PVC tiles: advantages and disadvantages

PVC tile has established itself as a worthy alternative to such coatings as linoleum or self-leveling floor. Comprehensive modernization of the production process of PVC coatings, carried out by the largest manufacturing companies, has contributed to a significant expansion of the range, improved design and improved product quality.

The natural reaction of the market to such changes was the increased interest on the part of buyers to a new high-quality finishing material, possessing a whole set of attractive performance characteristics combined with a presentable appearance.

The availability of prices is also important. PVC tile is considered the best solution for the repair of the apartment level of comfort. In our article we will find out what are its pros and cons, dwell on the features of use and the secrets of a good choice.

What it is?

There are two types of PVC tiles with different structure. It is homogeneous in the form of a homogeneous, elastic and durable material with a base of PVC and heterogeneous, which, like linoleum, has a multi-layered complex structure, like a sandwich.

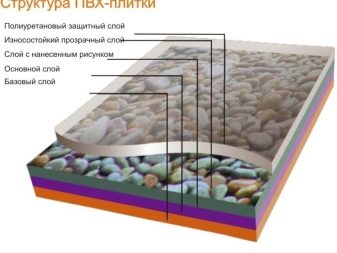

The design of the standard coating of a heterogeneous type is presented:

- Profiled base layer of glass yarn or PVC products.

- The main layer - the presence in its composition of various plasticizers makes the tile elastic and flexible, and the addition of stabilizers: talc, wood flour, kaolin, barite improves the strength properties of the material.

- A decorative color layer on which printing cylinders with an engraved pattern are applied various drawings, including those imitating the texture of various materials.

- Protective transparent polyvinyl chloride layer, which prevents abrasion of the pattern and prevents loss of color. Thanks to its protection, the material acquires the ability to withstand increased operational loads in places with intensive maneuverability.

- Wear-resistant layer of heterochain polymer (polyurethane).Its presence affects the ability of a material to resist premature wear and facilitates its maintenance.

Attention deserves compressed modular vinyl. It is called luxury vinyl tile - it is a luxurious vinyl tile. The fundamental difference between prestigious designer coats and standard materials of heterogeneous type lies in the manufacturing technology.

The composition of such coatings include vinyl and amorphous substances. with the addition of components that increase elasticity, stabilizing elements, in some cases - inactive mineral additives-fillers.

This mixture is pressed under conditions of high pressure and temperature, however, the final product is plastic and elastic.

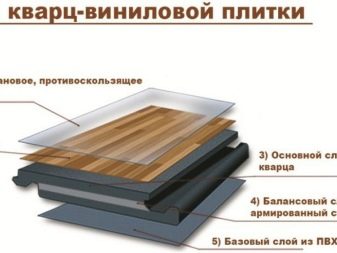

The heterogeneous structure of vinyl modules is arranged as follows:

- a two-layer substrate, the composition of which includes polyvinyl chloride and fillers;

- design film with individual drawings;

- pure polyvinyl chloride acts as the upper wear-resistant layer, thanks to which the product acquires exceptional strength characteristics.

The thickness of the protective layer is 0.3-1 mm.Vinyl tiles are included in the "T" group, combining materials with the highest resistance to abrasion. The presence of an additional protective layer is also intended to simplify the cleaning of the coating and reduce the cost of its maintenance.

Advantages and disadvantages

Sustained demand for PVC floor tiles due to the mass of positive qualities, including:

- aesthetics and a huge selection of designs with a variety of color and texture solutions;

- water tightness and water resistance (polyvinyl chloride is designed to operate in conditions of high humidity, which prevents its deformation upon contact with water);

- good heat and sound insulation properties;

- high wear resistance;

- resistance to various types of pollution and ease of maintenance - any household chemicals are suitable for cleaning PVC floor tiles;

- simple installation, easy cutting, which is important when laying curved sections of the floor, the possibility of sharing with different types of underfloor heating systems;

- complete maintainability - damaged parts are easily replaced with new ones without having to dismantle all floors;

- exceptional efficiency - waste material after installation is a maximum of 2%.

Compared with other flooring, PVC tiles:

- eliminates cracking, splitting into parts, as it can safely withstand dynamic loads: lateral impacts, pressure from furniture rollers and female studs, abrasion, burnout under the influence of ultraviolet due to the UV layer;

- seamlessly transported compared to bulky roll materials - linoleum or carpet;

- complies with fire safety requirements;

- provides tactile comfort when walking on the floor: the tile is warm, like wooden coverings, pleasant to the touch;

- Eliminates the "noise" effects when moving around the coating, thanks to the excellent shock-absorbing characteristics.

In more detail, I would like to talk about the environmental friendliness of this material, since quite often the refusal to purchase PVC tiles is argued by their unnatural.

Modern coatings are made on the basis of quartz sand, which is a completely natural material, with the addition of PVC granules as a binder component of various elements of the composition.According to the results of numerous tests, the composition was found to be absolutely safe for humans, as evidenced by the ECO mark on the products.

The main danger is glue, which manufacturers process the base of tiles for easy installation. If there is a lot of it, then the floors automatically become a source of toxic fumes. In order not to wrestle with the question of the integrity of the manufacturers of the cheapest self-adhesive tiles, we recommend considering other, clearly harmless coating options, provided with locking joints or in the form of smooth freely lying modules.

Like any finishing material, whether it is a premium or low-cost flooring, PVC tiles have weaknesses.

Negative points of use:

- Inconsistent composition. In the case of laying floors made of artificial material, to rely on the ideal microclimate in the house is no longer necessary.

- Limited temperature range of operation, if we are talking about floor heating systems. Permissible heating value + 28 ° C.

- Susceptibility to acetone containing solvents.

- Short operational period - maximum 15 years.

Types and characteristics

Polyvinyl chloride coatings are classified according to several criteria.

Field of use

- Domestic - the scope of application is limited to residential objects with low operational load, which corresponds to the durability of coatings from 23 to 31 classes. Such models have improved aesthetics with rather mediocre technical characteristics. The group of household floor coverings is represented by products with a needle-punched fibrous base and heterogeneous foam models.

- Semi-commercial - these models from the relatively recent intermediate group of PVC coatings have higher strength characteristics and are designed for operation in places with medium traffic.

- Commercial. These are high-strength models with increased wear resistance and extended service life.

Their field of application is public premises with a high degree of operational loads. This group includes products from 31 to 42 class.

- Special. A special kind of coatings, which has specific qualities - fire resistance, high sound-proofing ability, anti-slip, antistatic properties, etc.Their scope of application - production facilities and warehouses.

Way of laying

- Self-adhesive with a sticky back, treated with adhesive composition, which greatly simplifies the lining of non-flowing base;

- Chamocks, which have a tongue-and-groove joint, as in laminated floors. This ensures the reliability and durability of the joining of the tiles to each other, with their help it is convenient to install floating floors in places with a high level of operational load;

- Adhesive modules - laying is done using mounting glue, which fix the usual linoleum.

Appearance

On homogeneous tiles, drawings completely permeate the entire material.while maintaining aesthetic appeal even with uneven wear.The patterns of coatings are influenced by manufacturing methods: the drawing is directed or chaotic, which is undoubtedly practical, since the contamination on them is almost not noticeable.

An interesting option is self-adhesive flexible mirror polyvinyl coatings having a structure reinforced with stiffeners. The advantage of reflective surfaces in the interior is a visual expansion of the space and an increase in the height of the room due to optical illusions. Mirror decors can decorate walls, ceilings, furniture facades, doorways, arches, kitchen apron.

Separately, it should be said about tactile PVC tiles designed to inform people with visual disabilities (blind or visually impaired).

Dimensions

The most popular sizes of products include:

- square shape, mm - 300x300, 500x500 and 650x650;

- in the form of parquet boards, mm - 100x920 and 180x920, which makes it possible to create any herringbone and deck drawings during installation.

- the weight of 1 m2 of self-adhesive models, class 34, is 5.5 kg;

- adhesive plates, class 43, - 4.2 kg;

- castle, also under the label 43, - already 7.6 kg.

Style and design

Between today's PVC tiles and those unattractive, quickly decaying materials from the recent past,which many have finished at home for the sole purpose of saving, there is nothing in common. Modern products are impressive variety of patterns, among which there are even excellent imitations of palace mosaics, texture solutions, imitating a variety of materials, and the richness of a palette of colors.

With their help, you can bring to life a variety of design ideas and individualize floor design, turning it into a highlight of the interior.

Famous brands and reviews

The demand for PVC tiles proves the abundance of offers from domestic and foreign manufacturers of floor coverings. What brands are trusted by customers can be found in our mini-review.

Tarkett

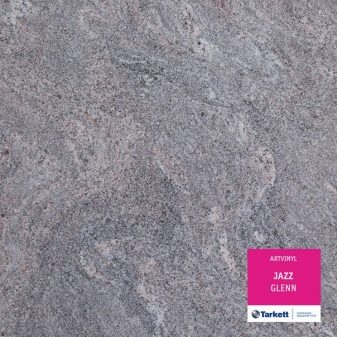

- Jazz - models of this series in the form of slats and squares attract with realistic relief of textures that mimic various natural materials, and delight the eye with noble calm shades of brown, gray and white gamma. The working surface is protected by a layer of EXTREME PROTECTION, which guarantees resistance to external influences.

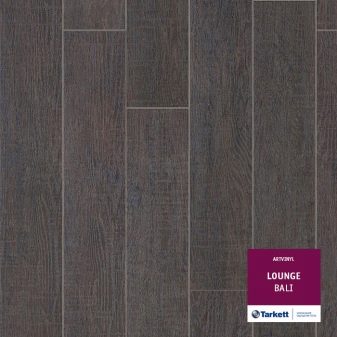

- Lounge - this collection includes high-density, wear-resistant coatings of class 34-43 abradability, intended for residential and commercial premises. The constructive solution of the modules provides for a 4-sided chamfer, which contributes to the visual expansion of the space,at the same time creating the illusion of completely natural floors. The series is represented by 21 coating designs: 15 models in the form of a bar with drawings imitating the texture of wood of various species and 6 models in the format of a tile for cutting stone. Of particular interest among buyers is the Nordic model, where the longitudinal texture of the slats is originally combined with the transverse one.

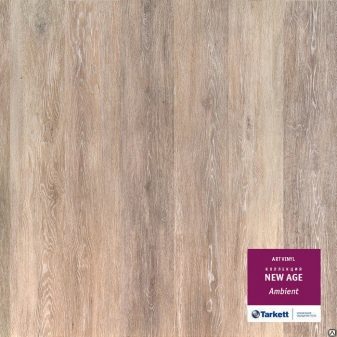

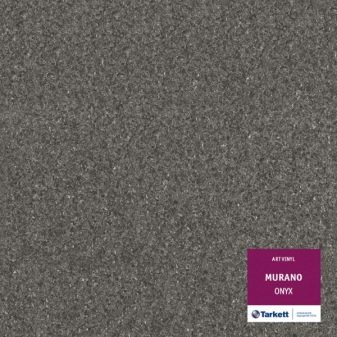

- New Age Series will appreciate the choice of original and very beautiful colors, and covers from the Murano collection will be appreciated by fans of glass-blowing art. It features 9 unique designs of vinyl modules with a 3D effect created by large metal chips on a contrasting background.

Graboplast

Heterogeneous materials produced by the Hungarian company differ from analogues of other brands by their structure with 4-8 structural layers. Such a solution can increase the exploitation of floors to the maximum possible period.

ReFloor

Floor coverings from the Korean brand have antibacterial properties due to a special vinyl layer with silver ions (Ag). In the collections there are many models with an attractive design, imitating the texture of wood, stone, leather, cut stone.

The manufacturer promises trouble-free operation for 20 years.

Lentex

PVC tiles, produced by the Polish brand, are semi-commercial and commercial type of coatings. The products of this brand attracts with original design, as in the manufacture of tiles used raw materials with the addition of special multicolored polyvinyl chloride chips.

Dumafloor

Designers of the Belgian-French brand beat the theme of imitation of wood of different species in different ways. As a result, collections were created with a variety of textural solutions for pine, wenge, oak, and walnut, to which fans of Scandinavian design, minimalism and classical style should look at.

Reviews

- visual appeal: realistic imitations of texture of various materials, nice looking colors, thoughtful design of models with chamfers;

- easy installation, which facilitates the self-adhesive surface, the room does not need to be freed from the furniture, as in the case of laying roll materials;

- simple cleaning without the need to use special tools to clean the floor;

- pleasant tactile sensations when walking, comparable to moving along the always “warm” wooden floor;

- safety is the quality noted by those who used tile as an alternative to tile in the bathroom; when splashing on the floor, the coating remains non-slip, which reduces the risk of injury to zero;

- sound insulation quality and the absence of unpleasant booming sounds when walking; Many of the floor tiles with PVC tiles helped to build relations with the neighbors below.

The main argument of those who are "against" PVC coatings remains - unnatural material. At the same time, the fact that we live surrounded by many things from PVC is often simply ignored by the “discontented”. We have already considered this issue at the beginning of the article. Decision is on you.

How to choose?

When choosing PVC tiles, you need to consider a few points.

Heterogeneous or homogeneous?

At once there can be a question what to give preference to heterogeneous or homogeneous coatings. Many buyers are guided by considerations that the latter will last longer due to the pattern that runs through the entire thickness of the tile. Yes, but there is one "but."

The fact is that when comparing two types of materials belonging to the same class, the wear resistance indices of them will be almost the same, that is, in terms of the time of wear they will differ little from each other.

This fact is explained by the fact that the composition of the protective layer of heterogeneous coatings of polyvinyl chloride is contained in its pure form, and it has extremely high strength characteristics. While the homogeneous tiles throughout the thickness are made of PVC with the addition of fillers, which give the desired weight, but lower strength indicators.

How to be? It's simple. Focus on the functional purpose of the roomwhere you plan to finish the floor. For example, cabinets, reception rooms, lobbies with an intensive maneuverability and a high probability that mechanical damage is possible here clearly require a homogeneous coating marked 32-42. If we are talking about an apartment, then such places include the entrance area, corridor and kitchen spaces.

For the garage, you can consider superstable homogeneous tiles of 43 classes, which are used in factories, workshops or warehouses.Do not forget that one of the advantages of this type of coating is increased elasticity, so it can be bent at the edges near the walls in order to reliably restrict access to the floor to moisture and bacteria.

When the device prioritizes additional sound and heat insulation, it is advisable to stop the choice on a heterogeneous coating or homogeneous acoustic material, which has a foam substrate. Bonuses when buying heterogeneous tiles - good cushioning properties, increased resistance to dirt, due to the protection of high-density top layer, and low maintenance. Remember that before mechanical damage they are powerless, unlike homogeneous counterparts.

Important indicators

You should be aware that the models of coatings that are included in different groups in terms of resistance to abrasion and having a different thickness can belong to the same class of wear resistance.

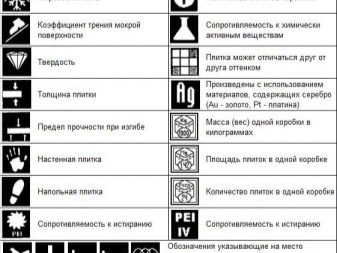

It will be necessary to study the information on the product labeling, paying particular attention to three indicators:

- class of operation;

- T / P / M / F group of abrasion resistance, where materials are referred to abrasion load depending on surface resistance;

- thickness - in this case, take into account the total thickness in relation to coatings of homogeneous type and the thickness of the additional upper layer for products of heterogeneous type.

Do not forget about the weight of the material on which the density of heterogeneous coatings depends.

In products of homogeneous type, high weight indicators often indicate a high content of products that increase elasticity. Models for cladding ceilings and walls will weigh less than floor coverings. Attempts to use tiles for other purposes and decorate vertical surfaces with floor models can lead to the fact that the material does not hold on to the base due to its own weight and will start to fall off.

And the last. When choosing a floor covering, be sure to inquire about the presence of accompanying documentation. Ideally, the seller should provide Russian certificates - for compliance with GOST, fire, hygienic and for compliance with ISO 9001/9002.

Styling methods

PVC flooring work includes preparation of the base and the installation procedure itself. We confine ourselves to general recommendations.A practical guide to installing a specific type of coating with specific recommendations for its installation contains technical or promotional and informational documentation attached to the supply.

How to prepare?

PVC tiles, similar to natural linoleum, need to be laid on a surface that has the following characteristics:

- flat and smooth - allowable deviations of the base - 2 mm on a 2-meter segment;

- clean - sand, dust, grease, oil, polish, paint should be removed;

- the presence of a dry draft basis;

- no excessive moisture - a hygrometer is used to measure the relative humidity of the base, values up to 0.05% are considered optimal indicators.

Concrete foundations on the first floor, in kitchens or bathrooms with high humidity conditions, need waterproofing. In cases of organizing underfloor heating, the “warm floor” systems are mounted a month before installation, de-energizing a day before preparing any surface of the coating.

Flooring technology

For those who work independently for the first time with PVC woodgrain coating in the slat format, the simplest, but very effective flooring scheme is optimal - displacement of modules by an arbitrary value.The advantage of this method is barely inconspicuous joints, subject to the minimum 15-centimeter spacing of the slats, and economical consumption.

The fragment remaining after trimming the extreme strip of the row can be used as the starting die of the next or subsequent row in case of a close joint arrangement to the wall.

The advantages of half or one third offset options are the possibility of obtaining an orderly regular pattern. Minus - docking places are more pronounced. Other variations of this scheme are offset by half or one third of the slats. All these methods of flooring involve laying parallel to the wall.

Modular vinyl is mounted differently: in a row, diagonally, by forming various parquet patterns - “herringbirds” or “decks”. Vinyl tiles significantly expand the possibilities of floor cladding, since in this case combinations of elements of different sizes and colors become available.

With professional installation, lockless modules begin to be laid from the middle of the room - the center is considered to be the point where two perpendicular center lines intersect. A line is drawn through the center using a paint cord.It will serve as a guideline for aligning the edges of the slats when the first two rows of vinyl modules fit.

Successful examples and options

The possibilities of PVC coatings in the interior are truly endless. This modern, practical, functional and very beautiful material is ideal for the implementation of really any creative design solutions. We propose to verify this with illustrative examples.

- Vinyl modules can be used as an effective tool for zoning space by combining different types of coatings. This technique is suitable for both apartments and commercial premises.

- PVC tiles with a pattern under the wooden floor of natural shades look organic in the interiors of the most diverse styles: from the brutal loft style and practical minimalism to timeless classics and scandi design.

- Decorating PVC wall tiles of accent walls, kitchen fronts and aprons is an effective way to diversify the interior. So you can emphasize the architectural features of the room, create interesting textured or color accents, or support the overall palette of the interior consonant shade of the coating.

- Floors, decorated with expressive black and white vinyl tiles, will definitely become a bright decoration of the interior. The duet of black and white has long become an interior classic, but only a few are decided to make a contrast to the floor. And you?

- With the help of vinyl floor tiles in combination with PVC panels, you can become the owner of a beautiful and modern bathroom without any special expenses.

Such a finish is affordable for most and will not exactly make a dent in the budget.

How to lay PVC tile, see the following video.