Glue Knauf Perlfix: pros and cons

Repair work involves the use of a sufficiently large number of installation components. As a rule, nails are used, but they are not always the best solution for surfaces such as drywall. This material is very thin, and holes for nails can harm it. Professional masters recommend using special construction glue in the work with plasterboard, which will be beneficial both from a practical and an economic point of view.

Knauf Perlfix glue is one of the best in this niche; it is an excellent alternative to nails and self-tapping screws.

Special features

Knauf was established in the middle of the last century.The small company quickly became a huge concern for the production of building materials due to the responsibility of the owners and careful quality control at each stage of the production of products. Today Knauf are among the leaders in their niche, their products are presented throughout the world.

Perlfix Adhesive is one of the most purchased items. The main objective of the product is frameless coating of surfaces with gypsum-based sheet materials. There are only two types of adhesives, differing from each other both in ingredients and in the level of adhesion to the surface: ordinary Perlfix and Perfix GW.

A simple mixture is made to coat the bases with gypsum plasterboard, and with additional gypsum fiber for gypsum plasterboard.

The material of the coating itself is not very important, since this mixture is perfectly combined not only with plaster, but also with concrete and brick, it is important only to choose the right soil. For example, in order to glue drywall to the base of concrete, you should take concrete contact, in the case of plaster or lime plaster, you can take a simple mixture of deep penetration. Knauf glue is also suitable for work with insulating materials, for example, polystyrene foam with extrusion or minplitom.

Perlfix can only be used for internal work. The composition is perfectly applied both in warm and cool rooms, but remember that the humidity level in the room should be above average. It is possible to glue them not only drywall, but also matte gypsum tiles, foam plastic, mineral wool and polystyrene foam. Try to prevent any direct water from entering the applied mixture. It is forbidden to handle wet surfaces with glue, as this may damage adhesion.

Gypsum assembly mixture is sold as a dry product ready for application, so there is no need to use any additional ingredients.

In the case of repair work under special conditions, the company manufactures products that differ from the base adhesive. Their composition involves the application of non-standard surfaces.

Specifications

Knauf Perlfix gypsum adhesive has excellent properties that correspond to the high quality of all the company's products. Increased service life, which is more than twenty years, is one of the consequences of this quality. The level of setting with concrete is 0.6 MPa. The presence of gypsum in the composition provides a higher compressive strength of 10.9 MPa, and at a bend of 3.4 MPa.Thanks to a thirty-minute setting, it is possible to correct plasterboard sheets with the help of a building level.

The mixture is available in packages weighing 15 and 30 kilograms, which is very convenient. It is necessary to store it only in a dry place, since it contains gypsum. It is better to store the mixture on wood pallets in order to facilitate optimal ventilation of the bags. This is done to prevent dampness of the dry composition in conditions of high humidity. If the packaging is damaged, transfer the mixture into a one-piece bag and then put it back in the bag. The shelf life of open packaging is six months.

Advantages and disadvantages

Glue Knauf Perlfix has both a large number of pluses and some minuses that must be taken into account when purchasing. One of its main advantages is the ecological purity of the mixture, as well as the absence of toxic odor, which makes it safe for health. When using glue repair work go much faster and easier. Due to the absence of the need to use a hammer or perforator for hammering nails and screws, your repair will be absolutely silent and economical, since you will not have to spend money on additional tools.The composition is applied with a special spatula ribbed form, either directly to the entire surface, or with cakes.

The great advantage of this product is its versatility, it works great with different materials. Some craftsmen use it during non-essential plastering work.

A great advantage of the Knauf company itself is the availability of quality certificates for each of its products, which guarantees the high quality of all products, as well as close inspection at various stages of production.

However, the adhesive mixture has several drawbacks.one of which is a long drying time of a week. This characteristic is associated with components that are part of the adhesive company Knauf. After drying, the glue becomes very durable and provides a secure fit for many years. During this process, that is, all seven days, the composition will increase the level of strength and how to shrink the material. During this period, it is necessary to postpone any filler work to prevent the appearance of cracks.

One more peculiarity of Perlfix is the short time for updating the GCR or GVL blocks.

It is only ten minutes, and sometimes five.Glue enough for a short period of time loses plasticity, which is why any changes in the imposition of sheets, the elimination of cones or pits that have appeared should occur in a short period of time. After ten minutes all your efforts will be in vain, as the mixture will no longer drag. Despite such a quick setting of the product, it finally hardens only after a week. The cost of this product is quite democratic and amounts to 300–350 rubles per bag.

How to use

Before working with Knauf Perlfix glue, determine its consumption on the desired surface. According to the instructions, the consumption of the installation for plasterboard is 5 kg per 1 m² when treating the gypsum board and gypsum plasterboard surfaces, in case of working with GWP, the consumption will be 1.5 kg per 1 m². However, in practice, the consumption of funds may be slightly different, it all depends on the experience of the master. Professionals, who have already pretty much gotten their hands on the installation of a tongue-and-groove tile (GWP), apply a slightly diluted glue to the surface so that after lining the sheet, a little money comes out of the joint. Newbies in the construction industry do not like to save the mixture, thinking that it is bad, and they put a lot of glue, because of which a large amount of excess composition remains.

Here it is necessary to take into account the fact that the work is done with plaster, and not with ordinary glue or cement. If in the second case it is possible to remove all surpluses with a spatula and put them back into the container, then in the first case it is impossible to do this, because the mixture collected from the plaster will greatly reduce the life of the glue. It simply dries directly in the bucket in about fifteen minutes, which would entail overruns. But thanks to its ease of use, you can quickly and easily learn how to prepare the mixture and apply it to the substrate to be processed.

The flow rate of the mixture for gypsum plastics is calculated more accurately, taking into account irregularities or roughness of the base.

One of the main conditions when working with Perlfix glue is the temperature level, which should not be below +5 degrees. When working with a product weighing 30 kg will need 16 liters of water.

Work with Knauf Perlfix glue is done in the following order:

- first you need to clean the wall from dirt, dust and scabs;

- in the case of working with gypsum plasterboard, a wall should be primed, preferably with a primer of the same brand as the drywall adhesive itself;

- make the process of mixing the mixture, usually it is done in a plastic container;

- dry mix is added to water in the ratio 1: 2;

- It is recommended to stir by a construction mixer, as a result you should get a mixture without lumps, similar in thickness to sour cream;

- in the case of strong density or liquid glue, you need to add water or dry product, respectively. Professional masters, not to be mistaken, add the mixture gradually, while stirring. This allows you to control the consistency of the adhesive;

- it is necessary to use the received mass within thirty minutes, therefore it is desirable to do small portions which will be used during this time;

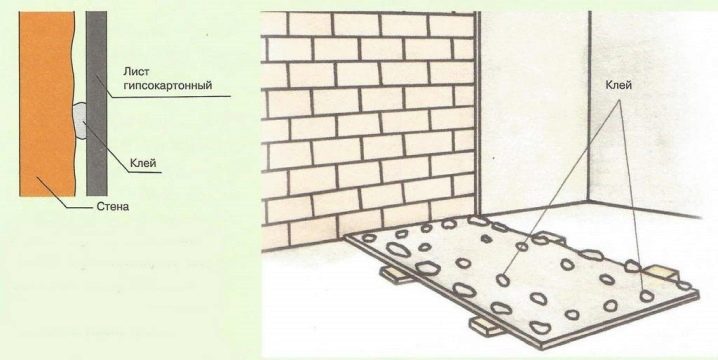

- it is recommended to overlay Perlfix pointwise, making distances of 30–35 centimeters;

- if drywall is less than one centimeter thick, glue is applied along the midline in a row, when working with a thickened sheet, it is applied in two rows along the entire plane;

- The sheet is gently applied to the wall from the bottom up, and then aligned.

Glue Knauf Perlfix has optimum plasticity and level of adhesion with materials. It perfectly shows its properties when working with tongue-and-groove tiles and frameless base cladding. The democratic price of the product and a large amount allow you to spend less money on repairs.

On how to properly glue drywall to glue Knauf Perlfix, see below.