Swedish thermal floor Thermo: advantages and disadvantages

Thermo Industri is a Swedish company that is well-known on the European market for building and finishing materials and is engaged in the production of Thermo warm floors. The domestic consumer got acquainted with the products of the enterprise several years ago and during this short time managed to appreciate the excellent quality, low cost and safe operation of the “warm floor” construction.

Features: advantages and disadvantages

Thermo Industri products have proven themselves in the harsh Scandinavian climate. Own authoring, accumulated experience and the use of high quality materials allowed the company to launch the production of unique heating systems that have no analogues in terms of safety and quality.

Thermo floors are steadily growing in demand, highly popular and endowed with the following undeniable merits:

- Products are absolutely eco-friendly and meet strict European sanitary and hygienic standards. Favorable air circulation completely eliminates the formation of convection currents and raising dust to the ceiling. This greatly alleviates the condition of people suffering from asthma and allergic reactions;

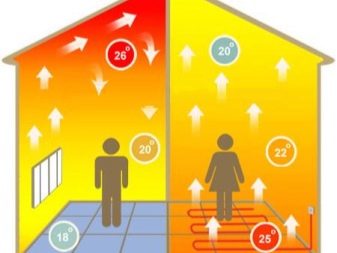

- Warm flows rise up evenly and provide a soft warming of the room, without concentrating high temperatures in one place, unlike, for example, from a heater. As a result, a comfortable temperature mode is created, which at the level of the floor reaches a value of 24 degrees, and at the level of human growth has an indicator of 16 degrees. When heating the room does not occur the combustion of oxygen, thereby maintaining a comfortable humidity;

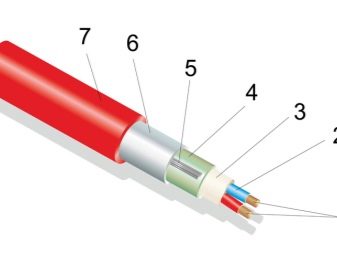

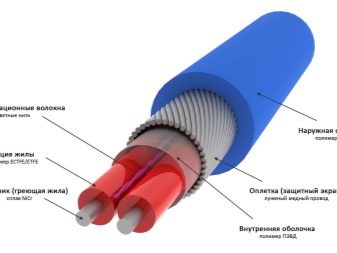

- Due to the use of two-core shielded cable, there is an absolute absence of electromagnetic radiation. This allows you to use the design in children's and medical institutions;

- A unique system of thermostats can set the desired temperature automatically. That allows you to change the mode of heat supply depending on the time of day and outdoor air temperature. Thanks to the autonomous control of any individual system, it is possible to individually set the desired temperature for each room. Modern thermal sensors make it possible to change the heating temperature with an accuracy of one degree;

- The hidden location of the heating system allows for the design of the room and the placement of furniture without restrictions. The advantage is the absence of wires and overall elements, which enhances the aesthetics of the room and does not visually litter the space. The thickness of the system is 2.8 mm, as a result of which raising the floor level during installation is excluded. This allows the construction to be used in rooms with low ceilings without the risk of reducing the height of the room;

- The durability of the models due to the simplicity of design and the use of high quality raw materials. Manufacturers guarantee flawless construction for over 20 years.The use of the cable system completely eliminates the need for maintenance, prevention and maintenance;

- Economical use of electricity is based on the rational distribution of warm air masses. The effect of uniform heat dissipation is achieved through the use of metal foil, which allows a 20% reduction in the cost of heating the room;

- The versatility of the Thermo system allows it to be used in all types of residential and public buildings. The absolute tightness of electrical elements, provided with five-layer insulation, allows the use of the structure in pools and bathrooms. Heated floor can serve as a primary, additional and alternative source of heating, as well as fit under all types of coverage. Installation of the floor is not difficult and can be done independently.

The disadvantages of floors Thermo Industri should include the short service life of the thermostat. This results from the fact that the enterprise independently is not engaged in their production. Sensors are ordered from partner companies, so their quality may differ from the quality of Thermo products.As a minus, it is possible to consider the impossibility of using warm sex for people suffering from varicose veins and having problems with the circulatory system. Judging by the reviews, the disadvantages include high energy consumption in models that are not equipped with thermal sensors. This makes it impossible for the system to control the level and duration of heating.

Species

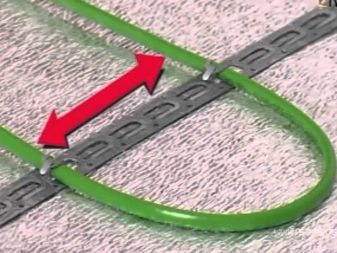

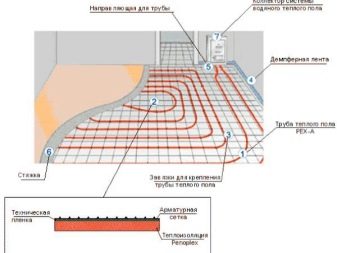

Thermo products have two types of “warm floor” design, each of which has its own advantages and disadvantages. The first type is represented by the “Thermocable” system, which consists of a cable, connecting wires and an end coupling. The cable is laid in a concrete screed and placed in rows. Power models is 130 watts per meter and is the main characteristic of the heating cable.

The system is very simple and durable, has many applications and does not break.

"Thermocable Profline" - the most budgetary option of a heat-insulated floor, represents the single-core shielded cable having threefold isolation from silicone. It differs from the traditional heat cable in that it is used in concrete screeds of non-residential premises that do not require a high level of heating.Power per meter cable product is 20 W at a voltage of 230 V.

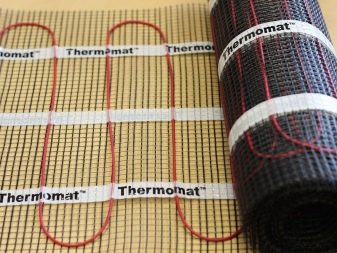

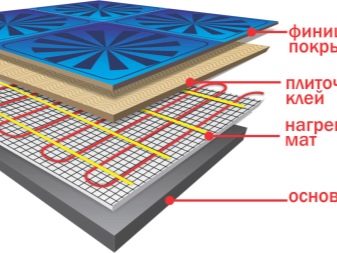

The second type of construction is represented by the “Thermomat” system, made in the form of a web with a thin two-core cable inside it. The canvas is made of fiberglass and has a width of 50 centimeters. Laying does not require the presence of a concrete screed: the canvas is mounted in a thin layer of glue, 4 mm thick. Thermomat has a power of 130 W / sq. m for models stacked in the screed, and 180 watts per square meter. m have products, the operation of which is expected in conditions of high heat loss. The model can be laid on top of an old tile.

The scope of a thermomat is very wide. It can be found in all types of residential and public spaces. Due to the convenient form of release, it is possible to place the product in any area of the room. High temperature resistance allows to operate the system in conditions of high humidity.

Thermomat for Parquet & Laminate is a qualitatively new and unique modification of the Thermomat system, which allows installation of a heated floor under parquet and laminate flooring. The model is made of two-core cable laid in reinforced foil.Installation of the product is very simple and consists only in the deployment of the web with further connection to the power supply. You can start the operation of the heater immediately after laying the floor covering. The advantage of this system is a uniform distribution of warm masses, five-layer insulation, moisture resistance and complete safety.

The manufacturer guarantees seven years of uninterrupted operation of the device, taking into account continuous operation in conditions of moderate heat loss.

Equipment

The electric system "warm floor" has a much more simplified configuration in comparison with water models, which are equipped with a collector and have a more complex principle of operation. Electric heaters consist of a single- or two-core cable, external or internal thermal sensors that control the heating level, and a thermostat that is responsible for maintaining the specified temperature and timely disconnecting the device. The cable consists of two cores, which have Teflon and fiberglass shells, and copper stranded ground. The canvas is a foil layer, covered with a protective PVC film, and contributes to the conversion of electrical energy into heat.

The system is equipped with fuses and electrical relays that can break an electrical circuit in case of an emergency, for example, an emergency overheating.

Mounting options

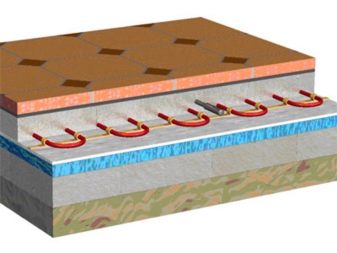

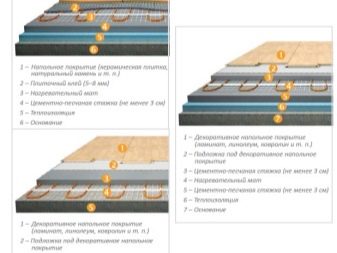

Installation of floor heating can be done independently. The type of system will depend on the installation technology. Before laying the thermomat, it is necessary to level and insulate the subfloor using foiled material. This will eliminate heat loss during heating and direct heat flux upwards. The following should proceed to the installation of the electrical heating system.

Putting a warm floor, you need to check the operation of the thermostat and the entire device in different modes. It should be connected to a separate electrical line. Then the floor is filled with self-leveling tile adhesive. Then you should wait until the surface is completely dry, after which you need to install the thermostat on the wall and check it again. The final stage will be the laying of the flooring, which can be tile, laminate, parquet and even palace.

When installing the cable, it is necessary to pre-mark and determine the location of the sensors, cable and coupling.Next, you need to expand the heat cable and fix it with a cement-sand composition. When laying should avoid passing the cable under the overall furniture and interior volume items. The screed must be left for 30 days until it is completely dry, and only after that you can proceed to the installation of the floor covering.

Successful examples and options

Floors Thermo made in Sweden are rapidly gaining popularity. Despite the fact that products began to be supplied to Russia relatively recently, buyers managed to evaluate its availability, reliability and safety in use. The system is hidden from the eyes and does not affect the interior design and space design.

- The ideal option for alternative heating is the Thermomat for Parquet & Laminate system, which perfectly heats the room and is completely safe for expensive floorboards;

- Thermo floor heating eliminates stationary heating devices, it emits soft and uniform heat, making your stay in the room pleasant and comfortable;

- When using ceramic plates as a floor covering, the electrical heating system will solve the problem of a cold floor,without resorting to additional heat sources.

For information on what kind of underfloor heating systems Thermo has, see the following video.