Types of self-leveling floor

The construction market offers a wide range of finishing for floors, among which are popular self-leveling floors. This coating impresses with its capabilities and has a large number of advantages.

This article describes the features and types of self-leveling floor, as well as options for the interior of your home.

What it is?

Bulk floor is a special screed, which is often called self-leveling, as it contains many binders, fillers and polymer additives, due to which you can eliminate all the defects of the rough surface.

In most cases, such mixtures help to carry out the finishing alignment of the base. The thickness of the finished surface is 0.2-2cm, based on the brand name and composition of the product.

Cement or gypsum is used as the basis for such a self-leveling floor.. When choosing a base you should start from the parameters of the room in which the floor will be poured, as well as from the goals of its installation.

In the role of aggregate, fine varieties of round limestone are usually used. Manufacturers of different brands offer the composition, where there is limestone of different sizes and shapes, which are suitable for certain conditions of use of ready-made mortar.

To improve the technical parameters, the physical qualities of the material along with its useful life, plasticizers are present in the composition. All the advantages of the self-leveling floor, its resistance to wear, mechanical damage and the speed of drying are directly assigned to them.

Special features

This flooring caused a sensation in the construction materials market. To understand the issue of acquiring a self-leveling floor, you should familiarize yourself in detail with the features of the material, discuss its advantages, design and negative features of the coating.

Liquid floors may differ in their purpose. Therefore, they can play the role of:

- screed bases;

- self-leveling layer on the screed;

- finishing layer.

Creating a base-screed, which is required for further installation of various floor surfaces of decorative nature, manufacturers use a special type of mixtures. Among the qualities of the components of such solutions can be attributed fluidity, due to which a flat surface is achieved.

Mixture for self-leveling floors can be prepared manually or by using a mechanical method.

When selecting components for the mixture, pay attention to the desired thickness of the future layer, as well as the residual moisture of the surface. In the process of cooking you will need water, due to which the required consistency of the solution will be achieved.

There are mixtures without water in which anhydrides are present. These include the gypsum screed, which is formed using calcium sulfate. Many Russian and foreign trade brands offer a similar product. Components of this product include:

- defoamers;

- superplasticizers.

Due to the defoamer air bubbles can not appear, which guarantees the necessary strength for the self-leveling floor.Thanks to superplasticizers, the amount of water and the fluidity of the solution are reduced.

This screed has several advantages compared with cement-sand mortar:

- forms a perfectly even layer;

- the mixture quickly sets;

- the floor retains heat well;

- screed has a slight degree of shrinkage.

An anhydride solution for a couple of weeks after laying will produce a return of a significant proportion of moisture. After a couple of days you can safely move on such a surface. Due to the low degree of shrinkage, no cracks appear on the surface.

Such a floor has good characteristics in terms of heat retention, which allows you to create the desired microclimate in the room and save on heating.

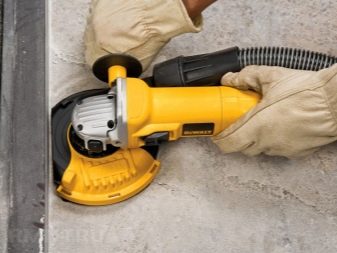

Anhydride mixtures are not suitable for pouring in the bathroom, as all qualities of the screed are lost after contact with water. It should also be borne in mind that after setting, a patina forms on the floor surface. It is a glossy layer. For this reason, experts recommend removing patina with sanding before mounting.

Self-leveling floor has many advantages:

- this floor is famous for its versatility, as it is acceptable for premises of any purpose;

- has antistatic properties. This suggests that dust practically does not settle on such a surface;

- chemical resistance;

- thanks to the seamless surface, dirt will not accumulate on such floors;

- easy care of a monolithic satin due to the fact that it does not absorb moisture;

- the materials used in the mixture do not have toxicity and do not affect the level of humidity in the room;

- self-leveling floors can be combined with the "warm floor" system;

- long service life. With proper care, the self-leveling floor can last for 20-25 years without any complaints.

Despite the weighty list of positive qualities, the cover still has disadvantages:

- it is impossible to remove the self-filled base;

- the pouring process is accompanied by numerous difficulties;

- if you have violated the technology of application, some areas of the self-leveling floor may swell.

Type and characteristics

Self-leveling floor has excellent technical characteristics, so it has almost no analogues.To make a choice, you should know how the different types differ from each other.

The self-leveling floor can be divided into several categories, which will differ in their composition, the room used (some types of coverage are suitable for the living room, can be poured for a warm electric floor on the balcony or in the toilet, other coatings are suitable for a warehouse or garage).

When dividing by purpose, the mixture for the self-leveling floor can be divided into three categories:

- for rough alignment. It will be relevant in areas where horizontal drops of up to 11 mm are observed. You can use the material as a base layer for further installation of floor tiles, laminated flooring, parquet;

- fine leveling mix, or finish coat. The thickness of this coating is 5 mm. Raw materials should be applied to the treated surface with preliminary preparation, as it is intended only to eliminate minor defects in the coating. In most formulations, a binder is present in the form of cement, which, after drying, allows for the laying of any floor coverings;

- for complex reasons. Such mixtures are modifying composition with reinforcing fibers and plasticizers. The material is used in the implementation of the alignment of wood bases, which is characterized by the structure of several layers.

Material

Mixtures for self-leveling floors differ in their composition. Each type of mixture has its own qualities that distinguish it from other varieties. Depending on the purpose and conditions of use, you need to choose a material for self-leveling floor.

High penetration impregnation

This option is considered the most economical. This technique is resorted to by people who need to make stronger weak and finely porous bases. After work, you will get a self-leveling layer that has a wet effect. Impregnation is responsible for a bunch of small particles of concrete, does not allow it to wash out, prevents the appearance of dust. Often this method is called "dust-free concrete."

If an epoxy compound is used, it can be impregnated up to 2 mm deep. When using polyurethane compounds, a deeper effect is observed, which reaches 5 mm.

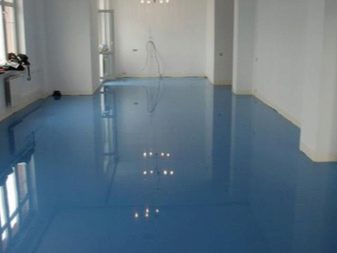

Epoxy and polyurethane floors

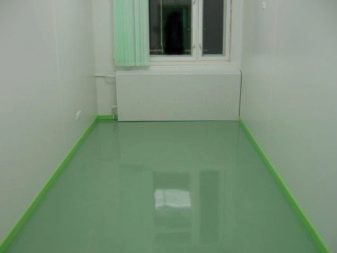

It should be applied in one or two layers.Epoxy floor is usually applied in a single layer. This method falls into the category of practical, since by choosing a smaller thickness of layers you can save on materials. Raw material consumption per layer is about 300-600 grams per square meter. After pouring, you will get a wear-resistant self-leveling floor that has half-gloss effects.

Both types of floor have similar technical parameters in terms of strength, but the floor covering made of polyurethane boasts a higher level of wear. This quality is achieved due to high elasticity. They ensure the safety of 3D floors in buildings where temperature fluctuations are observed, maintain long-term vibration contacts, as well as strong mechanical effects.

Polyurethane self-leveling floors practically do not react to contact with organic acids and other chemically active components. Because of this, they are often poured into rooms that are associated with the food and chemical industry. The flooring will not deteriorate due to the ingress of oil, automotive fuel and fuel.

Epoxy compounds are cheaper than polyurethane.Among the strong qualities of the epoxide can be attributed to the absence of odors during pouring, since there are no solvents in the composition of the solution.

Polyurethane flooring one-component, and epoxy consists of two elements - resin and hardener. Before use, you need to connect them together, which can create additional inconvenience.

The disadvantages of the mixture include:

- strict implementation of the guidelines for mixing the composition. It is necessary to carefully observe the proportions and mix the mixture well;

- limited time to use the mixture. Fill should take place within one hour. Before you knead the solution, it is recommended to specify the exact time.

Epoxy urethane floors

Formed by combining epoxy compounds that have strength and wear resistance, as well as polyurethane, which are famous for their durability and elasticity. The result was a unique blend that absorbed the best qualities of these components.

The advantages include:

- The epoxy-urethane floor is moisture resistant, it does not let water in at all, so it can be poured in places where there is a high level of humidity;

- obstruction of dust formation;

- increased level of tensile strength, resistance to wear;

- resistance to mechanical, vibration and electrical stress;

- the texture of the floor provides easy maintenance, allows the use of strong detergents and washing machines;

- liquid floor is immune to acids, alkalis, aggressive gases and petroleum products.

The disadvantages include:

- thorough preparation of the base before pouring;

- if you do not comply with the technology of mixing and pouring, the floor may delaminate;

- flooring removal requires special skills;

- Difficulties in choosing colors that fit the main surface;

- high cost of goods.

Polymer cement floors

They are considered the hardest and wear-resistant mixture that is used to level the surface. The material received all its qualities due to unique polymer additives and cement mineral mix.

It contains:

- polymers in the form of synthetic rubber, resin and acrylic. They constitute 5-20% of the total volume and affect the strength and elasticity of the surface;

- cement is responsible for the strength indicator;

- sand increases anti-slip properties;

- color pigments.

Polymer cement floor is not suitable for casting in living rooms. This coating was designed to increase the strength of various production areas, large car parks and airfield strips.

The high level of strength allows the coating to withstand the strongest mechanical loads, contact with the chemical and oil environment. This indicator indicates a long life of the floor. If the surface appeared decorative flaws, they are easily eliminated by dismantling.

Laying the mixture can be done on wet concrete or on a fresh screed. The floor itself is often used instead of a screed base, because the solution can be applied in a thick layer. To fill the material is not required to carefully prepare the base.

Formed coating is characterized by antistaticity, which will be optimal for industries where there is a large number of equipment. It is rather difficult to stain the surface, which reduces the number of wet cleaning.

Filling the mixture takes place without difficulty, it is ensured by the plasticity of the finished solution. It is quickly located on the surface and fills all defects, aligning itself.. The process of arranging such a floor is not accompanied by chemical aromas, since only natural substances are present in the composition.

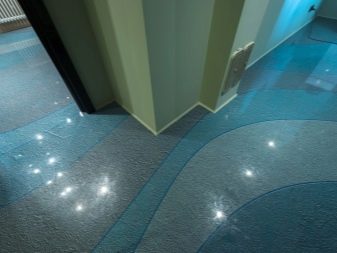

Quartz floor

It is considered multi-layered. It is distinguished by its efficiency, which is provided by an intermediate layer with quartz, dolomite and marble sand. After the first layer is poured, it is necessary to immediately apply sand and wait a day. In the future, surpluses are removed. After a day, you can cover the floor surface with a repeated layer, selecting its thickness for the desired effect.

Thickness will depend on what you want to get:

- glossy floor. To give this effect, you will need to increase the thickness of the layer. Experts recommend using an additional fill of polyurethane varnish;

- preservation of anti-slip characteristics. For this purpose only impregnation is required, and the surface itself is left rough.

Decorative bulk floor

This is one of the varieties of flooring, which is chosen for rooms where there is increased maneuverability, along with individual conditions for the aesthetic component.Such premises include halls of hotel complexes, shopping centers, halls of cultural and entertainment establishments. The technology of creating a decorative self-leveling floor is similar to the usual fill:

- on a perfectly flat, finished surface, primer or polymer impregnation is applied. The moisture requirements of the base should be observed, since this indicator should not exceed 4%;

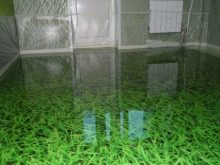

- then you can create a decor, during which three-dimensional drawings are pasted, the layout of the pattern and small 3D objects is carried out;

- this decorative layer needs to be filled in with a transparent polymer;

- to increase the strength factor, self-leveling floors covered with polyurethane varnish. In carrying out the work, it should be borne in mind that until the polymerization is completed, the solution will release toxic substances that adversely affect human health. For this reason, it is recommended that you take precautions and wear a mask;

- after completion of the work, the room is thoroughly ventilated. Peculiar odor may persist throughout the week.

3D self-leveling floor

This is a separate caste of floors, as they can boast all the advantages of a self-leveling surface, as well as a unique decorative appearance. Volumetric floors can be performed not only on the epoxy surface, for them suitable cement-acrylic floor, methyl acrylate.

Only for such a floor covering one finish layer is poured, the minimum thickness of which is 2 mm. This is the most expensive polymer floors, creating a unique decorative effect.

The finishing work includes a layer with non-woven materials on which the drawing is located. The picture must be of high quality. When choosing such a floor, remember that volume effect will be noticeable only from a certain position. Therefore, it is worthwhile to pre-design a viewing point and choose an image deliberately.

In a polymeric bulk field with fillers, photographs, coins, sand, beads, mineral types of crumbs, and even small pebbles can act as bulk fillers.

Many designers recommend using chopped pieces of acrylic paint. Such a quick-hardening floor has not only an attractive appearance, but also good technical characteristics.

Acrylic floor

Production takes place with the use of high-quality cement, special aggregates, polyacrylate copolymers. Initially, such a floor was used when pouring industrial premises, but at the moment its scope of operation has expanded. The mixture has a high strengththat allows you to fill it in places with maximum chemical and mechanical loads.

Acrylic floor is actively used in places with high humidity. For its arrangement, waterproofing is not required, since the coating itself finishes itself with excess water without absorbing it. Also, the mixture is characterized by anti-slip qualities, which expands the scope of its application.

Many experts advise to use this composition as a leveling surface for other floor coverings. For example, it is poured as a base for a laminate or porcelain tile.

Positive qualities of acrylic floor:

- with it you can get a matte or glossy surface;

- resistance to temperature extremes;

- raw materials are not subject to detachment from the base;

- long service life, which is 30 years;

- Smooth surface;

- elasticity;

- wide range of design solutions;

- easy installation;

- use of eco-friendly materials;

- moisture resistance;

- easy care;

- wear resistance;

- Record polymerization time.

Disadvantages of the acrylic surface are also available. Filling is accompanied by an unpleasant smell, which makes it difficult to work. However, when dried, the unpleasant odor disappears.

Before buying, take into account the fact that the solution was designed to work on a large area, so pouring it in the bathroom will be accompanied by additional difficulties. The high cost of the material is also among the disadvantages of the self-leveling coating.

Methyl Methacrylate Fluid Floors

They are a coating that contains two semi-synthetic components. This mixture dries quickly. The composition contains a dry mixture of filler, which is implemented in bags of 15 kg, and a liquid hardener in plastic canisters with a capacity of 2 liters. The floor is characterized by rapid polymerization, so you can walk on it after only a couple of hours.. Filling of a floor can be carried out on any basis: concrete, floor slabs and even on a surface with expanded clay.

Such a the coating can be poured even at sub-zero temperaturesthat does not affect the performance of the floor. Its toxicity can be attributed to the number of disadvantages; therefore, the work should be carried out in a mask and in a well-ventilated room.

When the layer is polymerized, no toxic substances are formed, so it can be laid in grocery stores or in a warehouse. The material is resistant to chemical reagents, does not conduct electrical current and does not pass moisture.

Plaster coatings

Used to level the bases inside the rooms. The thickness of the layer is 20-30 mm. The mixture contains gypsum base and cement. Operate the finished mixture can only be in rooms where humidity and temperature is controlled. Masters use such a solution only for leveling rough substrates on which there are significant drops and cracks.

Advantages of gypsum mix:

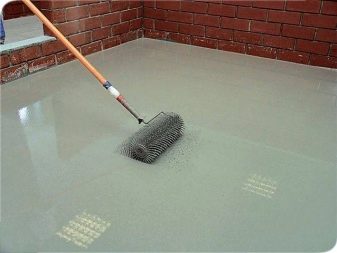

- self leveling layer. You are required to pour the solution onto the base and roll it out using a special roller;

- fast polymerization. The solution dries within 24 hours, which significantly shortens the repair period;

- the structure of the mixture allows manual filling or use mechanized methods;

- environmental quality materials. Gypsum screeds can be used in medical institutions.

Rubber liquid floors

The construction industry is constantly evolving, offering innovative solutions to its audience. These floors are among the innovations, they were able to gain respect in the market due to their technical characteristics.

Advantages of a rubber bulk surface:

- good depreciation;

- elasticity of the mixture;

- the material is characterized by elasticity and high level of resistance to mechanical loads;

- the surface of the floor is soft, so the probability of injury is reduced;

- anti-slip effect;

- attractive appearance;

- lack of joints;

- wear resistance;

- fire resistance

Manufacturers of liquid rubber coatings offer compounds that have different physical properties due to differences in modifying additives. By adding or reducing the number of components, you can focus on certain layer indicators.

Rubber floor can be used in a rather limited specialization, since its soft and elastic surface is not suitable for every room. Such a floor is widely in demand when pouring children's playgrounds and sports halls.. As rubber does not give in to influence of water and dust, similar material can be filled in in the closed and open rooms.

For playgrounds, you can use a thick layer of fill, which will soften the blows when the child falls. The soft structure of the raw material does not allow damage. For sports fields a thin layer is used. Also, this coating is found on underground parking, staircase and stairs.

The rubber composition can be painted in any color, therefore with its help the game fields on sports grounds are often painted. Due to the porosity of the mixture, the paint is held for a long time.

Thickness

The thickness of the layer is not chosen arbitrarily and should be determined on the basis of a list of conditions that should be observed before pouring. If you make a very thin layer of liquid floor in a room where there is a high dynamic load,the surface will quickly become worthless.

There are three criteria that affect the thickness of a layer:

- level of mechanical stress. Before filling the floor, it will be necessary to calculate such indicators as the level of vibration exposure, surface resistance to wear and the probability of striking the floor covering;

- laying the thinnest layer corresponding to the variety of the binder components of the mixture;

- the level that will be required to align the rough coverage.

If you fill the floor, the thickness of which will not be enough, it will not last long. It is not necessary to carry out the laying of a thicker layer, since you will spend money on excess raw materials.

In order to resolve the issue related to the minimum floor thickness, it is recommended that you familiarize yourself with the types of mixtures that meet these criteria:

- thin layer solution. The thickness of this layer should not be more than 5 mm. The coating is able to protect the substrate from the adverse effects of the environment. The consumption of the solution depends on the quality of the selected screed and the type of dry mix;

- self-leveling. The maximum thickness of such a layer will be equal to 20 mm.Such a flooring is characterized by antistatic qualities and resistance to mechanical stress;

- highly filled surfaces. The minimum thickness of the layer is 2 cm. The mixtures are made from special fillers, including clay, magnesite and quartz sand. They are often used in places where you need to get a thicker layer that exceeds the maximum value.

The thickness of the layer depends on the type of raw materials used. Masters recommend to pay attention to the characteristics of each material, and then decide on the choice:

- polymer floors. For such a surface, 4 cm is enough. The minimum value is 2.5 mm. If you plan on additional staining of the layer, you can lower this value to 0.3 mm;

- methyl methacrylate. Thin-level self-leveling floors are usually applied to concrete and steel foundations. Although the thickness of a single layer does not exceed a value of 0.6 cm, it is able to withstand a load of 15 tons;

- cement polymer Compounds were specially created for repair work on ceramic and wooden surfaces. The surface may be up to 5 cm thick.If you plan to fill in rooms with maximum load, the layer thickness of such a floor can not be less than 10 mm.

When pouring the floor in an apartment, the thickness of the layer should not exceed 8 mm. This indicator does not include the ground and the base itself.

It is enough such parameters that the floor covering was strong and steady against wear. If you use a liquid floor as a finishing surface, the layer can reach 0.2 mm, provided that the base is prepared at the proper level.

The minimum thickness of any liquid floor is 1.5 mm. However, for standard dwellings, a value of 2.5–4 mm should be chosen. With production objects, things are different, since the floors can reach 10 cm. The mixture should be applied in two layers so that the coating is provided with a sufficient level of strength. When you follow these rules, you will get a floor that can withstand a multi-ton load without deforming the layer.

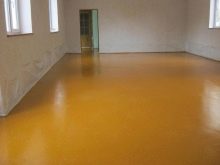

Colors

In the construction market there is a wide choice of polymer elements along with coloring pigments, thanks to which you can paint your polyurethane or epoxy floor in different colors.Such a coating may have a uniform surface, as well as combine several shades.

To get the original color effect, you can purchase various types of dyes and fillers that will not only decorate your floor, but also improve its structure.

Depending on your preferences, you can create a matte white floor or a bright surface with a pattern that does not burn out after 20 years of use. High quality coloring pigments due to the use of minerals that prolong the life of paints.

When choosing the texture and color solution of the floor covering, you should rely on the following parameters:

- room style. For classic interiors, it is better to choose gentle and calm surfaces, while modern rooms allow the use of contrasting shades;

- your own preferences;

- type of lighting and room layout;

- If you opt for bright colors, remember that colorful combinations can cause fatigue.

In addition to the choice of color, designers are ready to offer to use some of the techniques that will give originality to your room. These techniques include:

- decorative chips. They are pieces of paints of different colors, dimensions and shapes. They dilute the polymer solution, which gives the future floor similar to marble chips or granite. Marble will suit the classic interior, add a touch of chic and individuality to it;

- dyeing with polymer paints. This method creates an interesting artistic effect, which is achieved by applying paint on the base surface. After drawing the layer becomes varnished. Drawings are applied using stencils or manually;

- transparent liquid floor with filling. Many designers have resorted to this method, which consists in applying a transparent mixture to bulk objects. You can use for this purpose various pebbles, coins, and even seashells;

- volume 4D. This method is considered the most interesting, since it recreates the full effect of the volumetric pattern on the floor. The surface is formed using a realistic image, which is located under the transparent polymer mixture.

When choosing a self-leveling floor, consider its aesthetic qualities and practical component.For living rooms do not need to use a composition with a high level of strength, which will be relevant in industrial premises, and for a floor in a warehouse you should not pay for a three-dimensional image.

Which is better to choose?

The choice of self-leveling floor should be based on the following indicators:

- surface type:

- the degree of load on the floor;

- type of existing foundation;

- required layer thickness;

- the presence of defects on the leveling surface;

- climatic properties of the room.

For a room with a high level of terrain, you should choose floors with a high level of strength. Such floor coverings are called industrial. They are also suitable for arranging warehouses, as they withstand repeated transportation of carts and other heavy objects.

If you consider a liquid floor as an independent covering in the house, pay attention to solutions with a basis in the form of epoxy resin and acrylic dyes.

The variant without dyes is also suitable if there is a substrate from the canvas with an image in it. For other options, you can consider cement or gypsum solutions.

For arranging a bathroom suitable bulk floor with good moisture resistance. You can purchase a mixture of floor tiles or epoxy and polyurethane solutions that do not need a finishing coating.

For the kitchen, you can choose polyurethane or epoxy mixtures, in which acrylic pigments are added. With the help of this solution, a seamless smooth surface with the desired color solution is created. If you plan to further cover the surface with laminate or linoleum, pay attention to cement or plaster mixes.

Start from the cost, the right amount of raw materials and the timing of the work.

For the arrangement of the balcony will suit any polymer composition. The best solution is to choose a matte surface, as it has anti-slip effect. Cement-based mixtures can also be used for loggias and balconies, but gypsum mortars should be excluded.

For the bath, you will find the same solution as in the situation with the bathroom, but with increased requirements in terms of technology. Discard plaster mixes, even if they are protected from moisture tile.Choose a material based on the base used, since different composition of the mixture is required for concrete and for wood.

Self-leveling floors differ in the type of their intended purpose. Cement blends not suitable for topcoat, as they act as a normal cement screed to create a flat surface. Such a self-leveling floor differs from a standard screed in its liquid working condition, due to which the mixture spreads over the entire floor area, independently creating a perfectly flat surface. Such a liquid floor is used under the laminate, carpet or linoleum.

Polyurethane mixture can often be found among the "liquid linoleum." This is due to the fact that such a coating can boast not only operational characteristics, but also an aesthetic component. Such a floor is often poured in residential premises and in production.

Epoxy floor absolutely does not let moisture, so it can be purchased for pouring premises with swimming pools, car washes, chemical and food industries. Since the mixture is safe, it has found its use in living rooms, medical and children's institutions. but such a floor is quite fragile and may suffer from contact with a hammer or other heavy object. Therefore, it is not suitable for rooms in which shock loads are observed.

Methylcrylate solutions are suitable for industrial premises in which there is an increased load and chemical contacts.

Style and design

Bulk floors fit into any interior. However, they are most suitable for pouring in modern interiors, which include loft, modern, hi-tech and minimalism styles.

If you like classic interior design, the floor must comply with the room concept and fully harmonize with the decor. For such an interior, you should choose matte monochromatic shades or fill with imitation of natural stones, wood structure.

For lovers of minimalism and high-tech seamless floors are considered the best choice. The coating must contain strictly one color. Matte or glossy surface is allowed depending on your taste preferences.

For the Scandinavian interior should choose plain floors. White color is best suited for this purpose, but you can buy bright contrasting shades.Some designers offer to leave the floor in the form of a rough coating.

In rooms that are made in industrial or loft style, you can not pour decorative liquid floors. Pay attention to the screed without a glossy surface, which will create the necessary atmosphere in the room.

For the modern style of modern fit a glossy surface. Be sure to choose solid and neutral shades. The win-win is matte white or gray, woody shades.

Remember that these colors do not differ practicality, but only they can make the room more bright and spacious. In combination with a bright interior such floor creates the right atmosphere.

Important nuances

Arrangement of a bulk floor on a shoulder to the house master. When performing this type of work, you should familiarize yourself with the basic rules and nuances, thanks to which you will avoid some mistakes that may create difficulties in the future.

Subtleties that should be studied before pouring a liquid floor:

- Before pouring the mixture, carefully prepare the base. It should be dry, free from dirt.You will also need to align and degrease the surface;

- To make the solution better adhere to the base, coat the prepared surface with a primer;

- if you do this treatment, the self-leveling floor is no longer detached from the base. If you need to create a new coating, you will need to place it on the old layer;

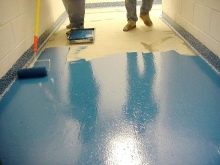

- if the liquid solution is poured onto the rough surface, it will independently begin to spread over the entire area of the room. At the same time, bubbles begin to form on the surface, which need to be smoothed using a special roller;

- Do not pour liquid floor if there is a draft in the room;

- the temperature in the equipped room should not be less than 10 degrees;

- equip the door limiter. It can be replaced by an ordinary rail, plasterboard strip or profile, whose width is 0.5 m. The first strip should be formed across the width of the wall, which is opposite the door;

- it is impossible to allow breaks in the work, so the next lane is poured immediately, along with the rest. Do not forget to level the floor and flatten the mixture with a spatula. Bubbles should also be removed immediately;

- the finished floor should be covered with polyethylene until polymerization. The drying time of each floor is indicated in the instructions;

- the self-leveling floor also has its expiration date. It depends on the composition of the mixture. Overdue self-leveling floor loses its binding qualities, which affects the whole process. As a rule, the shelf life of the mixture is six months.

After reviewing these subtleties, you can draw conclusions and create a quality floor covering in your home.

How to fill in a bulk floor, look in the following video.

Famous brands and reviews of the owners

Many brands offer their products to the audience to create a self-leveling floor. To make the right choice, you need to familiarize yourself with the most well-known brands and study the feedback that buyers leave.

- Mix "Found" is in great demand among buyers, as it has an important quality - fast polymerization rate. People who were able to evaluate this mixture report that it dries out after only a few hours. This is the most operational solution, which quickly hardens, allowing you to walk around the dwelling without restrictions.In small apartments, where there is only one room, this option is optimal.

The manufacturer himself reports that the mixture is made on the basis of mineral binders in which polymeric additives are present. The material can be used for arranging rooms with a normal degree of humidity.

Such a liquid floor is able to eliminate visible surface deficiencies and is suitable for a warm floor system. These characteristics are confirmed by customer reviews.

- For lovers of the German brand there Bergauf mixwhich managed to win its audience. Buyers choose this material because of its composition, in which cement is the binding component. This substance allows the use of a self-leveling floor for pouring not only living rooms, but also a bathroom. According to reviews, the solution fits perfectly on any surface, suitable for underfloor heating. Positive comments speak about its universality. The manufacturer was able to develop a coating that is suitable for any finish.

- Reviews of another brand - Knauf, speak about its operation on the bases from a tree and concrete.Buyers report that it is very convenient, since not every manufacturer can provide guarantees for a successful fill of the floor. In this mixture, Portland cement and gypsum are used as binding components. You can also pour the solution in wet rooms. Many people speak positively about the viability of the layer, due to which it covers large areas at once. You can operate the floor after six hours.

- Solution from "Bolars" those people who are planning to use a self-leveling floor as a finishing surface are gaining. Such a mixture boasts high compressive strength and after six hours you can walk along the floor safely. Often, such products are acquired by owners of one-room apartments in order to shorten the repair time and not to move to rental housing during the pouring period. The brand has earned the respect of customers due to the fact that the proposed mixture can be used for outdoor work. However, the layer should be poured after reading the instructions, as it will require a certain level of skill so as not to spoil the surface.

- Self-leveling floors Ivsil please with their wide range.Buyers can choose an ordinary screed or coating with high strength. Most people choose Ivsil Express, as this mixture dries quickly and reduces repair time.

- Those who are looking for a budget solution to fill the floor, opt for the brand "Hercules". This brand does not collect as many positive reviews about its positive qualities as other manufacturers, but it helps out in case of emergency and on a limited budget.

- Tikkurila mix differs in the environmental friendliness and comfortable conditions for work. Buyers respond positively to this manufacturer, noting the strength indicators, ease of pouring. Due to this solution, you can decorate your floor in any style.

Choosing a brand of self-leveling floor, you should build on customer feedback and technical characteristics of the required composition. Due to the high competition in the market, manufacturers are trying to offer the best conditions at a bargain price, which is confirmed by enthusiastic user comments.

Beautiful examples and options

Bulk floor is able to decorate any room.It is universal, it can be carried out in any color scale, due to which it is gaining its popularity. Liquid floor in the apartment will be the accent of the room, will emphasize its concept and design.

The original effect of self-leveling floors can bring in the living room. If earlier our grandmothers in such a room had expensive carpets, beautiful wallpapers and valuable items, by now these rules are a thing of the past. No one will be surprised if your flooring will be decorated with colorful carpets, and antique objects will be placed on the walls. To decorate the gray days, designers recommend to pay attention to the liquid floor with a panoramic image.

This decision will be the centerpiece of your living room, will attract attention, focusing on the good taste of its owner. To achieve the maximum effect, you should position the image along the longest wall.

In the interior of the bathroom often use bulk self-leveling floors. The 3D floor, which depicts the sea inhabitants and the beauty of the ocean, will delight not only the guests, but also give the right atmosphere during water treatments.

If you do not want to overpay for a three-dimensional image, designers recommend choosing a regular matte or glossy coating with any shades. Also You can decorate the solid floor with flockswhich will give a decorative effect even to a simple color.

Some apartment owners choose an imitation of ceramic tiles or natural stone, which also transforms the style of the bathroom. Bulk mixes are combined with a warm floor system, so it will be a complete replacement of the tile.

In the children's room, the liquid floor can also be surprising. Cartoon characters, which are depicted on the surface, will help not only make the room original, but also make it an ally in children's games. Your child will play with your favorite characters and give you rest after a busy day.

Polyurethane coatings are convenient to wash, so you can easily remove the traces of color "painting" from the surface.

The bedroom will look nice dazzling white floor. It will emphasize the crystal cleanliness of the room and will allow you to relax after working days. If you are bored with a monotonous surface, you can always paint it and diversify the familiar interior.

The self-leveling floor has found its application in all rooms and pleases its owners with their qualities, as well as the aesthetic component. You can always come up with your own unique design and even place your family photo on the floor in the bedroom or hallway. Such a decision will be exclusive and will surprise your soul mate. Since the self-leveling floor has been serving for about 30 years, you will be able to preserve your memories for a long time.