How to use a gun for foam?

The gun for polyurethane foam is an indispensable tool in the implementation of the repair. It provides an economical consumption of foam and ensures accurate application. Its use will save money, make repair work easily and quickly.

Special features

Polyurethane foam is required when installing doorframes, plastic windows and for other purposes. If applied manually, many problems arise, so it’s better to buy a special gun for it. Modern manufacturers of construction equipment offer a wide variety of guns for the use of foam. They differ in appearance, are represented by various designs.

Cylinders with foam are presented by the huge range: If you buy a quality tool for the application, it will fit under any cylinder. The gun for polyurethane foam is an easy-to-use tool, but you should not treat it lightly. Before using it, you should take measures for your own safety. It is recommended to use the tool only in protective glasses and special gloves.

Merits

The need to purchase a gun for mounting foam due to its advantages.

- provides the ability to produce accurate dosing of the material during use;

- provides high-quality sealing and excellent thermal insulation of joints;

- carries out an economical consumption of polyurethane foam; allows you to use cylinders with a sealant, even if it has already been used, and a lot of time has passed because it prevents the foam from freezing in the supply system.

Kinds of pistols

Modern manufacturers of construction equipment offer a wide range of guns to work with foam. To choose the right tool, you should familiarize yourself with its varieties. Of great importance is the material of the device.Plastic models are the most affordable because they are cheap. Manufacturers do not use metal parts, so they do not differ in durability.

Such options quickly break down or get clogged up by the installer. If the plastic gun stops working, you should buy a new one, since it is beyond repair. Often when buying a plastic gun in the kit they sell a few more tubes for changing. It should be understood that it is not separable. Even with a strong desire to clean it will not be able to disassemble it.

The plastic tool is durable to use. Basically, this option is the most convenient to perform a small amount of work. It is acquired by those who do not like to clean the tool after use. A good alternative to a plastic gun is a regular plastic tube that is attached to a cylinder of foam. The result of the work is the same, only the handset is cheaper. The difference is that the balloon is differently placed in the hand.

Pistols for metal foam are of good quality and are reusable.They can be disassembled and cleaned after use. If any kind of breakdown occurs, they can be repaired. A high-quality model will work for several years if handled with care. This option is chosen by many professionals who understand that a quality tool plays a big role in the performance of construction work. It allows you to do the job qualitatively.

It is worth paying attention to the combined models.which are made from plastic and metal. The barrel of the gun is made of metal, and the remaining parts (body, handle, trigger and adapter) are made of plastic. Combined tools are lightweight and can withstand shocks. If you drop a plastic gun from the height of the ceiling, then it is unlikely to work.

When choosing a combined model, you must make sure that it is collapsible. If the gun does not understand, it is not worth paying a lot of money for it, you can immediately buy a plastic option, because they will serve the same way. The best are models with a teflon coating. They are characterized by excellent quality, almost no inclination to breakdowns,differ in the long term of operation and ease of cleaning. Their only drawback is the high cost.

Tool device

Pistols for foam differ in a simple design. Even expensive models that have a huge amount of detail, work on a simple mechanism. Pistols differ in appearance and filling, but they all have the same main parts.

The main elements of the gun for mounting foam include:

- tool body (product basis);

- handle for ease of use;

- barrel (used to feed material);

- the nozzle (the tip of the barrel, helps the foam "shoot");

- needle rod or locking needle located inside the barrel;

- ball reducer or adapter (for mounting the cylinder, consists of a small spring and a ball, requires special care when flushing);

- trigger (responsible for opening the valve);

- adjusting screw (provides fixation of the needle, adjusts the feed rate and the amount of material).

- screw with gasket (to protect the trigger against foam leakage).

If the screw is tightened, the foam supply is completely blocked.If the screw is loosely screwed in, then the foam goes easily enough.

Instructions for use

The gun for polyurethane foam is characterized by ease of use. It is designed for operational work. To properly use the gun, you should follow a few simple rules that are based on the features of the tool and the cylinder. Before use, the container with foam should be thoroughly shaken. It is enough to perform this action for 30 seconds. If work with the sealant is carried out outdoors in the cold, it is necessary to warm up the container before use or wait until it is heated at room temperature.

How to charge?

To use the gun, you must install it correctly:

- the balloon must be placed on a flat surface;

- remove the protective cap from the sealant;

- it is necessary to put a tool on it, with the gun should be inserted from above;

- one another needs to hold the gun by the handle, and the second one to rotate the container with sealant up to the stop;

- it is necessary to turn the tool with the handle down and the balloon up to give it a working position;

- you need to turn the adjusting screw about a quarter of a turn and pull the trigger with ease;

- when the foam fills the entire barrel, the gun is ready for use;

The gun kit is additionally equipped with a tube that is used to fill the seams in hard to reach places.

How to work?

First you need to prepare the seam. It is enough to moisten it with water. These actions will improve adhesion.

Then you can start work.

- Need to direct the tip of the tool to the seam.

- It is necessary to gently pull the trigger of the tool to adjust the force with which to act to obtain the required flow of foam.

- If it is weak, it is necessary to slightly tighten the adjustment screw, which is located behind the tool.

- Fill the seam should be exclusively from the bottom up, performing with this zigzag movement.

- The seam should not be complete, because over time, the foam tends to expand in volume. If voids remain in the future, they can be filled with an additional layer (it will take more time to cut off the excess sealant).

- When working with a long seam, the foam can change its consistency over time, so it is worth stopping and vigorously shaking the balloon again.

- When stopping the tool nozzle must be cleaned from the foam with a cloth moistened with a solvent or special wipes. After completion of work it is necessary to tighten the adjusting screw.

How to remove?

If you do a lot of work, a single bottle of foam will not be enough. Then it is necessary to replace the empty container of sealant with a new one. If no foam is already coming from the tool nozzle, the container may still be under pressure. To change the balloon, you must first empty the container. You can take the construction bucket, send a barrel into it and pull the trigger. You must perform this action before stopping hissing sound.

Next, the gun must turn the handle up to the cylinder was at the bottom. Now you can carefully unscrew the empty container. The adapter should be immediately washed off with a special solution to eliminate excess foam and screw on a new bottle. If these steps are performed slowly, the sealant may freeze in the barrel, which will result in a thorough cleaning of the tool.

Care Tips

As proven in practice, even an inexpensive foam gun can produce a large number of cylinders with a professional sealant.It must be remembered that the working equipment does not need any external intervention: it is not necessary to disassemble it for thorough cleaning.

Just follow the simple care tips.

- Remove the container with foam only for its replacement. If the balloon is already empty, but you do not plan to continue working, you should not take it off.

- After work it is necessary to clean only the nozzle of the barrel and the shut-off valve from the remnants of the sealant.

- When changing the foam canister, always flush the adapter with a solvent to remove any sealant residue.

- If necessary, tighten the screw gasket, which is located between the rod and the trigger.

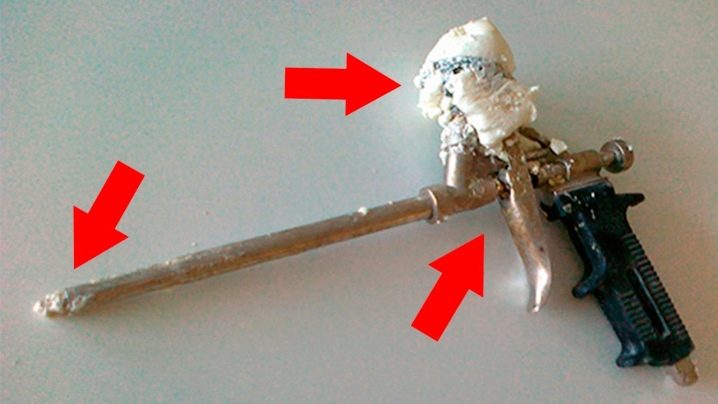

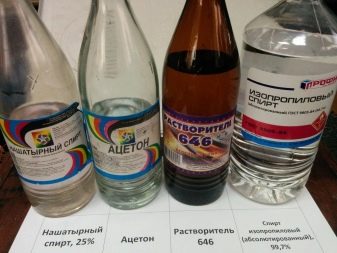

If the gun is broken for an unknown reason, there is no need to immediately throw it away. You can repair it yourself if you find a malfunction. To disassemble the tool, do not apply force. If hardened sealant prevents disassembly, it is worth using solvent 646 or acetone.

These fluids make it easy to scrub off frozen foam. After disassembly, you need to find what has broken, then replace the part with a new one. Before assembling all the details of the mechanism should be carefully lubricated.This will extend the life of the tool.

How to use the gun for foam, you can see in this video.