Features and basic rules for the installation of entrance gates

Wikipedia defines the gate as an opening in the wall or fence, locked with an interior door. Gates can be used to prohibit or to limit access to any territory. Another option for their purpose - the decoration, showing the passage, that is actually an arch.

Everyone knows that the gate is installed as part of the fence or the wall, and it is also possible that they can completely replace a wall (for example, a garage).

Gates are used to pass vehicles, thus, they can be designated as entry or exit.

Kinds

A huge choice of options offered in our time, universal lifting and lowering, sliding, automatic and other designs,A wide range of types and types of plastic, metal, wood and automation, which controls the gate, can often be stumped when choosing them.

Perhaps today the most relevant is the division of several types of gates.

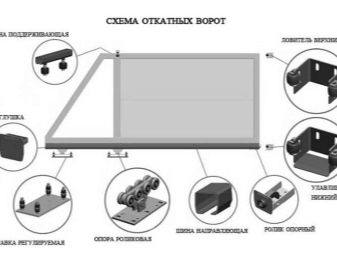

Retractable roller

Use: industrial hangars and other buildings, villas, country houses, estates.

The device: the sliding plane / leaf itself, the support beam, the runner rollers and the support columns.

The principle of action: the canvas / sash, mounted on a bracket beam, slides on the rollers.

In turn, the gate is divided into two types:

- open (the guide is located below) - it is used when the door is blind and for doors with glazing, with the upper edge of any kind;

- closed (the guide is located at the top) - applicable if increased aesthetic requirements are imposed on the appearance.

Pros:

- You can embed a window or gate / door directly into the leaf / sash;

- the opening is unlimited in height;

- shutters practically do not require a place when opening / closing;

- resistance to cracking;

- windproof.

Minuses:

- space is required to place the leaf in the extreme right / left position when the gate is opened to its maximum width;

- relatively expensive to acquire.

Swing

Usage: private plots, industrial and social facilities, farm building.

Device: mounted, double-leaf, with support on the hinges of metal, wooden or reinforced concrete pillars / bars.

Principle of operation: the gate is hinged clockwise / counterclockwise.

Pros:

- high availability;

- very easy to make and assemble;

- high protection against hacking;

- You can embed a window or wicket directly into the door leaf.

Minuses:

- sashes take up a lot of free space when opening / closing;

- sash may suffer from strong winds;

- low explosion protection.

Rolled

Use: as temporary partitions / walls in shopping centers, enterprises, as light gate.

Device: narrow horizontal lamellae with profiling, flexibly connected by long sides. The connected fragments are narrower than those of the sectional type gate; therefore, it is possible to use the shaft for raising / lowering them.

Principle of operation: the leaf / sash rises along the vertical iron guides and is wound on a shaft located in a protective box above the gate.

Pros:

- very convenient for rooms with a small height of the walls;

- it is very easy to mount and adjust later;

- much useful internal space is released.

Minuses:

- relatively frequent breakdowns;

- low thermal insulation characteristics (many gaps in the leaf / sash);

- high level of anti-theft features.

Sectional

Use: used in large industrial and commercial buildings and structures because of the ability to apply and regulate large-sized casement for the passage of trains, oversized trucks, platforms and so on.

Device: sets of polyurethane foam (sandwich) sandwich-panels of considerable thickness. In general, the leaf / sash has flexibility due to the fact that the panels are held together by hinged joints. Sealed due to the use of thermal and moisture resistant seals.

Principle of action: the canvas slides along the guides with the help of rollers and is placed under the ceiling parallel to it.

Pros:

- do not require free space around the opening;

- thermo- and wind-resistant according to these parameters are equal to a brick wall 30 cm thick;

- there are almost no restrictions on the choice of sizes;

- If desired, a window or wicket is built into the door leaf.

Minuses:

- require significant dimensions of the room to place the canvas under the ceiling with the door open;

- high price;

- difficult to install due to the large number of moving parts;

- require significant strength of the aperture structures (concrete, or steel) due to the considerable own weight.

Installation instructions

The difference between the most popular types of swing and sliding gates with us today is visible to the naked eye - the first hold the palm because of the greater degree of simplicity of their model, installation and production. Meanwhile, creating a sliding / roller door with your own hands, you can get a lot of advantages compared with a swing-type gate.

If you have decided to install the sliding / roller gates on your own, we will focus on installing and using just such a gate.

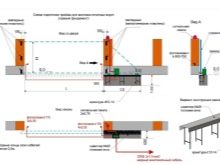

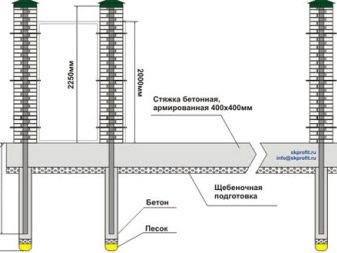

- Supports are installed, which are made of channel, steel pipes, concrete, reinforced concrete, brick, bar of wood.The level of freezing depth is taken for reliability equal in our latitudes to one meter. Accordingly, the work consists of digging a hole to a depth of 1 m or deeper, then the column installed in it is concreted.

The curing time of the concrete mix is about 7 days.

- The next stage is to fill the foundation. The most commonly used channel beam is from 16 to 20 cm in width and steel bar, which is used as reinforcement, with an external diameter of 10-14 mm. From it do pieces of 1 thousand mm and weld with channel regiments of supports.

- A moat is dug out at half the distance between the supporting pillars. Dimensions 400x1500 mm depth, the channel is installed in the opposite way (shelves down) and poured concrete mix. If the distance between the supports is 4 m, the length of the base of the gate will be 2 m.

- The correct upper surface of the channel must be flush with the surface of the coating in order to correspond to the level of the upper surface of the further coating. Subsequently, the carriage rollers are welded to this level area.

- Standing pouring the foundation for at least a month ideally.

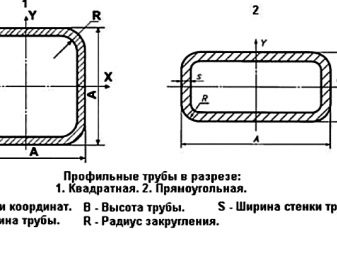

- Frame pipes are subjected to the procedures of degreasing and priming, using a spray gun, brushes, sponges.Their diameter can be different, you can use what you have on hand, what you like more or cheaper. An outer frame is welded from this material.

- Then the internal structure is mounted by means of welding. It will serve as a solid basis for fixing cladding (corrugated, siding). Welded it from a pipe 20x20-40 mm. The joints of the facing should be placed in such a way that they dock with the crate. Pipes grab 2 cm in increments of 20-30 cm. A guide is welded to the bottom of the finished frame. Everything is mounted in a checkerboard pattern to avoid losing the shape.

- The next stage is recommended cleaning of welds with a grinder and re-priming of those parts where the integrity of the primer is broken.

- When painting it is recommended to apply at least two layers with intermediate drying.

- After the pipes are completely dried, the gate frames are transferred to sewing the fabric itself. As a standard fixture fixing use screws or rivets. For the least labor, it is advised to use improved self-tapping screws with a drill at the end and a drill. In this case, it does not require large time costs.

After complete hardening of the concrete base begin directly the installation of the gate. First, rollers are welded to the channel foundation channel, placing them at the maximum possible distance. One should not forget that its diameter is approximately equal to 150 mm, therefore the carriage nearest to the aperture is slightly moved away.

Then the frame is installed on the rollers, the gate is set using the level, grabbed to the channel bar. If there are inconsistencies, they are corrected, the gate is re-set, when the desired result is achieved (position, absence of distortions, etc.) scrape the carts.

How to install by yourself?

Any installer will be able to mount and install the swing gates independently in various ways. Classification can be made according to the method of installation and installation. Accordingly, the service life depends on the method or method. Note several characteristics and indicators.

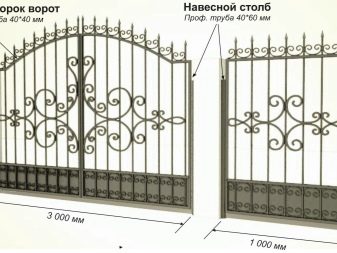

Today the highest demand is used swing doors, sheathed profiled. They are mounted in country houses, in country estates, on sites. Before installation, it is necessary to decide which material of the pillars should be preferred for the overhang of the valves, since the entire workload will fall on them.

Stands for swing gates can be made of wood, reinforced concrete, or metal.

If the swing gates are made of wood, they have a relatively low weight, the shutters are hung on metal poles, which hold the structure fairly tightly, and it is also possible to replace them.

The gates are mounted on metal poles with a section of 60 × 60, or 80 × 80 mm.

Useful life hack: not everyone understands the difference between the concepts of “pipe section” and “pipe diameter”, which results in many errors when using these two completely different, albeit interrelated concepts.

There is a formula for calculating the section.

If the support pipe is conventionally taken as a cylindrical figure, then in order to obtain the cross-sectional area, the classical planimetric formula for calculating the area of a circle is taken.

When the outer diameter and wall thickness are known, the inner diameter is calculated:

S = π × R2, where:

- π is a constant equal to 3.14;

- R is the radius;

- S - pipe section area for internal diameter.

From here is taken: S = π × (D / 2-N) 2, where:

- D is the external section of the pipe;

- N is the wall thickness.

Iron / metal / steel pill blocking has several positive sides.

The recommendations are as follows:

- profitable economically, because it does not require a long time;

- there is the possibility of replacement and repair;

- poles can be installed independently.

- metal poles driven into 1.5 m, constantly checking the level;

- among themselves they are connected by a temporary bar.

- welded frameworks of valves.

If the soil at the installation site is unsuitable for simply driving the pipe into the ground, there is a way to further strengthen the base using reinforcing glass.

In this case:

- drill a hole at least 200 mm in diameter;

- in addition, a so-called reinforcing glass is sometimes used for reinforcement;

- put a support in it, level it on level;

- the concrete is poured into the holes with a layer of 1.5 m deep.

When hanging the valves, the distance is left, as the ground shift is not excluded., which may lead to a change in the position of the pillars. To prevent such a shift is only possible with the help of a frame fixing the frame of the door around the perimeter, and this, in turn, can lead to inconveniences during operation, for example, limit the height of the vehicle.

The next important point affecting the usability of the gate is the side of opening the sash, namely: which way the sash will open.

To save space, the courtyard is made to open the door to the outside.

Structurally, swing gates are divided into double and single leaf. And it also makes sense to insert a gate into the casement; in this case, you will not have to create a gate separately, which will save time and materials.

From an aesthetic point of view, the choice of the external attractiveness of the gate for the owner. Sash can be closed professional sheet, openwork, forged.

Automation

Advanced opening / closing systems using automation systems are widely used. This will concern the setting of almost any type of gate - swing, sliding, roll, sectional.

This can be very useful electric drives. If, in addition to the electric motor, using the installation cables, install the control unit, the antenna and the electromagnetic lock, the automatic gates will turn into a completely modern complex. In addition, the undoubted convenience of automation lies in the fact that in our time there is absolutely no need to leave the car in rain or snow, in the cold season or in the heat.It is enough to program the key fob and set the automatic gate system to its signal.

Conveniently, the power supply to all these devices is supplied from a standard household AC mains 220V.

Special features

Each type of gate has its own characteristics, due to the specifics of their use pattern, on the one hand, and convenience, on the other.

For example, sectional doors will be more convenient than hinged economy of free space below, but will require for installation them parallel to the ceiling a considerable depth of the garage or other room where they are used. They do not limit the width of the opening in which they are used. With the help of rollers on ball bearings, the lifting and lowering of the leaf of such gates is very easy, especially if torsion springs are used.

Sliding gates do not impose requirements on the height of vehicles passing through them, but you will have to think about the distance to one side or the other from the opening to place the leaf / sash there in a fully open position.

Manufacturers

Barriers, electric drives with modern installation of cable tracks for various rolling gates, as well as roller shutters Came, Nice, Game have long and firmly gained popularity in the Russian market and are in great demand because of their reliable connection and high quality workmanship, as well as the ability to adjust and programming remote control devices.

According to some reports, many companies are represented on the Russian market.producing fabrics and mechanisms for mounting sliding / sliding and sectional doors. Currently, DoorHan (Russia) is in the conditional second place at the moment according to the results of surveys and marketing data. First of all, this is achieved by low prices for high quality products that DoorHan can afford. A big advantage is also the availability of spare parts on the Russian market.

Of course, it is impossible not to say about the manufacturer’s cons: low corrosion resistance and a small margin of safety. This leads to forced repairs and ongoing maintenance.

Increased air humidity and low temperatures prevailing in most of the territory of Russia,They do not allow to fully use the gates of this manufacturer, therefore they are recommended to be used mainly in the southern regions of our large country, where their functioning practically does not cause any complaints.

In the first place, respondents put the company Zaiger. This is one of the leaders of not only the Russian, but also the European market.

Successful examples and options

If you want to look at your summer cottage with different eyes, many do not know where to start. Experts recommend starting from the beginning, like all things.

Start over again - change or make the shape and color of the gate and gate with your own hands. The self-made gray wicket is magically transformed into the magic door from Pope Carlo's closet or some narnia that has intruded on his teeth.

First you should choose the material from which such a miracle will be made.

A tree, MDF / chipboard, professional sheet is quite suitable for giving.

In the case of a stone fence, forged metal gates are best suited.

Size is selected according to the size of the plot. Of course, for economic purposes, a sufficient width of the gate is necessary for the passage of wagons / tractors / trucks / bicycles.

The standard for wickets is wider than 1 m, and for gates it is wider than 2.6 m.

The gap above the ground should not be less than 20 cm. This is important because it is convenient to open the door leaves on top of a layer of snow in winter.

To paint the gate, you must invoke your imagination. Of course, the colors will be very different when coloring the wicket from colored pencils from the range of colors of the forged bars of the gate base.

It is necessary to carefully consider the organization of space, free entry / entry and exit / exit. The human factor also plays a significant role, since not everyone likes publicity, and the neighbors are usually curious.

If the soil at the gate or gate is marshy, it will be necessary to take measures to strengthen the surface with sand, gravel, lay tiles or asphalt the ground and walkways.

Of course, wood can be processed much more easily than metal, but if there is a welding machine available, the simplest metalworking tools, fittings, skillful hands and a helper - nothing is impossible!

- Usually start with drawing a sketch. Sketch a drawing with preliminary dimensions, decide on the materials that you have available.

- It is necessary to begin with the manufacture of the frame: an outer rectangle is assembled from the channel or pipe, and the outer rectangle is respectively assembled. All parts are welded.

- Of course, when working with a welding unit, you should not ignore the rules of fire and personal safety: use a protective mask with a light filter, special clothes, shoes. If it rains, outdoor welding is prohibited.

- The frame is sheathed using various materials: boards, metal sheet, plastic panels.

- The next step is awnings. On the frame and the support mark attachment points, weld the hinges.

- At the end of the work, they are engaged in the finishing of the gate - they attach handles, bolts, hinges for the padlock, paint the canvas.

Nothing is easier than making a tree gate!

Pretty often after any work there is wooden material, trimming boards and so on, which is the best fit for the execution of a wonderful wicket or gate.

The sequence of actions will be approximately the same, unless you need a welding machine, and the tools and fasteners will not differ much from those mentioned above.

Successes!

How to make your own wrought-iron gate with a wicket, see the following video.