Attic insulation from the inside: the choice of material and work order

Attic in the house - a space with great potential. It has a spacious area to serve as a place to store things or a seasonal holiday, and a non-trivial form, which can be the basis for the realization of design ideas. Not to use her opportunities is a big omission.

Arrange the space attic floor in different ways. But the most rational of them is the arrangement for living quarters. This will help self-warming attic from the inside. The choice of material and the order of work will also not be difficult after a detailed consideration of the characteristics of materials and the process of insulation.

Why warm?

A good, warm attic has a number of advantages over an unheated floor:

- Can be used as a living room year-round.

- Uninteresting form suitable for interior decoration in an unusual style.

- The upper floor due to its isolation and singularity can serve as a bedroom, study or children's room. Especially in the attic like, of course, children.

- Dormer windows are arranged differently than usual and let in a lot of light. This is useful if there is a children's room, and also suitable for other purposes, because natural lighting is always better than artificial.

- When you transfer the function of any room in the house to the attic floor, a lot of usable space is released.

At the same time, the attic insulation, despite the name, works in the opposite direction. Summer stuffiness and heat, concentrated under the roof of the house - not the best companions of comfort. So that the air in the space of the attic floor does not heat up because the sun heats the roof all day, you need thermal insulation.

Many people forget about this, choosing insulation attic from the inside, and instead of a room for all-season use, get the option for wintering. In the summer it is impossible to stay there because of high temperatures and stuffy air.

Why warm the attic is clear: increase the effective area of the house due to the conversion of the attic into the living room. What type of room this will be depends on the individual needs of the family. There may be a greenhouse, a dining room (which is very convenient, since it will be easier to arrange the hood, and the smells of food will not exactly penetrate into other rooms), a children's room, a bedroom, a study, a room for pets, a dressing room, a guest room.

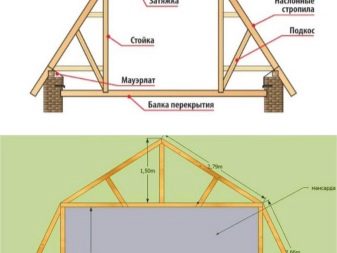

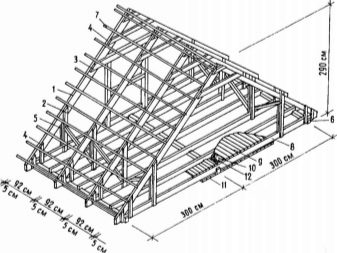

Roof construction options

The convenience of the attic for living depends largely on its size and shape of the roof, which forms the walls and ceiling of the room. The complexity of the warming procedure form also affects. Type of roof is laid during construction in accordance with the design of the building.

In total there are about a dozen types of roof, in varying degrees, suitable for decorating the attic:

- Saw The slope can be on the left or right side. This determines the scheme of the future house, designed in accordance with building codes. This type of roof is not the best, but not the most inconvenient option for residential premises. At least one half of the attic is suitable for a person to fit in her full height and be able to move freely.The second can be taken under the organization of storage systems or bed.

- Gable or gable. It is widespread both in symmetric and asymmetrical versions. In the attic of this type all free space is concentrated in the place where the roof is the highest point. Under the slopes it is less and less, and if the slope is flat, then most of the area will not be used.

- Hip. The roof has four slopes: two in the form of a trapezoid, two in the form of beveled triangles.

- Hip. A kind of hip roof, which is erected above the base of a square-shaped house. All 4 slopes in this case have the same type of beveled triangles.

- Half-hardened. This is a kind of gable roof, which for practical purposes cut side ramps on the gable part. It is more convenient for arranging the attic floor than the previous two options.

- A little less common poluvalmovaya hipped roof. Its gable parts are formed by windows, and under them are slopes.

- Mansard roof. It is considered optimal because it is closest to the cherished U-shaped form of the dwelling.Such a roof does not impose any restrictions on the arrangement of functional areas inside the attic floor. It is easy to place the child’s room in it, which can later be converted into his own office or bedroom.

- Polygonal or polycline. These are options for complex design ideas. It is impossible to say unequivocally how suitable they are for arranging a warm attic, since their shape can be very diverse. But those species that are most similar to the U-shaped, are definitely suitable for this purpose.

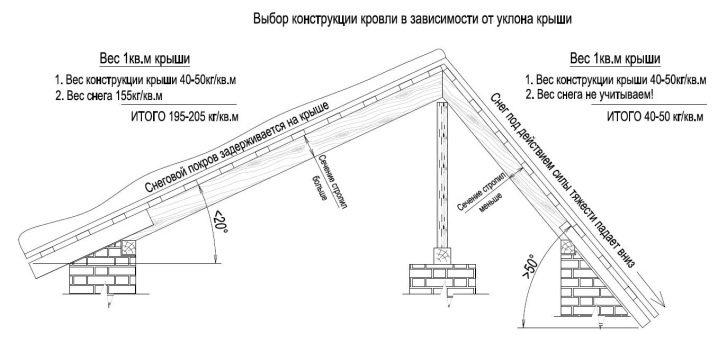

Load calculation according to SNiP

When it comes to attic insulation, it is necessary to consider several types of SNiP: general rules for the arrangement of residential premises and the rules for choosing materials for thermal insulation of a residential structure.

- Calculation of the load on the supporting structure of the building. Own weight and thickness of materials, decorative trim, interior arrangement of the attic significantly increase the load on the supporting structures in a house of any type. The maximum permissible load of each option is different, but the planned changes should not exceed it.

- The correct assessment of the erected structures. For the reconstruction of the house, to which in many cases will be attributed the reorganization of the attic into the residential attic, we need legal grounds. Each case is individual.

In one, if the documents are executed correctly and the house is built immediately with the attic, it can be altered in any way without unnecessary red tape.

In another, the attic may be considered illegal expansion of the area. This entails a fine and dismantling of the building at its own expense.

In a private house, the construction of an attic depends only on the height of the floors and compliance with the load on the supporting structures, in an apartment building it is important to consider its status. If this is an architectural monument, the construction of the attic will not succeed.

- Compliance with hygiene standards. They regulate the minimum height of the attic room, the degree of illumination and insolation - protection from ultraviolet rays.

- The number of floors in the house. Construction standards allow a maximum of three floors, while the basement and semi-basement, which stand above the ground more than a meter, are also considered. If after the attic insulation it becomes a full-fledged living room and the fourth floor of the house, then such a building will be considered illegal. In theory, it is subject to demolition.

- The degree of fire resistance. It is measured in minutes and in most positions is:

- for lower floors 60 minutes,

- for the attic - 30, because the fire spreads upwards and the risk of ignition of the lower floors from the attic is less.

When arranging the attic, especially wooden, under the dwelling, you need to comply with all requirements: process the tree with special impregnations that prevent the spread of flame, choose fire-resistant materials, build communication quality.

It is also important to calculate which layer is needed when using different materials. As a rule, the recommended thickness and density of the foam, mineral wool, polyurethane foam or foam glass is specified by the manufacturer or GOST for a particular material.

Review of materials: pros and cons

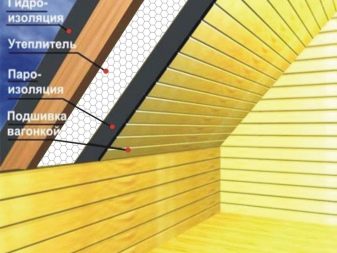

The construction materials market itself offers in abundance. However, only insulation is not enough, because technology involves the layered use of materials for various purposes:

- Material for roofing and walls. These are the elements that form the basis of the attic. The walls of the house can be wooden, brick, block.For the roof choose professional sheets, ondulin, slate, metal tile or ceramic tile.

- Bars for counterbribbles. Timber used wooden, mounted on rafters. The contra lattice is necessary to create air circulation so that no condensation forms under the sheet material of the roof.

- Wind insulation and waterproofing. Polypropylene and polyethylene films, various non-woven roll materials are used. In the priority of the film with anti-condensate coating. They are laid overlapped by 20-25 cm between the bars and roofing material, glued together.

- Thermal insulation. Different types of insulation, which are placed at a distance of 25 cm from the waterproofing film under slate or tile, and 45-50 cm under the sheet materials.

- Vapor barrier. It is needed from the outside of the insulation to protect it from vapors and moisture contained in the air inside the room. Various film and foil materials are used to prevent the formation of condensate and the greenhouse effect.

- Internal crate. Decorative decoration of the ceiling and walls. In some cases, when the height of the roof allows, you can "hem" the ceiling. The air space between it and the roof will make the insulation more efficient.

If with the majority of points of questions does not arise, then the choice of a heater - the most responsible moment. His choice is wide, which is both a plus and a minus, since it is necessary to evaluate a large number of options.

Insulate the attic:

- sawdust;

- mineral wool;

- ecowool;

- basalt type of wool;

- polyurethane foam plates;

- extruded foam;

- penoplex;

- foam glass;

- construction foam;

- foil and heat reflecting material.

Use for thermal insulation of sawdust - a proven and effective method. It is cheap, the mixtures are prepared with their own hands, but in the presence of alternative materials, the method is already outdated. A lot of time is spent, work with sawdust is clean but unpleasant, and the flooring will not differ in its durability. Ecological cleanliness in this case is probably not at hand, because wood fibers are an excellent environment for the reproduction of organisms.

By the materials in the past applies and ordinary foam. It has a number of advantages: low weight, low price, ease of installation alone, rather long service life, good insulating properties.But the disadvantages are still significant: fragility and fragility, retains moisture inside, suitable environment for the reproduction of living organisms, you need a thick layer of material.

Mineral wool - more relevant insulation. Its advantages:

- high coefficient of thermal insulation;

- resistant to moisture, chemicals and alkalis;

- provides good ventilation in the room;

- helps to increase sound insulation;

- high fire resistance;

- long service life;

- strength;

- security for residential use.

Disadvantages:

- With poor organization of waterproofing and vapor barrier layers, contact with precipitation material, mineral wool loses a few percent of thermal conductivity.

- Able to accumulate dust over time.

- Quality mineral wool is quite expensive, but is environmentally friendly. On the market there are often fakes in which the formaldehyde content exceeds the norm. They are harmful to health and are prohibited for use in residential areas.

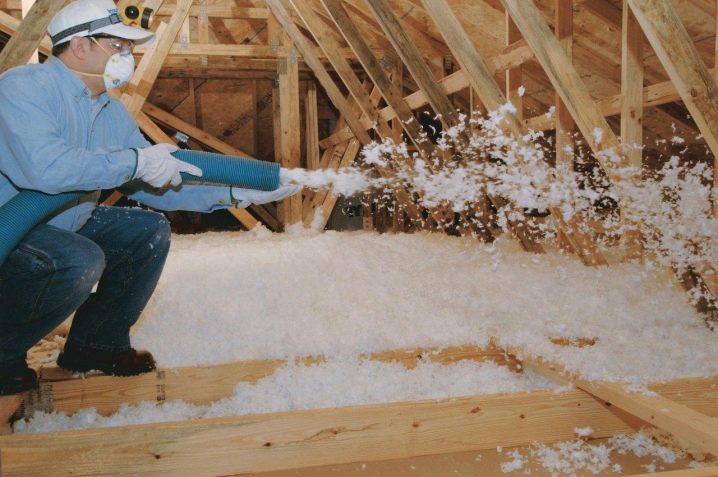

Ecowool is essentially cellulose fiber in three-fourths of the composition, and the remainder contains substances that allow the use of cellulose as a building material - this is borax and boric acid.They increase the fire resistance of cotton wool, prevent the appearance of microorganisms, fungi, rot.

The advantages include the good ability of insulation to retain heat in the room, do not interfere with ventilation, high-quality insulating properties, natural and safe raw materials at the base of eco-wool.

The material has a minus too, and a significant one. Ecowool is not made in the form of plates or sheets, it is a crumbly fiber that must be applied wet when using special equipment. And to work with the equipment will need qualified installers.

In addition to ecowool, foreign manufacturers offer other types of insulation based on plant fibers: eco-cotton and cotton fabric insulation.

Another type of wool is basalt. It is related to mineral. Since its components are present in the composition, but the basis of the material is basalt rock. Basalt gives the material unique qualities.

Its advantages:

- components of organic origin without formaldehydes and harmful resins;

- thermal insulation quality, insulation;

- does not ignite, does not sustain combustion;

- biostable;

- The plates are comfortable and easy to use;

- serves dozens of years.

Disadvantages:

- the high cost of warming a square meter with basalt slabs;

- absorbs moisture well.

The third kind of cotton wool - glass wool has similar characteristics. It is more convenient to use because the material is rolled.

Extruded polystyrene or extruded polystyrene combines the qualities and benefits of mineral plates and conventional polystyrene, thanks to a special production technology.

Its performance characteristics are mostly positive:

- lightweight, but durable - it allows you to use it for warming in large quantities, working with it just alone;

- closed pores of the material are moisture resistant;

- easy to cut into fragments, it is non-friable and does not crumble;

- does not cause interest, as a habitat, neither in fungi, nor in rodents;

- low cost

The disadvantages include: vapor permeability, low fire resistance.

The group of gas-filled plastics of the new generation includes polyurethane foam (PUF).Its advantages make the material one of the best for insulating the attic floor: it is light, moisture resistant and fire resistant, does not accumulate dust, does not attract living organisms, is very durable.

There are two types: sheet and sprayed. Sheet material is very convenient in that it does not crumble in the process of cutting fragments and the detail is closely fitted to the part. Sprayed type of protection creates a monolithic layer under the roof, due to which he is not afraid of ingress of precipitation, cold. It also has good adhesion with various surfaces, is resistant to the appearance of microorganisms and allows for installation work as soon as possible.

Spray material creates better insulation and helps to mute extraneous sounds, but it has two serious drawbacks. First, for the application will need an expensive service of professionals with special equipment. Secondly, it is so dense that it "does not breathe." The room will accumulate humid and sultry air if it was not possible to organize additional ventilation.

It is advisable to use both types of PUF at the same time. Large areas are covered with sheet material, and hard-to-reach places and slots are sprayed. This will completely solve the problem of even the coldest attic.

Foamglass is an uncommon and unfairly relegated material. The reason for this is simple - a very high price. Foam glass, as the name implies, is produced by foaming glass fiber. It turns out porous (cellular) material, which is absolutely not susceptible to fire, safe, durable and meets all the requirements for insulation. If financial capabilities allow, then foam glass as thermal insulation should be considered first.

A separate group from derivatives of plastic and glass are foiled materials for warming rooms from the inside. By themselves, they have a small thickness, so they are often combined with various variations of foamed cellular materials that are inside between two layers of foil.

The advantages of reflective materials are obvious:

- Light weight and small thickness. Attic is rarely large, especially given the fact that its dimensions are concealed by the shape of the roof, and 20 mm foil sheet is much more practical than 200 mm of foam plastic.

- The material is easy to cut, does not crumble, does not slide on the surface.

- There are variants of self-adhesive sheets, in which one side is covered with a reflective layer and the other with an adhesive adhesive. They at times simplify installation work.

- Foil is an excellent heat reflector. Thanks to her abilities, in the cold season, the heat does not leave the room, and in hot weather it remains outside.

- Reflective coatings are hydrophobic, they just repel water.

- It is at the same time isolation from precipitation, dust, wind, cold.

- Despite the minimum thickness, copes with the function of noise insulation.

- Elastic and flexible.

- Bio-resistant.

- Do not emit toxins and formaldehyde when heated.

- Durable.

How to choose?

The choice of a suitable heater is a crucial stage in the arrangement of residential premises on the attic floor.

There are several important factors to consider:

- Consideration of climatic conditions. If severe frosts rage in the region during the cold season, the insulation should be cellular or porous. Its structure allows the warm air to fill the empty spaces and retain heat in the room. It works like PVC profiles and double glazing on windows.The more layers of cells, the better the material, so the thickness of the layer should be greater than 1-2 cm.

- For regions with high humidity in the first place is the hydrophobicity of the material. All types of wool are undesirable here, but derivatives of polyethylene and plastics will be just right. You can safely use polystyrene foam and polyurethane foam.

- With a large amount of precipitation in winter, giving the load on the roof, lightweight materials are preferable. For example, foam and foil.

- Accounting indicators of moisture and fire resistance. Even if the climate is not teeming with rains, protection of the insulation from moisture is very important. Wet material ceases to perform its functions, since its heat conductivity changes, and is gaining weight.

- As for fire safety, it is more likely compliance with all norms of SNiP. Selecting a fire resistant material is not difficult. Most manufacturers add substances called flame retardants to organic materials for making insulation. They prevent the spread of fire.

- The ability of the material to keep the shape. Measured as modulus of elasticity and resistance to deformation.It depends on it, whether it will create a monolithic reliable protection or it will begin to sag and drafts and blown places will appear in the room. Unconditional leaders in this respect are not sheet, but sprayed materials.

- The coefficients of the material according to several characteristics: thermal conductivity, vapor permeability, sound insulation index.

- The composition of the substance. For the arrangement of the living room in the attic recommended the use of environmentally friendly materials, without resins, formaldehydes and toxic substances. Different impregnations are permissible if their presence meets the requirements of GOST.

The type of materials used in the finishing of the roof also matters.

Under the metal tile

Warming of the attic ceiling under such material should be properly carried out using a layer that is not afraid of moisture. Features of the structure and installation of metal tiles are such that under it can get water. Optimal here is the use of foamed materials based on plastic or glass, but if the choice fell on mineral wool, it is important to take care of a good waterproofing layer.

It is also necessary to choose a material with anti-condensate coating.After the condensation reaches a certain temperature, it will also turn into water that is dangerous for the heat-insulating layer. The problem can be solved with the help of polypropylene films, geotextile coatings and super-diffuse membranes.

The disadvantages of metal include the fact that its unusual shape allows the sediments to accumulate between the layers of the coating, which is almost impossible to make completely sealed. Maximum leveling the damage from this will help high-quality ventilation under the roof. Natural in this case may be small, it is necessary to equip the forced.

Such problems also extend to ceramic relief coating and slate sheets. All of them have the same shape, which does not allow to fit the sheets closely.

Under a professional flooring

It is less problematic in relation to leaks and the occurrence of condensate, since the sheets fit snugly, and the joints are treated with sealant and paint. But the material has its own characteristics. First, it is very cold and the insulation should be of high quality and impressive in thickness. Secondly, during the rain under the roof of corrugated board is very noisy, you need a material with high rates of absorption of sounds.

From the list of suitable materials, it is necessary to exclude thin foiled sheets, fiberglass, cellulose heaters on the type of ecole. Their thickness and sound insulation performance are not sufficient to ensure a comfortable stay in the attic under the professional flooring on the roof.

For the attic over the bath

Along with the type of materials for the roof you need to take into account the location of the attic: either it is above all living quarters, or above part of the house.

One of the problematic options is the attic over the bath. With this arrangement, it is difficult to equip a dwelling in it. It is more suitable for a rest room, a small living room or a game corner, which is necessary after bath procedures.

The main difficulty in the choice of materials lies in the microclimate of the room above the bath, different from the microclimate above the living rooms. Temperature and humidity conditions in it are unstable, and the possibility of condensate is very high. Of course, under such conditions neither sawdust, nor cotton wool, nor environmental insulation based on cellulose are suitable. It requires hydrophobic materials such as polystyrene foam and polyurethane foam, foil coatings, good vapor insulation, forced ventilation.

Winter Homes

There is no universal solution for warming the attic of winter residence. It all depends on the climatic conditions and materials used in the construction of the house.

Long and severe winters - a warm, porous insulation resistant to temperature extremes. Warm climate - any suitable type of roof material.

In a private wooden house because of the properties of the tree to keep warm enough thin insulation. Suitable materials based on cellulose, glass or plastic. You can use foil with a minimum thickness.

In brick houses with roofs of corrugated, tile or slate, additional insulation in the form of air spaces is necessary. It can be dense porous materials and several interlayers between them. Warming of a frame house does not require much effort, since its design already provides all the features of specific climatic conditions. Any moisture and fire resistant materials will do here.

How to warm yourself?

The technology of creating thermal insulation in the attic is also available to non-professionals. The key to success is not in the experience of installation work, but in the proper selection of material,consistently performing actions to create a solid insulated circuit and accuracy.

The procedure is as follows:

- Calculation of the allowable load and the optimal material thickness.

- Selection of materials and necessary tools (including equipment for compliance with safety regulations).

- Room preparation: cleaning, dusting, processing of wooden structures with protective impregnations.

- Mounting battens. This is an important and mandatory stage, which lovers skip unknowingly. The device of the thermal insulation of the attic without crates and counter grilles is considered a gross error. She nailed from the inside of the entire area of the roof.

- Laying waterproofing film or diffuse membrane. The mount should not be tight, better let the material sag a little. Overlapping sheets overlap each other (15-25cm) and fasten with tape or foil. Between the membrane and the crate is required a gap of 20 to 50 cm.

- Installation of insulation. Different methods depend on the type of material and the location of the rafters. The rolled material can be fastened with a small overlap and fixed with tape or stapler. Sheet insulation for finishing the roof and walls is laid close,given a slight shrinkage in the future. The junction is made as close as possible, the seams are processed with adhesive tape. Screws and nails can be used for very dense materials.

It is important to dock well in the corners of the pediment and in such difficult areas as the ridge, endova, and overhangs. To do this, use small parts of the material, separated by an improvised method.

Particular attention is paid to the contour of the windows. The room will remain cold if warm air flows out through the cracks at the window.

The sequence is as follows: insulation of the roof, ceilings, gables, partitions, walls. The floor can be insulated both before and after.

Warming of the floor is more variable, since it is less affected by precipitation, winds and frosts.

This may be dry backfill, sawdust, and mineral wool:

- Installation of vapor barrier. It overlaps as a membrane, is fixed in different ways. As a rule, there is a line on the material that marks the width of the junction between two sheets.

- Crate if necessary.

- Decorative trim.

Common mistakes

The correct thermopie for roof insulation is mounted in compliance with many nuances.

Non-professionals often make the same mistakes that affect the quality of thermal insulation of the attic:

- no ventilation gap from the ceiling to the membrane.As a result, the insulation freezes and ceases to act;

- strong sagging of the membrane - this shortens the interval required for ventilation and leads to the formation of condensate;

- attempts to save on insulating materials, laying them without the necessary joints, as a result of which gaps are formed and the heat comes out, heating the roof, and not the room;

- ramming the material to such an extent that it warps and crumples, losing its properties;

- unstitched cornices - this leads to the fact that the sediments get free access to the insulation and saturate it with moisture;

- lack of ventilation;

- no adhesive tape or tape in the joints of the sheet material.

Useful tips

Professionals in the field of installation recommend to follow a few simple rules when we warm the attic, so that work and finances are not in vain:

- Use hard and dense materials or spray. They are better fixed and not deformed in the process.

- Increasing the distance between the attic ceiling and the upper point of the ridge will create an “air cushion” and improve the quality of the warm contour.

- It is better to leave a gap for ventilation not only between the crate and the membrane,but also between the membrane and insulation.

- Processing of wooden structures with special impregnations will prolong the life of the roof and insulation.

- Optimal thermal insulation implies small air vents for every 10-15 square meters.

On the choice of material and the order of work on the insulation of the attic from the inside, see the following video.