How to use cold welding?

The essence of welding lies in the strong heating of metal surfaces and their interconnection while hot. As the cooling of the metal parts are tightly connected to each other. The situation is completely different with cold welding. Under this name, we are offered a certain substance that can not have anything in common with a welding machine.

Special features

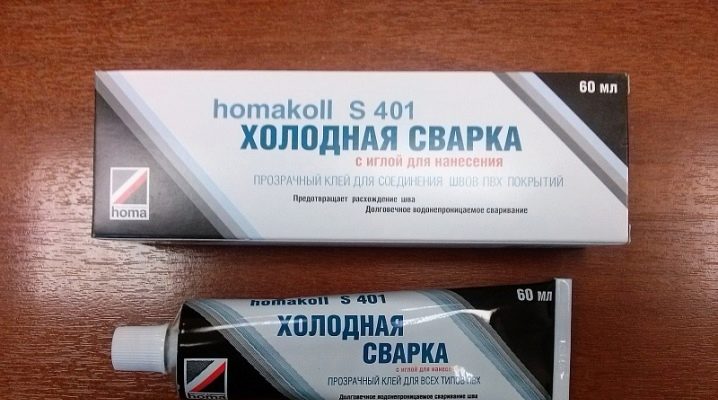

The concept of "cold welding" is a beautiful marketing ploy that has become firmly established in our everyday life. It denotes a large bonding force, which can be compared to a real welding seam. By cold welding is meant a strong component adhesive, which is created from epoxy resins, reinforcing powders and thickeners.

Species

Before we consider application options, You must be familiar with the varieties of this material and methods of its application.

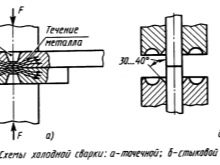

- Point material is used to work with tires, handles, linings, used for the manufacture of finned coolers.

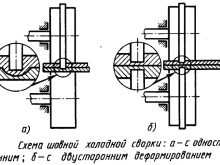

- Seam welding is used in hermetic structures. The scope of its application is huge and diverse. Such welding is convenient in work and demonstrates high reliability of the connection. Working with this material involves the use of contour punches.

- Butt application method helps in the production of rings and connecting the ends of the wires.

- T-shaped method allows connecting brass pins and aluminum leads, for example, from transformer windings, busbars of electric locomotives.

- Welding shift helps in the repair of the heating system and water supply, in the case of work with adapters in the railway lines electricity

Another classification is based on the consistency and composition of the material.

- Liquid material consists of two components that need to be mixed with each other. Glue and hardener are bonded before being applied to the surface.

- Plasticine material is produced in the form of a bar. It can be homogeneous or consist of several layers. Before work the bar needs to be mixed and well softened.

The basis of the following classification is the purpose of the material.

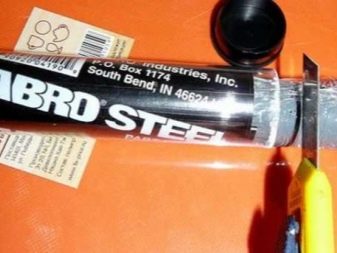

- Welding for working with metals incorporates a metal component. This material is suitable for working with any metals and connects them just as well as conventional welding.

- The material for the repair of automotive parts consists of a metal component, is able to withstand high working loads, can work at high temperatures and frost.

- Universal glue is capable of joining all materials without exception. With this advantage, welding is less durable compared to narrowly focused options.

- For work in special conditions, for example, under water, specialized formulations are produced.

Where can I apply?

Cold welding is a unique product, it can be used in a large number of cases. True, there are some limitations, after all, the glue is not as powerful as we would like.

Consider the cases when the use of adhesive epoxy composition is recommended.

- With this welding, metals are very well connected. Even disparate materials can be glued together with high reliability.

- Hard plastic is also well fixed with innovative material. Why exactly? The reason is the hard joint that forms the weld after solidification. The hard joint is not combined with flexible parts.

- Ceramic tiles perfectly fixed by liquid cold welding. Tested by experience: the crack will go through the tile, but not through the seam. The place treated with glue will remain unchanged.

- Stone and glass firmly glued to the base and firmly held for several years.

- It is convenient and reliable to fix the floor covering (carpet, linoleum, carpet) by means of cold welding. You can simply glue them to the floor or make a beautiful joint - in any case, it will be right.

- The plumbing area is the ideal front for this material. Cold welding can work well in contact with water. This circumstance does not affect the bonding strength or durability of the seam. This feature allows you to seal leaks without the need for water.This fact is actively used in case of damage to the heating system, water supply or sanitation.

Such repairs will not only allow you to hold out until some time (the end of the heating season, global repairs, the onset of heat), the seam will be firmly fixed for several years.

Car muffler repair does not imply a major overhaul of malfunctions, but it will work comfortably for some time. The glue will not suffer from heating, it will not crumble, but before buying it, it is necessary to study the temperature at which such material can be used.

Cold welding is a unique invention.which has the highest degree of universality. In the home set of tools, this adhesive material is thoroughly prescribed and is not going to lose its position.

How to use?

Some of the popularity and demand for cold welding is provided by the convenience and ease of use. You do not need to have skills to work with complex equipment, you also do not need professional tools and expensive consumables.All that is required from the user is a detailed study of simple instructions and compliance with it in the process.

Operating rules

- Countertops need careful preparation. This stage is important, it determines the success of the final result. The surfaces on which the adhesive composition will be applied must be thoroughly cleaned of dirt and treated with emery paper: roughness will provide higher adhesion.

Also, the working field must be degreased. For this you can use acetone. At this preparation can be considered complete.

- In most cases, cold welding sticks to the hands, which complicates the process of creating a smooth and beautiful weld. You can eliminate this problem by wetting your hands. This will not affect the performance, but the mass will be more docile.

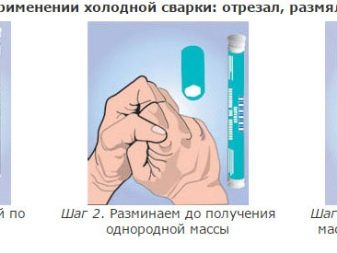

- When working with a two-component material, it is necessary to mix the glue and hardener. Plasticine welding is mixed until a homogeneous mass, in the liquid version, the two components are connected to each other. It is necessary to do this before applying, it takes about three minutes to work. During mixing, the mass may generate heat.

- The prepared material is applied to the work area at the location of the future seam. The adhesive mass is distributed over the surface, pressed and smoothed. It is necessary to achieve maximum tightness.

- When planes are connected, they need to be fixed with clips. In this case, the seam will be much stronger and safer. For work with pipes special plaits are used. When gluing a floor covering roller rollers are applied.

- The total solidification time may vary, depending on the manufacturer, the type of adhesive and the thickness of the seam.

- After the glue has completely cured, you can do plastering, painting and other repair work.

It is impossible to break the instruction, it can lead to reduction of service life and decrease in characteristics.

Precautionary measures

When working with cold welding, you must protect yourself and protect against the harmful effects of some components.

To do this, you must strictly observe the precautions.

- Gloves must be worn on your hands to protect your skin from resins (epoxy, amine), various fillers and hardeners.

- After completing the work hands should be thoroughly washed under running water with soap and water.

- The room must be aired during operation. If this is not possible, after finishing work, the room should be well ventilated, and when in contact with glue, use personal protective equipment for the respiratory system.

- If the glue comes into contact with the skin or eyes, immediately rinse them under running water. You should immediately consult a doctor.

- Do not violate the rules of storing adhesive composition. Usually, the manufacturer does not recommend to break the original packaging, and it is necessary to store the glue at a temperature from +5 to + 30 ° С.

- Packaging with glue should be kept away from children.

Useful tips

Finally, we advise you to familiarize yourself with useful tips that will facilitate the work, help you avoid mistakes and allow you to achieve an excellent result from the first time.

- When exposed to warm air mass hardening occurs faster. To reduce the time of hardening, you can use a building dryer or even an ordinary household appliance. You can also slightly warm the surface before applying the adhesive, for example, linoleum.

- In the area of application, which is hidden from the eyes, you need to act very carefully.

- Choosing a versatile material, you need to remember about its reduced strength. If you can buy a narrowly targeted glue, then you need to choose it.

- When choosing an adhesive, you should carefully inspect the packaging for integrity and pay attention to the production date.

For more information on using cold welding, see the video below.