Cork compensator between tile and laminate: application features

If you are going to change the floor in the room, prepare in advance for the fact that the problems of joining different surfaces can not be avoided. Even the same materials must be joined together in order not to spoil the general appearance of the repair. Many do not want to make joints using the nut, and the installation of liquid materials is impossible without special skills. The best choice in this situation are cork compensators that perfectly complement any interior.

Features and benefits

Having decided to close the transition without a threshold, you will encounter a problem - the movement of two facing materials. This is especially true of the laminate.That is why most people opt for sills with gaps and seats for joints.

Modern manufacturers offer a large selection of profiles, which differ in the material of manufacture, price and properties. Among the technologies without sills, the best choice is a cork compensator. It has an affordable price, easy installation and high quality.

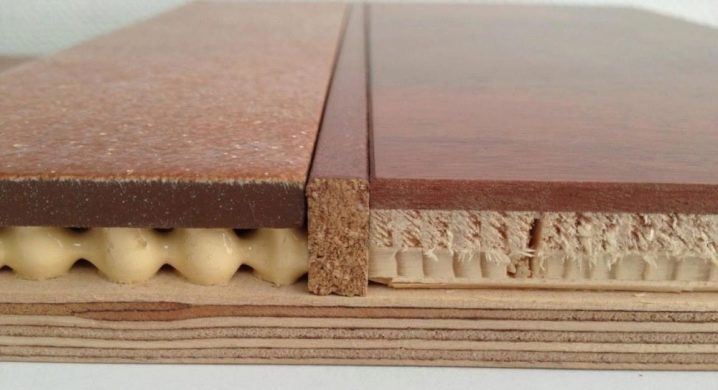

Cork compensators are widely used to design the joint of the laminate with other materials., for example, with floor tiles. The device is a strip of cork, which is attached to the joint. After that, it is polished with parquet and covered with a protective varnish. Dust and dust accumulate in large quantities on unprotected cork material. Also, over time, it often begins to deteriorate and crumble. Therefore, experts recommend not to ignore the moment of varnishing.

On the market compensators are presented in different colors. This allows you to choose the best option that fits perfectly into the interior of a particular room or other room.

The compensator is produced in the form of sheets. The buyer independently cuts a strip of the necessary width. All you need is a ruler, a pencil and a sharp knife.

Unlike rubber parts and silicone, the compensator does not surely harden for the whole period of operation. Another distinctive characteristic of such a connector is its elasticity. As the laminated board is compressed and unclenched during use, the compensator must also be elastic.

Regardless of the board changes, the cork will constantly take on its original look. Rubber elements do not have this property.

The undeniable advantage of using cork between tile and laminate is the ability to easily give it any shade using tinting. An important point is also the environmental friendliness of the material. Thanks to this cork can be safely used in residential areas.

Independently install the cork compensator is a snap. If you choose the right size, installation will take a minimum of time. With the same ease, even a beginner will be able to dismantle a part without making much work to do.

The parameters of the compensator may be different:

- standard length - 900 mm, the maximum length of products under the order is 3000 mm;

- width - 7 mm and 10 mm;

- minimum height - 15 mm, maximum - 22 mm.

Material having a standard length is appropriate to apply if the joint is located under the door. In this case, this size will be quite enough. In other situations, it is necessary either to connect several compensators to each other, or to make an individual order.

Installation requirements

Specialists have strict requirements for the transition between tile and laminate.

Only taking into account all the nuances you can achieve an excellent result:

- The edges of the slab and laminate should not be flawed.

- Laminate does not tolerate exposure to high humidity, so its edges should be treated with special substances.

- If the tile keeps within the cut side to the joint, it is polished.

- The compensator is cut to height. This process is influenced by the thickness of the materials used. For example, if a material of 12 mm is laid and a substrate of 1 mm, the material with a construction knife is cut to 13 mm in height.

Laying technology

There is an opinion that the tile is first laid, then the compensator is installed, and only after that it is worthwhile to start laying the laminate.This order of procedures is incorrect, since the thickest material is always mounted first. It depends on it the final level of the renovated floor.

In addition to facing materials, do not forget to buy a sealant and strong glue (for example, liquid nails). Sealant is needed in order to hide the small bends of the slab or laminate.

Choosing a color, stop on the one that will match the tone of the floor covering.

The compensator between the plate and the laminate fits while observing a certain sequence of actions:

- Clean the floor thoroughly from dirt and dust.

- Apply a thin strip of glue near the edges of the cladding material.

- Lay the compensator on the glue and fix it with the end.

- Lift the strip from the laminated edge and fill with a little sealant. This will allow to hide minor flaws, as well as glue the strip to the panels.

- Remove the sealant between the compensator and the laminate with a wet sponge, and then wipe the surface with a dry cloth.

- Start laying tiles. To do this, use a special glue, not forgetting to put the material level.

The maximum standard length of the compensator is 0.9 m.Accordingly, several bands are used for joints with a greater length, which is why additional joints will be formed.

Cork compensator is also used for curved joints. It is flexible, so there are no problems with its installation. But note that over the entire length of the transition the thickness of the gap should be the same. So cut tile and laminate with maximum precision.

When is a liquid tube used?

Also, manufacturers offer a compensator in the form of a liquid mixture. The liquid tube between the two facing materials allows the coating to move freely. The increase and contraction of the laminate does not affect the appearance of the surface.

Liquid cork is used to close gaps in the parquet, remove squeak and resume the original type of floor. It is successfully used not only for parquet, but also for places where it is necessary to install protection from noise and high humidity, retaining heat.

Special skills for working with a liquid tube will not be needed. The main thing is to adhere to the basic requirements (clean the surface from dirt and dust, dry it and treat it with a primer).

However, the liquid tube has disadvantages.After her laying in the room you have to do spring cleaning.

In addition, it is necessary to work with this material very quickly due to the high speed of its drying.

Famous manufacturers and price category

In the modern market, cork compensators from the companies of Russia, Germany and Poland are the most popular. Among the manufacturers of liquid compensators, French brands have superbly recommended themselves.

Elements of cork trees, which are grown on plantations of the Mediterranean and the Caucasus, are used as raw materials.

The price of such seals is not too high:

- The cost of the compensator varies from 100 to 150 p. a piece. The price is more affected by the size of the threshold.

- Leaf compensator is estimated at 1000 r. for one sheet.

- 0.5 l. liquid plug costs about 180 p. In this case, the cost affects the manufacturer and the region.

Choosing such materials, do not forget about safety. Natural wood and chemical compounds that permeate the material are highly flammable. When buying building materials, be sure to read the documents confirming the authenticity of the goods.Prefer options from reputable manufacturers.

How to make the perfect joint between laminate and tile, see the following video.