Installation of a fence from a universal grid giter

In the past few years, a fence for various territories in the form of a gitter grid belonging to 3D type fences has gained considerable popularity. In constructive terms, such a grid consists of individual fragments or panels of wire that are joined by welding, the diameter of which ranges from 3 to 5 mm. To protect against corrosion, this wire is coated with zinc. Today let's talk about the features of the fence from the grid giter.

Technical parameters and equipment

There are varieties of 3D-fences, in which, besides galvanizing a bar, its protection is applied by layers of nano-ceramics and PVC. Sections of such fences are welded structures with a wave-like bend of a rod in the form of a Latin letter V in the horizontal plane, which greatly increases the strength characteristics and resistance to fracture.

Each fragment of such a fence is provided with stiffening ribs, which allows the structure to retain its original shape for a long time.

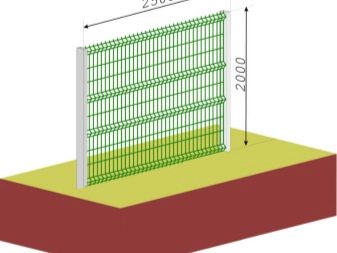

Sectional 3D fences are supplied by manufacturers in the form of sets, fully prepared for installation and assembly, and consisting of mesh sections, each of which is 2.5 meters in length. These sections are equipped with several stiffeners in the form of steel rods coated with zinc and placed in a horizontal plane. The height of these fragments is within 1.5-2.5 meters in the standard version, but may vary at the request of the consumer.

The latter can also change at its discretion the size of the intake cell, which in its standard form is equal to 50x200 mm. The minimum value of the bar diameter is Ø 3.7 mm, but there are structures with a thicker bar, as exemplified by the Gitter 3D fence with a working bar diameter of about 5 mm.

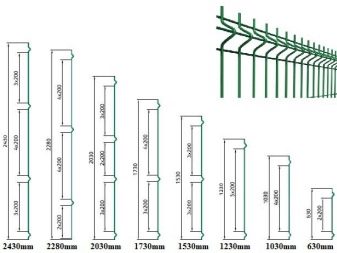

This also includes pillars. In cross section, they are round or square structural elements and have a wall thickness of 1.5-2 mm. Mounting holes are drilled in these pillars. The package of such support pillars also includes special protective plugs. They are designed to prevent the ingress of atmospheric moisture into the pillar.

Complete with the posts are flanges or screw supports. The selection of these parts depends on the chosen mounting technology.

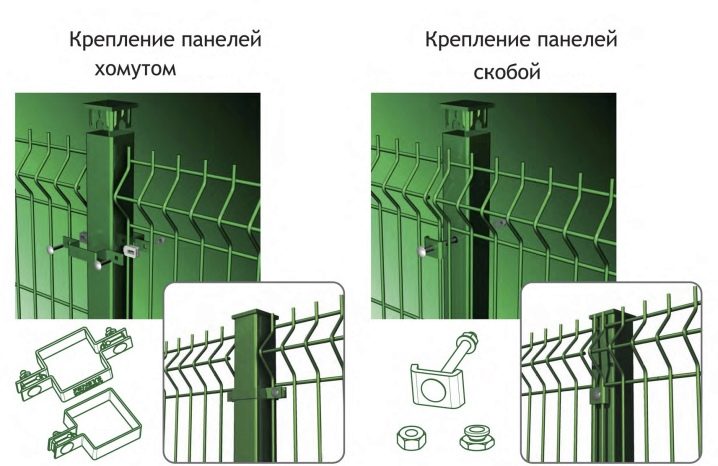

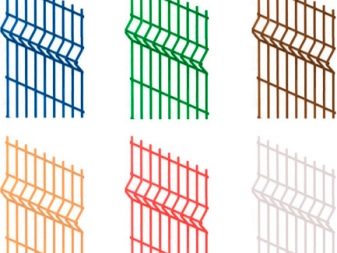

The fastener kit consists of brackets and clamps made of metal or plastic. All components of the fence are resistant to adverse atmospheric factors. The welded mesh gitter has a PVC coating or is painted with powder, and for the supporting fence posts it is provided for dyeing with powder paint, the color of which is chosen at the discretion of the client according to the RAL table.

Marking the territory and installation of pole supports

The universal nature of the assembly of 3D fences allows you to install and assemble the grid yourself without the involvement of third-party specialists, which allows you to do without the cost of money to pay for their labor.

Operating procedure:

- The installation of such a fence should be started with marking the area at the corners, installing stakes, pulling the cord around the perimeter and marking the place for the gate or wicket. The markup is done using a tape measure, and the vertical alignment of the pillars is done by level.

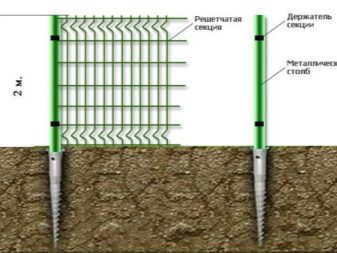

- Further, along the marking lines, support columns are established, the distance between which should be equal to the width of the intake sections.

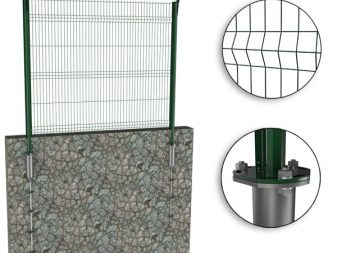

- If such pillars are placed on a concrete or asphalt surface of a territory or on a pre-filled strip foundation, then attach them to it with anchor bolts. At the same time, fence posts have flanges welded to them with several mounting holes into which these anchor bolts are screwed.

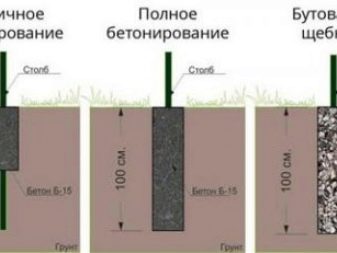

- If they are installed in the ground, then, depending on its type, they can be fixed in the ground with the help of concreting or rubbing with crushed stone. Filling with concrete can be carried out both partially and carried out to the entire depth to which the underground part of the pole support descends. The application of the first variant relates to soils having sufficient strength. The post is buried to the ground at a depth of one meter, but the concrete is poured only in half of this depth.

- For weak bulk and light soil soils, full concrete pouring of the entire depth of the underground part of the column is used.

To enhance the strength characteristics, you can use the reinforcement cage.

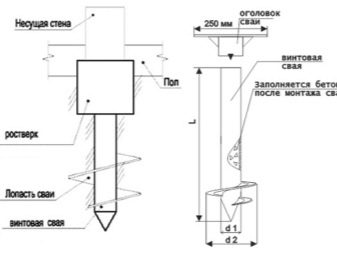

- Another way to install pillar supports for subsequent fastening to them of the intake mesh of the gitter is to place them on screw piles, which are simply screwed into the ground,and then the pillar bases are fastened to them and poured with concrete. This method is the most rapid and the least labor intensive. The sections can be mounted immediately after the supports are installed, without waiting for the concrete mixture to set.

Installation of intake sections

This final part of the 3D fencing device is distinguished by the greatest ease of execution. After the supports are installed in one of the methods described above, the performer can only mount the sections to the supports. To do this, use clamps, brackets or pressure plates with bolts and nuts.

Advantages of 3D fencing:

- The popularity of this type of fencing due to the fact that their transparency does not reduce the review and allows air and sunlight to penetrate unhindered to plantings and plantings. This is especially valuable in a garden plot. At the same time such fences serve as reliable protection of the territory from unwanted penetrations. This is due to the special demand for 3D fencing for fencing of dacha plots, gardens, orchards and other territories where fruit crops and trees, vegetables and flowers are grown.

- Low cost and the ability to install such a fence on our own without significant labor costs in a relatively short time is another argument in its favor. A variety of colors of the intake grid Hitter allows you to select any color of the fence in full accordance with the design of the site and buildings on it.

The fence posts and the gitter net itself can be painted the same or have different colors.

- The simplicity of the design of such intake structures is the key to high speed of their installation. Thanks to a technically competent set of special mounts 3D-fencing, fences assemble with speed and ease of the individual sections, with the bulk of the time spent on it to mark the territory and install the pillars.

- 3D fences serve as a refutation for the popular belief that low cost cannot be a guarantee of quality. The principle of their manufacture is based on the technology of circular welding. Thanks to the application of this method it is almost impossible to break out the bars of the intake grille. Therefore, such fences in terms of reliability do not differ from solid metal or stone fences.

- The same can be said about their durability, which is achieved due to the high quality of the external level of protection of all the structural elements of such fences. Life time, declared by manufacturers for such fences, is about 15-20 years, and they are produced at many of our domestic enterprises. For this purpose, imported equipment is used, and the technological process is based on European technologies and international standards.

- Another important advantage of 3D grid fencing is their ease. Each intake section has a relatively low weight. This circumstance makes it possible to install such fences without the use of special equipment, doing so with a small number of assistants.

Each type of fence enclosures has certain advantages. Wooden fences are distinguished by their beauty and environmental friendliness, concrete or stone - by durability and thoroughness, corrugated fences - by ease of maintenance and ease of installation and installation.

The uniqueness of the 3D grid lies in the fact that it has absorbed the whole set of the above advantages at once, but it is almost devoid of drawbacks.This explains the fact that it is on her that an increasing number of homeowners and managers and business owners stop their choice.

The process of mounting the fence from the welded mesh - see the video.