Features and types of lightweight concrete wall blocks

The use in the construction of a wide range of different materials allows you to solve all sorts of tasks, sometimes very specific. But this can be done only with full knowledge of the characteristics of each substance. A mixture of expanded clay with concrete also deserves close attention.

Characteristics of lightweight aggregate

Expanded clay is one of the lighter concrete, expanded clay is used as a filler. For a bunch of components, mainly cement is used. Much less common lime and gypsum, always in the composition of the material includes sand. Expanded clay is divided into a dense and containing large pores varieties.The lightest type of material used in the preparation of wall panels.

Single-layer panels on the basis of expanded clay concrete are so called only conditionally. In reality, such a unit is formed from the following components:

- the main layer of cellular concrete;

- inner decorative shell;

- outer sheath covering from external influences.

Inside, a solution of increased density (1.8 tons per 1 cubic meter) is used. The thickness of this material is 1.5 cm. The purpose of such a coating is to protect the main part from contact with water vapor.

Looking at the street layer has not only a protective, but also a decorative function. Its thickness is from 1 to 2.5 cm. Aerated concrete capable of passing steam is used to manufacture the outer shell. As a result, block tightness is guaranteed for dampness. The outer surface of the block has a density of 1200 to 1400 kg per 1 cu. m

Three-layer claydite panels are less common than their single-layer counterparts. To construct such blocks, several layers of light or heavy concrete are used. They try to distinguish the following heaters:

- mineral wool;

- foam glass;

- fibrolite;

- glass wool;

- Styrofoam.

In any case, these materials should have a density not exceeding 400 kg per 1 cu. m. To eliminate the accumulation of water in the insulating layer between the core and the shell must be maintained a ratio of 1.2: 1. Additionally used a vapor barrier, most often roofing material and foil. This barrier must separate the insulating layer from the main part. In order for the block to be as reliable and durable as possible, special connections of rigid or flexible type must be created.

In addition to the number of parts, the products can be sorted and by structure. A full-body lightweight aggregate block is used for the construction of houses with a height of 2 and 3 floors. Still, these products are needed to create even less high, but very important constructions.

Hollow block type of expanded clay concrete is mainly needed for the construction of single-storey houses and individual partitions. And also these products are characterized by low thermal conductivity.

It is worth paying attention to the cladding structures, which allow to reduce the total time of construction of buildings. If you use them, you can immediately create a trimmed surface. One of the faces of such blocks necessarily has a special coating or paint layer.There are clay blocks, the color of which is due to the addition of natural colored clay or certain pigments. Finishing panels can have 1-3 layers, and the multi-layered versions are distinguished by the highest resistance to heat transfer.

Kinds

Structural keramsit concrete blocks are needed to build objects that are experiencing significant loads. First of all, this refers to bridges and large structures. The density of products in this group ranges from 1400 to 1800 kg per 1 cu. In this case, the compressive strength is 100–500 kg per 1 cu. See. In addition to reducing the mass of structures, the attractive side is the high resistance to frost (about 500 cycles).

Equally important in practice are structurally insulating products that are needed to produce wall panels in a single layer. More on the basis of such expanded clay slabs formed larger blocks. Resistance to compression ranges from 350 to 1000 kg per 1 sq. Km. cm. At the same time, the density is 700–1200 kg per 1 cu. m. Frost resistance is not uniform (15–100 cycles, depending on the characteristics of the technology).

There are also claydite-concrete blocks used for thermal insulation of enclosing structures.For them, the normative compressive strength ranges from 5 to 25 kg per square meter. cm, and density - from 350 to 600 kg per 1 m³. Quality ceramsite wall panel is always easier than elements made of simple concrete. In some places it is the best solution for construction. Most orders are for slabs made from expanded gravel of the lung fraction. The bulk density of such plates falls into one of such three categories as:

- M300;

- M400;

- M500.

Typical panel thickness is 0.6 m. If necessary, you must submit an individual order. Then blocks can be made according to specially selected dimensions. In any case, the production of hinged wall panels GOST must be observed very strictly. In the composition of each shipment lot no more than 10% of blocks with cracks are allowed.

Size and weight

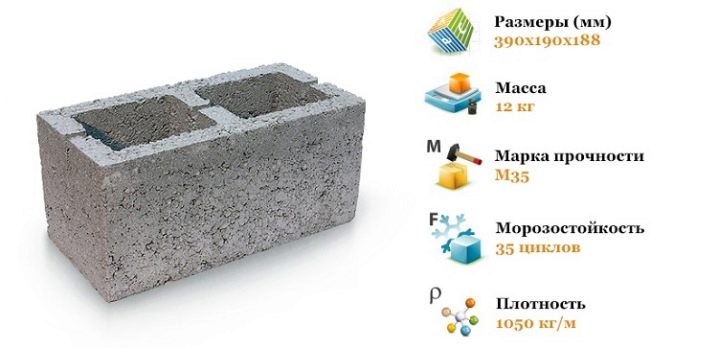

SCC 390x190x188 mm is one of the most common dimensions of claydite-concrete blocks. The mass of this design is 12 kg. If the description of the goods indicates a thickness of 400 mm, in reality it is 390 mm (rounding is done for convenience of calculations). As the concentration of the filler increases, the block becomes lighter, while its thermal conductivity decreases.You can often find mention of claydite-concrete stones 390x188x120 mm. Their main characteristics are as follows:

- weight - 6 kg;

- storage capacity per 1 square. m - 12.5;

- the number of freezing and defrosting cycles is 50;

- mechanical strength corresponds to category M50.

Pros and cons of expanded clay products

Claydite ahead of the usual concrete to protect the premises from frost. At the same time, its market value is somewhat lower than that of high-class cellular concrete. Mechanical characteristics are approximately at the same level. But the clay is characterized by high resistance to moisture and aggressive chemical compounds. Increased porosity makes the material unsuitable for the construction of foundations and dimensional structures.

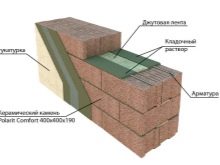

Slabs and panels of expanded clay concrete are mainly used in the construction of apartment buildings and cottages, and they are also needed when creating internal partitions. Another use is the saturation of the frame, which is made of reinforced concrete.

If you compare the claydite blocks with silicate bricks, you will find such advantages as:

- reducing cement costs;

- increase in speed of work;

- reducing the volume of the wall and the expansion of the premises themselves;

- excellent environmental and sanitary parameters.

But keramsit concrete has a number of problems, namely:

- there are almost no ready-made instructions for use;

- high price in comparison with brick (fully justified by the characteristics of the material);

- relatively poor appearance of the building blocks;

- a large number of cold bridges.

About features and types of expanded clay concrete wall blocks, see below.