Foam Gun: Tips for choosing

Polyurethane foam is very often used for repair work. For high-quality and efficient application of this material the ideal solution is to use a special gun. Today, manufacturers of construction equipment and tools offer a wide selection of guns for sealants. If you understand the features of their choice, you can purchase a quality and reliable model for long-term use.

Features of the device

Today, a wide assortment of tools is on the shelves, among which the attention is attracted to a gun for working with assembly foam. It allows you to easily issue the required amount of polyurethane sealant in the right places.Polyurethane foam is used to fill seams when installing door frames, windows and window sills, slopes and ebbs, as well as various slots and holes. The gun for the sealant should be at each master at hand.

The advantages of a pistol, in comparison with a conventional sealant cylinder, are quite numerous.

- Economical expense. The tool is designed in such a way as to independently dosage of the outgoing material. This allows almost three times to reduce the consumption of foam. Uniform distribution of funds has a positive effect on the quality of the seam.

- Practicality and convenience. The gun works by pressing the trigger. The mechanism is characterized by practicality, since the foam comes out in small quantities, filling only the voids. If you use only a cylinder of sealant, it is difficult to cope with a large flow of foam. It fills not only the seams, but also falls on objects and walls.

- Ease of work in hard to reach places. The narrow barrel of the tool allows you to pour foam, even in places that are difficult to access. This is especially true for filling gaps in the ceiling.

- Reuse of foam canister. The gun is characterized by the presence of special valves that are responsible for tightness. If the work has already been done, and sealant remains in the cylinder, the gun prevents it from freezing, and in the future it can be used again. If you work only with a foam balloon, then you can throw it away, because in the open balloon the foam quickly hardens.

Mounting gun will last a long time if you know its characteristics and principle of operation. If you follow the elementary rules of use, the tool will last much longer. Do not forget that the sealant is unsafe, as it has a slight ignition and can cause severe irritation when it comes into contact with exposed areas of the body or eyes.

Before using the gun, you should study how it works:

- To begin with, it is necessary to thoroughly shake the can with the sealant, put it on a flat surface vertically and carefully screw the gun on it, and the tool should be located at the top. When the cylinder is tightly fixed to the gun, it is necessary to turn the design. The gun must be located at the bottom, this is its working position.It must be firmly held by the handle.

- First you need to clean the surface on which the sealant will be sprayed. For better adhesion it can be slightly moistened. Work with sealant is preferably carried out at room temperature.

- To increase the intensity of the foam supply from the pistol, it is not necessary to press the trigger with greater force, just tighten the control screw a little. Pressure contributes to the rapid release of the material, so you should first prepare the entire space where you need to fill the foam. This will allow to do the work with high quality and competently organize the consumption of sealant.

- When working with the tool it is desirable to be in special gloves, overalls and goggles. If you need to remove excess sealant from the surface, then it is strictly forbidden to do it by hand. For this purpose, you need to have a spatula or at least an ordinary rag on hand.

- To zamenit vertical seam, you should start at the bottom and climb up. It is this procedure that allows to control the uniform filling of voids with material. When the nozzle of the gun goes higher, you can immediately see the result of filling the seam.This will allow to analyze and determine the need for pressure regulation.

- After work, the gun needs cleaning. To get rid of the stiffened foam, it is worth applying solvent. Cleaning the tool after performing the work will allow to extend its service life.

- When working with a gun stops even for a few minutes, the cylinder must always be in a vertical position. It is necessary to exclude hit of direct rays of the sun on it, and also to work with it far away from open fire.

- If after performing all the tasks in the tank there is foam, then the gun does not need to be disconnected, because it will allow to keep the foam in a liquid state. To use the sealant again, you will first need to clean the nozzle of the gun, otherwise the tool may break.

Materials and structures

Before choosing a particular model of the gun, you must first familiarize yourself with its design features.

The product consists of several separate elements:

- Body products. It can be made of plastic or metal.Higher quality are metal guns with Teflon-coated.

- The barrel is an important element of the tool, since it is responsible for creating a jet of foam. It has a needle rod.

- Pistol grip should be conveniently located in the hand. It is located on the trigger responsible for adjusting the supply of sealant. Clicking on the trigger, the exhaust valve begins to move.

- The nozzle is presented in the form of a tool tip. He is responsible for the amount of sprayed foam. You can use interchangeable nozzles to create the necessary stream of sealant.

- Adapter or gearbox. His task is to fix the balloon with foam, because it is through him that the flow of sealant to the tool system begins. It has a valve that produces control for a portion of the supply of sealant.

- The adjusting screw or clamp is located behind the gun. He is responsible for the pressure of foam in the tool barrel.

The material from which the gun for the assembly foam is made plays a very important role in its selection, since the duration of use of the product depends on it.

Manufacturers use various materials in the manufacture of mounting gun.

- Low quality plastic. Products are inexpensive and unsuitable for repeated use. They can be called disposable. The plastic tool will turn out to be used only for one cylinder of sealant, after which it can be simply thrown away. And not always the quality of work meets all requirements, if you use such a tool.

- High impact plastic. Products from this material are in demand, because high-impact plastic is of excellent quality and lightness. Working with such a tool, the hand does not get tired, and the quality of the work performed pleasantly surprises.

- Metal. Quality metal guns are a classic choice. They are characterized by reliability, convenience at work and durability. They can be cleaned and, if necessary, even disassembled.

- Teflon-coated metal. Pistols of this material are professional and are quite expensive. The uniqueness of Teflon spraying is that the foam does not strongly adhere to it, so this gun can be easily cleaned after use.

Criterias of choice

To date, a huge selection of high-quality, stylish and durable guns for polyurethane foam is on sale, but you can also buy fragile tools that you can immediately throw away after the first use.

To make the right choice, you need to pay attention to several criteria.

- Popularity of the manufacturer and the selected model. It is worth reading the reviews of this product.

- The design of the product. It is better to choose a model of metal than plastic. The barrel and valves must be made exclusively from high-quality metal, this will extend the life of the product. Your choice is to give a collapsible design. If the tool is clogged with foam, it can be disassembled for cleaning.

- The quality of the handle and its location in the hand. When performing work with a pistol, the handle should be conveniently placed in the hand, not slide.

- The cost of the product. Cheap tools will not last long, should be focused on pistols of the average price category.

Experts advise when buying a gun for the installation fluid immediately in the kit and take a special fluid to clean it.After all, the tool needs a high-quality cleaning of sealant residues after each use of the product. The seller must know about the warranty on the purchased product so that in the event of a malfunction of the instrument it can be returned back to the store. And, of course, the instruction manual from the manufacturer should be included with the product.

Professional

Professional pistols are intended for regular work with sealant. They will help to carry out huge amounts of work. The devices are distinguished by a durable casing, which is made from metal of excellent quality. Some models also have Teflon spraying.

All professional models are characterized by convenient access to the inner tube of the tool in order to clean the product from the dried foam quickly and easily. All types of professional pistols have an excellent system of fastening a cylinder with a sealant.

An important role is played by the cost of the product. The minimum price of a professional tool for working with sealant is 800 rubles.

German equipment "Solid Metal" from the brand Kraftool is a prime example of professional equipment.It is characterized by functionality and reliability, as well as ease of cleaning after use. This model is equipped with a removable spout to provide access to cleaning the inside.

The fastener for the cylinder with a sealant is made of brass, and the tool body is made of copper alloy, which protects it from mechanical damage. It is durable. The tightness of the product prevents the sealant from freezing inside, which allows you to use a half-empty container in the future.

If we talk about the shortcomings of the gun, then we can note its great weight. If you use the tool for a long time, the hand begins to tire. The product is characterized by a high price, but it pays off completely, since the tool can be used for about seven years.

Professional model Matrix 88669 German-made attracts the attention of a heavy-duty metal body coated with Teflon-coated, which prevents strong fixation of the foam to the internal elements. Cleaning the sealant supply tube is quick and easy, as are other parts of the tool. After using the gun, it is enough to clean the spout with a special nozzle and wipe it outside.

All parts of the model are made of metal alloy "tsam", so it is characterized by reliability and durability. The convenient handle has in addition protection against pinching of a finger as there are two stoppers located on it. The thin nose allows you to work even in hard to reach places.

The disadvantages of this model include the fact that it should be stored in a separate case. If a Teflon coating is scratched when cleaning, it loses its properties. Some buyers complain about the overestimated cost of the model, but very soon the tool pays off.

Model Matequs Super Teflon It is one of the most famous Italian-made pistols. The unique design of the tool contributes to the formation of plastic foam. Sealant, entering inside the tool, expands, which contributes to its plasticity.

The model is equipped with a needle with a diameter of 4 millimeters, which allows you to cope even with wide seams in just one pass. The design of the product allows you to choose an economical supply of sealant, which will allow the installation of five windows with just one cylinder of foam.

The ergonomic handle allows you to work with the tool for a long time.It has a nylon coating that prevents slipping. The gun can be easily disassembled for cleaning, as all connections are threaded. Parts of the tool are made of high-quality metal and coated with Teflon-coated, therefore, the foam does not strongly stick to them.

Model Matequs Super Teflon characterized by durability. The valves are seals made of high quality rubber, which are not only responsible for the tightness of the product, but also maintain contact with the solvent. The narrowed nose allows to fill even hard-to-reach slots.

This option has a high cost. Cleaning the instrument must be done carefully so as not to damage the Teflon coating.

Amateur

If you make repairs yourself and you need to use sealant to install several doors or windows, then there is no need to buy a professional tool for a one-time job. On sale is a wide range of amateur pistols. They are cheaper relative to professional options.

A great choice of mounting gun for lovers is the model Stayer econom German production. It is characterized by strength, since it has a stainless steel supply tube. It can not be removed for internal cleaning, so you need to use solvent washing to remove any residual sealant. For reliable fixation of the sealant bottle, a threaded grip made of aluminum protrudes. The tool trigger is also aluminum.

In order to use the tool many times, it is necessary to clean the barrel after each use. This will avoid blocking the tube. The sealant supply system is characterized by the presence of a ball valve at the inlet and a needle mechanism at the outlet.

Among the advantages of this model it is worth mentioning the acceptable cost, comfortable grip, high-quality aluminum body. The disadvantage of the tool is a non-separable design. Threaded grip is only suitable for some sealant bottles. If you do not clean the nozzle after work, then after a while it will be very difficult to remove the foam from the tube.

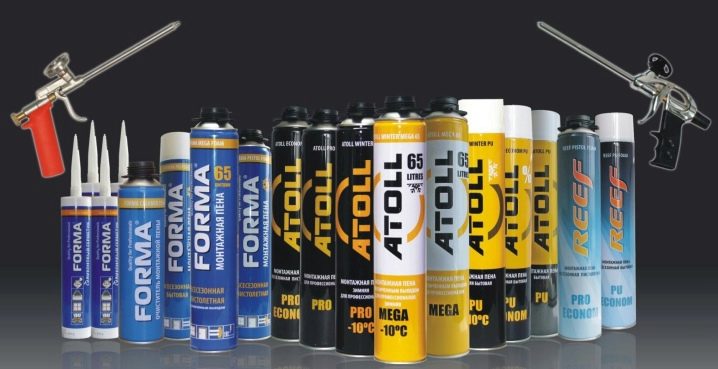

The cheapest gun to use sealant is the model Atoll G-116, but it can be used repeatedly if the device is cleaned on time. The gun has a wide edge in the place where the cylinder is fixed. This allows you to quickly change an empty cylinder to a new one. The presence of a full thread allows you to securely seal the sealant for future use.

Indisputable advantages of the model Atoll G-116 is convenience and ease. The tool body is made of aluminum, therefore it is characterized by ease of maintenance. The disadvantages of the tool include the absence of a stopper before the trigger, which can lead to pinching of the fingers. The constant use of cleaners over time adversely affects the tightness of the rubber rings located on the valves.

The leading brand of pumping equipment and electric tools in Russia is company "Whirlwind". It produces high-quality pistols for working with foam, using high-quality metal. Its products are intended for reusable use, while it can be purchased at an affordable price. The thin barrel allows you to work even in hard to reach places. The convenient handle promotes long work.Acceptable price and excellent quality are successfully combined in the brand's products.

Blast extra light - a model from a Chinese manufacturer that is in demand despite the fact that all the parts are completely made from plastic. The main advantage of this gun is the ease of construction. It has a large and comfortable grip, so even for a long time, working with such a gun, the hand does not get tired. This model is equipped with a needle valve that reliably holds the foam.

To adjust the sealant supply, it is necessary to rotate the folded lever of the tool. Sealant supply lock is also carried out using a lever. It must be inserted into a special groove.

Disadvantages Blast extra light models This refers to the fact that the tool should be cleaned immediately after operation, since the frozen foam is very difficult to remove from the plastic. The presence of a wide latch allows you to quickly replace the cylinder, but the gun will not last long because of the plastic construction. It is necessary to avoid dropping the pistol, because it immediately breaks down due to a strong mechanical impact.

Manufacturers Overview

Today a wide selection of amateur and professional guns for polyurethane foam is on sale. To purchase a quality product, you should pay attention to the fame of the tool manufacturer. Popular brands have already established themselves as the best manufacturers, and many reviews have already been left about their products.

Rating the most popular manufacturers of guns to work with sealant.

- German company Kraftool offers high quality tools that are characterized by versatility and reliability. Tools are made from durable metal. They perfectly regulate the flow of foam.

- German brand Matrix offers stylish, high-quality pistols for true professionals. They are made from high quality and reliable copper alloy, Teflon spraying contributes to the ease of cleaning tools. Accuracy and convenience are the strengths of products from this manufacturer.

- Company Soudal acts as a well-known manufacturer of polyurethane aerosol foams and sealants, as well as equipment for professional craftsmen. Its products are represented in 130 countries, and representative offices in 40 countries.Pistols from the brand have metal movements with high-quality Teflon coating.

- German brand Hilti is a manufacturer of construction equipment since 1941. Foam guns are among the best in the world.

- Among the Russian manufacturers of construction equipment, the company deserves attention. "Varangian". It offers professional guns for working with sealant, made of high quality metal with Teflon coating. The rubberized handles guarantee convenience when working with the tool. Lightweight body, proven mechanism and affordable price made the guns from "Varyag" popular among amateurs and professionals.

How to check?

Before use, the gun must be checked for tightness and valve retention.

You can perform this check yourself at home:

- A solvent bottle is required.

- It is necessary to attach the washing, slightly unscrew the adjusting screw and pull the trigger several times until liquid appears.

- After disconnecting the cylinder and leave the tool for a day.

- Then again pull the trigger.If a liquid is sprayed from a nozzle, this means that the gun is hermetically protected.

Useful recommendations

Before using the gun for foam, you should carefully read the instructions, which include several important points:

- Before use, all threaded connections must be tightened slightly, since they may become loosened during transport.

- To check the valves for leaks, pour cleaning fluid into the gun and leave it for a day. If you then pull the trigger and the liquid is sprayed, the mechanism works normally.

- Before connecting the cylinder with the gun, you first need to shake it well for several minutes.

- For each cylinder change, the gun should be located at the top.

- If foam remains in the cylinder after the work, the tool can be stored together with the cylinder, but the gun should be located at the top.

- If after the construction work the balloon has remained empty, then it must be removed, the gun must be cleaned and rinsed with solvent for further storage.It is strictly forbidden to leave the gun without cleaning, since it will no longer be able to perform its functions.

When working with a mounting gun, it is necessary to follow the advice of experts:

- all places that need to be filled with foam must be cleaned of dirt and dust and slightly moistened with water;

- work should be done in warm weather, so that the moisture evaporated slowly, the optimum temperature is 20 degrees;

- working with a pistol, the cylinder should always be at the top, otherwise only gas will flow out of the tool barrel;

- it should be filled with foam at the top, when the sealant cylinder is still full, after that the work should be done from the top down. The seams below are filled in last;

- if the cylinder is half-empty, then work should be carried out from the middle and gradually move down, and after replacing the cylinder with a new one, blow out the upper seams;

- if it is necessary to work in deep joints or under the ceiling, then a flexible extension cable will help to get into such hard-to-reach places.

When the work is done, it is necessary to perform operations for the maintenance and cleaning of the instrument:

- If the foam bottle is half empty, then it can be used in the future.You do not need to unscrew the sealant and wash the gun; on the contrary, you should only wipe the nozzle of the instrument from the foam residues using a cloth moistened with acetone or other solvent and put the gun with the bottle down for storage. In this form, the sealant can be used for five months.

- If the container is empty, unscrew it.

- To properly clean the tool, it is necessary to fasten a can of solvent. Then pass the liquid through the whole mechanism. This will avoid drying out the foam inside.

- For external cleaning of the gun, you can use a cloth dipped in acetone.

- If the foam inside the gun is dry, then you can disassemble it with your own hands and clean the internal parts.

For information on how to choose a gun for foam, see the following video.