indoors, but also outdoors.This allows waterproofing of wells, water tanks, bowls of artificial reservoirs and basements. For the work takes 10 parts of concrete and one part of liquid sodium.

The structure was widely used as an additional component to masonry structures. It is often added to the facing solutions intended for exterior decoration of fireplaces and stove flues. In everyday life, liquid glass is used to repair aquariums and clean household utensils. To prepare the cleaning solution, it is necessary to mix 25 parts of water and one part of sodium silicate. The resulting mixture should be poured into a large container. Then you should put there the dishes you want to clean, and boil the composition.

Soda glass can be applied to putty damaged sections of water supply, remove grease stains from clothes and as an additive in lime, intended for finishing any surfaces. When lime and sodium silicate are mixed, a highly durable material is formed - calcium silicate, which significantly increases the resistance of the limestone coating to external factors, and significantly prolongs the service life of the limestone coating.

Benefits

The popularity of liquid sodium glass, both as a fixed asset and as an additive in various construction solutions, is due to a number of positive material properties.

- Good elasticity of the composition allows to use it as an additive for concrete solutions. The material penetrates any, even the smallest cracks and fills them, thus preventing the appearance of voids and cavities in the formed concrete layer. In addition, the overall strength of the concrete pavement is significantly increased.

- The optimum ratio of price and quality. The cost of 5 kg of the mixture is about 200 rubles, which significantly increases consumer demand and the use of material in construction.

- Sodium glass has high strength. It is resistant to chemicals and extreme temperatures.

- The material significantly reduces the time of complete hardening of the cement, so that the repair time can be significantly reduced.

- Low thermal conductivity of liquid glass allows the use of a means to create insulation of premises. The composition perfectly withstands temperature jumps up to 1200 degrees and is able to withstand numerous freeze-thaw cycles.

- Full environmental safety of the material due to the absence in its composition of toxic and toxic substances. Although it is worth remembering that alkali, which is one of the components of the solution, is dangerous for the skin during the installation phase. Therefore, when working with liquid glass is necessary to use protective gloves.

- The tool has a pronounced antiseptic effect, so there is no risk of mold, fungus and pathogens on the treated surfaces.

The disadvantages of liquid glass include setting and hardening too high.and the undesirability of using the material for the treatment of surfaces intended for painting.

Instructions for use

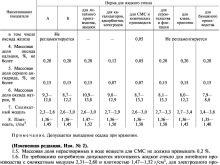

In order to properly prepare the mortar with the addition of liquid sodium glass, it is necessary to observe the proportions:

- in concrete solutions, the amount of liquid glass may be 5-20% of the total mass of the composition;

- to obtain a refractory composition requires one part of cement, three parts of sand and 10-25% of liquid glass;

- priming mixtures consist of cement and sodium glass, taken in a 1: 1 ratio,and diluted with liquid to the desired consistency;

- 400 g of silicate glass and 1 liter should be taken for antiseptic base treatment. water;

- when using the product as an adhesive for linoleum, the material consumption should be 200-400 g per square meter of base;

- for the preparation of waterproofing mortar cement, sand and silicate glass should be taken in equal quantities.

Work on silicate glass should be carried out in a well-ventilated area. using personal protective equipment. In case of contact with the skin or mucosa, immediately rinse the contaminated area with plenty of cool water and contact a medical institution. In order to avoid fakes, you should buy the composition only from reliable manufacturers. It is also advisable to check the availability of certificates of conformity and other supporting documentation.

Reviews

Liquid sodium glass is in high consumer demand and has many positive reviews. Buyers note the affordable cost of the material, which allows it to be widely used as an additive in various construction and priming solutions,so as an independent means. Attention is drawn to the ease of preparation and ease of application of the composition. The excellent waterproofing properties of sodium glass are also highly appreciated, which makes it possible to carry out hermetic lining of basements and swimming pools. Cons of the buyers include the need for rapid use of the composition due to its short "viability".

In more detail about nuances of work with liquid glass it is told in video.