Ceresit CM 11 glue: properties and application

When working with tiles used materials for various purposes. They allow you to qualitatively prepare the base, attach different cladding such as ceramics, natural stone, marble, mosaic and fill the tile joints, providing the product with hermetic protection from moisture and fungus. Reliability and durability of laying tile coatings largely depends on the quality of tile adhesive and grouting.

Among the auxiliary products for the repair of reputable brands, the integrated Ceresit systems created by Henkel and designed to work with all possible types of facing materials for interior and exterior decoration deserve special attention.In this article we will focus on Ceresit CM 11 basic adhesive mixture, consider the variations of this product, their working properties and the nuances of use.

Special features

Adhesive compositions for laying tiles Ceresit differ in scope, as can be seen on the label on the packaging:

- CM - a mixture with which to fix the tile;

- SV - materials for fragmentary repair of cladding;

- ST - assembly mixtures, with the help of which they arrange external heat insulation on facades.

Ceresit CM 11 glue - material with cement knitting as a basis, the addition of mineral fillers and modifying additives that enhance the technological properties of the final product. Ceramic granite or ceramics is fixed on it when carrying out internal or external types of interior decoration at housing and civil facilities and in the manufacturing sector. It is combined with any typical non-deformable mineral bases: cement-sand screed, concrete, plaster leveling coatings based on cement or lime. Recommended for rooms that experience constant or short-term regular exposure to the aquatic environment.

CM 11 plus is used for cladding with ceramics or natural stone with dimensions of maximum 400x400 and a water absorption value of 3 percent. According to “SP 29.13330.2011. Floors ”, it is also allowed to plant tiles (porcelain stoneware, stone, clinker) with water-absorbing ability of less than 3% for flooring without electric heating. In these cases, the composition is used exclusively for the internal finishing works in the premises of household and administrative purposes, that is, where the operation does not imply high mechanical loads.

Kinds

For the device of screeds on the bases with internal heating and work with deformable bases in the line of glues Ceresit - Henkel there are highly elastic mixtures СМ-11 and СМ-17 with low-modular filler CC83. By adding this elastomer, the final product acquires the ability to withstand shock and alternating loads. In addition, the presence in the composition of the elasticizer prevents the formation of microcracks in the bonding base.

Highly elastic SM-11:

- to carry out external facing of floors and walls with any existing types of tiles;

- arrange screeds on the foundations with underfloor heating;

- make facing socles, parapets, external flight of stairs, private areas, terraces and verandas, flat roofs with an angle of inclination of up to 15 degrees, outdoor pools and a closed type;

- to veneer deformable foundations from the ABS and chipboard, gypsum, gypsum, anhydrite, light and cellular concrete foundations or recently filled with less than 4 weeks of age;

- work with ceramics, including glazed inside and outside;

- make facing works on surfaces with durable paint, plaster or anhydrite coatings, which have good adhesion.

For facing with marble, clinker of light shades, glass mosaic modules, it is recommended to use CM 115 of white color. Large-format floor tiles are laid using CM12.

Benefits

Sustained interest in Ceresit CM 11 due to a set of attractive working qualities, including:

- water resistance;

- frost resistance;

- manufacturability;

- stability when facing vertical surfaces;

- eco-friendly composition that eliminates harm to health;

- incombustibility in accordance with GOST 30244 94;

- ease of use and long period of adjustment;

- universality of use (suitable for tiled cladding in the performance of internal and external works).

Specifications

- Liquid dosage for mixing: to prepare a working solution, a 25-pound bag of powdered product is mixed with 6 liters of water, that is, approximately in proportions 1: 4. The number of ingredients for preparing a solution with CC83: powder 25 kg + liquid 2 l + elastomer 4 l.

- The production time of the working solution is limited to 2 hours.

- Optimum working conditions: t of air and working surface up to + 30 ° С degrees, relative humidity less than 80%.

- The open period is 15/20 minutes for a normal or super elastic mixture.

- The allowable adjustment time is 20/25 minutes for a standard or highly elastic composition.

- The limit of slipping of the tile facing is 0.05 cm.

- Grouting of joints when working with a non-elastomer compound is made after a day, in the case of using a highly elastic composition - after three days.

- Adhesion to concrete with glue without CC83 is more than 0.8 MPa, for an elastic one - 1.3 MPa.

- Strength at compression - more than 10 MPa.

- Frost resistance - at least 100 freeze-thaw cycles.

- The operating temperature range varies from -50 ° C to + 70 ° C.

Mixtures are packed in multi-layered paper bags of various sizes: 5, 15, 25 kg each.

Consumption

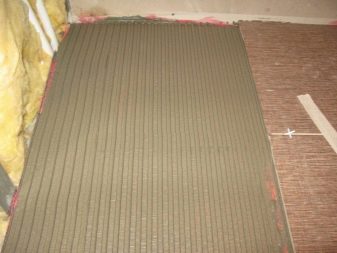

Between the theoretical norms of consumption of adhesive mixture and practical indicators most often there are discrepancies. This is due to the fact that the consumption per 1m2 depends on what size the tile and trowel-comb are used, as well as on the quality of the foundation and the level of the wizard’s professional training. Therefore, we present only approximate values of flow rate at an adhesive layer thickness of 0.2-1 cm.

Tile length, mm | The dimensions of the teeth of the putty knife, cm | Consumption rates, kg per m2 | |

CM-11 | SS-83 | ||

≤ 50 | 0,3 | ≈ 1,7 | ≈ 0,27 |

≤ 100 | 0,4 | ≈ 2 | ≈ 0,3 |

≤ 150 | 0,6 | ≈ 2,7 | ≈ 0,4 |

≤ 250 | 0,8 | ≈ 3,6 | ≈ 0,6 |

≤ 300 | 1 | ≈ 4,2 | ≈ 0,7 |

Preparatory work

Facing work is performed on bases with a high bearing capacity, processed in accordance with sanitary standards, which means cleaning them from pollutants, reducing the adhesive properties of the adhesive mixture (efflorescences, fats, bitumen), removing loose crumbly areas and dust removal.

For leveling the walls it is desirable to use the repair plaster mixture Ceresit CT-29, and for floors - the leveling compound Ceresit CH. Plastering work should be carried out 72 hours before the device tiled cladding.Construction defects with a height difference of less than 0.5 cm can be corrected with a mixture of CM-9 24 hours before fixing the tile.

For the preparation of typical bases use CM 11. Sand-cement, lime-cement plastered surfaces and sand-cement screeds older than 28 days and humidity less than 4% require treatment with ST17 soil followed by drying for 4-5 hours. If the surface is dense, durable and clean, then you can do without a primer. In cases of preparation of atypical bases, the combination of CM11 with CC-83 is used. Plastered surfaces with moisture less than 0.5%, wood-shaving, particle-cement, hygrochny bases and bases from light and cellular or young concrete, whose age does not exceed a month, and humidity - 4%, as well as sand-cement screeds with internal heating Recommended priming CN94 / CT17.

Facings made of stone tile or under stone, surfaces treated with water-dispersion coatings with high adhesive properties, floating screeds of cast asphalt are necessary to be treated with primer CN-94. Drying time - at least 2-3 hours.

How to breed?

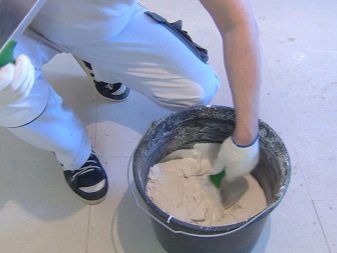

To prepare the working solution, water is taken at a temperature of 10–20 ° C or an elastomer diluted with water in the proportions 2 parts CC-83 and 1 part liquid. The powder is metered into a container with liquid and immediately mixed with a construction mixer or a drill with a spiral nozzle-mixer for viscous consistency solutions at 500-800 rpm. After that, a technological pause is maintained for about 5-7 minutes, due to which the mortar mix has time to mature. Then it remains only to re-mix and apply as intended.

Recommendations for use

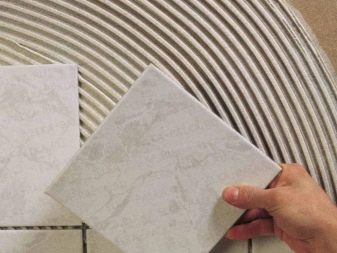

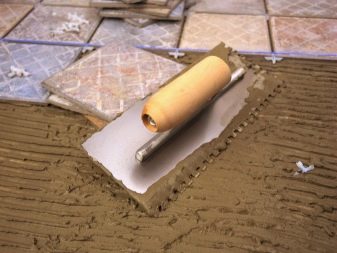

- For the application of cement tile glue, a notched trowel or a toothed grater is suitable, in which a smooth side is used as the working side. The shape of the teeth should be square. When choosing a tooth height, they are guided by the tile format, as shown in the table above.

- If the consistency of the working solution and the height of the teeth are chosen correctly, then after the tile is pressed to the base, the wall surface to be coated should be covered with an adhesive mixture of at least 65%, and floors - by 80% or more.

- When using Ceresit CM 11, pre-soaking the tiles is not required.

- Butt tile installation is not allowed. The width of the seams is chosen based on the format of the tile and the specific operating conditions. Due to the high fixing ability of the glue, there is no need to use cross-stitching, which ensures evenness and the same width of the inter-gap gap.

- In cases of making stone cladding or performing facade work, a combined installation is recommended, which implies an additional application of glue mixes to the tile installation base. When forming the adhesive layer (thickness up to 1 mm) with a thin spatula, the consumption rate will increase by 500 g / m2.

- The seams are filled with the appropriate trowel mixtures under the CE mark after the day has passed since the end of the facing work.

- Water is used to remove fresh residues of the mortar mixture, whereas dried spots and spills of the solution can only be disposed of with mechanical cleaning.

- Due to the content of cement in the composition of the product when it is in contact with the liquid, an alkaline reaction occurs. For this reason, when working with CM 11, it is important to use gloves to protect the skin and prevent its contact with eyes.

Reviews

Basically, reviews of users of Ceresit CM 11 are positive.

Of the benefits buyers most often point out:

- high quality bonding;

- profitability;

- long service life;

- the reliability of fixing heavy tile (SM 11 does not allow it to crawl);

- comfort at work, as the mixture is stirred without problems, does not spread, does not form lumps and dries quickly.

This product has no serious minuses. Some are dissatisfied with the high price, although others consider it to be fully justified if we take into account the high performance of the CM 11. Most users advise purchasing adhesive mixtures from official Ceresit dealers, as otherwise there is a risk to buy a fake.

For the properties and application of Ceresit CM 11 glue, see the following video.