Insulation of the attic from the inside, if the roof is already covered: the choice of material and order of work

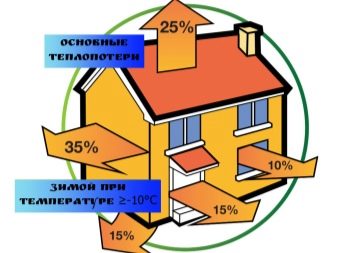

Attic is most often equipped to obtain additional living space. At the same time, it is not necessary to live in the attic - all work on the insulation of the upper room is carried out with the expectation of high-quality thermal insulation of the house in order to save energy resources. In addition, it is much more comfortable to stay in a warm attic than in an unheated room.

Special features

Residential attic - has long been not uncommon in the construction of a private house on two floors. More and more attention is paid to the functional qualities of each centimeter of the attic area. Therefore, it is important to renovate or make the project at home in such a way that, if necessary, it is possible to use separate rooms, make them functional and more suitable for living.In order to feel warm and cozy under the roof at any time of the year, we carry out work on the insulation, taking into account the characteristics of the attic. For example, special warming matters when the roof is already covered.

There are certain standards for such work from the inside in the attic under the finished roof. It is worth considering that the attic as such is not equivalent to an attic room. At the attic there is always a characteristic slope, and the highest point of height is usually at the level of 2.5 m. Different materials can be used for thermal insulation of such a room. Of the most common can be called mineral wool and foam. When working on the attic weatherization, it is necessary to consider what the room will be in appearance, whether it will lose “extra” meters.

For high-quality insulation of the attic from the inside, if the roof is already covered, the right technology is important. So, at warming of walls and a ceiling this or that method of performance of work is used. For example, a multi-layer structure is used to insulate the roof of the attic (for example, a 5 layer screed with foam adhesive).

All work on the interior decoration of the attic for the purpose of insulation is carried out in five stages.

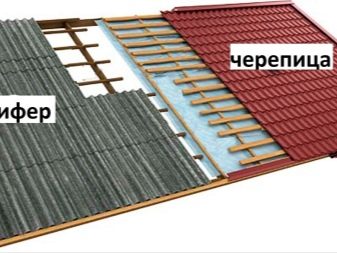

- The roof is warmed, the rafter system is processed. Rafters from a wooden bar can be seen under the roof of houses built according to the old construction technologies. Usually the roof of such houses is covered with tiles or slate. Materials have a very high thermal conductivity. In such cases, it is said that the roof is simply protected from wind and external weather conditions.

- Waterproofing quality - Another important criterion for ensuring the reliability of the roof structure as a whole. Waterproofing is simply necessary in the attic. For this purpose, membrane films are usually used that can pass steam, but do not let moisture through. In old houses you can often see instead of a special film a simple roofing material with similar properties. The main feature of insulating materials is the optimal protection of the roof at the joints, preventing moisture from entering the insulating material. Waterproofing coatings today differ in vapor conductivity.

- Insulation materials. Of the modern tools used are those that are characterized by low thermal conductivity.Insulation parameters between 0.03-0.04 Vi / micron in quality and durability are comparable with reinforced foam. Minvat or extruded polystyrene foam (penoplex, penoizol) are also actively used for insulating the attic from the inside. By efficiency, penoplex is rated higher than others, but costs more. Selected materials must meet the main requirements - to provide heat exchange in winter, to protect against overheating in summer.

- Steam insulation materials. Usually we are talking about a membrane film that will help preserve the original properties of the insulation. The material should not provoke the formation of condensate, which is a disaster for thermal insulation materials.

- Decorative properties. Insulated attic should meet the requirements of the design of the room, comply with the general concept of design design of the house. Therefore, facing is given so much attention. Plasterboard, OSB or other types of materials that can be laid on the ceiling, on the walls, and on the attic floor are often used as decorative finishes.

Roof structures

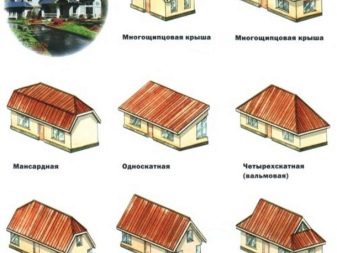

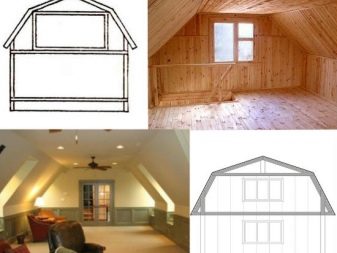

The reliability of the house is determined, including the roof structure.The roof can be gable, sloping, sloping. Due to the design features of the attic it is possible to obtain additional usable space. To do this, you must correctly dispose of the attic space of the house, especially for low-rise buildings. An important role in this case is given to the characteristics of the roof. Traditionally, pentagonal gable structures with a gradient of various sizes were suitable for organizing the attic space. A convex fracture on such roofs was formed due to the difference in slopes.

Many schemes of country houses meet the definitions of "broken" roof. Today the configuration of such mansard roofs has undergone many modifications. Now it is not only a pentagon and not only a gable roof. But their main technological features remain.

Externally, the shape of the attic structure can be assessed by several parameters.

By slope and roof configuration:

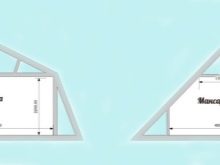

- a triangular roof with a multi-level slope of the lower and upper parts in the form of a gable structure without kinks;

- Pentagonal variations on the roof with slopes on convex corners (in the construction two docked parts are clearly visible).

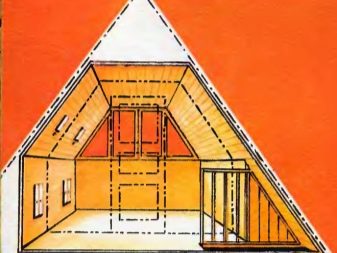

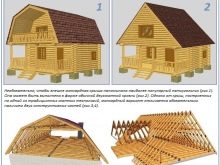

At mansard roofs multilevel truss system. In the lower tier there is a useful area with a height of 2-2.5 m (the scheme is prepared in advance). Height parameters are indicated for easy movement inside. The second tier is the shape of the top of the roof, which can have an arbitrary height. Although here you can experiment with the height to get the most convenient form of the roof. In this aspect, it is more advantageous to use a pentagonal attic, whose corners, as it were, run along an imaginary circle. It is worth considering that the attic can be equipped not only in the presence of a gable roof. Using basic technologies, it is possible to arrange and warm the attic in single-pitch or tent roof structures.

So, the main feature of the mansard roof should be recognized as two adjacent trusses, which are connected in a triangle or pentagon, thereby creating the desired shape of the roof of the house.

The main technology of the pitched roof, known today.

- Inclined The lower tier of the attic is built, then the upper part is settled.

- Hanging. Depending on the technical features of the roof structure equip the upper part.With a schematic section of the attic roof, you can see that at the bottom it looks like a trapezoid, and from above it looks like a triangle.

If you do not need to do anything with the form of an attic, you can proceed directly to the work on the insulation of the room from the inside, choosing the appropriate quality material.

Types of insulation

Selecting the best insulating material for the attic, you should take into account the main characteristics of the material, its valuable properties, advantages and disadvantages for a particular structure.

As the main criteria for the selection of insulation should highlight the following:

- good thermal insulation (for example, foil material, mineral wool insulation, polystyrene foam, basalt material);

- economical use (rational warming);

- strength and durability;

- water repellent properties;

- insulation;

- ease of installation.

It is important to remember that the main value of the material will be its ability to retain heat, that is, the thermal conductivity of thermal insulation materials.

The best qualities have that heater, in which the coefficient of thermal conductivity will be lower. For example, less than 0.04 W / ms. This is subject to material thickness and climatic conditions.There remains the question of the possibility of using the same insulating material for facing walls and floors. More universal qualities of the material will allow to work on any surface (walls, floors, ceiling). Typically, this material "wrapped" walls, pediments and floors. This allows you to achieve insulation to the same extent around the perimeter of the room.

When choosing insulation should not forget about the sound-absorbing properties of the material. To understand this question, it is worthwhile to imagine the noise on the steel roof even from a small rain, especially if we are talking about a residential attic. Calm and comfort - the most important criteria for home improvement. Also, when choosing insulation, it is necessary to check the supporting structure, from which materials it is made (metal, wood, reinforced concrete). Combustible materials (rafters) will not allow the use of some types of insulation. But, for the most part, today safe and eco-friendly lining materials are used. Among them are both traditional (glass wool) and more technological (ecowool, foil plate). Consider some of them.

Plates and mats

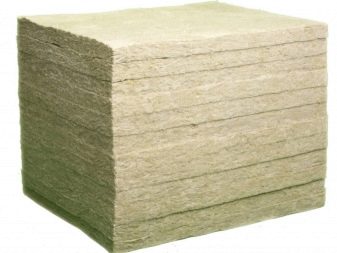

For the inner insulation of the attic in the presence of the roof, such fireproof and water-repellent materials are used as mineral wool, glass wool, ecowool, penofol, foam plastic, cake made of sawdust, extruded polystyrene foam. The warming material in the form of slabs and mats is suitable for single or multiple slope roofs. Crate is done in a similar way. Plates are convenient during transportation and installation.

Rolled

It is more convenient for many to use materials in rolls. You can easily cut a piece of the desired length. Rolled insulation from traditional materials are suitable for roofs with rafters located at a standard distance from each other. If necessary, the material can fill the remaining free space.

Sprayed

The so-called sprayed materials for lining the attic do not leave joints and areas for the penetration of cold. For example, you can use the method of polyurethane foam spraying. For such insulation does not require prior preparation of the attic. The material is simply poured at a certain thickness (usually the thickness of the rafter). These materials are distinguished by the fact that they are resistant to the development of mold and mildew.Spray is convenient to carry out both on the walls and on the ceiling.

How to choose?

The quality and durability of the material depends on the manufacturer, operating conditions and the characteristics of the material. Insulation should be as resistant to mechanical stress, so you should always choose the one that is better for specific indicators. The construction market today is replete with modern insulators of different brands, differing in weight, color, installation features.

Here it is important to determine the parameters:

- material may be light weight;

- the material must be sufficiently rigid;

- it is necessary to choose a heater that is resistant to any deformation for the entire period of operation.

A small mass of insulation allows you to use it between the rafters of the construction of the attic. With a more durable frame, it is possible to use heavier material (plates). They are mounted on the crate or on the truss structure. Depending on the frequent load on the roof (snow), you can decide on a soft or hard insulation. Too soft will have to be repaired. Excessively hard may lose in the insulating properties, for example, when insulating the ceiling.And, of course, the insulating material for the attic should not crack, deform or change over time. It is not always immediately possible to decide on the choice of material for warming the attic from the inside, even when it is not necessary to cover the roof.

All insulation materials have their advantages and disadvantages. Having unique characteristics, such materials are evaluated according to universal characteristics.

- Even the budget version of insulation (for example, foam) must retain heat in the house. Therefore, it is necessary to use a material with a thickness of at least 10 cm. Plates of the same foam are practically weightless, no special installation is required, they are suitable for attic rooms of any type. However, the foam is easy to ignite. Therefore, when choosing insulation, one should not always give preference to cheap counterparts.

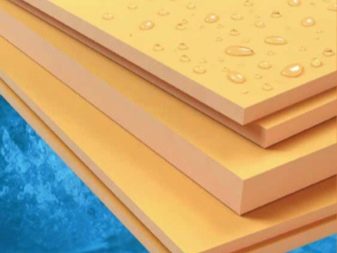

- Extruded polystyrene can be used as a heater, both inside and outside the room. Do not confuse it with foam, the latter has a different structure. Expanded polystyrene does not react to chemical reagents, has a low thermal conductivity, does not absorb moisture.The plates of the material may have different densities, but they can be severely deformed.

- Penofol is used as a more modern tool as a heater, but also as more expensive. Insulation in the form of a roll material can easily replace mineral wool. It is not affected by moisture. It is believed that this material has properties capable of protecting against radioactive waves.

- Spray liquid polyurethane foam will achieve the desired resistance to drafts. Rather, they will not, because the insulation can close the joints and gaps on any surface. When using material there is no need for additional laying of heat-insulating material.

- Ecowool for attic is used relatively recently. This material consists of 80 percent cellulose. The rest is antiseptic. When using ecowool, shrinkage of the material during operation is taken into account. Modern material is resistant to fire, not subject to wetting, does not collect bacteria.

- Mineral wool we have covered almost all the attic structures of country houses. This material is very popular due to the quality of heat and sound insulation.You can lay on the crate or on the frame. Minvat is not subject to rotting, but you need to remember that the material is able to absorb moisture and due to this increase in size. This gives extra weight to the structure.

Thickness calculation

The material with universal parameters - modern insulation, allows you to create in the upper part of the house the most comfortable conditions and the desired microclimate, protecting from heat loss. Installation of insulation depends on its technical characteristics. Consumption is determined by its thickness. There are different installation options, because in the construction business today almost everything is used - from mineral wool to foam plastic. It is possible to calculate the required thickness of the insulation material according to a certain scheme and based on the basic parameters of the SNiP. Calculating the thickness, the masters are guided by regulatory requirements. The characteristics of both the insulator itself and the attic structure are taken into account.

The rules in the calculations.

- At the choice of a heater for the mansard room the operational density of material is considered. The heat insulator is selected in such a way as to ensure the overall thermal conductivity of the wall materials.

- Should be taken into account indicator of the load on the structure when installing insulation. Thermal insulation materials differ in weight - it is more with a greater density of the insulator. So, if the construction is stone or made of brick, this will allow you to use any material for cladding. For a wooden frame suitable insulation of lower density.

- Determination of the dew point. According to this parameter, when calculating the choice of heat insulator, the quality of wall finish, both inside and outside, is taken into account. The presence of dense plaster, for example, allows you to "save" on the insulation. Incorrect thickness of the insulation will lead to the accumulation of condensate, which will adversely affect the performance characteristics of the whole structure.

Calculate the thickness of the insulating material can be according to the formula: R = P / K, where

- P is a measure of the thickness of the material;

- K - the value of thermal conductivity.

When choosing insulating materials compare the parameters of their thermal conductivity. Thus, the thermal conductivity coefficient of expanded polystyrene (the most popular) is 0.042 with a thickness of 124 mm. Usually used thinner material up to 100 mm.Minwat (the next in popularity) has a thermal conductivity of 0.046, where the thickness of the material is 135 mm. The heat insulator is used in the form of plates or rolls.

Warmer ceramic blocks, more like bricks, are stacked on a special glue. The coefficient of their thermal conductivity is 0.17 with a layer thickness of up to 575 mm. Wood (for example, glued timber or solid wood) has a thermal conductivity with a coefficient of 0.18 and a thickness of 530 mm.

How to do it yourself?

Attic insulation works at the same time affect the insulating qualities of the roof. The mansard roof is also the roof of the house, representing the inclined part of the rafters, on which the installation of waterproofing and insulation takes place. All waterproofing runs along the rafters. Thermal insulation is more "economical", the insulation is placed between the attic ceiling beams, the material is hemmed from below.

Works are carried out in stages.

- Warming floors attic. The technology of warming attic space allows you to start from the floor. The process resembles the installation of insulating cladding on wooden floors.In this case, mineral wool mats or polystyrene foam plates are used.

- We warm the walls of the attic. If the house is insulated from top to bottom, then additional insulation of the walls of the attic is not required. But in general, it is not bad to use a thin heat insulator to enhance the effect of junction with the wall. To do this, wooden slats are nailed on the back sides of the uprights (poles) (with a distance of 30-40 cm, similarly the slats are stuffed on the ceiling), heat insulators are mounted on the slats. This can be, for example, pre-cut sheets, which are placed between the supports. Above is provided vapor barrier.

- Insulated attic ceiling. For this part of the work are used such insulation materials as basalt insulation, polyurethane foam, mineral wool or foam. Modern roofing insulation is a heat-saving layers. Here it is important to ensure that in the process of laying there are no gaps and cracks between the plates. You can use a more convenient material - rolled insulation. Be sure to conduct waterproofing and vapor barrier.

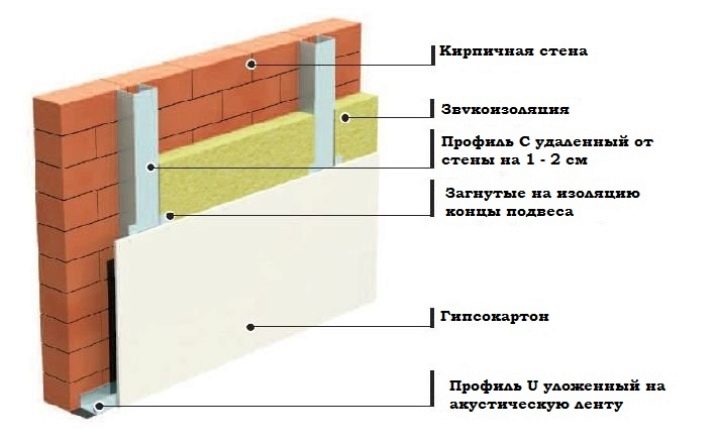

- Finishing the attic. At this stage, a series of works on imparting a finished attic look is meant.Usually for this purpose sheets of drywall are used. Mounted on a frame with crate. The ceiling and walls of the room are often sheathed clapboard. It all depends on personal preference.

Useful tips

To warm the attic is better in spring or autumn. In the process of work between the roof and the insulating material should be enough space for ventilation - the air gap. This will help protect the surface from the formation of mold, rot, fungus. The thickness of this layer depends on the thickness of the material itself, its shape. To improve the tightness of the construction, the vapor barrier is overlapped, and then all the joints are closed with adhesive tape.

When you make a plasterboard ceiling in the attic room (provided the finished roof) profiles are used. It is possible to perform thermal insulation of the gable after warming the attic of the house (work is being done outside). Before insulating floors, you need to make sure that they do not need to be further strengthened.

Even if all the work done correctly, there is a risk of formation of small condensate. Therefore, it is better to provide a double air cushion design (for insulation).This will help maintain continuous air circulation and moisture withdrawal.

Warm attic from all sides is perfect for winter living!

In the video below, see tips on how to make a mansrade.