Adhesive Sealant: Pros and Cons

Every time, undertaking repair, many face the problem of choosing high-quality finishing materials. When plastic windows are inserted, and the tiles in the bathroom are laid, the question arises of how to protect the result obtained from damage and give it an aesthetic look. Glue-sealant comes to the rescue - a universal tool for applying to the seams and joints between different surfaces. This glue will protect against cold and against fungus, if it is selected correctly.

Special features

Glue-sealant is a mixture consisting of a set of polymeric materials with various both organic and artificial additives.The scope of its mission depends on the main element included in the tool.

Sealant must have a number of useful qualities.

- The ability for adhesion, that is, good adhesion with other surfaces, so that the edges never lag behind, the surface with glue does not swell and does not go mounds. The greater the number of surfaces that can be treated with the same type of sealant, the more versatile it is considered, and, accordingly, the more expensive it is.

- Opposition to the development of mold fungi, which is especially important for the joints between the tiles in the bathroom, where, because of poor-quality sealant, it is sometimes necessary to redo all repairs.

- Resistance to the formation of cracks in the seam and their destruction, because glue is not a consumable material that must be changed every year. Ideally, the sealant should withstand both mechanical shocks and internal tremors and vibrations over the years. If at least a small crack forms in a hermetically sealed seam, he immediately starts to transmit heat and moisture.

- The ability to easily tolerate changes in the environment, such as sudden changes in temperature, increased exposure to moisture, dust, or ultraviolet radiation.Many types of sealants are used for objects located in the open air, so it is important that they do not crumble after the first rain.

- Persistence when interacting with aggressive chemical elements, such as gasoline or alkali, is also very important, even if it is not about industrial facilities. For example, you can only glue door rubber bands on your car so that they will last at least a year, you can only with very high-quality material.

- Plasticity and viscosity also play an important role in choosing the right adhesive sealant, because it should go smoothly into the gap and the seam of any shape and depth, evenly distributed over the surface.

- The speed of drying and hardening, because the faster these processes occur, the safer the repair algorithm. Especially this characteristic of sealants is important when repairing in an open area, when a long-hardening adhesive just creeps away from the weather. Slow pouring tempo in some cases, on the contrary, can be salutary, especially when the seam is patched carelessly from sudden movement or inattention. Otherwise, the quickly hardened material will have to be cut off at the places where the excess is formed with a knife or left as it is.

Kinds

There are many classifications of sealants according to the criteria of their chemical composition, properties and functionality. Before going to the store, it is better to familiarize yourself in advance with the basic characteristics of the glue on the Internet and mark several specific modifications and manufacturers needed for this type of work, for example, to decide whether a sanitary sealant or universal is needed. For each type of gluing, there are many identical names, and the box with the sealant is very small, and there is not always a detailed instruction for use.

Depending on the complexity of its polymer composition, glue is of several types.

- Single component sealants, sold as a ready-to-use mixture with one main active ingredient. Such a sealant does not require additional manipulations, it is ready to work after opening the container and contact of the composition with air. It is worth remembering that as soon as the integrity of the package is broken, you should immediately start working, because soon the glue will harden, even if nobody touched it.

- Two component glue comes with an activator (catalyst), which must be added after opening the package. Only then will the reaction begin, and the composition will be ready for use.There are different types of additives to the glue, and if work is impossible without them, they are usually applied in a set in a separate package. Most often, they can be purchased additionally, if the substance was not enough to dilute the entire volume of glue or the coveted bag was lost.

The main classification of sealants is considered to be based on the basis of the main active element in the mixture.

- Polyurethane sealant, which has a very high strength and durability, so it is often used in industry. But also for domestic purposes, it is suitable if it is necessary to fasten and form gaskets, as well as to seal the seams of the car. However, its increased adhesion to other materials has a reverse side - in its properties it resembles polyurethane glue, therefore it holds everything tightly together, so this sealant is not suitable for moving and collapsible parts of the mechanism.

The seam made by polyurethane sealant is not afraid of moisture or aggressive sun, so the glue is often used for work outdoors, especially when repairing the roof of buildings. Also polyurethane sealant actively resists potent chemicals,therefore, when repairing a car after its application, it is possible to treat everything from above with a protective or anti-corrosion coating. Possessing excellent elasticity and resilience to deformations, such glue is good for repairing building facades.

The main drawback of polyurethane compounds is their high toxicity and an unpleasant caustic odor at work, which is why this sealant is not suitable for interior use. Yes, and on the street with him it is necessary to observe all the rules of precaution, and to glue the details in a protective suit and mask.

- Anaerobic sealant - a sufficiently strong tool used for sealing seams and creating gaskets in the threaded sections of both pipes and various mechanisms, such as flanges. The peculiarity of anaerobic compounds is that they harden, in fact, without contact with air, but by means of polymerization when in contact with metal. This method of drying ensures maximum durability of the compound and its strength.

Before buying such a sealant, it is necessary to clearly understand for which particular elements it will be used, because depending on this, a means of varying degrees of strength will be required.Thus, anaerobic adhesive sealant with a low degree of strength should be used for joints that are in constant motion, subjected to heavy loads or frequent dismantling.

Glue with an average degree of strength is needed for joints that are rarely dismantled and are mainly at rest, for example, car parts. Sealant with the strongest strength should be used only for fixed parts and threaded connections, since they are then almost impossible to separate.

Among the obvious advantages of anaerobic sealants can be distinguished resistance to high temperatures or heat resistance, up to 100-150 ° C for the average adhesive in this line and up to 175 ° C in individual names. In addition, this sealant is resistant to the interaction with complex chemicals, such as gasoline, motor oil or ethylene glycol. Due to this factor, anaerobic substances are used in the repair of both automobiles and, for example, a home generating set on a diesel or boiler house.

Anaerobic sealant is very economical in consumption, but still it is worth buying it with a minimum margin.It fits well with the surface only if it is distributed evenly over the entire seam area. If the pipe is being repaired from the inside, it is not immediately clear how much sealant will be needed to seal the seam. If the gap is not completely filled or the sealant is applied in several stages, it will harden unevenly. In such a situation, it is not necessary to count on the durability of the joint, since under the influence of vibrations the seam can crumble.

The high degree of adhesion of the anaerobic sealant to the metal surface also has a reverse side - when removing or replacing the joints, it is sometimes necessary to use special tools to separate the elements from each other. In some cases, it is even necessary to heat the gluing place to an ultra-high temperature so that it will break up, which is not always possible in the domestic environment. Another feature of anaerobics is compatibility only with substances of similar composition, which are not always similar even within the line of the same, at first glance, sealants. When buying an additional can of such a composition, it is better to know exactly how the seam was sealed before, and choose an anaerobic composition that is as close as possible to the previous one.

- Acrylic Sealant It is very popular for interior work, especially decoration and decoration. It is the safest, environmentally friendly, quick-drying, and also virtually odorless. The zone of its application is extremely narrow - acryl is unstable in front of low temperatures, it is destroyed by deformations and vibrations under pressure, and low elasticity does not allow them to glue moving parts of mechanisms. Such a sealant is good for use in a warm building, and the humidity should not be too high.

Despite the fact that all acryl is made on a water basis, sealants here are also divided into waterproof and not waterproof. Ordinary acrylic glue is dissolved with water, it can be tinted in any desired color with the same acrylic paint, if the basic white or transparent modification is not satisfied. From temperature fluctuations or contact with moisture, it may crack within a few days after application, but for a plastic and, most importantly, dry surface, it will work fine and will last a long time.

Waterproof acrylic sealant can no longer be called absolutely harmless to people, but the possibilities of its use are much wider.It has good adhesion, that is, it is combined with many surfaces, even uneven and with previous colorful layers. You can also glue the seams even in the bathroom, because waterproof acrylic reacts normally to periodic moisture on the seam surface. You should not use it in places of constant interaction with water such as pools, no acrylic can withstand such loads.

Another type of acrylic sealant is an adhesive with the addition of a latex component. Possessing high elasticity and not amenable to deformation, it is often used for installation work in the repair of doors and window openings. Of the advantages of such a sealant, it is possible to note the ability to color the resulting seams not only with acrylic paint, but also with the usual oil paint.

- Bituminous sealant It has been very popular since ancient times, due to its unpretentious operation, increased strength and fast-setting. In addition to natural bitumen and rubber components, it consists of polymer additives, due to which this sealant is applicable to almost any type of repair.Most often it is used in the repair of slate or tile roofs, as well as foundations and foundations of the fence. Bituminous material is also good for communication and bonding joints in drainpipes.

In fact, bitumen is a derivative of petroleum products and looks like black resin or liquid rubber in appearance. This structure has a very good viscosity and fluidity, so the sealant evenly falls on the most difficult and uneven surfaces. It is often written on its packages that bitumen is applied on any, even uncleaned surface. This applies only to situations where particles of dust or small construction debris remain on the items for sealing. If the surface is not cleared of the previous paint and varnish layers, then the clutch will not happen, and the entire effect will disappear in a month.

The natural origin of the bitumen resin also determines its excellent hydrophobic properties, so often such a sealant is used not only for fastening seams, but also as a waterproofing agent. They love to use such material in the country or in the village for waterproofing barrels under rain water or sewage pipes in privatehomes. Good bitumen is not only that it is water resistant, but also the ability to prevent the formation of mold and mildew.

Adding to the composition of polymers has allowed to expand the scope of application of bitumen sealant, as it has become more frost-resistant and therefore suitable for work in the open air. Also, seams, taped with bitumen fillers, do not sag and do not crack when dry. If we take into account the relatively low price of this sealant compared to the same silicone or acrylic, then you can get an excellent price-performance ratio with sufficient durability of the material.

Despite the good resistance to aggressive environmental effects and temperature changes, bitumen sealant should not be used in the construction of chimneys, boilers or saunas. Yes, he calmly reacts to exposure to ultraviolet radiation, so nothing will happen to him in the heat of the street. However, with a sharp increase in temperature above 50 ° C, it may melt slightly and return to its initial state of aggregation of the liquid resin.

At low temperatures bitumen can be worked without danger., but then its ability to withstand strong vibrations is lost, which is especially important when sealing foundations. For this type of repair work, it is better to choose a rubber sealant with approximately the same set of qualities as bituminous, but at the same time retaining resistance to the impact of earthquakes at a sufficiently large temperature range: from -50 ° C to about + 60 ° C.

Another significant disadvantage of this sealant is its glossy black shade, and it can not be painted. This means that bitumen is not suitable for interior or decorative works if the owner is concerned about the visual aesthetics of the seams. The exception is the situation according to which the black color of the interior, for example, in the bathroom is the author's idea. Then the brilliant oil shade of bitumen will, on the contrary, organically merge with the environment.

Bitumen is not just used mainly for outdoor work: being quite toxic, it releases harmful substances when uncorking a can, especially at low temperatures. Any seller will recommend to pick up gloves and a protective mask for safe work with this sealant.It would seem that by itself, natural bitumen, which goes as the basis of the composition, is a substance safe for humans that does not carry toxins and carcinogens. The danger lurks just in polymer additives, but thanks to them, the seam becomes so plastic after application.

If the penetration of the sealant into the lungs is extremely undesirable, then in contact with the skin should not be afraid of burns. Of course, the bituminous composition can not be washed off with simple water like acrylic. Sealant can be wiped off with white spirit, and if it is not at hand, then it is an ordinary nail polish remover, only preferably with acetone content.

Bituminous material has good anti-corrosion properties., therefore, is the best option when installing metal pillars, as well as sizing joints in the roof. It is good to fit the cornices, sheet profiles, fasteners of the holder for the antenna on it. It is also great for sealing wooden poles and beams, as it prevents them from rotting from moisture, forming a protective film at the joints.

Bitumen is suitable not only for work on metal or wood, but also for such modern materials as aerated concrete or foam concrete, because it has a high degree of adhesion.To better seal the sealant, the surface must first be primed, otherwise the bitumen can be partially absorbed into the base itself and not so well protected from the penetration of moisture. Also, it is not recommended to spread it with a thick layer when you want to create the maximum effect of sealing and waterproofing.

If the bitumen components do not dry out, then such a sealant will not last long. To enhance its protective properties, it is better to apply the material several times, giving each individual layer a maximum time to dry. How much exactly each layer should dry is indicated on the packaging of a specific sealant.

The resin viscous structure of the sealant allows you to work with it even in the raintherefore, craftsmen love to use it so much for works on the roof, which, because of its large area, is simply impossible to cover or glue in one day. Bitumen is also suitable for metal tiles, and for plywood, and for professional flooring. If a leak is detected just in the rain and only in this way it is possible to understand exactly where it comes from, then this material can provide urgent repair in 20 minutes.

Bituminous sealant is sold in two main packages - a narrow tube or a can of metal. The first option is more often used for minor repairs and sizing narrow seams.It is most convenient to move the contents of the tube into an air pistol for more accurate application.

Sealants in large containers are used for large-scale objects such as, for example, the foundation. When carrying out this kind of work, it is necessary to purchase a spatula in order to level the layer of sealant applied to the surface with it, as well as to remove the uncured surplus.

- Silicone is considered the most universal sealant. It is preferred by most masters during repairs, despite the relatively high price compared to counterparts made of acrylic or polypropylene. They are trying to patch not only the cracks, joints and seams on various surfaces, but, above all, they are used when installing plastic windows or repairing cracks in old wooden frames.

The chemical composition of silicone sealant can be attributed to the so-called composite compositions, that is, multicomponent. The basis of the material is natural silicone rubber - in itself is quite plastic, but at the same time strong material. Additional elastic is obtained by the inclusion of a silicone plasticizer.The strength of the sealant give polymer amplifiers, and the viscosity - special hitch - vulcanizers. For good compatibility with different surfaces, there is no need for pretreatment with special primer or enhanced cleaning of previous layers, because the sealant already has a coupling primer.

The undoubted convenience of silicone lies in the possibility of adding coloring fillers to the composition, therefore at the output we get both black and white, and any other colors. These fillers contribute to the volume of the foam, which fills every corner of a crack or seam more evenly. The complex composition of silicone sealant often includes additives based on mechanical particles of quartz chips or glass for better adhesion to the surface.

The main characteristic when choosing a silicone material is its moisture resistance. It is achieved by including in the composition of special substances - fungicides, which not only prevent the development of mold, but even stop the growth of already formed fungi. That is why for the bathroom there is no sealant better, especially considering the expanding, but not cracking silicone joints, which occur when the temperature drops.

Silicone mass is extremely mobile and can stretch to an area many times larger than the original coverage area, but the connection does not break. Due to this, the sealant can withstand the temperature range from -60 ° C to + 230 ° C, and in some markings even higher. In addition to temperature extremes, the sealant resists well to aggressive environmental influences, including various corrosive chemical elements. The big disadvantage of silicone is that it cannot safely contact petrol and its derivatives, as well as antifreeze. This means that it is absolutely impossible to apply this sealant to repair car parts in contact with motor fuel.

Of the advantages, it is necessary to note both the frost resistance of the silicone sealant and its safety under the influence of ultraviolet radiation. Therefore, it is suitable for outdoor work, because here you can not even wear a special mask in most cases. Even in the winter outside, you can safely glue together cardboard, rubber and cork gaskets, as well as various car parts, including moving parts. When the sealant hardens,it becomes rubber-like in a jelly-like state, so even after applying the bonded parts can be moved in space and interchanged for some time.

A separate category is aquarium silicone sealant, used, however, not only for repairing aquariums. They can also handle bathrooms, showers, as well as various ceramic surfaces and glass containers. Such a sealant has a number of undeniable advantages, such as good adhesion to various surfaces, elasticity, and fast drying time. The main thing is that the seams treated with this sealant do not spread at elevated temperatures in the manner of liquid nails, but remain in an unchanged form, they only stretch.

The most expensive among silicone sealants is heat resistant. It is chosen for the repair and sealing of the chimney or heating pipe, as well as electrical wiring. The composition retains its elasticity and strength, regardless of the temperature altitude. If the usual silicone sealant is operated at a maximum of 250 ° C, then the heat resistant can withstand up to 350 ° C.There is a line of heat-resistant sealants with an additive based on copper, and their deformation does not occur even at a temperature of 380 ° C.

Colors

During repair the master is very important that the joints and seams are not visually conspicuous, do not pay attention to themselves. The ability to glue the sealant at the eye level to the tone of the main product is a very important thing. Transparent sealant is considered the most universal, therefore it is most often used in the repair of plumbing in the joints. The colorless composition retains the same degree of water resistance as the painted versions, so it is applied even where water leaks and excessive mold formation are possible. Sealant is also very popular when grouting during the assembly of kitchen sets, because the color of natural wood or stone is extremely difficult to imitate with a single-color composition.

White sealant - the most common in any hardware store. Most often, white is the natural color of the composition, so it is not mixed with coloring additives that increase the final cost of the product. It is convenient for gluing the seams of mostly white sanitary ware, between the tiles in the bathroom, and also the slopes of the plastic windows.

Black sealant, if it is of natural origin, is a saturated color of oil with a glossy sheen. It is not much suitable, only for the internal sizing of pipes or threaded mechanisms, as well as in places inaccessible to the daily look of a person. The only exception is the deliberate use of black sealant as a decorative element inside art spaces and lofts, when they want to emphasize the texture of an uneven wall with a dark gasket.

Sealants with colored pigments, such as red, yellow or beige, are far from uncommon today. They cost more than a white hue, but for the correct aesthetic perception of repair, it is worth overpaying slightly, given the fact that silicone sealants, unlike acrylic ones, are almost impossible to paint with ordinary paint after hardening.

Scope of application

Sealants are used in almost all types of repair and finishing works. Due to their numerous advantages, such as resistance to temperature changes, exposure to aggressive chemical elements, water and ultraviolet, such compositions are used during outdoor work and in harsh industrial conditions.

As for domestic use, most often sealants are indispensable when installing plumbingas well as other equipment and decor items in the bathroom. Any other glue here will be of little use, since the constant humidity and the formation of mold fungi do not allow non-sealing compounds to serve in such conditions for a long time and fix all items securely. It is good to seal up joints between a sink, a bathroom, a toilet bowl and walls with white silicone sealant. For gluing pads at the drum of the washing machine is also a perfect silicone or polyurethane composition. It is possible to completely put a mirror in the bathroom on liquid nails on especially durable types of sealant and not be afraid that it will move away from the wall from the increased humidity in the room.

The sealing properties of bitumen glue are actively used in the treatment of threaded connections in various mechanisms, as well as seams in drainpipes, even from the inside. It is also popular during repair work on the facades and roof of buildings, during the reconstruction of PVC products and even vinyl siding. Reliable adhesion of parts located on the street and exposed to temperature fluctuations - all this bitumen sealant on the shoulder.And the elements of the tile, through which water flows from the roof, and the steps peeling off at the threshold of the house, and tiles made of natural stone - everything is easily fixed by the above composition.

The most famous application area for both silicone and acrylic sealants is the installation of plastic windows., as well as the insertion of gaskets on the closing mechanisms adjacent directly to the glass. The second most popular room after the bathroom when working with sealants is the kitchen. There are seams on the tables and window sills, they are amenable to sizing, regardless of whether they are made of artificial material on a composite base or from natural stone. This also includes works on coupling between each other parquet or laminate bars, which require a moisture-resistant composition, which reflects well mechanical shocks.

Drying time

The time required for complete drying of each sealant is different, it all depends on the composition and the thickness of the applied layer. Practice shows that natural-type specimens of bitumen dry up more slowly than artificial composites, which already include a polymer accelerator, affecting the rate of solidification.

Most sealants have a primary hardening in 20-30 minutes.but it is a deceptive effect. The formation of a solid film does not mean complete shrinkage of the material, and if the next layer is immediately applied on top, then as a result, the entire mass of the seam under the influence of the environment will simply lag behind the surface to be glued in a couple of days.

In an amicable way, you need to give each separate layer to dry for at least 24 hours, then the entire gasket will last for a long time. If the time is catastrophically short, then for certain types of silicone and acrylic sealants primers or accelerators are additionally sold, which help the material to harden much faster.

Using

Sealant is easy to use, it does not need special training.

It is enough to adhere to a certain algorithm of its deposition on any surface.

- Before opening the container, make the room ventilated, wear protective gloves and a mask.

- The surface on which the sealant will be applied must be wiped off, cleaned from the previous paint and varnish layers and degreased. If you do not completely remove all unnecessary,You can first prime the coating with a special compound. It is better to seal the neighboring elements with masking tape and oilcloth so that the sealant does not stain the excess.

- For small indoor work, it is recommended to load the sealant into the mounting gun, and squeeze the compound at an angle with thin strips into the place of the intended seam. If two moving parts are glued together, then they can be mechanically flattened together and held for a minute or two in this position.

- Excess sealant can be removed with a spatula or white spirit, until the composition is dry. After it hardens, unnecessary residues are either cut off with a special knife, or they acquire a solvent for a particular type of sealant.

Advantages and disadvantages

All sealants, regardless of their chemical composition, have the same set of advantages:

- adhesion or ability to coalesce with many materials;

- water resistance, heat resistance and resistance to aggressive environmental influences, including caustic chemical elements;

- Some types of sealants differ in the composition of substances - fungicides that have antifungal effect;

- high elasticity coupled with durability, which allows it to withstand vibrations, mechanical shocks and temperature extremes without cracking.

Of the few cons, the following can be distinguished:

- acrid smell and the presence of toxic substances in the composition of certain types of sealants;

- sufficiently long drying period of each layer.

Manufacturers

The most popular manufacturers of sealants are considered to be Moment and Soudal. They have a large range of materials for small household repairs, and at a price they are available for the middle class buyer. According to reviews, these compounds resemble quick-drying foam, but much more resistant to moisture and ultraviolet.

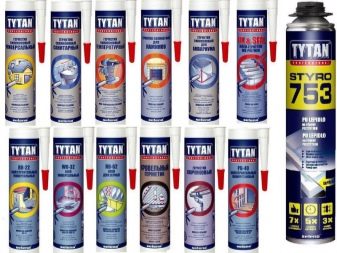

Brand Sealants "Clamp number 3" good for the bathroom, as they quickly freeze and do not form bubbles on the surface. Composition called "Titanium" also fully corresponds to its name - it is heat-resistant and strong, but as a disadvantage - its surplus is difficult to remove from the surface within 15 minutes after application.

Penosil as a sealant, it has very good hydrophobic properties, elasticity, and is compatible with almost any surface.Its only drawback is the relatively high price.

Tips and tricks

One-component silicone sealants can form an environment of different composition, where one or another element stands out, and each name should work differently.

- Often the environment is acidic, since the sealant contains acetic acid concentrate. It has a characteristic strong odor, which completely disappears during the day. But in any case, it is recommended to be careful, as its vapor in some people may cause allergies with symptoms such as dizziness and nausea.

- Acid sealant should not be used for metal surfaces, as they will simply oxidize, and corrosion will occur. Also, such silicone will not work for cement foundations, aluminum and even marble. And in principle, before applying it on any surface, it is better to first carry out a rapid test on a small area, because there could be previous uncleaned layers, which then react with the acid. A distinctive feature of the acid sealant is the marking in the form of the letter "A" on the packaging and low price,what makes it so popular.

- The most versatile and quick-setting environment for silicone sealants is considered neutral. It is created on the alcohol or amide basis, therefore, does not have a strong odor. The price of this sealant is higher, but then it can be applied to any surface. This heat-resistant composition can withstand temperatures up to 300 ° C, so it is convenient when restoring radiators and pipes for heating, as well as repairs in the bathroom or in the kitchen - places with high humidity. If the owner is not sure of his professionalism, it is better to choose this composition, since it does not cause problems even with inept application.

- Especially distinguished sanitary silicone composition, which includes most of all substances - fungicides with a high level of antibacterial protection. This sealant can be used in the construction of baths or saunas, as well as for repairs in the nursery or hospital, where sterile cleanliness is so important.

How to choose glue-sealant, see the next video.