How to make a floor on the loggia?

Doing the arrangement of the balcony on your own, you can significantly save and realize your design ideas. First you need to think about how to make the floor on the loggia. Each of the ways to finish it has its own advantages and disadvantages.

Materials, their pros and cons

The balcony is present in the layout of most modern apartments. However, in old buildings, loggias are often unglazed and uninsulated. To turn a room into a residential or make it a separate room, you need to repair the balcony. This applies not only to changing its visual appearance and changing the interior, but also to laying a new floor.

The balcony can be used as an extra room, make an office there, arrange a small garden or a summer dining room. In this case, before laying the floor loggia must be warmed. This can be done in several ways.

The following insulation materials are used:

- Mineral wool. The best option would be basalt.

- Styrofoam. Panel dimensions 1000x2000 mm.

- Penoplex. The plate size is 1200x600x30 mm.

- Penofon. Together with the material should be purchased adhesive tape.

- Expanded clay. Used to position between lags.

- Dry screed. A set of backfill and MDF-plates, located as the top layer.

Together with heaters, you must additionally purchase polyurethane foam and vapor barrier film (membranes) to remove possible gaps between the blocks.

Before installing the flooring it is necessary to level the base so that the material lays down better and does not fail prematurely. For these purposes plywood is often used: this method is one of the simplest and cheapest. There are also special self-leveling compounds used as a base for self-leveling floors.

Another version of the rough coating - screed (sand-cement coating). They are used to stiffen the surface and improve the heat absorption of the floor. A leveling polymer compound is applied to the screed, then the floor is laid. In some cases it is allowed to make the layer not too smooth.

Different materials are used for flooring. Let's talk about them in more detail.

Paint

The cheapest option. It is suitable for renovation, when the loggia is not planned to be used as a living space, as in this case the surface is not leveled or insulated. The advantage of painting the floor is a variety of colors and shades, the simplicity of the procedure.

Ceramic tile

The material is resistant to adverse weather conditions: it is not afraid of moisture, as well as snow, wind, sudden changes in temperature. Ceramics will look at open and closed loggias. There are several types of tiles. Experts recommend to give preference to materials with a rough surface. It does not slip, it does not remain defects.

Before installing such a floor surface must necessarily be leveled with cement composition. If necessary, it will allow to raise the level of the base.The advantage of the material is the speed of its installation.

Decking

Modern type of flooring, characterized by high resistance to external influences and durability. Due to its durability it is suitable for installation on open loggias. Before mounting the decking, the base is lifted, for fitting materials, special mounts are used, supplied in the kit.

A wide variety of colors and textures allows you to choose the material for any design.

Wooden floor

The most common way to finish the floor on the loggia. The tree is durable, resistant to wear, and you can install it yourself. Laying is carried out on the logs or lag crates. The latter is a box located around the perimeter of the loggia.

Such a floor, made in natural shades, fits well into any interior. Wooden walls can be added to it.

Linoleum

Suitable in the case when the alignment of the rough base of the loggia is performed using plywood. This is one of the budget options for finishing the floor on the loggia. The material is relatively inexpensive, has good performance.It is easy to wash and clean the surface, there are almost no scratches and stains on it.

Due to the variety of colors you can choose linoleum, imitating parquet, decorated with patterns or geometric shapes.

Laminate

Wood floor with improved features. It also fits over the plywood base. Many modern models are equipped with a locking system that simplifies the installation of laminate and does not require the involvement of professional workers. Laying is done without attachment to the rough base, so highly specialized tools are not needed.

Main steps

Laying the floor is made in compliance with special rules and requirements. Following them, you can get a durable coating that does not deteriorate over time. The process is divided into several stages.

It requires not only the laying of materials, but also the preparation of the surface.

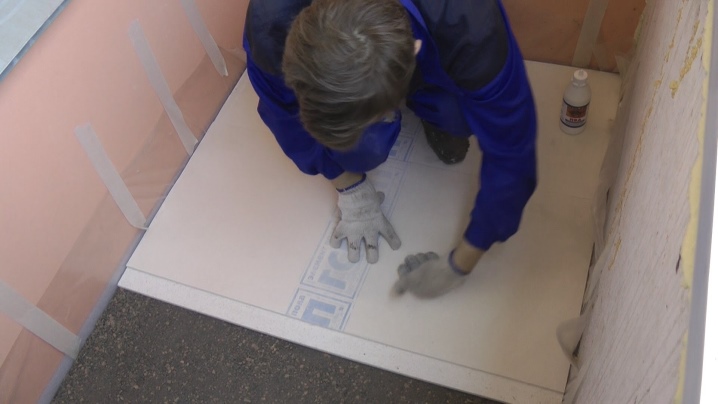

Surface leveling

In the houses of the old buildings are often uneven surfaces. Before the main work required to level the floor. Initially, it is necessary to remove the remnants of old tiles, linoleum or paint, to get rid of mold and dampness.Next, close up the seams and cracks through which precipitation can penetrate, and process all the antifungal drugs. The finishing line is the sealing of the balcony and the preparation of the base for the final finish.

A popular method of leveling the surface is installing lags. These are the elements of the crates for flooring used to strengthen the final floor design. Without them, the flooring will creak and vibrate when walking, can bend under the weight of furniture.

The functions of the lags include the ventilation of the space under the boards to prevent them from rotting.

When installing the elements take into account the height of the threshold, the thickness of the insulation. The lattice is located on the concrete plate of the loggia, it is recommended to spread a film waterproofing. Lags are set across at regular intervals, and clay is covered with sleep between the bars.

How to make a rough floor, see the following video:

To hide the drop in the level of the floor and the gap, at the edges of the balcony have powders.

To create a screed, a sand-concrete mixture is prepared based on water. The proportions of each manufacturer are different, and they must be carefully observed. Too rare solution will crack, and thick will be difficult to lay.Good cement resembles the consistency of mashed potatoes.

There are three types of screeds:

- Ordinary. Poured cement mortar.

- Semi-dry. Sand mixed with cement. To prepare the mixture using a minimum of water.

- Dry Installation of gypsum fiber or fiber cement slabs. Stacked on the surface of expanded clay.

Floor insulation

When there is a need to warm the flooring, initially the surface is covered with expanded polystyrene, which is placed over the screeds. Then OSB-plates and flooring are put on the material. A more complicated method is the installation of heating elements. They are located on a concrete screed, include electrical components or pipes.

Warming the floor with mineral wool - one of the most common options. The material muffles the sound, retains heat, it is environmentally friendly and does not burn, is quite inexpensive. Easy installation makes it suitable for home use.

Features of the installation of mineral wool:

- The panels are laid as closely as possible to each other.

- When the surface is lined completely, it is covered with a vapor barrier membrane, plastic wrap.Fix the material with staples and a construction stapler.

- Plywood sheets (16–20 mm) are placed on top of the log, a gap of 8–10 mm is left on the side of the walls. The material is fastened with screws to the guides of the lattice.

- The remaining gaps are filled with putty, the surface of the composition is carefully leveled.

- Clearances along the walls are filled with foam. When it hardens, it is necessary to cut the excess to the level of the floor covering.

Mineral wool may have a thermo-reflective layer of foil, it is placed outside. When the guides on the walls and on the floor coincide, rolled material can be used that will simultaneously lining both surfaces.

Approximately the same fit foam.

Penofol is mounted directly on the floor surface, protected from liquid ingress. When using lags, they are located above the material. The foil layer is located on the upper side, the joints between the layers are sealed with construction tape.

When the loggia is sufficiently well insulated, the flooring can go directly to penofol. Penoplex costs without crates (due to its high density).The material is attached to the base using dish-shaped dowels, guarantees the solidity of the surface. Layers can be mounted in all weather conditions and temperatures.

Penoplex is resistant to moisture and chemical compounds, it does not burn.

Raising the floor

Sometimes when repairing a loggia you need to raise the floor. At home, this can be done at a distance of 10 to 30 cm - depending on the method chosen. To increase the width of the coating by the following methods:

- Wooden logs. Allow to vary the height of 10, 15 or 20 cm. The design is durable, waterproof and soundproof.

- Metal structures. Allow you to raise the floor by 20-30 cm. Installation tools will require welding tools. More expensive option, characterized by high strength. Above the design lay tile, laminate, use them to warm the floor with carpet.

- Dry screed. The advantage of the method is the simplicity of its use. Enough to fill the clay and level the baby. Thermal insulation for this method is not required. The height of the filling is up to 20 cm.

- Sand cement screed.Suitable only for loggias, because the material weighs a lot. Used to raise the floor by 8-10 cm.

To determine the method, you need to determine the desired height of the floor and the available budget, to find out how much weight the balcony will sustain. Applying each of the methods, it is important to purchase materials with a margin, and during installation to avoid the occurrence of cracks. Before installation it is important to completely clean the balcony from dirt, otherwise the lift will be uneven.

Tips for choosing

When planning repairs on the loggia, you should determine the purpose of use. You can arrange there a gym, library, and someone room will serve as a pantry. Materials for surface insulation and installation of the coating should be selected, based on this. When purchasing goods, the following criteria are taken into account:

- loggia design and its size;

- type of glazing;

- degree of insulation;

- estimated temperature;

- possible amount of costs.

The weight of the floor covering is taken into account when repairing the protruding balcony. Overlaps must withstand increasing load. When buying, they prefer durable, moisture-resistant materials that do not crack with time and will not begin to depart.

It is necessary to consider the type of premises. For open loggias, it is recommended to use materials that are resistant to changeable weather conditions, temperature extremes, high humidity. Suitable claydite, tile, ceramics, natural or artificial stone. It will be appropriate and self-leveling floor.

And the use of linoleum or carpet is meaningless, because they can not withstand heavy precipitation.

For installation of glazed loggias fit any floor coverings. Use laminate, wall paneling, thick linoleum. Ceramic tiles will be good in the case when you plan to make a heated surface. Usually when repairing take into account the compatibility of materials with systems "warm floor".

Loggia design is another relevant criterion. The flooring is chosen taking into account the color of the walls, furniture and decorative elements. You can use similar shades or put contrasting colors in the basis of the interior.

Light pastel colors will visually enlarge a small room, while rich and vibrant will give the interior a concept.

Manufacturers offer a wide range of artificial materials that mimic natural coatings: stone, metals.Today it is possible to purchase linoleum or laminate at a low price, which cannot be distinguished at a glance from marble or mahogany. At the same time building materials have excellent performance characteristics.