Paint for concrete floor: types and properties

Concrete is one of the most widely used building materials for creating floors in residential and industrial premises. Concrete floor with full compliance with the technology of laying has excellent quality characteristics, but even such strong surfaces have their drawbacks.

Without a special protective layer, this floor can quickly wear out. To avoid such unpleasant consequences will allow a good paint for coatings of concrete.

Special features

In different spaces of the technical plan, the concrete screed is left unpainted. And after a while, it was discovered that the concrete had worn out and was dusty. In addition, depending on the place of application, concrete can be adversely affected by sudden drops in high and low temperatures, constant humidity, aggressive reagents, and substantial loads.

Painting the floor of concrete with paint will help to effectively preserve this flooring.

Modern manufacturers create the highest quality protection for the new floor of concrete. This paint will increase its strength, as well as improve the performance of exceptional resistance to wear for any bases of concrete, due to the presence in the composition of special reinforcing substances. Many paints create such a strong layer of protection on a concrete floor that it will be possible to use a coupler even under significant loads without damage to it.

What characteristics can your chosen paint have?

- It is imperative that the dye composition for concrete meets all expectations.

- The paint should penetrate well into the layers of concrete, ensuring reliable adhesion to its surface.

- Ensures the absence of cracks and delamination when temperature drops.

- Should not be afraid of abrasion with prolonged use.

- Withstands heavy loads.

- Will keep beautiful appearance on all extent of operation term.

- Promotes improvement of various properties of the painted floor.

Selection options

Selecting exactly how to paint concrete, you need to know exactly the technological parameters of the space.Wear-resistant paint is used for painting workshops, where shock impact on the coating all the time, and therefore you need to create an especially durable layer. The choice of coloring composition for concrete floors depends more often on specific goals.

Acrylic paint, for example, perfectly fit for loggias and balconies; epoxy can be used in hangars and auto repair shops; tool with excellent resistance to wear is the best option for areas with huge mechanical or transport loads.

There is no universal option here, but there are features that need to be taken into account in the final selection of paint:

- For use in residential buildings, it is best to choose an odorless composition that dries very quickly. Epoxy paint can be operated only with the uninterrupted flow of air into the room. It is better if the coloring composition will be odorless and environmentally friendly.

- A special criterion for the selection of such paints can be called the type of future work. They can be outside the room and inside it, but you need to know the optimum temperature ranges for using the mixture.

- If you need to perform work outside, then you should first make sure that the chosen paint has wear-resistant parameters, you should also check it for the presence of antibacterial elements, which will stop the process of mold growth on the concrete.

- Think about what kind of floor surface you end up dreaming about: you are more interested in dullness or gloss. Glossy floor can be obtained with the help of enamel from acrylic. But the coloring composition for the floor of the concrete for the garage because of the frequent mechanical action select only matte.

And, of course, the selected material must comply with the parameters of GOST, so that you are fully confident in its high quality characteristics.

How to paint?

Nowadays, in any construction market, you can easily choose different types of painting compositions for floors made of concrete.

Acrylic paint

Paint on concrete is produced on the basis of special acrylic resins, including organic dyes and inorganic compounds. This is a composite based on acrylates and polyacrylates with different minor elements that will serve to form a special protective layer.

Components of such paint are ester substances, which will ensure the resistance of the composition to the influence of moisture and guarantee its quick drying. Many manufacturers of paints claim that in order to end up with the highest quality and resistant to various influences coating, just one layer of the composition is enough. But in practice, most often it turns out that a quality result can only be obtained by applying at least 2, and better - 3 layers of paint.

Among other things, these paints make resistant to short exposure to moisture and aggressive chemistry. This kind of paint can be found in a chic range of colors and shades. You can buy matte or glossy shades for every taste. Dries the concrete coating, painted with acrylic paint, at least 2 days.

Among the most powerful positive features worth mentioning are:

- no fear of moisture;

- environmental safety;

- resistance to heat and cold;

- wear resistant.

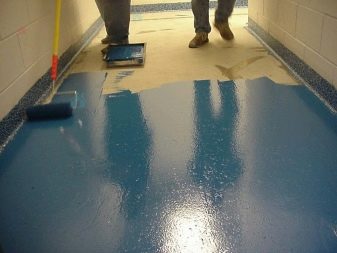

Acrylic paint should be used only for the cleaned surfaces of concrete with a special brush or a convenient roller. If you need to paint a large area - you can use sprayers.

Acrylic silicone enamel

The composition of such products include copolymers and resins, the main component of which is silicone. Such paints for concrete with acrylic for flooring are the most wear-resistant. This two-component paint combines all significant advantages of acrylics and silicones. These elements, combined, form a stable structure, not afraid of different types of wear.

To make the coating more elastic, polymer silicone resin is introduced into its composition - a substance that guarantees the coating strength due to the presence of silicon in it. Thanks to resins, the enamel becomes electrostatic for effective dedusting. Immediately after drying, the dedusting paint will give the effect of cleanliness and comfort. The advantages of such paint from dust weight, and the disadvantage so far one - a small color gamut.

This paint for concrete floors is very wear-resistant, while it must be applied in 2-3 layers. It is necessary to observe a break between painting - at least 3 hours.

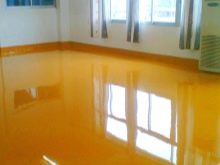

Epoxy paints

Epoxy concrete coloring agent is also a two component blend. As a solvent, water is most often taken.A characteristic feature of this material is the need to mix both components to a uniform monochrome mass before the very beginning of work. The choice of paint colors is actually small, but it is balanced by the wear resistance of the material.

Epoxy enamel for concrete surfaces after dyeing and drying becomes a very durable coating that can be used even in factory profile rooms. This floor can withstand severe loads, does not fear different temperatures and precipitation and can be used in open areas.

Epoxy paint has such advantages as:

- excellent indicators of resistance to high humidity;

- high level of resistance to chemicals (acids, alkalis, salts, oils);

- high adhesion to concrete floor with thorough degreasing;

- the shade will not be changed and will not burn out;

- Wear-resistant epoxy gloss enamel for concrete can be odorless.

Apply this composition in 2 or more layers. Each applied layer must dry thoroughly for 12-14 hours.

Alkyd-urethane enamel

This concrete floor covering is especially in demand,if it is necessary to perform work indoors. It will effectively prevent abrasion, and the surface will remain beautiful and shiny for a long time.

Apply this enamel on the floor can be different devices, including using a professional console with paint. The service life of such enamel will be 15 years.

Vinyl paint

These materials are known among buyers for an average service life - it is about 7 years old. For complete drying, it takes 2 hours. You just need to apply 1 coat of paint, and it will give a thick and beautiful uniform coating.

This paint is considered the most environmentally friendly, because they use it more often in homes and apartments. In addition to popular vinyl floor paints often finish ceiling and wall coverings in homes.

Rubber paint

This paint has unique properties and the best parameters. It dries pretty quickly when compared with others - it only takes 20-25 minutes. The term of operation can be up to 10 years. Such coatings are particularly suitable for the temperature regimes of our country.

Rubber paints can be operated even at very low temperatures - from minus 50 to Celsius. The coloring composition can also withstand up to plus 60 degrees.

After painting, the material creates a durable polymer-based coating. This layer in the form of a film will be extremely resistant and can easily transfer even frequent power loads. This coating will be a good protection for screed against cracks and various chips. If you mix pigments into rubber paint, you end up with a rich gamut of all kinds of colors.

Polyurethane compounds

These representatives of wear-resistant finishing compositions for concrete also consist of two components and are perfect for painting inside and outside the building.

Before actively using these materials, the solution must be very well mixed. When mixing, it is worthwhile to make sure that no lumps or bubbles appear in the paint.

Such paint will dry for 2 weeks. At first, excess moisture will slowly evaporate from the coating, then it will harden, and then gradually acquire excellent resistance. After coating will be qualitatively withstand the influence of various aggressive reagents.

Polyurethane floors are self-leveling coatings that are used as finishing floors on concrete screeds.

We consider consumption

Properly calculate the flow of the right amount of paint is not very simple. Even specialists who work with these compositions every day will not always be able to correctly calculate the necessary amount of coloring composition for painting the floor from concrete. The consumption rate of the composition is a loose concept.

There are no exact consumption rates of various coloring compositions, and therefore how much paint is needed depends on a number of significant nuances:

- characteristics of the selected composition;

- properties of the floor surface that you need to cover the composition;

- What kind of painting you choose.

The approximate amount of consumption of any composition will allow you to more realistically estimate the desired amount of materials used: for example, the consumption of painting a concrete coating in one layer is usually 150-200 g per square meter. The consumption of the coloring matter (varnish or enamel) can also be affected by the way you apply the coloring composition.

The initial color of the base can also significantly affect the cost of the coloring material. If you have long wanted to paint a very dark surface in a lighter tone, you will have to either get rid of the old coating first, or apply several layers on the floor (which can again increase your costs).

It is worth noting that the quality of proper preparation of the concrete surface for painting also very seriously depends on the consumption of the necessary paint.

Carefully prepare the concrete floor for painting, and then you will spend a lot less paint, and the floor as a result will look quite beautiful. The better the surface of the concrete will be cleaned from dirty stains or the old layer of paint, the smoother the new paint will fall on it and the stronger it will hold. The use of soil and putty will provide a higher quality of adhesion of the paint and will significantly reduce its consumption.

Areas of use

Epoxy composition for painting concrete cover used in the apartment, and in spaces such as hangars and workshops, parking lots and stairs. High-quality epoxy substance can be easily used in open space. In addition, it has excellent properties, allowing it to be applied to wet concrete. And this not only does not harm the whole structure, but, on the contrary, will strengthen it.

Acrylic paint is actively used for painting garages, loggias and balconies, dry basements. The peculiarity of this composition is the fact that it is excellent for oversized premises.Acrylic paints are best used for coatings in dry basements or on 2 floors of buildings, if they are there. As a basic cover, this option is clearly not perfect. The protective layer will withstand not only high humidity, but also the influence of a substantial mass.

You can easily use such paint in the bathroom or in the bath.

Polyurethane coatings have proven themselves in garages and car repair shops, in technical premises. Also, they are not afraid of painting on the landing.

Painted with rubber paint floor will have excellent anti-skid properties. On it you will never slip.

Manufacturers

In the Russian market of building materials, paints intended for concrete floors are offered from domestic and foreign companies, among them you can find products from Finland and Germany, Sweden and Poland, Turkey and the USA.

All consumers are wondering which of them will give their preference. The answer to it may depend on the available free cash and the criteria that apply to the surface to be painted.

Company "KrasKo" It is considered a manufacturer of a huge range of only the highest quality paints and coatings to protect concrete.

One of the highest quality rubber paints consumers call Texil. It guarantees reliable protection of the coating and, most importantly, it dries only 2 hours. The base paint is made of PVC resin.

Texipol - glossy paint composition for floors made of concrete, having water resistance, lack of fear of detergents, having excellent spreadability, simplicity and convenience with proper application, the best decorative indicators.

Acrylic paint for flooring on concrete from the company "Grid" it is used for painting various types of concrete both inside the building and in outdoor conditions. This paint is most often used in industrial facilities and in entrances, utility rooms and warehouses, in large garages and other spaces with a high percentage of abrasion of floors.

Beautiful interiors

- Gray concrete floor perfectly emphasizes natural wood, metal and plastic elements in the interior.

- The new format of the apartment decor: a large open living room in a modern style with bright walls and a concrete floor.

- In many interiors, a concrete floor that merges in color with concrete walls is the best solution for decoration.

Review and recommendations on the use of paint "Texipol" see in the video below.