Granite tiles: selection criteria

Granite tiles are increasingly used as the main finishing material. The natural stone from which it is made gives it durability and high strength. In addition, granite decoration gives the room a special style and attracts attention.

This building material is suitable for almost any project and advantageously transforms the space.

Special features

It is not for nothing that granite is considered, if not the hardest and densest finishing material, then, undoubtedly, one of them. It is widely used in construction, as well as used in interior decoration and in the arrangement of the floor.

Facing plates from a natural stone are very strong, durable. In addition, they differ in special decorative properties, due to their natural origin.The drawing of each plate is individual, it is impossible to find an exact copy of it. Therefore, during the laying of plates for a beautiful result you need to carefully follow the pattern on the stone.

Natural materials are rarely characterized by a homogeneous structure. For them, the presence of veins, color transitions and various mineral inclusions is typical. This is easily noticeable during inspection of the plates selected for installation.

Before facing any surface with granite slabs, one should not neglect the procedure of preliminary selection. Modular plates are chosen for the specified characteristics, paying attention to the uniformity of color, the presence of similar inclusions.

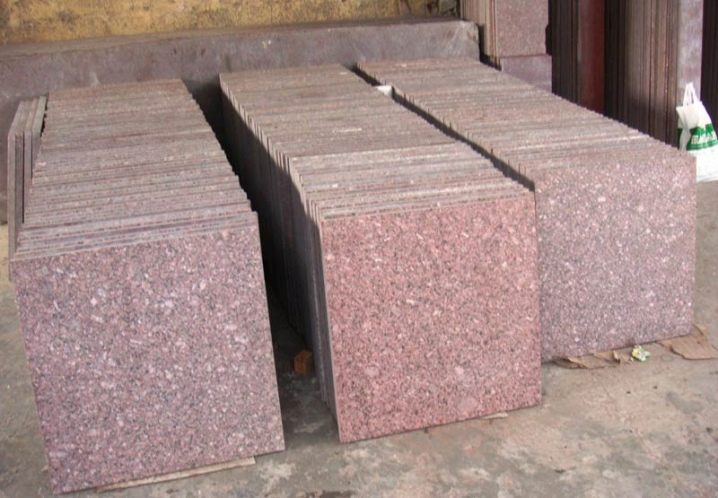

Slabs of granite can be square or rectangular. They are found in various sizes, from fairly large to small. The parameter of their thickness also varies from 10 to 50 mm. Square plates of granite are often placed on horizontal plates, and rectangular on vertical plates. Modular slabs 600x300x20 are used in arranging the floor, facing facades and stairs. Tiles with a thickness of 40 mm can be used for the manufacture of steps or lining the sill.

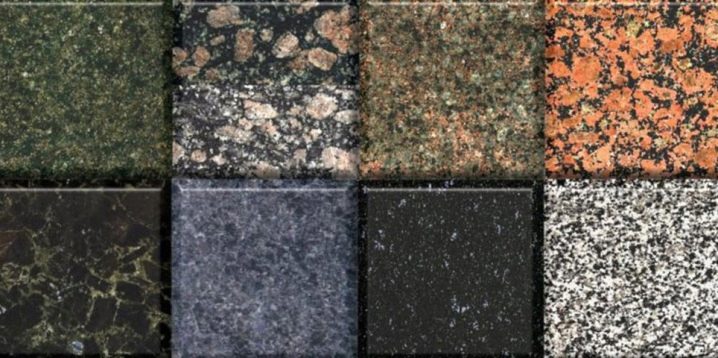

Kinds

Granite tiles can be presented in various designs. In order to distinguish the plates from each other, a classification has been developed, which is based on a special GOST. According to it, there are 5 types of plates made of natural stone. They differ from each other in the texture of the stone and the features of its processing.

Polished plates are characterized by a mirror surface and a clear texture of the pattern.

Heat-treated plates have a rough surface. Due to the treatment with very hot gas jets, specific peeling remains on the stone. As a result, they get a non-slip structure.

On sawn slabs, uneven troughs can be seen. This is made specifically to simulate natural damage on the stone.

On the bachardirovannogo finishing material specially create small differences in depth. Small roughness evenly distributed over the surface.

Polished granite tiles also have a clear pattern, but, unlike polished, do not have a visible shine.

Advantages and disadvantages

The popularity of granite cladding material is inextricably linked with all the advantages that it has.In addition to indicators of high strength, for which it is well ahead of even marble, granite material boasts a long service life. Granite slab is slowly aging and is able to serve for several centuries.

Granite perfectly serves as a foundation for buildings, since it is practically not subject to mechanical stress, it is easy to resist temperature changes and chemical aggression. Granite slabs are also permeable, so they are widely used for exterior cladding. They are not afraid of high humidity and are actively used for arranging embankments.

Granite is an eco-friendly material. It does not harm the environment and human health. In nature, it is found in various colors and shades. With it you can make amazing and original compositions, to make a variety in the interior. Various methods of stone processing can create unusual effects. Floors made of granite are very easy to clean, and their brilliant surface reflects the light beautifully.

However, when choosing this material, it should be remembered that it significantly exceeds the cost of other types of plates.In addition, its installation requires a large amount of additional materials and it should be carried out only with the help of highly qualified specialists. The heavy weight of granite slabs complicates the process of their delivery to their destination. In addition, due to the large weight of the material during its installation, it is necessary to provide a very strong base.

Granite is a fairly cold material. And if in the summer it provides a pleasant coolness to the legs, in the winter, rather, it will bring inconvenience.

Criterias of choice

When choosing granite slabs, they are guided by where they will be used - for external or internal facing of the room. Based on this, choose a stone with the necessary texture.

Polished and polished slabs are most often used for interior decoration. They are used to pave the floor or make steps. Due to their slippery surface, outdoor use will be traumatic. As for polished slabs, they can be cladding the facades of buildings and interior walls.

Thermoprocessed, buchardirovannuyu, polished and sawn tiles are widely used for finishing on the street. They can revet steps and platforms.Due to the special processing on the surface of these types of plates there are special roughness, which make it non-slip, and therefore applicable for paving streets. The heat-treated plate does not slip even during heavy rainfall.

Decorative decoration of walls and fireplaces often requires the use of sawn tiles. With the help of chipped plates it is also possible to get interesting decorative effects. Often ordered monuments - heat-treated products from granite chips.

When buying granite slabs you need to pay attention to the country of origin. Chinese granite is considered one of the cheapest. But often such savings are inexpedient, since the production of plates from this material sometimes does not meet all the requirements. China does not always supply high-quality granite slabs.

Laying specifics

High-quality laying of material from a natural stone can be made only in the presence of special devices. Such tools, as a rule, are always with highly qualified specialists.

Perform several styling steps:

- during the preparatory work, the old finishing materials are cleaned from the surface, then it is leveled and the ground is applied;

- glue is applied to the required area;

- directly stack the granite tile, selecting if necessary drawing;

- gently smooth out the seams.

One person will be quite difficult to engage in laying granite tiles, as they are very heavy. It is recommended to wait 2 days until the glue is completely dry and plates are evenly laid. At the end of all the work you can polish the surface with liquid wax.

Granite tile is a reliable and durable material for both internal and external cladding. Due to the presence of different types of tiles, it is possible to make a surface with a different texture that is appropriate for different occasions. This finishing material will serve for a long time without significant changes in appearance. That is why financial investments in this type of lining always justify themselves.

On the criteria for selecting granite tiles, see the following video.