Winter foam: features and application

Many construction and repair work include the use of foam. Subzero temperatures should not be the cause of the suspension of construction. Thanks to the special types of polyurethane foam sealant, work can be continued under any weather conditions. However, before buying such a product, you should find out what is a winter foam, what are the features of its application.

Features and properties

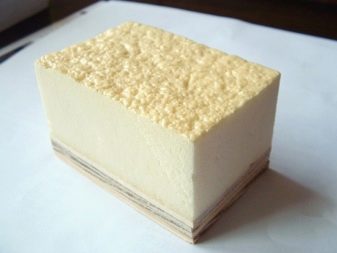

Polyurethane foam is a substance released in an aerosol package. It contains a liquid prepolymer, displaced from the balloon by a mixture of gases. Due to this composition, the mounting foam, displaced from the container, foams and expands under the influence of moisture.Then, during the polymerization process, the product is completely hardened. The result is a fairly strong substance - polyurethane foam, which fills all the necessary cavities, seams and hard-to-reach joints. With the help of one cylinder you can perform a fairly large amount of work, which is facilitated by a significant coefficient of expansion of the substance.

In the period of cold spring or autumn, the use of winter varieties of foams is mandatory. If the air temperature falls below +5 C, then summer foam will become unsuitable for installation.

The performance of the material decreases with decreasing temperature. At negative temperatures, the amount of foam is reduced to a minimum. In addition, the layer may not harden properly, the substance during the application process will not be able to achieve the required consistency and will not form the required hermetic base. Winter varieties of sealant are able to solve this problem, ensuring stable operation at temperatures as low as -10 ° C. Therefore, in winter, it is necessary to use only special high-performance foam options.

The winter polyurethane foam sealant differs from the summer mainly in the chemical composition of the propellant, the propellant, which makes the foam much more productive. According to the main characteristics, winter types of foaming sealants have the same adhesion and insulation data as summer ones. With positive air temperatures, winter sealants work just as well, so they can be used in summer too.

Applying polyurethane foam, it is necessary to remember one important nuance. The hardening time of the polyurethane foam sealant depends on the ambient temperature and increases with each decrease in degree. Experts advise not to proceed with further processing until the foam layer completely hardens. In the winter season, this process takes longer than in summer. Non-observance of material hardening periods leads to deterioration of the properties of the assembly foam, as well as disruption of the layer structure and dimensional stability.

Types and specifications

All existing mounting foam can be divided into several types according to various criteria.

For components of the product is:

- single component;

- two component.

According to the ambient temperature during the application period, three types of foam are distinguished:

- Summer - marking on the package indicates the surface temperature at the time of application from + 5 ° to + 35 ° C, but at the same time the frost resistance of the hardened foam ranges from -50 ° to + 90 ° C.

- Winter - the temperature range at the time of application is mainly from -10 ° to + 35 ° C (some manufacturers were able to lower the lower limit to - 20 ° C).

- All-season - the most versatile option that combines the properties of the two previous foams. Due to the special formula, the substance is able to increase in volume and quickly polymerize even in the cold.

According to the method of application foam is:

- professional, requiring the use of a special dispensing gun;

- household or semi-professional, not requiring special devices (for applying apply a special tube adapter).

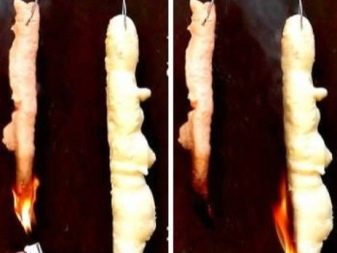

Class of flammability foam is divided into:

- fireproof or fireproof B1;

- self-extinguishing B2;

- combustible B3.

The technical characteristics and properties of the winter installation foam include several main points:

- Adhesion ability of a variety of parts during installation.

- Frost resistance.In the hardened state, the foam layer is able to withstand low temperatures, retaining all performance data.

- Good sound and thermal insulation characteristics.

- The ability to fill and seal air voids, cavities in hard to reach places.

- Excellent compatibility with most building materials (except Teflon, silicone, polyethylene, oily surfaces, etc.).

- Porosity capable of providing stability in various combinations.

- Good adhesion, providing the ability of a substance to adhere to any base. This property helps ensure a quick and high-quality installation process.

- Shrinkage. The smaller this value, the stronger the connection will be. The substance possesses this characteristic after solidification.

The quality characteristics of the installation sealant depend on several parameters:

- Surface and ambient temperature at the time of use. In the cold, working with sealants becomes more difficult, as cold air is characterized by low humidity. In such conditions, the foam does not expand so well and does not harden quickly enough.

- Expansion - this property of the sealant affects the quality of the seal.With excessive expansion, it can lead to deformation of building structures.

- The viscosity of the substance - this parameter characterizes the ability of the sealant not to crawl off the surface at the time of installation.

Scope of application

Due to its properties (high coefficient of expansion and excellent adhesion to most building materials), frost-resistant foam is widely used for both internal and external works.

This material is very popular among builders and is used as:

- sealant and sealant in structures for filling gaps, voids and joints;

- insulation and soundproof material (due to its porosity);

- fixing material and retainer of individual parts during installation, for example, when installing windows, doors or wall insulation;

- heat insulator in heating or cooling systems;

- an insulator at distributing distribution and electric networks.

Manufacturers

One of the most prominent examples of the mounting foaming substance most commonly found in construction work is the foam sealant. Soudal. According to the specifications, it is recognized as a high-quality material, as evidenced by the number of sales of this sealant, and positive feedback from satisfied customers.

Soudal is the world's largest manufacturer of polyurethane spray foam. The highest quality and wide range of products allow the manufacturer to lead in the market of building materials for about 20 years. The assembly Soudal foam has excellent operational characteristics, uniform structure, high degree of isolation and moisture resistance. Winter line of this manufacturer can be used at temperatures up to -250 ° C.

Another example of high-quality installation material is frost-resistant one-component aerosol foam. Penosil. It has good technical characteristics: high material yield, excellent adhesion, uniform uniform structure, small secondary expansion. This is a universal professional installation tool that can be used in all weather conditions.

Polyurethane foam Makrofleks - it is a one-component polyurethane material having good adhesion, a long operational period during which the material does not break.Despite the good technical characteristics, the product has a low cost.

Adhesive foam TechnoNIKOL - good mounting material with excellent performance. This product of domestic production is convenient and effective in use, it is actively used for warming rooms by installing polystyrene foam boards, sheets of gypsum cardboard, gypsum fiber, blocks of aerated concrete.

Excellent winter foam is considered Tytan professionalrepresenting the new generation of polyurethane foams. It is absolutely harmless material, safe even at the time of application. The product can be used at temperatures up to –200 ° C without pre-heating the cylinder.

Before purchasing foam, it is necessary to determine the requirements for this material. Sales assistants in hardware stores will help you deal with the assortment and make the right choice.

Usage tips

Before using foam, you should remember some basic rules:

- The temperature of the surface on which the foam will be applied must comply with the limits indicated on the packaging.

- The foam cylinder must not be stored at temperatures below zero. If the sealant was located somewhere at sub-zero temperatures, it is necessary to warm it to room temperature before use. Heating with warm water of 30-500 ° C is possible, although the products of some manufacturers do not require such procedures. In any case, it is better to carefully study the instructions for use.

- Apply foam, holding the cylinder upside down. Voids and seams must be filled with ca. 1/3 of volume. It should be remembered that during the polymerization layer tends to expand. The lower the temperature, the higher the viscosity of the material. Content sticks to the walls of the cylinder, it becomes impossible to use the entire mixture. If used horizontally, the valve may become clogged.

- Shake well before use. This is necessary in order to mix the components.

- Surfaces to be treated should be thoroughly cleaned from dust and debris. You can slightly moisten them with a spray bottle, but do not allow the accumulation of liquid. Otherwise, ice may form in such places, preventing the adhesion of materials.

- If the slit thickness is more than 5 cm, it should be closed on the opposite side with cardboard, foam plastic or other material.

- Further surface treatment should be carried out no earlier than 24 hours. If necessary, you can apply the next layer of foam.

- Hardened foam must be protected from direct sunlight, otherwise the layer will become porous and brittle, which will reduce the performance characteristics of the material.

- If the composition has not been completely consumed, it can be used after a while.

Careful examination of the manufacturer's advice on the use and storage of winter foam will help you achieve good results with this material at any time of the year.

More details about using different types of foam are described in the video.